Laser Welding in New Material Development: Use Cases

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Welding Technology Evolution and Objectives

Laser welding technology has evolved significantly since its inception in the 1960s, transforming from a niche industrial process to a mainstream manufacturing technique. The journey began with basic CO2 lasers offering limited power and precision, primarily used for simple metal joining applications. The 1970s and 1980s witnessed the introduction of Nd:YAG lasers, which provided better beam quality and enabled more precise welding operations, particularly in electronics and jewelry manufacturing.

The 1990s marked a pivotal shift with the development of fiber and disk lasers, revolutionizing the field by delivering higher power efficiency, superior beam quality, and enhanced reliability. These advancements expanded laser welding applications across automotive, aerospace, and medical device industries, where precision joining of complex materials became increasingly critical.

In recent years, the evolution has accelerated with the introduction of ultra-short pulse lasers and direct diode systems, enabling unprecedented control over heat input and weld characteristics. This technological progression has been driven by the growing demand for joining dissimilar and advanced materials, including high-strength alloys, composites, and engineered polymers that traditional welding methods cannot effectively process.

The current technological landscape focuses on intelligent laser welding systems incorporating real-time monitoring, adaptive control algorithms, and machine learning capabilities. These systems can automatically adjust welding parameters based on material variations, joint geometries, and environmental conditions, ensuring consistent weld quality while minimizing defects and post-processing requirements.

The primary objectives of modern laser welding technology in new material development center around four key areas. First, achieving high-quality joints between dissimilar materials with vastly different physical and chemical properties, such as metal-to-ceramic or metal-to-polymer combinations. Second, developing energy-efficient processes that minimize heat-affected zones and thermal distortion, particularly critical for temperature-sensitive advanced materials.

Third, creating scalable solutions that can transition seamlessly from laboratory prototyping to high-volume manufacturing environments without compromising weld integrity or production efficiency. Finally, establishing comprehensive process monitoring and quality assurance protocols that can validate weld characteristics in real-time, essential for safety-critical applications in aerospace, automotive, and medical sectors.

The trajectory of laser welding technology continues to align with broader industrial trends toward lightweighting, miniaturization, and sustainable manufacturing, positioning it as a cornerstone technology for next-generation material processing challenges.

The 1990s marked a pivotal shift with the development of fiber and disk lasers, revolutionizing the field by delivering higher power efficiency, superior beam quality, and enhanced reliability. These advancements expanded laser welding applications across automotive, aerospace, and medical device industries, where precision joining of complex materials became increasingly critical.

In recent years, the evolution has accelerated with the introduction of ultra-short pulse lasers and direct diode systems, enabling unprecedented control over heat input and weld characteristics. This technological progression has been driven by the growing demand for joining dissimilar and advanced materials, including high-strength alloys, composites, and engineered polymers that traditional welding methods cannot effectively process.

The current technological landscape focuses on intelligent laser welding systems incorporating real-time monitoring, adaptive control algorithms, and machine learning capabilities. These systems can automatically adjust welding parameters based on material variations, joint geometries, and environmental conditions, ensuring consistent weld quality while minimizing defects and post-processing requirements.

The primary objectives of modern laser welding technology in new material development center around four key areas. First, achieving high-quality joints between dissimilar materials with vastly different physical and chemical properties, such as metal-to-ceramic or metal-to-polymer combinations. Second, developing energy-efficient processes that minimize heat-affected zones and thermal distortion, particularly critical for temperature-sensitive advanced materials.

Third, creating scalable solutions that can transition seamlessly from laboratory prototyping to high-volume manufacturing environments without compromising weld integrity or production efficiency. Finally, establishing comprehensive process monitoring and quality assurance protocols that can validate weld characteristics in real-time, essential for safety-critical applications in aerospace, automotive, and medical sectors.

The trajectory of laser welding technology continues to align with broader industrial trends toward lightweighting, miniaturization, and sustainable manufacturing, positioning it as a cornerstone technology for next-generation material processing challenges.

