Laser Welding vs Electron Beam: Which Provides Better Accuracy?

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Precision Welding Technologies Evolution and Objectives

Precision welding technologies have undergone significant evolution over the past century, transforming from rudimentary manual processes to highly sophisticated automated systems. The journey began with traditional flame and arc welding methods in the early 20th century, which provided limited precision and required considerable operator skill. The mid-century saw the emergence of TIG (Tungsten Inert Gas) welding, offering improved accuracy for specialized applications but still facing limitations in terms of heat-affected zones and material compatibility.

The 1960s marked a revolutionary turning point with the introduction of electron beam welding (EBW) technology, initially developed for aerospace applications. This vacuum-based process enabled unprecedented precision and penetration capabilities, particularly for high-value components in critical industries. The 1970s witnessed the commercial emergence of laser welding technology, which initially struggled with power limitations but promised non-vacuum operation advantages.

The subsequent decades have seen remarkable technological advancements in both laser and electron beam welding systems. Laser technologies evolved from CO2 systems to Nd:YAG, fiber, and now direct diode lasers, each generation offering improvements in beam quality, energy efficiency, and control precision. Similarly, electron beam systems have advanced with digital controls, improved vacuum systems, and enhanced beam manipulation capabilities.

Today's precision welding landscape is characterized by the parallel development of these two advanced technologies, each finding specialized applications across industries including automotive, aerospace, medical device manufacturing, and electronics. The technical evolution has consistently pursued several key objectives: increasing joining precision, minimizing heat-affected zones, enabling dissimilar material joining, improving process repeatability, and enhancing automation compatibility.

The current technological frontier focuses on achieving sub-micron welding accuracy for increasingly miniaturized components, particularly in electronics and medical devices. Industry demands are driving development toward systems capable of maintaining extreme precision while accommodating higher production volumes and greater material diversity. Additionally, there is growing emphasis on energy efficiency, process monitoring capabilities, and integration with Industry 4.0 manufacturing environments.

The comparative analysis of laser welding versus electron beam technologies represents a critical evaluation point in this evolutionary trajectory, as manufacturers seek optimal solutions for increasingly demanding precision applications. Understanding the relative strengths and limitations of these technologies within specific application contexts has become essential for strategic technology investment decisions across multiple industries.

The 1960s marked a revolutionary turning point with the introduction of electron beam welding (EBW) technology, initially developed for aerospace applications. This vacuum-based process enabled unprecedented precision and penetration capabilities, particularly for high-value components in critical industries. The 1970s witnessed the commercial emergence of laser welding technology, which initially struggled with power limitations but promised non-vacuum operation advantages.

The subsequent decades have seen remarkable technological advancements in both laser and electron beam welding systems. Laser technologies evolved from CO2 systems to Nd:YAG, fiber, and now direct diode lasers, each generation offering improvements in beam quality, energy efficiency, and control precision. Similarly, electron beam systems have advanced with digital controls, improved vacuum systems, and enhanced beam manipulation capabilities.

Today's precision welding landscape is characterized by the parallel development of these two advanced technologies, each finding specialized applications across industries including automotive, aerospace, medical device manufacturing, and electronics. The technical evolution has consistently pursued several key objectives: increasing joining precision, minimizing heat-affected zones, enabling dissimilar material joining, improving process repeatability, and enhancing automation compatibility.

The current technological frontier focuses on achieving sub-micron welding accuracy for increasingly miniaturized components, particularly in electronics and medical devices. Industry demands are driving development toward systems capable of maintaining extreme precision while accommodating higher production volumes and greater material diversity. Additionally, there is growing emphasis on energy efficiency, process monitoring capabilities, and integration with Industry 4.0 manufacturing environments.

The comparative analysis of laser welding versus electron beam technologies represents a critical evaluation point in this evolutionary trajectory, as manufacturers seek optimal solutions for increasingly demanding precision applications. Understanding the relative strengths and limitations of these technologies within specific application contexts has become essential for strategic technology investment decisions across multiple industries.

