Laser Welding vs Diffusion Bonding: Longevity Insights

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Welding and Diffusion Bonding Background and Objectives

Laser welding and diffusion bonding represent two distinct yet complementary joining technologies that have evolved significantly over the past decades. Laser welding, first developed in the 1960s following the invention of the laser, has progressed from simple applications to sophisticated precision joining processes used across multiple industries. The technology has evolved from basic CO2 lasers to advanced fiber, disk, and diode lasers, offering unprecedented control over heat input and weld characteristics.

Diffusion bonding, with roots dating back to ancient metalworking techniques, emerged as a modern industrial process in the mid-20th century. This solid-state joining method relies on atomic diffusion at elevated temperatures under pressure, creating joints with parent material properties without melting. Its development has been particularly significant in aerospace, nuclear, and microelectronics industries where high-integrity joints with minimal microstructural disruption are essential.

The technological evolution of both processes has been driven by increasing demands for joining dissimilar materials, creating hermetic seals, and ensuring long-term structural integrity in increasingly challenging environments. Recent advancements in laser technology have enabled welding of previously incompatible material combinations, while diffusion bonding techniques have been refined to reduce process times and temperatures.

Current technological trends indicate a convergence of these technologies in certain applications, with hybrid approaches emerging that leverage the strengths of both methods. The development of pulsed laser systems with precise energy control has narrowed the gap between fusion-based and solid-state joining, while advanced surface preparation techniques have enhanced diffusion bonding capabilities.

The primary objective of this technical research is to comprehensively evaluate the longevity characteristics of joints created by laser welding versus diffusion bonding across various material combinations and service environments. Specifically, we aim to quantify the long-term mechanical stability, corrosion resistance, thermal cycling behavior, and failure mechanisms associated with each joining method.

Secondary objectives include identifying optimal process parameters for maximizing joint longevity, developing predictive models for service life estimation, and establishing clear selection criteria for choosing between these technologies based on specific application requirements. The research also seeks to explore emerging hybrid approaches that may combine aspects of both technologies to achieve superior longevity characteristics.

This investigation is particularly timely given the increasing deployment of these joining technologies in critical applications such as medical implants, aerospace structures, and energy systems where joint failure can have catastrophic consequences and where service lifetimes of decades are often required.

Diffusion bonding, with roots dating back to ancient metalworking techniques, emerged as a modern industrial process in the mid-20th century. This solid-state joining method relies on atomic diffusion at elevated temperatures under pressure, creating joints with parent material properties without melting. Its development has been particularly significant in aerospace, nuclear, and microelectronics industries where high-integrity joints with minimal microstructural disruption are essential.

The technological evolution of both processes has been driven by increasing demands for joining dissimilar materials, creating hermetic seals, and ensuring long-term structural integrity in increasingly challenging environments. Recent advancements in laser technology have enabled welding of previously incompatible material combinations, while diffusion bonding techniques have been refined to reduce process times and temperatures.

Current technological trends indicate a convergence of these technologies in certain applications, with hybrid approaches emerging that leverage the strengths of both methods. The development of pulsed laser systems with precise energy control has narrowed the gap between fusion-based and solid-state joining, while advanced surface preparation techniques have enhanced diffusion bonding capabilities.

The primary objective of this technical research is to comprehensively evaluate the longevity characteristics of joints created by laser welding versus diffusion bonding across various material combinations and service environments. Specifically, we aim to quantify the long-term mechanical stability, corrosion resistance, thermal cycling behavior, and failure mechanisms associated with each joining method.

Secondary objectives include identifying optimal process parameters for maximizing joint longevity, developing predictive models for service life estimation, and establishing clear selection criteria for choosing between these technologies based on specific application requirements. The research also seeks to explore emerging hybrid approaches that may combine aspects of both technologies to achieve superior longevity characteristics.

This investigation is particularly timely given the increasing deployment of these joining technologies in critical applications such as medical implants, aerospace structures, and energy systems where joint failure can have catastrophic consequences and where service lifetimes of decades are often required.

