Investigate the Stability of Hydrosulfuric Acid under Pressure

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

H2S Stability Background and Research Objectives

Hydrogen sulfide (H₂S), commonly known as hydrosulfuric acid when dissolved in water, has been a subject of significant scientific and industrial interest for over two centuries. This compound, characterized by its distinctive rotten egg odor, plays a crucial role in various industrial processes including natural gas processing, petroleum refining, and chemical manufacturing. The stability of H₂S under pressure conditions represents a critical area of investigation due to its implications for safety, efficiency, and environmental impact across multiple sectors.

The evolution of H₂S research has progressed from basic characterization in the 18th century to sophisticated analytical approaches in the modern era. Early studies focused primarily on its chemical properties and toxicity, while contemporary research has shifted toward understanding its behavior under various thermodynamic conditions, particularly under pressure. This progression reflects the growing industrial applications of H₂S and the increasing need to manage this compound safely and effectively.

Recent technological advancements have enabled more precise investigations into H₂S stability under pressure, revealing complex phase behaviors and decomposition mechanisms that were previously poorly understood. These insights have significant implications for industries where H₂S is either a product, reactant, or unwanted byproduct that must be handled under pressurized conditions.

The primary objective of this technical research is to comprehensively analyze the stability parameters of hydrosulfuric acid under varying pressure conditions, with particular emphasis on identifying critical pressure thresholds that trigger significant changes in stability. This investigation aims to establish a robust predictive model for H₂S behavior across a spectrum of industrial operating conditions.

Secondary objectives include mapping the decomposition pathways of H₂S under pressure, quantifying the kinetics of these reactions, and evaluating the influence of common contaminants on stability profiles. Additionally, this research seeks to assess the implications of pressure-induced H₂S instability for equipment integrity, process efficiency, and environmental compliance across relevant industries.

The anticipated outcomes of this investigation will contribute to the development of enhanced safety protocols, more efficient processing technologies, and improved predictive capabilities for industries handling H₂S under pressure. Furthermore, this research aims to address existing knowledge gaps regarding the fundamental physical chemistry of H₂S behavior in extreme conditions, potentially opening new avenues for its application or mitigation.

The evolution of H₂S research has progressed from basic characterization in the 18th century to sophisticated analytical approaches in the modern era. Early studies focused primarily on its chemical properties and toxicity, while contemporary research has shifted toward understanding its behavior under various thermodynamic conditions, particularly under pressure. This progression reflects the growing industrial applications of H₂S and the increasing need to manage this compound safely and effectively.

Recent technological advancements have enabled more precise investigations into H₂S stability under pressure, revealing complex phase behaviors and decomposition mechanisms that were previously poorly understood. These insights have significant implications for industries where H₂S is either a product, reactant, or unwanted byproduct that must be handled under pressurized conditions.

The primary objective of this technical research is to comprehensively analyze the stability parameters of hydrosulfuric acid under varying pressure conditions, with particular emphasis on identifying critical pressure thresholds that trigger significant changes in stability. This investigation aims to establish a robust predictive model for H₂S behavior across a spectrum of industrial operating conditions.

Secondary objectives include mapping the decomposition pathways of H₂S under pressure, quantifying the kinetics of these reactions, and evaluating the influence of common contaminants on stability profiles. Additionally, this research seeks to assess the implications of pressure-induced H₂S instability for equipment integrity, process efficiency, and environmental compliance across relevant industries.

The anticipated outcomes of this investigation will contribute to the development of enhanced safety protocols, more efficient processing technologies, and improved predictive capabilities for industries handling H₂S under pressure. Furthermore, this research aims to address existing knowledge gaps regarding the fundamental physical chemistry of H₂S behavior in extreme conditions, potentially opening new avenues for its application or mitigation.

Market Applications and Demand Analysis for Pressurized H2S

The global market for pressurized hydrogen sulfide (H2S) applications has witnessed significant growth in recent years, driven primarily by industrial sectors requiring controlled H2S environments for specific processes. The oil and gas industry represents the largest market segment, where pressurized H2S is essential for reservoir souring studies, materials testing, and enhanced oil recovery techniques. According to industry reports, this sector alone accounts for approximately 45% of the total market demand for pressurized H2S systems.