Market Applications and Industry Demand Analysis

The global market for precision welding technologies has witnessed significant growth, with laser welding and electron beam welding emerging as dominant technologies across multiple industries. The combined market value for these advanced welding technologies exceeded $2.5 billion in 2022, with projections indicating a compound annual growth rate of 6.8% through 2028.

Aerospace and defense sectors represent the largest market segment for high-precision welding technologies, accounting for approximately 32% of the total market share. In these industries, the demand for electron beam welding remains particularly strong due to its superior vacuum environment capabilities and deep penetration characteristics essential for critical components such as jet engine parts and structural elements for spacecraft.

The automotive industry has increasingly adopted laser welding technology, particularly for battery enclosures in electric vehicles, lightweight body structures, and powertrain components. This sector has shown the fastest growth rate at 8.3% annually, driven by the rapid expansion of electric vehicle production and the push for lightweight materials to improve fuel efficiency and range.

Medical device manufacturing represents another significant market, valued at approximately $420 million for precision welding technologies. The demand in this sector is primarily for laser welding due to its non-contact nature, minimal heat-affected zone, and ability to join dissimilar materials—critical factors for manufacturing implantable devices, surgical instruments, and diagnostic equipment.

Electronics manufacturing has shown a distinct preference for laser welding technology, particularly in consumer electronics, semiconductor packaging, and microelectronic components. The market size in this segment reached $380 million in 2022, with laser welding capturing over 75% of the share due to its superior accuracy for miniaturized components.

Regional analysis reveals that Asia-Pacific dominates the market with a 42% share, led by manufacturing powerhouses like China, Japan, and South Korea. North America follows at 28%, with particularly strong demand in aerospace and medical device sectors. Europe accounts for 24% of the market, with Germany and Italy leading in automotive and industrial equipment applications.

Industry surveys indicate that manufacturers prioritize accuracy as the third most important factor when selecting welding technologies, behind reliability and total cost of ownership. However, in high-precision industries such as medical devices and aerospace, accuracy consistently ranks as the primary selection criterion, highlighting the strategic importance of the comparative accuracy between laser and electron beam welding technologies.

Aerospace and defense sectors represent the largest market segment for high-precision welding technologies, accounting for approximately 32% of the total market share. In these industries, the demand for electron beam welding remains particularly strong due to its superior vacuum environment capabilities and deep penetration characteristics essential for critical components such as jet engine parts and structural elements for spacecraft.

The automotive industry has increasingly adopted laser welding technology, particularly for battery enclosures in electric vehicles, lightweight body structures, and powertrain components. This sector has shown the fastest growth rate at 8.3% annually, driven by the rapid expansion of electric vehicle production and the push for lightweight materials to improve fuel efficiency and range.

Medical device manufacturing represents another significant market, valued at approximately $420 million for precision welding technologies. The demand in this sector is primarily for laser welding due to its non-contact nature, minimal heat-affected zone, and ability to join dissimilar materials—critical factors for manufacturing implantable devices, surgical instruments, and diagnostic equipment.

Electronics manufacturing has shown a distinct preference for laser welding technology, particularly in consumer electronics, semiconductor packaging, and microelectronic components. The market size in this segment reached $380 million in 2022, with laser welding capturing over 75% of the share due to its superior accuracy for miniaturized components.

Regional analysis reveals that Asia-Pacific dominates the market with a 42% share, led by manufacturing powerhouses like China, Japan, and South Korea. North America follows at 28%, with particularly strong demand in aerospace and medical device sectors. Europe accounts for 24% of the market, with Germany and Italy leading in automotive and industrial equipment applications.

Industry surveys indicate that manufacturers prioritize accuracy as the third most important factor when selecting welding technologies, behind reliability and total cost of ownership. However, in high-precision industries such as medical devices and aerospace, accuracy consistently ranks as the primary selection criterion, highlighting the strategic importance of the comparative accuracy between laser and electron beam welding technologies.

Current Capabilities and Technical Limitations

Laser welding and electron beam welding represent two advanced joining technologies widely used in precision manufacturing industries. Both technologies offer distinct capabilities and face specific limitations that influence their suitability for high-precision applications.