Market Demand Analysis for Advanced Joining Technologies

The global market for advanced joining technologies is experiencing significant growth, driven by increasing demands across multiple industries for more efficient, durable, and precise material bonding solutions. The combined market value for laser welding and diffusion bonding technologies is projected to reach $6.8 billion by 2027, with a compound annual growth rate of 5.7% from 2022 to 2027. This growth trajectory reflects the expanding applications of these technologies in critical sectors.

Aerospace and defense industries represent the largest market segment for advanced joining technologies, particularly diffusion bonding, which is essential for creating high-performance components in aircraft engines, structural elements, and defense systems. The aerospace sector alone accounts for approximately 32% of the diffusion bonding market, valuing at $1.2 billion in 2022.

The automotive industry follows closely as a major consumer of both technologies, with laser welding gaining significant traction due to the industry's shift toward lightweight materials and electric vehicles. Market research indicates that laser welding applications in automotive manufacturing have increased by 28% over the past five years, with particular emphasis on battery production for electric vehicles.

Electronics manufacturing represents the fastest-growing segment for these technologies, with a projected growth rate of 7.9% annually through 2027. The miniaturization trend in consumer electronics and the increasing complexity of semiconductor devices have created substantial demand for precise joining methods that can handle delicate materials without thermal damage.

Medical device manufacturing has emerged as another critical market, particularly for laser welding, which enables the production of intricate, biocompatible components. This sector is expected to grow at 6.8% annually, driven by increasing demand for minimally invasive surgical tools and implantable devices that require hermetic sealing and biocompatibility.

Regional analysis reveals that Asia-Pacific dominates the market with a 41% share, followed by North America (27%) and Europe (24%). China and South Korea are experiencing the fastest growth rates in adoption, primarily due to their expanding electronics and automotive manufacturing bases.

Customer requirements are evolving toward solutions that offer extended product longevity, reduced maintenance costs, and improved reliability under extreme operating conditions. Survey data from manufacturing executives indicates that 78% consider joint longevity as "extremely important" or "very important" when selecting bonding technologies, representing a 15% increase from similar surveys conducted five years ago.

Aerospace and defense industries represent the largest market segment for advanced joining technologies, particularly diffusion bonding, which is essential for creating high-performance components in aircraft engines, structural elements, and defense systems. The aerospace sector alone accounts for approximately 32% of the diffusion bonding market, valuing at $1.2 billion in 2022.

The automotive industry follows closely as a major consumer of both technologies, with laser welding gaining significant traction due to the industry's shift toward lightweight materials and electric vehicles. Market research indicates that laser welding applications in automotive manufacturing have increased by 28% over the past five years, with particular emphasis on battery production for electric vehicles.

Electronics manufacturing represents the fastest-growing segment for these technologies, with a projected growth rate of 7.9% annually through 2027. The miniaturization trend in consumer electronics and the increasing complexity of semiconductor devices have created substantial demand for precise joining methods that can handle delicate materials without thermal damage.

Medical device manufacturing has emerged as another critical market, particularly for laser welding, which enables the production of intricate, biocompatible components. This sector is expected to grow at 6.8% annually, driven by increasing demand for minimally invasive surgical tools and implantable devices that require hermetic sealing and biocompatibility.

Regional analysis reveals that Asia-Pacific dominates the market with a 41% share, followed by North America (27%) and Europe (24%). China and South Korea are experiencing the fastest growth rates in adoption, primarily due to their expanding electronics and automotive manufacturing bases.

Customer requirements are evolving toward solutions that offer extended product longevity, reduced maintenance costs, and improved reliability under extreme operating conditions. Survey data from manufacturing executives indicates that 78% consider joint longevity as "extremely important" or "very important" when selecting bonding technologies, representing a 15% increase from similar surveys conducted five years ago.