Market Demand Analysis for Advanced Welding Solutions

The global market for advanced welding solutions is experiencing significant growth, driven by the increasing demand for high-precision joining technologies across multiple industries. The laser welding segment, particularly for new material development, has emerged as a critical area with substantial market potential. Current market analysis indicates that the automotive industry represents the largest consumer of advanced laser welding technologies, accounting for approximately 30% of the total market share, followed by aerospace, electronics, and medical device manufacturing.

Market research reveals that manufacturers are increasingly seeking welding solutions capable of joining dissimilar and advanced materials, including high-strength steels, aluminum alloys, titanium composites, and various non-metallic materials. This trend is particularly evident in lightweight construction applications where traditional welding methods often fail to deliver satisfactory results in terms of joint strength, precision, and aesthetic finish.

The demand for laser welding in new material development is further accelerated by stringent regulatory requirements for fuel efficiency and emissions reduction in the automotive and aerospace sectors. These regulations have prompted manufacturers to adopt lightweight materials that require specialized joining technologies. Market forecasts suggest that the global laser welding equipment market will grow at a compound annual growth rate of 5.8% through 2028, with the new materials application segment growing even faster at 7.2%.

Regional analysis shows that Asia-Pacific currently leads the market demand, particularly in countries like China, Japan, and South Korea, where manufacturing sectors are rapidly adopting advanced production technologies. North America and Europe follow closely, with their demand primarily driven by high-tech industries and stringent quality requirements.

Customer surveys indicate that key purchasing factors for advanced welding solutions include process reliability, joint quality, operational flexibility, and total cost of ownership. Manufacturers are increasingly willing to invest in premium welding technologies that can demonstrate clear advantages in handling complex material combinations and reducing post-weld processing requirements.

The market is also witnessing a growing demand for automated and robotic laser welding systems that can be integrated into smart manufacturing environments. This trend aligns with the broader Industry 4.0 movement and offers significant opportunities for solution providers who can deliver comprehensive welding packages with advanced monitoring, control, and data analytics capabilities.

Emerging application areas showing promising growth include electric vehicle battery manufacturing, renewable energy infrastructure, and advanced medical devices, all of which require precise joining of specialized materials under strictly controlled conditions.

Market research reveals that manufacturers are increasingly seeking welding solutions capable of joining dissimilar and advanced materials, including high-strength steels, aluminum alloys, titanium composites, and various non-metallic materials. This trend is particularly evident in lightweight construction applications where traditional welding methods often fail to deliver satisfactory results in terms of joint strength, precision, and aesthetic finish.

The demand for laser welding in new material development is further accelerated by stringent regulatory requirements for fuel efficiency and emissions reduction in the automotive and aerospace sectors. These regulations have prompted manufacturers to adopt lightweight materials that require specialized joining technologies. Market forecasts suggest that the global laser welding equipment market will grow at a compound annual growth rate of 5.8% through 2028, with the new materials application segment growing even faster at 7.2%.

Regional analysis shows that Asia-Pacific currently leads the market demand, particularly in countries like China, Japan, and South Korea, where manufacturing sectors are rapidly adopting advanced production technologies. North America and Europe follow closely, with their demand primarily driven by high-tech industries and stringent quality requirements.

Customer surveys indicate that key purchasing factors for advanced welding solutions include process reliability, joint quality, operational flexibility, and total cost of ownership. Manufacturers are increasingly willing to invest in premium welding technologies that can demonstrate clear advantages in handling complex material combinations and reducing post-weld processing requirements.

The market is also witnessing a growing demand for automated and robotic laser welding systems that can be integrated into smart manufacturing environments. This trend aligns with the broader Industry 4.0 movement and offers significant opportunities for solution providers who can deliver comprehensive welding packages with advanced monitoring, control, and data analytics capabilities.

Emerging application areas showing promising growth include electric vehicle battery manufacturing, renewable energy infrastructure, and advanced medical devices, all of which require precise joining of specialized materials under strictly controlled conditions.

Current Challenges in Laser Welding for New Materials

Despite significant advancements in laser welding technology, several critical challenges persist when applying these techniques to new materials. The primary obstacle remains the inherent diversity of emerging materials, each possessing unique thermal, optical, and mechanical properties that demand specialized welding parameters. Advanced composites, high-entropy alloys, and next-generation ceramics often exhibit unpredictable behavior during the welding process, leading to inconsistent results and quality issues.