Laser welding currently achieves positional accuracy of ±0.01mm in optimal conditions, with beam diameters ranging from 0.2mm to 0.6mm for most industrial applications. Modern fiber lasers can deliver power densities up to 10^7 W/cm², enabling weld penetration depths of 5-10mm in a single pass. The technology excels in speed, with welding rates reaching 10m/min for thin materials, though this decreases significantly with material thickness.

Despite these impressive capabilities, laser welding faces several technical limitations. Reflective materials like aluminum and copper present challenges due to poor beam absorption, requiring higher power inputs that can introduce thermal distortion. The technology also struggles with thick sections beyond 10mm, where multiple passes become necessary, compromising dimensional accuracy. Beam stability issues can arise from plasma formation during high-power welding, creating inconsistencies in weld quality.

Electron beam welding, by comparison, demonstrates superior positional accuracy of ±0.005mm under vacuum conditions. The technology can achieve extremely narrow beam diameters of 0.05mm to 0.5mm, with power densities reaching 10^8 W/cm². This enables exceptional aspect ratios (depth-to-width) of up to 30:1, allowing single-pass penetration of materials exceeding 50mm thickness while maintaining precision.

However, electron beam welding's primary limitation stems from its vacuum requirement, necessitating specialized chambers that restrict workpiece size and add significant processing time. Modern partial vacuum systems have improved this limitation but still require 30-60 minutes of pump-down time. The technology also demands higher capital investment, with systems typically costing 2-3 times more than equivalent laser welding equipment.

Both technologies face challenges with certain material combinations. Laser welding struggles with dissimilar metals having vastly different melting points, while electron beam welding can experience beam deflection when working with ferromagnetic materials. Additionally, both technologies require sophisticated monitoring systems to maintain accuracy during production, with electron beam systems generally requiring more complex calibration procedures.

Recent developments have focused on overcoming these limitations through hybrid approaches. Oscillating beam techniques have improved both technologies' performance with reflective materials, while advanced process monitoring using high-speed cameras and spectroscopic analysis has enhanced real-time quality control. These innovations continue to expand the capabilities of both welding methods, gradually narrowing the gap between their respective performance characteristics.

Laser welding currently achieves positional accuracy of ±0.01mm in optimal conditions, with beam diameters ranging from 0.2mm to 0.6mm for most industrial applications. Modern fiber lasers can deliver power densities up to 10^7 W/cm², enabling weld penetration depths of 5-10mm in a single pass. The technology excels in speed, with welding rates reaching 10m/min for thin materials, though this decreases significantly with material thickness.

Despite these impressive capabilities, laser welding faces several technical limitations. Reflective materials like aluminum and copper present challenges due to poor beam absorption, requiring higher power inputs that can introduce thermal distortion. The technology also struggles with thick sections beyond 10mm, where multiple passes become necessary, compromising dimensional accuracy. Beam stability issues can arise from plasma formation during high-power welding, creating inconsistencies in weld quality.

Electron beam welding, by comparison, demonstrates superior positional accuracy of ±0.005mm under vacuum conditions. The technology can achieve extremely narrow beam diameters of 0.05mm to 0.5mm, with power densities reaching 10^8 W/cm². This enables exceptional aspect ratios (depth-to-width) of up to 30:1, allowing single-pass penetration of materials exceeding 50mm thickness while maintaining precision.

However, electron beam welding's primary limitation stems from its vacuum requirement, necessitating specialized chambers that restrict workpiece size and add significant processing time. Modern partial vacuum systems have improved this limitation but still require 30-60 minutes of pump-down time. The technology also demands higher capital investment, with systems typically costing 2-3 times more than equivalent laser welding equipment.

Both technologies face challenges with certain material combinations. Laser welding struggles with dissimilar metals having vastly different melting points, while electron beam welding can experience beam deflection when working with ferromagnetic materials. Additionally, both technologies require sophisticated monitoring systems to maintain accuracy during production, with electron beam systems generally requiring more complex calibration procedures.