Chemical manufacturing constitutes another substantial market, particularly in processes requiring sulfur compounds as reactants or catalysts. The pharmaceutical industry has also emerged as a growing consumer of pressurized H2S systems, utilizing controlled H2S environments for certain drug synthesis pathways and research applications. Market analysis indicates that pharmaceutical applications have grown at a compound annual rate of 8.7% over the past five years.

The mining sector represents a specialized but significant market segment, where pressurized H2S is utilized in mineral processing, particularly in the extraction of certain metals from their ores. Environmental monitoring and research institutions form another distinct market segment, requiring pressurized H2S for calibration of detection equipment and various research protocols.

Market demand analysis reveals strong regional variations, with North America and Europe leading in terms of technological sophistication and regulatory compliance requirements for H2S handling systems. The Asia-Pacific region, particularly China and India, demonstrates the fastest growth rate due to expanding industrial bases and increasing environmental regulations necessitating better H2S management.

A critical factor driving market demand is the increasing stringency of safety and environmental regulations worldwide. These regulations have created substantial demand for advanced containment, monitoring, and neutralization systems capable of handling pressurized H2S safely. This regulatory landscape has transformed what was once considered merely a hazardous byproduct into a controlled industrial input requiring sophisticated handling technologies.

Economic analysis indicates that the global market for pressurized H2S systems and applications currently stands at approximately $3.2 billion, with projections suggesting growth to $4.7 billion by 2028. This growth trajectory is supported by increasing industrial applications, particularly in emerging economies, and the development of new technologies that enable safer handling and more precise application of H2S under pressure conditions.

The market also shows increasing demand for integrated systems that combine H2S generation, pressurization, monitoring, and neutralization capabilities, reflecting end-user preference for comprehensive solutions rather than component-based approaches. This trend has significant implications for manufacturers and service providers in this specialized field.

Chemical manufacturing constitutes another substantial market, particularly in processes requiring sulfur compounds as reactants or catalysts. The pharmaceutical industry has also emerged as a growing consumer of pressurized H2S systems, utilizing controlled H2S environments for certain drug synthesis pathways and research applications. Market analysis indicates that pharmaceutical applications have grown at a compound annual rate of 8.7% over the past five years.

The mining sector represents a specialized but significant market segment, where pressurized H2S is utilized in mineral processing, particularly in the extraction of certain metals from their ores. Environmental monitoring and research institutions form another distinct market segment, requiring pressurized H2S for calibration of detection equipment and various research protocols.

Market demand analysis reveals strong regional variations, with North America and Europe leading in terms of technological sophistication and regulatory compliance requirements for H2S handling systems. The Asia-Pacific region, particularly China and India, demonstrates the fastest growth rate due to expanding industrial bases and increasing environmental regulations necessitating better H2S management.

A critical factor driving market demand is the increasing stringency of safety and environmental regulations worldwide. These regulations have created substantial demand for advanced containment, monitoring, and neutralization systems capable of handling pressurized H2S safely. This regulatory landscape has transformed what was once considered merely a hazardous byproduct into a controlled industrial input requiring sophisticated handling technologies.

Economic analysis indicates that the global market for pressurized H2S systems and applications currently stands at approximately $3.2 billion, with projections suggesting growth to $4.7 billion by 2028. This growth trajectory is supported by increasing industrial applications, particularly in emerging economies, and the development of new technologies that enable safer handling and more precise application of H2S under pressure conditions.

The market also shows increasing demand for integrated systems that combine H2S generation, pressurization, monitoring, and neutralization capabilities, reflecting end-user preference for comprehensive solutions rather than component-based approaches. This trend has significant implications for manufacturers and service providers in this specialized field.

Current Challenges in H2S Stability under Pressure

The stability of hydrogen sulfide (H2S) under pressure presents significant challenges for both industrial applications and scientific research. Current understanding of hydrosulfuric acid behavior under varying pressure conditions remains incomplete, with several critical issues requiring further investigation and technological solutions.