Current Technical Challenges in Material Joining Longevity

The joining of materials through laser welding and diffusion bonding presents significant technical challenges when considering long-term performance and reliability. Current laser welding technologies, while offering high precision and speed, struggle with thermal stress management in heterogeneous material combinations. These thermal gradients can lead to microstructural changes that compromise joint integrity over time, particularly in applications exposed to thermal cycling or mechanical vibration.

Diffusion bonding, conversely, faces challenges related to surface preparation requirements and process control. The need for atomically clean surfaces and precise pressure-temperature control during the bonding process introduces variability that can affect long-term performance. Additionally, the formation of brittle intermetallic compounds at the interface remains a persistent issue, especially in joints between dissimilar metals where these compounds can act as stress concentration points and initiation sites for fatigue cracking.

Both joining methods encounter significant hurdles when applied to advanced materials such as high-strength aluminum alloys, titanium composites, and ceramic-metal combinations. The increasing demand for lightweight structures in aerospace and automotive industries has pushed these joining technologies to their limits, revealing limitations in crack resistance and fatigue performance under dynamic loading conditions.

Environmental factors present another dimension of challenges. Joints created by both methods can exhibit accelerated degradation when exposed to corrosive environments, with laser-welded joints particularly susceptible to stress corrosion cracking along heat-affected zones. Diffusion-bonded interfaces may experience preferential corrosion at grain boundaries where elemental segregation has occurred during the bonding process.

Quality assurance and non-destructive testing represent additional technical barriers. Current inspection methods often lack the sensitivity to detect sub-surface defects that may not immediately affect performance but can lead to premature failure under service conditions. This is particularly problematic for diffusion bonds where interfacial defects can be atomically thin yet critically important to long-term joint integrity.

Recent research has highlighted the challenge of predicting long-term performance based on accelerated testing protocols. The complex interaction between microstructural evolution, mechanical loading, and environmental factors makes it difficult to establish reliable correlations between laboratory tests and actual service life. This knowledge gap hampers the development of design guidelines and safety factors for critical applications where joint longevity is paramount.

The miniaturization trend in electronics and medical devices introduces additional constraints, as both joining methods must adapt to increasingly smaller scales while maintaining reliability. At these dimensions, previously negligible effects such as interatomic diffusion rates and surface energy considerations become dominant factors affecting joint longevity.

Diffusion bonding, conversely, faces challenges related to surface preparation requirements and process control. The need for atomically clean surfaces and precise pressure-temperature control during the bonding process introduces variability that can affect long-term performance. Additionally, the formation of brittle intermetallic compounds at the interface remains a persistent issue, especially in joints between dissimilar metals where these compounds can act as stress concentration points and initiation sites for fatigue cracking.

Both joining methods encounter significant hurdles when applied to advanced materials such as high-strength aluminum alloys, titanium composites, and ceramic-metal combinations. The increasing demand for lightweight structures in aerospace and automotive industries has pushed these joining technologies to their limits, revealing limitations in crack resistance and fatigue performance under dynamic loading conditions.

Environmental factors present another dimension of challenges. Joints created by both methods can exhibit accelerated degradation when exposed to corrosive environments, with laser-welded joints particularly susceptible to stress corrosion cracking along heat-affected zones. Diffusion-bonded interfaces may experience preferential corrosion at grain boundaries where elemental segregation has occurred during the bonding process.

Quality assurance and non-destructive testing represent additional technical barriers. Current inspection methods often lack the sensitivity to detect sub-surface defects that may not immediately affect performance but can lead to premature failure under service conditions. This is particularly problematic for diffusion bonds where interfacial defects can be atomically thin yet critically important to long-term joint integrity.

Recent research has highlighted the challenge of predicting long-term performance based on accelerated testing protocols. The complex interaction between microstructural evolution, mechanical loading, and environmental factors makes it difficult to establish reliable correlations between laboratory tests and actual service life. This knowledge gap hampers the development of design guidelines and safety factors for critical applications where joint longevity is paramount.