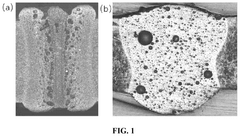

Thermal management presents another significant challenge, particularly with heat-sensitive materials. The concentrated energy of laser beams can create excessive heat-affected zones (HAZ) in materials with poor thermal conductivity, resulting in microstructural changes that compromise mechanical integrity. This is especially problematic in aerospace and medical applications where material property preservation is critical.

Reflectivity variations among new materials significantly impact laser absorption efficiency. Highly reflective materials like aluminum alloys and copper-based composites can reflect up to 98% of incident laser energy, drastically reducing process efficiency and requiring substantially higher power inputs. Conversely, materials with variable absorption characteristics throughout the welding process present difficulties in maintaining consistent energy transfer.

Joint design complexity increases substantially when working with dissimilar materials. The formation of brittle intermetallic compounds at the interface between different metals remains a persistent challenge, often resulting in joints with compromised mechanical properties. This is particularly evident in automotive and electronics industries where lightweight metal-to-metal connections are increasingly demanded.

Process monitoring and quality control systems struggle to keep pace with new material developments. Current sensing technologies often lack the capability to detect defects in real-time when working with novel materials, as traditional indicators may not apply. This creates a significant gap in quality assurance protocols, particularly for critical applications in aerospace and medical device manufacturing.

Material preparation requirements have become more stringent with advanced materials. Surface contamination, oxide layers, and moisture content can dramatically affect weld quality in ways that differ from conventional materials. The development of specialized cleaning and preparation protocols lags behind material innovation, creating implementation bottlenecks.

Finally, the knowledge gap in understanding fundamental laser-material interactions for new materials presents a systemic challenge. The physics of laser absorption, heat transfer, and solidification behavior often differs significantly from established models, requiring extensive empirical testing and characterization before reliable welding parameters can be established.

Thermal management presents another significant challenge, particularly with heat-sensitive materials. The concentrated energy of laser beams can create excessive heat-affected zones (HAZ) in materials with poor thermal conductivity, resulting in microstructural changes that compromise mechanical integrity. This is especially problematic in aerospace and medical applications where material property preservation is critical.

Reflectivity variations among new materials significantly impact laser absorption efficiency. Highly reflective materials like aluminum alloys and copper-based composites can reflect up to 98% of incident laser energy, drastically reducing process efficiency and requiring substantially higher power inputs. Conversely, materials with variable absorption characteristics throughout the welding process present difficulties in maintaining consistent energy transfer.

Joint design complexity increases substantially when working with dissimilar materials. The formation of brittle intermetallic compounds at the interface between different metals remains a persistent challenge, often resulting in joints with compromised mechanical properties. This is particularly evident in automotive and electronics industries where lightweight metal-to-metal connections are increasingly demanded.

Process monitoring and quality control systems struggle to keep pace with new material developments. Current sensing technologies often lack the capability to detect defects in real-time when working with novel materials, as traditional indicators may not apply. This creates a significant gap in quality assurance protocols, particularly for critical applications in aerospace and medical device manufacturing.

Material preparation requirements have become more stringent with advanced materials. Surface contamination, oxide layers, and moisture content can dramatically affect weld quality in ways that differ from conventional materials. The development of specialized cleaning and preparation protocols lags behind material innovation, creating implementation bottlenecks.

Finally, the knowledge gap in understanding fundamental laser-material interactions for new materials presents a systemic challenge. The physics of laser absorption, heat transfer, and solidification behavior often differs significantly from established models, requiring extensive empirical testing and characterization before reliable welding parameters can be established.