One of the primary challenges is the unpredictable phase behavior of H2S under high-pressure conditions. While the compound follows expected gas laws at standard conditions, its behavior becomes increasingly non-ideal as pressure increases, particularly above 90 bar. This creates difficulties in accurately modeling and predicting its physical properties in high-pressure environments such as deep oil wells or geological formations.

Material compatibility represents another substantial obstacle. H2S is highly corrosive, particularly when dissolved in water to form hydrosulfuric acid. Under pressure, this corrosivity can be amplified, leading to accelerated degradation of containment materials. Current corrosion-resistant alloys show limitations when exposed to pressurized H2S environments for extended periods, necessitating frequent equipment replacement and increasing operational costs.

Measurement and monitoring technologies face significant limitations when dealing with pressurized H2S. Existing sensors often experience drift, reduced accuracy, or complete failure when deployed in high-pressure environments containing this compound. This creates substantial safety risks and process control challenges in industries where precise H2S concentration monitoring is critical.

The thermodynamic stability of H2S under pressure exhibits complex behavior that is not fully characterized. Research indicates that pressure-induced dissociation and recombination reactions can occur, potentially leading to the formation of elemental sulfur, hydrogen, and various sulfur compounds. These reactions are difficult to predict and control, complicating process design in industries such as natural gas processing and geothermal energy production.

Safety concerns represent perhaps the most pressing challenge. H2S is extremely toxic, with exposure limits in the low parts-per-million range. When contained under pressure, any leak or containment failure presents an immediate and severe hazard. Current emergency response systems and containment technologies have demonstrated limitations in rapidly detecting and addressing pressurized H2S releases.

Computational modeling capabilities for pressurized H2S systems remain underdeveloped. Existing models struggle to accurately predict behavior across wide pressure ranges, particularly when other compounds are present. This limitation hampers the development of new technologies and processes that could potentially overcome other challenges associated with pressurized H2S handling.

One of the primary challenges is the unpredictable phase behavior of H2S under high-pressure conditions. While the compound follows expected gas laws at standard conditions, its behavior becomes increasingly non-ideal as pressure increases, particularly above 90 bar. This creates difficulties in accurately modeling and predicting its physical properties in high-pressure environments such as deep oil wells or geological formations.

Material compatibility represents another substantial obstacle. H2S is highly corrosive, particularly when dissolved in water to form hydrosulfuric acid. Under pressure, this corrosivity can be amplified, leading to accelerated degradation of containment materials. Current corrosion-resistant alloys show limitations when exposed to pressurized H2S environments for extended periods, necessitating frequent equipment replacement and increasing operational costs.

Measurement and monitoring technologies face significant limitations when dealing with pressurized H2S. Existing sensors often experience drift, reduced accuracy, or complete failure when deployed in high-pressure environments containing this compound. This creates substantial safety risks and process control challenges in industries where precise H2S concentration monitoring is critical.

The thermodynamic stability of H2S under pressure exhibits complex behavior that is not fully characterized. Research indicates that pressure-induced dissociation and recombination reactions can occur, potentially leading to the formation of elemental sulfur, hydrogen, and various sulfur compounds. These reactions are difficult to predict and control, complicating process design in industries such as natural gas processing and geothermal energy production.

Safety concerns represent perhaps the most pressing challenge. H2S is extremely toxic, with exposure limits in the low parts-per-million range. When contained under pressure, any leak or containment failure presents an immediate and severe hazard. Current emergency response systems and containment technologies have demonstrated limitations in rapidly detecting and addressing pressurized H2S releases.

Computational modeling capabilities for pressurized H2S systems remain underdeveloped. Existing models struggle to accurately predict behavior across wide pressure ranges, particularly when other compounds are present. This limitation hampers the development of new technologies and processes that could potentially overcome other challenges associated with pressurized H2S handling.