Recent developments have focused on overcoming these limitations through hybrid approaches. Oscillating beam techniques have improved both technologies' performance with reflective materials, while advanced process monitoring using high-speed cameras and spectroscopic analysis has enhanced real-time quality control. These innovations continue to expand the capabilities of both welding methods, gradually narrowing the gap between their respective performance characteristics.

Comparative Analysis of Laser and Electron Beam Solutions

01 Precision control systems for welding accuracy

Advanced control systems are essential for achieving high accuracy in both laser and electron beam welding. These systems incorporate precise positioning mechanisms, real-time monitoring, and feedback loops to maintain welding accuracy. Computer-controlled positioning systems can achieve micrometer-level precision, allowing for extremely accurate welds in critical applications such as electronics manufacturing and aerospace components.- Precision control systems for welding accuracy: Advanced control systems are essential for achieving high accuracy in both laser and electron beam welding. These systems incorporate precise positioning mechanisms, real-time monitoring, and feedback loops to maintain welding accuracy. Computer-controlled positioning stages and beam deflection systems allow for precise movement and placement of the welding beam, resulting in highly accurate welds with minimal deviation. These control systems can compensate for environmental factors and material variations to maintain consistent welding quality.

- Beam focusing and alignment technologies: The accuracy of laser and electron beam welding heavily depends on proper beam focusing and alignment. Advanced optical systems for laser welding and electromagnetic lenses for electron beam welding enable precise focusing of the energy source onto the workpiece. Alignment systems ensure that the beam strikes the intended weld location with high precision. These technologies allow for creating extremely narrow weld seams with minimal heat-affected zones, which is particularly important for welding thin materials and precision components.

- Monitoring and quality control methods: Real-time monitoring systems play a crucial role in maintaining welding accuracy. These include optical sensors, thermal cameras, and spectroscopic analyzers that can detect deviations during the welding process. Advanced systems incorporate machine vision and artificial intelligence to analyze weld quality in real-time and make automatic adjustments. Post-weld inspection techniques such as X-ray analysis, ultrasonic testing, and computer tomography help verify weld accuracy and integrity, ensuring that precision requirements are met consistently.

- Material-specific welding parameters: Different materials require specific welding parameters to achieve optimal accuracy. The power density, pulse duration, beam focus, and travel speed must be carefully calibrated based on the material properties such as thermal conductivity, melting point, and reflectivity. For example, highly reflective materials like aluminum require different laser parameters compared to steel. Electron beam welding parameters must be adjusted for materials with different electron scattering properties. Proper parameter selection ensures precise energy delivery to the weld joint, minimizing distortion and improving overall accuracy.

- Environmental and vacuum conditions: Environmental conditions significantly impact welding accuracy, particularly for electron beam welding which typically requires vacuum conditions. Vacuum chambers eliminate atmospheric interference, allowing for more precise beam control and reducing beam scattering. For laser welding, shielding gases help prevent oxidation and plasma formation that could deflect the beam. Controlled environments with stable temperature and humidity also contribute to consistent welding results. Proper fixturing and workpiece preparation further enhance accuracy by preventing movement during the welding process.

02 Beam focusing and alignment technologies

The accuracy of both laser and electron beam welding heavily depends on proper beam focusing and alignment. Advanced optical systems for laser welding and electromagnetic lenses for electron beam welding enable precise control of beam characteristics. These technologies allow for narrower focus spots, resulting in higher energy density and more precise welds. Proper alignment systems ensure that the beam hits the target area with minimal deviation.Expand Specific Solutions03 Comparative accuracy between laser and electron beam welding

Electron beam welding typically offers higher precision than laser welding in vacuum environments, achieving accuracies down to micrometers. Laser welding provides excellent accuracy in atmospheric conditions and is more versatile for various materials and thicknesses. The choice between these technologies depends on specific application requirements, material properties, and environmental constraints. Each technology has distinct advantages in terms of weld penetration, heat-affected zone size, and distortion control.Expand Specific Solutions04 Material-specific welding parameters for accuracy

Achieving high accuracy in both laser and electron beam welding requires optimized parameters specific to the material being welded. Parameters such as beam power, pulse duration, travel speed, and focus position must be carefully calibrated for different materials to achieve precise welds. Advanced systems incorporate material databases and adaptive control algorithms to automatically adjust parameters based on material properties, thickness variations, and joint configurations.Expand Specific Solutions05 Monitoring and quality control systems