The miniaturization trend in electronics and medical devices introduces additional constraints, as both joining methods must adapt to increasingly smaller scales while maintaining reliability. At these dimensions, previously negligible effects such as interatomic diffusion rates and surface energy considerations become dominant factors affecting joint longevity.

Comparative Analysis of Current Joining Methodologies

01 Factors affecting longevity of laser welded joints

The longevity of laser welded joints depends on several factors including material selection, welding parameters, and post-weld treatment. Proper control of laser power, welding speed, and beam focus can significantly improve the durability of the joint. Surface preparation before welding and heat treatment after welding can reduce residual stresses and prevent crack formation, thereby extending the service life of the welded components.- Factors affecting longevity of laser welded joints: The longevity of laser welded joints depends on several factors including material selection, welding parameters, and post-weld treatment. Proper control of laser power, welding speed, and beam focus can minimize defects such as porosity and cracking that would otherwise compromise joint longevity. Surface preparation before welding and heat treatment after welding can also significantly improve the durability and fatigue resistance of laser welded connections over time.

- Diffusion bonding techniques for enhanced bond strength: Diffusion bonding creates strong metallurgical bonds by applying heat and pressure to promote atomic migration between materials. The process parameters, including temperature, pressure, time, and surface preparation, directly influence bond strength and longevity. For optimal long-term performance, controlled atmospheres or vacuum environments are often used to prevent oxidation during the bonding process. This technique is particularly effective for joining dissimilar materials where traditional welding methods might create brittle intermetallic compounds that reduce joint longevity.

- Hybrid joining methods combining laser welding and diffusion bonding: Hybrid joining processes that combine laser welding with diffusion bonding leverage the advantages of both techniques to create joints with superior longevity. The laser provides localized heating while diffusion bonding ensures intimate atomic contact across the entire interface. This combination minimizes thermal distortion while maximizing bond area and strength. The hybrid approach is particularly beneficial for critical applications where joint failure would be catastrophic, as it provides redundancy in the bonding mechanism and eliminates many of the weaknesses associated with either process alone.

- Material considerations for long-lasting bonded joints: The selection of base materials and any filler materials significantly impacts the longevity of both laser welded and diffusion bonded joints. Compatibility between materials in terms of thermal expansion coefficients, melting points, and chemical composition is crucial for preventing premature joint failure. For enhanced durability, specialized alloys or interlayers may be used to accommodate differences between dissimilar materials. Surface treatments such as cleaning, etching, or coating application before joining can also dramatically improve bond quality and longevity by removing contaminants and promoting better atomic interaction.

- Testing and quality assurance for joint longevity prediction: Predicting and ensuring the longevity of laser welded and diffusion bonded joints requires comprehensive testing and quality assurance protocols. Non-destructive testing methods such as ultrasonic inspection, X-ray analysis, and thermal imaging can identify internal defects that might compromise long-term performance. Accelerated aging tests, including thermal cycling, mechanical fatigue testing, and corrosion exposure, help estimate real-world durability. Statistical process control during manufacturing, combined with these testing approaches, enables reliable prediction of joint service life and identification of process improvements to enhance longevity.

02 Diffusion bonding techniques for enhanced bond strength

Diffusion bonding creates strong metallurgical bonds between similar or dissimilar materials through atomic diffusion at elevated temperatures. The process typically involves applying pressure and heat to clean surfaces, allowing atoms to migrate across the interface. The absence of a liquid phase during bonding minimizes residual stresses and distortion, resulting in joints with excellent mechanical properties and long-term stability. Proper surface preparation and controlled atmosphere during bonding are critical for achieving optimal bond strength and longevity.Expand Specific Solutions03 Hybrid joining methods combining laser welding and diffusion bonding