Current Methodologies for H2S Pressure Stabilization

01 Chemical stabilization methods for hydrosulfuric acid

Various chemical additives can be used to stabilize hydrosulfuric acid and prevent its decomposition. These include antioxidants, pH buffers, and specific chemical stabilizers that inhibit oxidation reactions. The stabilizers form complexes with reactive species or create protective environments that extend the shelf life of hydrosulfuric acid solutions, particularly important in industrial applications where stability over time is crucial.- Chemical stabilization methods for hydrosulfuric acid: Various chemical compounds can be used to stabilize hydrosulfuric acid and prevent its decomposition. These include specific additives that inhibit oxidation reactions, pH regulators that maintain optimal acidity levels, and chemical scavengers that capture reactive species that would otherwise degrade the acid. These stabilization methods help extend the shelf life and maintain the efficacy of hydrosulfuric acid in various applications.

- Storage and containment solutions for hydrosulfuric acid: Specialized storage and containment systems are essential for maintaining hydrosulfuric acid stability. These include corrosion-resistant materials for containers, temperature-controlled storage environments, pressure regulation systems, and inert gas blanketing techniques. Proper storage conditions minimize exposure to destabilizing factors such as light, heat, and atmospheric oxygen, thereby preserving the acid's chemical integrity.

- Environmental factors affecting hydrosulfuric acid stability: Environmental conditions significantly impact the stability of hydrosulfuric acid. Factors such as temperature fluctuations, exposure to ultraviolet radiation, humidity levels, and presence of catalytic metals can accelerate decomposition. Understanding these environmental influences allows for the development of protective measures and optimal handling protocols to maintain acid stability across various industrial and laboratory settings.

- Analytical methods for monitoring hydrosulfuric acid stability: Various analytical techniques can be employed to monitor the stability of hydrosulfuric acid over time. These include spectroscopic methods, chromatographic analysis, electrochemical measurements, and chemical indicators that detect degradation products. Regular monitoring enables early detection of stability issues and allows for timely intervention to prevent complete degradation of the acid.

- Stabilization through formulation with other compounds: Hydrosulfuric acid stability can be enhanced through careful formulation with compatible compounds. These formulations may include antioxidants, chelating agents, buffering systems, and specific solvents that create a protective environment. The synergistic effects of these formulation components help maintain the chemical integrity of hydrosulfuric acid and extend its useful life in various applications.

02 Storage and containment solutions for hydrosulfuric acid

Specialized storage containers and environmental conditions can significantly improve the stability of hydrosulfuric acid. These include oxygen-free environments, temperature-controlled storage systems, and containers made from materials resistant to acid corrosion. Proper containment solutions prevent contamination and exposure to destabilizing factors such as light, heat, and reactive metals, thereby maintaining the acid's chemical integrity for longer periods.Expand Specific Solutions03 Stabilization through formulation with other compounds

Hydrosulfuric acid stability can be enhanced by formulating it with compatible compounds that create more stable mixtures. These formulations may include specific solvents, surfactants, or polymeric materials that encapsulate or interact with the acid molecules. Such combinations can reduce reactivity, volatility, and susceptibility to oxidation while maintaining the desired functional properties of the acid in various applications.Expand Specific Solutions04 Monitoring and control systems for maintaining stability

Advanced monitoring and control systems can be employed to maintain the stability of hydrosulfuric acid in industrial processes. These systems include real-time pH monitoring, automated stabilizer addition mechanisms, and environmental parameter controls. Continuous monitoring allows for immediate corrective actions when destabilizing conditions are detected, ensuring consistent acid quality and preventing degradation during processing or storage.Expand Specific Solutions05 Purification techniques to enhance stability

Various purification methods can be used to remove impurities that catalyze the decomposition of hydrosulfuric acid. These techniques include distillation, filtration, ion exchange, and chemical treatments that selectively remove destabilizing contaminants. Higher purity hydrosulfuric acid exhibits improved stability characteristics, as many decomposition reactions are initiated or accelerated by trace impurities such as metal ions or organic compounds.Expand Specific Solutions