Existing Laser Welding Solutions for Novel Materials

01 Laser welding techniques for specific materials

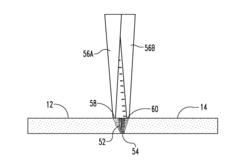

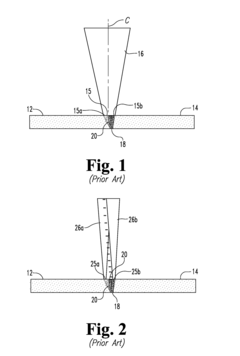

Various laser welding techniques have been developed for specific materials, including metals, plastics, and composites. These techniques optimize parameters such as laser power, wavelength, and pulse duration to achieve strong bonds while minimizing thermal damage. Material-specific approaches address challenges like thermal conductivity differences and melting point variations to ensure high-quality welds with minimal distortion.- Laser welding techniques for specific materials: Various laser welding techniques have been developed for specific materials, including metals, alloys, and composites. These techniques optimize parameters such as laser power, pulse duration, and beam focus to achieve strong welds while minimizing heat-affected zones. Different materials require specific approaches to address challenges like thermal conductivity, reflectivity, and potential for cracking or distortion during the welding process.

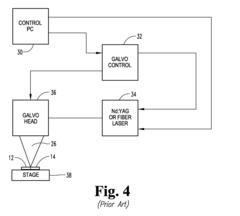

- Advanced laser beam control systems: Advanced control systems for laser welding incorporate real-time monitoring and adjustment of beam parameters. These systems utilize sensors and feedback mechanisms to maintain optimal welding conditions throughout the process. Technologies include beam shaping, power modulation, and precise positioning control to enhance weld quality, increase process stability, and accommodate variations in workpiece geometry or material properties.

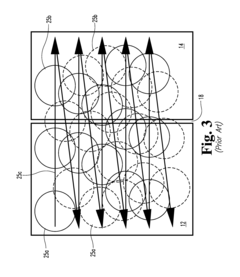

- Hybrid and multi-beam laser welding processes: Hybrid and multi-beam laser welding processes combine conventional laser welding with other techniques or utilize multiple laser sources simultaneously. These approaches can include laser-arc hybrid welding, dual-beam configurations, or sequential laser treatments. Such combinations leverage the advantages of different energy sources to improve penetration depth, reduce porosity, control cooling rates, and enhance overall weld quality for complex applications.

- Laser welding monitoring and quality control: Advanced monitoring and quality control systems for laser welding incorporate sensors, cameras, and analytical software to detect defects in real-time. These systems can identify issues such as porosity, cracks, incomplete fusion, or improper penetration during the welding process. By providing immediate feedback, they enable automatic adjustments to welding parameters or flagging of defective welds, thereby reducing waste and ensuring consistent quality in production environments.

- Specialized laser welding applications: Specialized laser welding applications have been developed for specific industries and unique joining requirements. These include micro-welding for electronics and medical devices, remote welding for automotive components, and high-precision welding for aerospace parts. Each application utilizes tailored laser parameters, fixturing methods, and process controls to address the particular challenges of joining specific components while meeting stringent quality and reliability standards.

02 Advanced laser beam control systems

Advanced control systems for laser welding incorporate real-time monitoring and adjustment of beam parameters. These systems use sensors to track weld quality, temperature, and penetration depth, allowing for dynamic adjustments during the welding process. Beam shaping technologies and precision optics enable customized energy distribution patterns that optimize weld characteristics for different applications and joint configurations.Expand Specific Solutions03 Hybrid and multi-beam laser welding processes

Hybrid laser welding processes combine laser technology with conventional welding methods like arc or MIG welding to leverage the advantages of both techniques. Multi-beam approaches use multiple laser sources or beam splitting to create simultaneous welds or to pre-heat and post-heat the workpiece. These combined methods improve weld penetration, speed, and quality while reducing defects and distortion in the welded components.Expand Specific Solutions04 Laser welding for specialized applications

Specialized laser welding applications have been developed for industries with unique requirements, such as medical device manufacturing, electronics, automotive, and aerospace. These applications often involve welding dissimilar materials, micro-welding of sensitive components, or creating hermetic seals. Tailored laser parameters and fixturing methods address the specific challenges of joining thin, heat-sensitive, or precision components while maintaining dimensional stability.Expand Specific Solutions05 Automation and robotics in laser welding