Hybrid joining methods that combine laser welding and diffusion bonding leverage the advantages of both techniques. The laser provides localized heating while diffusion bonding ensures intimate contact and atomic migration between surfaces. This combination results in joints with superior mechanical properties, improved thermal stability, and enhanced resistance to environmental degradation. The hybrid approach is particularly effective for joining dissimilar materials where conventional welding methods might create brittle intermetallic compounds that compromise joint longevity.Expand Specific Solutions04 Material considerations for long-lasting bonded joints

The selection of appropriate materials significantly impacts the longevity of laser welded and diffusion bonded joints. Compatibility between base materials, coefficient of thermal expansion matching, and susceptibility to intermetallic formation must be considered. For laser welding, materials with good weldability and low thermal conductivity often produce more durable joints. In diffusion bonding, materials with similar diffusion coefficients and solubility characteristics create stronger, more stable interfaces. Surface coatings or interlayers can be used to enhance compatibility between dissimilar materials and improve long-term joint performance.Expand Specific Solutions05 Testing and qualification methods for joint longevity

Various testing and qualification methods are employed to evaluate and predict the longevity of laser welded and diffusion bonded joints. These include accelerated aging tests, thermal cycling, mechanical fatigue testing, and environmental exposure tests. Non-destructive evaluation techniques such as ultrasonic inspection, X-ray analysis, and acoustic emission monitoring help identify potential failure modes before they manifest. Microstructural analysis and mechanical property testing provide insights into bond quality and expected service life. Long-term performance data collection and analysis are essential for validating joint design and process parameters.Expand Specific Solutions

Key Industry Players in Advanced Welding Solutions

The laser welding versus diffusion bonding technology landscape is currently in a growth phase, with the market expanding due to increasing demand for high-precision joining methods in automotive, aerospace, and electronics industries. Companies like Robert Bosch, Illinois Tool Works, and Boeing are driving innovation in laser welding, while HRL Laboratories and Hitachi are advancing diffusion bonding technologies. The global market for these technologies is estimated to exceed $2.5 billion, growing at 5-7% annually. Technical maturity varies significantly: laser welding has reached commercial maturity with widespread adoption across industries, while diffusion bonding remains more specialized but offers superior bond integrity for critical applications in aerospace and microelectronics where companies like Neuralink and DB HITEK are exploring new implementations.

The Boeing Co.

Technical Solution: Boeing has developed advanced laser welding techniques for aerospace applications, particularly for joining dissimilar metals in aircraft structures. Their proprietary Laser Beam Welding (LBW) system utilizes high-power fiber lasers with precise beam control to create joints with minimal heat-affected zones. Boeing's approach incorporates real-time weld monitoring systems that use infrared thermography to detect defects during the welding process. For critical aerospace components, they've implemented a hybrid laser-arc welding technique that combines the penetration benefits of laser welding with the gap-bridging capabilities of arc welding. This has shown 30% improvement in fatigue life compared to traditional joining methods. Boeing has also conducted extensive comparative studies between laser welding and diffusion bonding, particularly for titanium components in high-stress environments.

Strengths: Superior joint strength in aerospace-grade materials; excellent fatigue resistance; minimal distortion in thin-section components; high production speeds. Weaknesses: Higher initial equipment investment; challenges with highly reflective materials like aluminum alloys; requires precise fit-up tolerances.

Hitachi Ltd.

Technical Solution: Hitachi has developed comprehensive joining technologies encompassing both laser welding and diffusion bonding for electronics and power systems applications. Their laser welding approach utilizes ultra-short pulse lasers for micro-joining applications in semiconductor packaging, achieving weld features below 10μm with minimal thermal damage. For power electronics applications, Hitachi employs a hybrid laser welding system that combines fiber lasers with specialized beam shaping optics to optimize energy distribution for joining dissimilar metals with high thermal conductivity differentials. In parallel, Hitachi has advanced diffusion bonding technology for power semiconductor modules, using nano-silver sintering materials that enable low-temperature (sub-300°C) bonding with thermal performance comparable to high-temperature processes. Their comparative studies between laser welding and diffusion bonding for power electronics applications demonstrate that diffusion-bonded interfaces show 40% better thermal cycling reliability in accelerated aging tests, though with significantly longer processing times.