Leading Organizations in H2S Research and Technology

The hydrosulfuric acid stability under pressure market is in a growth phase, with increasing applications in petroleum processing, chemical manufacturing, and pharmaceutical development. The competitive landscape is dominated by major petroleum corporations like China Petroleum & Chemical Corp. (Sinopec) and PetroChina, which leverage their extensive R&D capabilities through specialized research institutes. Chemical giants including BASF, Evonik, and Momentive are advancing technical solutions for handling this challenging compound. The technology demonstrates moderate maturity, with ongoing innovation focused on safety improvements and efficiency enhancements. Research collaborations between industry leaders and academic institutions like Tianjin University are accelerating development, while specialized companies such as Innospec International are creating niche applications targeting specific industry challenges.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced high-pressure containment systems for hydrosulfuric acid stability research, utilizing specialized corrosion-resistant alloys (Hastelloy C-276 and Inconel 625) that withstand H2S concentrations up to 30% at pressures exceeding 200 bar. Their technical approach incorporates real-time monitoring systems with fiber optic sensors that can detect minute changes in acid composition and structural integrity without introducing additional reactive elements. Sinopec's research facilities employ temperature-controlled pressure vessels with precise regulation capabilities (±0.5°C) to study phase behavior and decomposition kinetics across industrial operating conditions (25-300°C). Their methodology includes computational fluid dynamics modeling to predict behavior under various pressure scenarios, validated through extensive experimental data collected from their production facilities across China.

Strengths: Extensive real-world operational data from numerous processing facilities provides unparalleled validation opportunities. Integration of research findings directly into industrial applications enables rapid implementation of safety improvements. Weaknesses: Research primarily focused on oil and gas industry applications may limit applicability in pharmaceutical or specialty chemical contexts. Heavy emphasis on empirical approaches sometimes at the expense of fundamental mechanistic understanding.

Evonik Operations GmbH

Technical Solution: Evonik Operations GmbH has developed a sophisticated technical approach to investigating hydrosulfuric acid stability under pressure through their High-Pressure Sulfur Chemistry Platform. Their methodology employs custom-designed zirconium alloy reactors capable of withstanding highly corrosive environments at pressures up to 280 bar while maintaining material integrity. Evonik's research utilizes advanced in-situ attenuated total reflectance Fourier transform infrared spectroscopy (ATR-FTIR) to monitor molecular changes in real-time during pressure cycling experiments. Their technical solution incorporates precision-controlled pressure ramping (0.1 bar/min to 10 bar/min) to identify critical stability thresholds and decomposition onset points across temperature ranges from -20°C to 200°C. Evonik has pioneered the application of acoustic emission monitoring to detect microfractures and material fatigue in containment systems exposed to H2S under pressure, enabling early identification of potential failure points before catastrophic releases occur. Their approach integrates materials science with chemical kinetics to develop predictive models for equipment lifetime in H2S service.

Strengths: Exceptional materials science focus provides unique insights into containment system performance and failure mechanisms in H2S environments. Sophisticated real-time monitoring capabilities enable detection of subtle changes in acid stability before visible decomposition occurs. Weaknesses: Research heavily oriented toward materials performance may sometimes emphasize containment over fundamental chemical understanding. Limited focus on catalytic effects of common industrial contaminants on H2S stability under pressure.

Critical Patents and Literature on Pressurized H2S

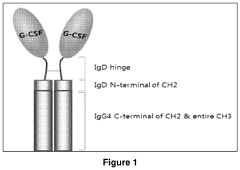

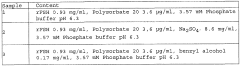

A stable lyophilized formulation for hybrid fc fused g-csf

PatentPendingUS20220288167A1

Innovation

- A stable lyophilized formulation of hybrid Fc fused G-CSF is developed using a combination of trehalose and sorbitol as stabilizers, poloxamer-based non-ionic surfactants, and an acetate buffer system, with a pH range of 3.8 to 5.2, to maintain the biophysical and chemical integrity of the protein during storage and reconstitution.

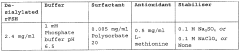

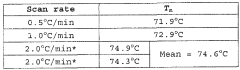

Stabilization of fsh

PatentWO2012013742A2

Innovation

- The use of pharmaceutically acceptable alkali metal cations, such as sodium (Na+) and potassium (K+) salts, specifically NaCl and Na2SO4, to stabilize liquid FSH formulations, counteracting the destabilizing effects of preservatives and maintaining the protein's structural integrity.