Real-time monitoring and quality control systems are crucial for maintaining welding accuracy. These systems use sensors, cameras, and advanced analytics to detect deviations during the welding process. Thermal imaging, spectroscopic analysis, and acoustic monitoring provide immediate feedback on weld quality and position accuracy. Integration with artificial intelligence and machine learning algorithms enables predictive corrections to maintain precision throughout the welding process.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The laser welding versus electron beam welding market is currently in a growth phase, with an estimated global market size of $2.5 billion and projected annual growth of 6-8%. The competitive landscape features established industrial equipment manufacturers like TRUMPF Laser- und Systemtechnik and pro-beam GmbH specializing in high-precision welding technologies, alongside diversified conglomerates such as Hitachi, General Electric, and Honeywell that integrate these technologies into broader manufacturing solutions. Academic institutions including Huazhong University of Science & Technology and Harbin Institute of Technology are advancing fundamental research, while specialized players like Aquasium Technology focus on niche applications in aerospace and medical sectors. The technology maturity varies by application, with electron beam welding showing higher precision capabilities for specialized applications, while laser welding offers greater flexibility and accessibility across diverse manufacturing environments.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced materials joining solutions incorporating both laser and electron beam technologies optimized for aerospace applications. Their proprietary Automated Precision Joining (APJ) system integrates real-time monitoring with adaptive control algorithms that adjust welding parameters based on material conditions. Honeywell's research has demonstrated that their laser welding systems achieve positional accuracy of ±0.08mm for aerospace alloys, while their electron beam systems achieve ±0.015mm for critical components. Their systems incorporate dual-beam technology that allows simultaneous processing of different material thicknesses within the same component. Honeywell has also developed specialized solutions for joining dissimilar materials, particularly for applications requiring hermetic sealing in harsh environments.

Strengths: Comprehensive integration capabilities with existing manufacturing systems; specialized solutions for aerospace-grade materials with stringent quality requirements. Weaknesses: Systems are highly specialized for aerospace applications and may be less cost-effective for general manufacturing applications.

TWI GmbH

Technical Solution: TWI has developed comprehensive technical solutions for both laser and electron beam welding, positioning them as a neutral authority on comparative performance. Their research has demonstrated that electron beam welding achieves positional accuracy of ±0.02mm compared to laser welding's typical ±0.1mm for similar applications. TWI's proprietary SurfiScan technology enables real-time monitoring of weld quality through analysis of surface topography during the welding process. Their comparative studies have shown that electron beam welding produces narrower heat-affected zones (typically 0.5-1mm) compared to laser welding (1-2mm) in similar materials. TWI has also pioneered hybrid joining techniques that leverage the advantages of both technologies for specialized applications, particularly in aerospace and nuclear sectors.

Strengths: Extensive research capabilities with objective comparative analysis between technologies; development of specialized monitoring systems for quality control. Weaknesses: Solutions often require customization for specific industrial applications, leading to longer implementation timelines.