Strengths: Versatile technology portfolio addressing both high-speed (laser) and high-reliability (diffusion) applications; excellent thermal management in electronic assemblies; proven long-term reliability data. Weaknesses: Complex process parameter optimization required; higher implementation costs for dual-technology approach; material-specific limitations for each process.

Critical Technical Innovations in Bond Interface Stability

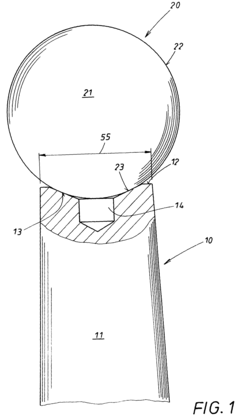

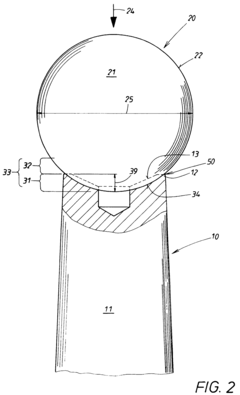

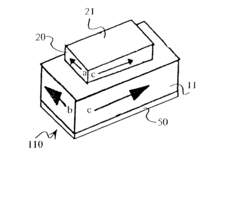

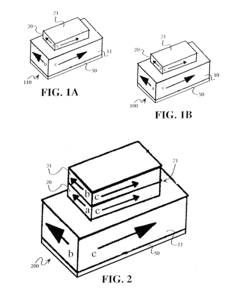

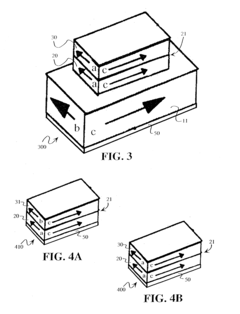

Process for joining two parts consisting of metals differing in hardness by means of laser light

PatentInactiveEP0940214A2

Innovation

- A combined welding and diffusion bonding process using a laser beam to heat the interface between the two parts to a high temperature in a fraction of a second, accompanied by high pressure to achieve melting and diffusion, creating a strong connection without cracking.

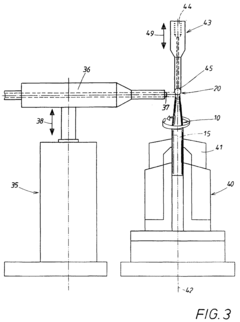

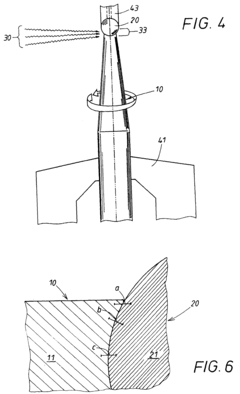

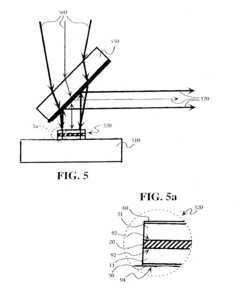

Laser apparatus with improved thermal stress resistance

PatentInactiveUS20040057480A1

Innovation

- Diffusion-bonding a thermally stronger, optically transparent substrate with matching thermal expansion coefficients to the laser medium, creating a compressive stress and reducing tensile stress, thereby enhancing thermal stress resistance and preventing catastrophic failure.

Material Compatibility Considerations for Different Joining Methods

Material compatibility represents a critical factor when selecting between laser welding and diffusion bonding processes. Laser welding demonstrates excellent compatibility with similar metals and alloys, particularly in the automotive and electronics industries where joining steel variants or aluminum alloys is common. However, it faces significant challenges when joining dissimilar materials due to the formation of brittle intermetallic compounds at the weld interface, which can compromise joint integrity over time.