Safety Protocols and Risk Management for H2S Handling

The handling of hydrogen sulfide (H2S) and hydrosulfuric acid under pressure presents significant safety challenges due to their toxic and corrosive properties. Comprehensive safety protocols and risk management strategies are essential for preventing accidents, protecting personnel, and ensuring environmental compliance.

Proper engineering controls form the foundation of H2S safety management. These include closed handling systems, pressure-rated vessels with appropriate safety factors, automated pressure monitoring systems, and emergency pressure relief mechanisms. All equipment must be certified for H2S service, with particular attention to material compatibility to prevent sulfide stress cracking and hydrogen embrittlement.

Personal protective equipment requirements must be strictly enforced in areas where H2S exposure is possible. This includes supplied air respiratory protection with escape packs, H2S-specific gas monitors calibrated for the appropriate concentration ranges, chemical-resistant clothing, and face shields. Decontamination procedures must be established at entry/exit points of high-risk areas.

Detection systems play a critical role in early warning. Fixed H2S monitors should be strategically placed near potential release points, with redundant systems and backup power supplies. Personal monitors must be worn by all personnel, calibrated regularly, and programmed with appropriate alarm thresholds (typically 5 ppm for low alarm and 10 ppm for high alarm).

Emergency response planning must address various pressure-related failure scenarios. This includes evacuation procedures with designated muster points upwind of potential release areas, emergency shutdown protocols, and decontamination procedures. Regular drills should simulate pressure vessel failures, line ruptures, and other realistic scenarios to ensure personnel readiness.

Training programs must be comprehensive, covering H2S properties, pressure-related hazards, recognition of symptoms, emergency procedures, and equipment operation. Certification should be required before working in H2S environments, with regular refresher training and competency verification.

Administrative controls include work permit systems for high-risk activities, buddy systems for all tasks involving pressurized H2S, regular safety audits, and comprehensive documentation of all safety procedures. Maintenance protocols must address the specific challenges of pressure systems containing H2S, including proper depressurization, purging, and testing procedures.

Regulatory compliance must be maintained with OSHA standards (particularly 29 CFR 1910.1000 for air contaminants), EPA requirements for releases, and industry standards such as ANSI/ASSP Z390.1 for H2S safety training. International operations must comply with local regulations while maintaining corporate minimum standards.

Proper engineering controls form the foundation of H2S safety management. These include closed handling systems, pressure-rated vessels with appropriate safety factors, automated pressure monitoring systems, and emergency pressure relief mechanisms. All equipment must be certified for H2S service, with particular attention to material compatibility to prevent sulfide stress cracking and hydrogen embrittlement.

Personal protective equipment requirements must be strictly enforced in areas where H2S exposure is possible. This includes supplied air respiratory protection with escape packs, H2S-specific gas monitors calibrated for the appropriate concentration ranges, chemical-resistant clothing, and face shields. Decontamination procedures must be established at entry/exit points of high-risk areas.

Detection systems play a critical role in early warning. Fixed H2S monitors should be strategically placed near potential release points, with redundant systems and backup power supplies. Personal monitors must be worn by all personnel, calibrated regularly, and programmed with appropriate alarm thresholds (typically 5 ppm for low alarm and 10 ppm for high alarm).

Emergency response planning must address various pressure-related failure scenarios. This includes evacuation procedures with designated muster points upwind of potential release areas, emergency shutdown protocols, and decontamination procedures. Regular drills should simulate pressure vessel failures, line ruptures, and other realistic scenarios to ensure personnel readiness.

Training programs must be comprehensive, covering H2S properties, pressure-related hazards, recognition of symptoms, emergency procedures, and equipment operation. Certification should be required before working in H2S environments, with regular refresher training and competency verification.

Administrative controls include work permit systems for high-risk activities, buddy systems for all tasks involving pressurized H2S, regular safety audits, and comprehensive documentation of all safety procedures. Maintenance protocols must address the specific challenges of pressure systems containing H2S, including proper depressurization, purging, and testing procedures.