Integration of automation and robotics with laser welding systems has significantly enhanced precision, repeatability, and productivity. Robotic systems with multiple degrees of freedom enable complex welding paths and access to difficult-to-reach areas. Advanced vision systems and AI-based process monitoring allow for adaptive control and quality assurance during welding operations. These automated solutions reduce human error and enable consistent high-quality welds in high-volume production environments.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Laser welding in new material development is experiencing rapid growth in a maturing market estimated at $2.5 billion globally. The technology has reached moderate maturity, with significant advancements in blue laser technology from Nuburu Subsidiary for e-mobility and battery manufacturing applications. Key players demonstrate diverse specializations: IPG Photonics and TRUMPF lead in fiber laser development; Han's Laser and Shenzhen Tete focus on industrial automation integration; while materials giants like ArcelorMittal, LG Chem, and DuPont provide specialized substrates. Automotive manufacturers (GM, Volkswagen, Ford) are driving adoption through R&D partnerships, particularly for lightweight materials joining. The competitive landscape shows regional clustering with strong representation from Asian manufacturers, European engineering firms, and American technology innovators.

Nuburu Subsidiary, Inc.

Technical Solution: Nuburu has revolutionized laser welding for new materials through their pioneering development of high-power blue laser technology. Their proprietary blue laser systems operate at 450nm wavelength, achieving 10-20x better absorption in reflective materials like copper, gold, and aluminum compared to traditional infrared lasers. This enables stable, spatter-free welding processes for these challenging materials. Nuburu's AO-650 and AI-1500 systems deliver up to 1.5kW of blue laser power with exceptional beam quality (BPP <2.5 mm·mrad), enabling precise welding of thin foils and dissimilar material combinations critical in battery and electronics manufacturing. Their patented technology addresses copper welding challenges through controlled keyhole formation and reduced plasma shielding effects, resulting in welds with up to 3x higher electrical conductivity compared to infrared laser welding. Nuburu has also developed specialized optical delivery systems and process parameters specifically optimized for joining new battery materials, including tab-to-busbar connections for next-generation cell designs.

Strengths: Unique blue wavelength technology providing superior results for reflective materials; specialized expertise in battery and electronics applications; patented processes for high-conductivity copper welding. Weaknesses: More limited power range compared to established infrared laser manufacturers; narrower application focus primarily on copper and precious metals; relatively young company with still-developing global support infrastructure.

ArcelorMittal SA

Technical Solution: ArcelorMittal has developed advanced laser welding applications specifically for next-generation steel materials in automotive and construction sectors. Their proprietary Usibor® and Ductibor® press-hardened steels utilize tailored laser welding processes that maintain material properties after joining. ArcelorMittal's laser welded blanks (LWB) technology enables the production of components with multiple steel grades and thicknesses, optimizing weight and crash performance. Their S-in motion® program incorporates laser welding of advanced high-strength steels (AHSS) with tensile strengths exceeding 1500 MPa, achieving weight reductions of 20-25% compared to conventional steel designs. ArcelorMittal has pioneered laser-assisted hot-stamping processes that enable the welding of ultra-high-strength steels while controlling microstructural transformations. Their research centers have developed specialized laser welding parameters for new steel compositions containing increased aluminum, silicon, and manganese content, addressing challenges like zinc vapor management and preventing intermetallic formation.

Strengths: Unparalleled expertise in steel metallurgy combined with laser process development; vertical integration from material development to application engineering; extensive automotive industry relationships. Weaknesses: Primary focus on steel materials with less expertise in non-ferrous applications; solutions often require specialized equipment beyond standard laser systems; more limited experience with very high power laser applications.

Key Innovations in Laser-Material Interaction

Laser welding system and method

PatentInactiveUS20160016261A1

Innovation

- The implementation of Pulse Spread Technology, which involves varying the intensity and speed of laser pulses across the material junction in a zig-zag pattern, ensuring that the power density is customized to match the thermal characteristics of each material, creating a more uniform weld pool by applying higher power density to the higher melting point material and lower power density to the lower melting point material.

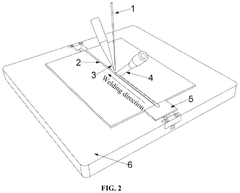

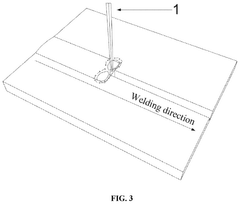

Oscillating laser welding with filler wires for jointing aluminum alloy sheets with a large gap therebetween

PatentPendingUS20240383073A1

Innovation

- An oscillating laser welding method with filler wires that reserves a gap between aluminum alloy sheets to reduce dilution and prevent porosity and brittle phase formation, using a wire feeding nozzle and laser welding head to fill the gap with molten wires, while maintaining a stable molten pool and controlling the oscillating path to enhance energy utilization and reduce residual stress.