Diffusion bonding, conversely, excels in joining dissimilar materials by creating atomic bonds without melting the base materials. This process is particularly valuable for aerospace and medical device applications where titanium alloys must be joined to stainless steels or nickel-based superalloys. The solid-state nature of diffusion bonding minimizes thermal stresses and prevents the formation of detrimental intermetallic phases that would otherwise reduce joint longevity.

Thermal expansion coefficient matching plays a crucial role in determining long-term joint reliability. Materials with significantly different coefficients can experience cyclic stress during temperature fluctuations, leading to premature failure. Laser welding joints are particularly susceptible to this phenomenon due to the localized heat-affected zone, whereas diffusion bonded joints distribute thermal stresses more uniformly across the interface.

Surface preparation requirements differ substantially between these methods. Laser welding tolerates moderate surface contamination due to its high energy density that can vaporize surface oxides. Diffusion bonding demands exceptionally clean, oxide-free surfaces to facilitate proper atomic diffusion, requiring more rigorous pre-processing protocols including chemical etching or mechanical polishing to achieve optimal bond strength.

Corrosion resistance at the joint interface represents another critical compatibility consideration. Laser welded joints may exhibit galvanic corrosion when joining dissimilar metals, particularly in humid or saline environments. Diffusion bonded joints typically demonstrate superior corrosion resistance due to the absence of filler materials and the gradual transition zone between base materials, which minimizes electrochemical potential differences.

Material thickness compatibility also varies significantly between these joining methods. Laser welding performs optimally with thin to medium-thickness materials (typically 0.1-6mm), while diffusion bonding can accommodate a wider range of thicknesses and is particularly effective for joining thin foils to thicker substrates without distortion, a capability crucial in heat exchanger manufacturing and microelectronic applications.

Diffusion bonding, conversely, excels in joining dissimilar materials by creating atomic bonds without melting the base materials. This process is particularly valuable for aerospace and medical device applications where titanium alloys must be joined to stainless steels or nickel-based superalloys. The solid-state nature of diffusion bonding minimizes thermal stresses and prevents the formation of detrimental intermetallic phases that would otherwise reduce joint longevity.

Thermal expansion coefficient matching plays a crucial role in determining long-term joint reliability. Materials with significantly different coefficients can experience cyclic stress during temperature fluctuations, leading to premature failure. Laser welding joints are particularly susceptible to this phenomenon due to the localized heat-affected zone, whereas diffusion bonded joints distribute thermal stresses more uniformly across the interface.

Surface preparation requirements differ substantially between these methods. Laser welding tolerates moderate surface contamination due to its high energy density that can vaporize surface oxides. Diffusion bonding demands exceptionally clean, oxide-free surfaces to facilitate proper atomic diffusion, requiring more rigorous pre-processing protocols including chemical etching or mechanical polishing to achieve optimal bond strength.

Corrosion resistance at the joint interface represents another critical compatibility consideration. Laser welded joints may exhibit galvanic corrosion when joining dissimilar metals, particularly in humid or saline environments. Diffusion bonded joints typically demonstrate superior corrosion resistance due to the absence of filler materials and the gradual transition zone between base materials, which minimizes electrochemical potential differences.

Material thickness compatibility also varies significantly between these joining methods. Laser welding performs optimally with thin to medium-thickness materials (typically 0.1-6mm), while diffusion bonding can accommodate a wider range of thicknesses and is particularly effective for joining thin foils to thicker substrates without distortion, a capability crucial in heat exchanger manufacturing and microelectronic applications.

Environmental Impact Assessment of Joining Technologies

The environmental impact of joining technologies has become increasingly important as industries strive for sustainability alongside performance. When comparing laser welding and diffusion bonding, several environmental factors must be considered across their entire lifecycle.