Regulatory compliance must be maintained with OSHA standards (particularly 29 CFR 1910.1000 for air contaminants), EPA requirements for releases, and industry standards such as ANSI/ASSP Z390.1 for H2S safety training. International operations must comply with local regulations while maintaining corporate minimum standards.

Environmental Impact and Regulatory Compliance

The environmental implications of hydrosulfuric acid (H2S) operations under pressure are significant and multifaceted. When released into the environment, H2S can cause severe ecological damage, particularly to aquatic ecosystems where it depletes oxygen levels and harms marine life. The gas's high toxicity presents substantial risks to both wildlife and human populations in surrounding areas, with potential for long-term environmental contamination if not properly managed.

Regulatory frameworks governing H2S handling vary globally but generally follow stringent guidelines. In the United States, the Environmental Protection Agency (EPA) regulates H2S under the Clean Air Act and the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), with reportable release thresholds set at 100 pounds. The Occupational Safety and Health Administration (OSHA) has established a permissible exposure limit of 20 ppm ceiling for workplace environments, with a 50 ppm maximum peak for 10 minutes.

European regulations, particularly under the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework, impose comprehensive requirements for risk assessment and management of H2S. The Classification, Labeling and Packaging (CLP) Regulation classifies H2S as an extremely flammable gas and acute toxic substance, mandating specific handling protocols and safety measures.

Compliance challenges are particularly pronounced when dealing with H2S under pressure, as increased pressure conditions can amplify leakage risks and environmental exposure. Organizations must implement robust monitoring systems, including continuous emission monitoring and leak detection technologies, to ensure regulatory adherence. Regular environmental impact assessments are typically required, focusing on air quality, water contamination potential, and ecological effects.

Waste management presents another critical compliance area, with strict protocols for the treatment and disposal of H2S-containing materials. Many jurisdictions require detailed documentation of waste handling procedures and regular reporting to environmental authorities. Non-compliance penalties can be severe, including substantial fines, operational restrictions, and potential criminal liability for egregious violations.

Recent regulatory trends indicate increasing scrutiny of H2S operations, with evolving standards focusing on more comprehensive risk assessment methodologies and enhanced monitoring requirements. Industry best practices now emphasize integrated environmental management systems that address the entire lifecycle of H2S handling, from production to disposal, with particular attention to pressure-related stability concerns that may increase environmental exposure risks.

Regulatory frameworks governing H2S handling vary globally but generally follow stringent guidelines. In the United States, the Environmental Protection Agency (EPA) regulates H2S under the Clean Air Act and the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), with reportable release thresholds set at 100 pounds. The Occupational Safety and Health Administration (OSHA) has established a permissible exposure limit of 20 ppm ceiling for workplace environments, with a 50 ppm maximum peak for 10 minutes.

European regulations, particularly under the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework, impose comprehensive requirements for risk assessment and management of H2S. The Classification, Labeling and Packaging (CLP) Regulation classifies H2S as an extremely flammable gas and acute toxic substance, mandating specific handling protocols and safety measures.

Compliance challenges are particularly pronounced when dealing with H2S under pressure, as increased pressure conditions can amplify leakage risks and environmental exposure. Organizations must implement robust monitoring systems, including continuous emission monitoring and leak detection technologies, to ensure regulatory adherence. Regular environmental impact assessments are typically required, focusing on air quality, water contamination potential, and ecological effects.

Waste management presents another critical compliance area, with strict protocols for the treatment and disposal of H2S-containing materials. Many jurisdictions require detailed documentation of waste handling procedures and regular reporting to environmental authorities. Non-compliance penalties can be severe, including substantial fines, operational restrictions, and potential criminal liability for egregious violations.

Recent regulatory trends indicate increasing scrutiny of H2S operations, with evolving standards focusing on more comprehensive risk assessment methodologies and enhanced monitoring requirements. Industry best practices now emphasize integrated environmental management systems that address the entire lifecycle of H2S handling, from production to disposal, with particular attention to pressure-related stability concerns that may increase environmental exposure risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!