Material Compatibility and Weldability Assessment

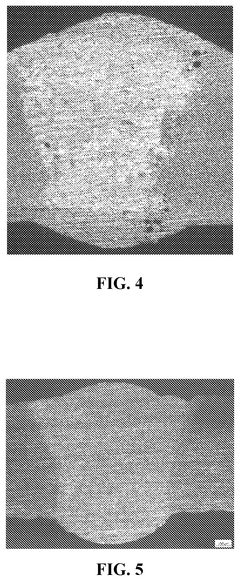

Material compatibility is a critical factor in determining the success of laser welding processes across new material developments. The fundamental challenge lies in understanding the metallurgical interactions between different materials when subjected to the intense heat of laser beams. Not all material combinations exhibit favorable weldability characteristics, with issues such as brittle intermetallic formation, thermal expansion mismatches, and differences in melting points creating significant barriers to effective joining.

For advanced composites and multi-material assemblies, compatibility assessment requires systematic evaluation of physical, chemical, and mechanical properties. Research indicates that materials with similar thermal conductivity and expansion coefficients generally demonstrate superior weldability. However, the introduction of novel alloys, high-performance polymers, and ceramic-reinforced composites has complicated traditional compatibility matrices, necessitating more sophisticated assessment methodologies.

Weldability assessment protocols have evolved significantly, incorporating both empirical testing and computational modeling approaches. Standard testing procedures now include lap shear strength evaluations, microstructural analysis, and corrosion resistance testing of welded joints. Advanced techniques such as high-speed thermal imaging and in-situ X-ray diffraction provide real-time insights into material behavior during the welding process, enabling more precise compatibility predictions.

The development of weldability maps has emerged as a valuable tool for materials engineers, offering visual representations of compatible material combinations across various laser parameters. These maps typically plot energy density against material thickness, identifying optimal processing windows for specific material pairs. Recent research has expanded these maps to include additional dimensions such as pulse duration and beam profile characteristics.

Material surface preparation has proven to be a critical factor in enhancing compatibility between otherwise challenging material combinations. Techniques such as surface activation, nanoscale coatings, and interlayer insertion have demonstrated significant improvements in weld quality for dissimilar materials. For instance, titanium-aluminum joints, traditionally prone to brittle intermetallic formation, have shown enhanced performance through the strategic application of copper or vanadium interlayers.

Predictive modeling of material compatibility has advanced considerably, with machine learning algorithms now capable of forecasting weld quality based on material composition and process parameters. These models integrate thermodynamic databases with experimental results to provide increasingly accurate compatibility assessments, reducing the need for extensive physical testing and accelerating new material implementation in industrial applications.

For advanced composites and multi-material assemblies, compatibility assessment requires systematic evaluation of physical, chemical, and mechanical properties. Research indicates that materials with similar thermal conductivity and expansion coefficients generally demonstrate superior weldability. However, the introduction of novel alloys, high-performance polymers, and ceramic-reinforced composites has complicated traditional compatibility matrices, necessitating more sophisticated assessment methodologies.

Weldability assessment protocols have evolved significantly, incorporating both empirical testing and computational modeling approaches. Standard testing procedures now include lap shear strength evaluations, microstructural analysis, and corrosion resistance testing of welded joints. Advanced techniques such as high-speed thermal imaging and in-situ X-ray diffraction provide real-time insights into material behavior during the welding process, enabling more precise compatibility predictions.

The development of weldability maps has emerged as a valuable tool for materials engineers, offering visual representations of compatible material combinations across various laser parameters. These maps typically plot energy density against material thickness, identifying optimal processing windows for specific material pairs. Recent research has expanded these maps to include additional dimensions such as pulse duration and beam profile characteristics.