Laser welding demonstrates significant energy efficiency advantages during operation. The process requires precise energy input concentrated at specific points, resulting in lower overall energy consumption compared to traditional welding methods. Modern laser welding systems have achieved energy efficiency improvements of up to 30-40% over the past decade. However, the production of laser equipment involves energy-intensive processes and rare earth elements, creating an initial environmental footprint.

Diffusion bonding presents a different environmental profile. The process typically requires sustained heating of entire components, consuming substantial energy during operation. However, it eliminates the need for additional materials like fillers or fluxes, reducing resource consumption. The absence of melting also means fewer emissions of potentially harmful metallic vapors and particulates that are common in fusion-based joining processes.

Waste generation differs significantly between these technologies. Laser welding produces minimal direct waste during operation but may require more frequent replacement of optical components and specialized parts. Diffusion bonding generates almost no process waste but may require more extensive surface preparation chemicals, some of which pose environmental concerns if not properly managed.

Carbon footprint analysis reveals that laser welding typically produces 15-25% lower CO2 emissions during operation compared to conventional joining methods. However, when accounting for equipment manufacturing, this advantage narrows. Diffusion bonding shows higher operational emissions due to extended heating cycles but benefits from simpler equipment requirements and longer service intervals.

Water usage presents another environmental consideration. Laser systems often require cooling water circuits, with high-power industrial systems consuming 5-10 gallons per minute. Diffusion bonding processes may use less water directly but often require more intensive cleaning procedures before bonding, potentially increasing overall water consumption and contamination.

End-of-life considerations favor diffusion-bonded components, as they typically contain fewer mixed materials and can be more easily recycled. Laser-welded components may contain more diverse material combinations at joint interfaces, potentially complicating recycling processes.

Recent lifecycle assessments indicate that the environmental superiority of either technology depends heavily on specific application parameters, production volumes, and operational lifespans. For high-volume production with long service lives, laser welding's operational efficiency often provides the better environmental profile, while diffusion bonding may be preferable for specialized, lower-volume applications where joint longevity is paramount.

Laser welding demonstrates significant energy efficiency advantages during operation. The process requires precise energy input concentrated at specific points, resulting in lower overall energy consumption compared to traditional welding methods. Modern laser welding systems have achieved energy efficiency improvements of up to 30-40% over the past decade. However, the production of laser equipment involves energy-intensive processes and rare earth elements, creating an initial environmental footprint.

Diffusion bonding presents a different environmental profile. The process typically requires sustained heating of entire components, consuming substantial energy during operation. However, it eliminates the need for additional materials like fillers or fluxes, reducing resource consumption. The absence of melting also means fewer emissions of potentially harmful metallic vapors and particulates that are common in fusion-based joining processes.

Waste generation differs significantly between these technologies. Laser welding produces minimal direct waste during operation but may require more frequent replacement of optical components and specialized parts. Diffusion bonding generates almost no process waste but may require more extensive surface preparation chemicals, some of which pose environmental concerns if not properly managed.

Carbon footprint analysis reveals that laser welding typically produces 15-25% lower CO2 emissions during operation compared to conventional joining methods. However, when accounting for equipment manufacturing, this advantage narrows. Diffusion bonding shows higher operational emissions due to extended heating cycles but benefits from simpler equipment requirements and longer service intervals.

Water usage presents another environmental consideration. Laser systems often require cooling water circuits, with high-power industrial systems consuming 5-10 gallons per minute. Diffusion bonding processes may use less water directly but often require more intensive cleaning procedures before bonding, potentially increasing overall water consumption and contamination.

End-of-life considerations favor diffusion-bonded components, as they typically contain fewer mixed materials and can be more easily recycled. Laser-welded components may contain more diverse material combinations at joint interfaces, potentially complicating recycling processes.

Recent lifecycle assessments indicate that the environmental superiority of either technology depends heavily on specific application parameters, production volumes, and operational lifespans. For high-volume production with long service lives, laser welding's operational efficiency often provides the better environmental profile, while diffusion bonding may be preferable for specialized, lower-volume applications where joint longevity is paramount.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!