Material surface preparation has proven to be a critical factor in enhancing compatibility between otherwise challenging material combinations. Techniques such as surface activation, nanoscale coatings, and interlayer insertion have demonstrated significant improvements in weld quality for dissimilar materials. For instance, titanium-aluminum joints, traditionally prone to brittle intermetallic formation, have shown enhanced performance through the strategic application of copper or vanadium interlayers.

Predictive modeling of material compatibility has advanced considerably, with machine learning algorithms now capable of forecasting weld quality based on material composition and process parameters. These models integrate thermodynamic databases with experimental results to provide increasingly accurate compatibility assessments, reducing the need for extensive physical testing and accelerating new material implementation in industrial applications.

Environmental Impact and Energy Efficiency Considerations

Laser welding technology demonstrates significant environmental advantages over traditional welding methods, particularly in terms of energy consumption and carbon footprint. The process typically consumes 20-30% less energy compared to conventional arc welding techniques, primarily due to its precise energy delivery mechanism that minimizes heat-affected zones. This efficiency translates directly into reduced greenhouse gas emissions, with studies indicating potential CO2 reductions of up to 40% when implemented at scale in manufacturing operations.

Material utilization represents another critical environmental benefit of laser welding in new material development. The precision of laser systems enables joining with minimal filler material requirements, reducing waste generation significantly. For advanced materials such as high-strength steels and lightweight alloys, this precision allows manufacturers to achieve up to 95% material utilization rates, compared to 70-80% with conventional methods.

The environmental impact assessment of laser welding must also consider the entire lifecycle of welded components. New materials joined via laser technology often demonstrate enhanced durability and corrosion resistance, extending product lifespans by an estimated 15-30% depending on application environments. This longevity factor compounds the environmental benefits through reduced replacement frequency and associated resource consumption.

Energy efficiency in laser welding continues to improve through technological advancements. Modern fiber and diode lasers achieve wall-plug efficiencies exceeding 40%, representing a dramatic improvement over earlier generation lasers with efficiencies below 20%. These improvements directly translate to lower operational costs and reduced environmental impact, particularly important for energy-intensive industries like automotive and aerospace manufacturing.

Water consumption presents another environmental consideration, with laser welding requiring significantly less cooling water than traditional welding processes. Advanced closed-loop cooling systems have further reduced water requirements by up to 80% compared to earlier laser systems, addressing water scarcity concerns in manufacturing regions with limited resources.

Emissions control represents a final critical environmental advantage. Laser welding produces minimal airborne particulates and harmful gases compared to conventional welding, reducing workplace exposure risks and environmental contamination. This characteristic is particularly valuable when working with new materials that may contain potentially hazardous elements or compounds, as the controlled energy delivery minimizes volatilization of these components.

Material utilization represents another critical environmental benefit of laser welding in new material development. The precision of laser systems enables joining with minimal filler material requirements, reducing waste generation significantly. For advanced materials such as high-strength steels and lightweight alloys, this precision allows manufacturers to achieve up to 95% material utilization rates, compared to 70-80% with conventional methods.

The environmental impact assessment of laser welding must also consider the entire lifecycle of welded components. New materials joined via laser technology often demonstrate enhanced durability and corrosion resistance, extending product lifespans by an estimated 15-30% depending on application environments. This longevity factor compounds the environmental benefits through reduced replacement frequency and associated resource consumption.

Energy efficiency in laser welding continues to improve through technological advancements. Modern fiber and diode lasers achieve wall-plug efficiencies exceeding 40%, representing a dramatic improvement over earlier generation lasers with efficiencies below 20%. These improvements directly translate to lower operational costs and reduced environmental impact, particularly important for energy-intensive industries like automotive and aerospace manufacturing.

Water consumption presents another environmental consideration, with laser welding requiring significantly less cooling water than traditional welding processes. Advanced closed-loop cooling systems have further reduced water requirements by up to 80% compared to earlier laser systems, addressing water scarcity concerns in manufacturing regions with limited resources.

Emissions control represents a final critical environmental advantage. Laser welding produces minimal airborne particulates and harmful gases compared to conventional welding, reducing workplace exposure risks and environmental contamination. This characteristic is particularly valuable when working with new materials that may contain potentially hazardous elements or compounds, as the controlled energy delivery minimizes volatilization of these components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!