Key Patents and Technical Innovations in Precision Welding

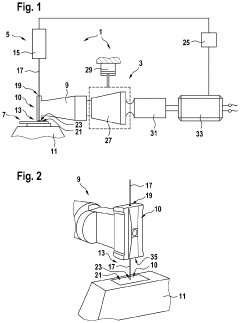

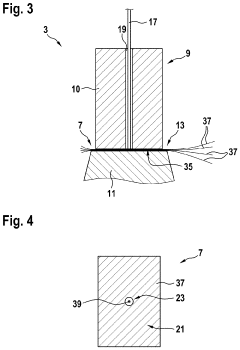

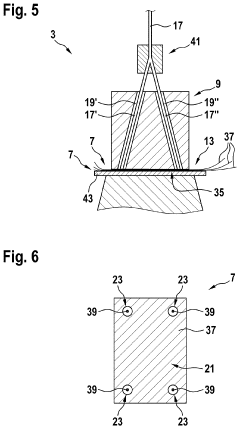

Electron beam welding methods and apparatus

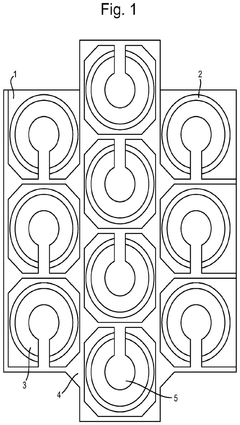

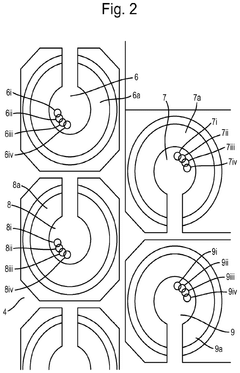

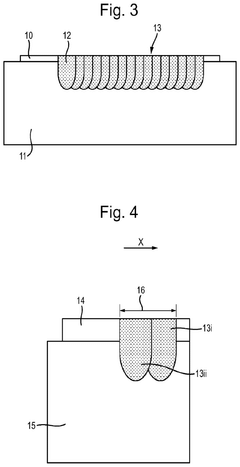

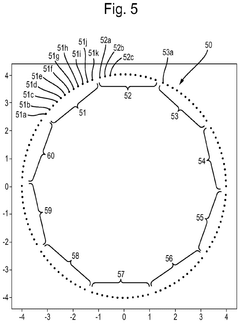

PatentPendingUS20240359254A1

Innovation

- The method involves forming a series of spot welds using electron beam welding, where each spot weld is allowed to solidify before subsequent welds are formed, using electromagnetic coils to rapidly position and focus the electron beam, reducing the time spent traversing between weld locations and mitigating the 'humping' effect, resulting in consistent and high-quality joints.

Welding device and method for welding at least two components

PatentPendingUS20220281028A1

Innovation

- A welding device and method that combines ultrasonic welding with simultaneous laser welding, using an ultrasonic sonotrode and anvil with a through opening to allow a laser beam to weld a smaller area within the periphery of the ultrasonic weld zone, enabling both technologies to operate simultaneously and reducing the need for high laser power.

Material Compatibility and Weldability Considerations

Material compatibility represents a critical factor when selecting between laser welding and electron beam welding technologies. Laser welding demonstrates exceptional versatility across a wide range of materials, including various metals, alloys, and even certain polymers. It performs particularly well with stainless steel, aluminum, titanium, and nickel-based alloys. However, laser welding encounters challenges with highly reflective materials such as copper and gold, as the beam energy may be reflected rather than absorbed, reducing process efficiency.

Electron beam welding, conversely, exhibits superior performance with high-density metals and refractory materials. It excels at welding materials like tungsten, molybdenum, and tantalum that typically present difficulties for other welding methods. The vacuum environment required for electron beam welding also provides significant advantages when working with reactive metals such as titanium and zirconium, as it prevents atmospheric contamination that could compromise weld integrity.

When considering material thickness, electron beam welding generally achieves deeper penetration capabilities, with single-pass welds possible in materials exceeding 50mm thickness. Laser welding traditionally operates more effectively with thinner materials, though advancements in high-power laser systems have expanded this range considerably in recent years.

Joint configuration compatibility also differs between these technologies. Laser welding typically requires precise fit-up with minimal gaps between components, generally less than 0.1mm. Electron beam welding can accommodate slightly larger tolerances but still demands careful joint preparation. Both technologies excel at producing autogenous welds (without filler material), though laser welding offers greater flexibility for incorporating filler materials when necessary.

Thermal conductivity characteristics of the target materials significantly impact weldability with both processes. Materials with high thermal conductivity, such as copper and aluminum, present challenges for laser welding due to rapid heat dissipation. Electron beam welding, with its higher energy density and vacuum environment, can often overcome these limitations more effectively.

Dissimilar material joining represents another important consideration. Laser welding demonstrates advantages for certain dissimilar metal combinations due to its precise heat input control, which minimizes the formation of brittle intermetallic compounds. Electron beam welding, while also capable of joining dissimilar materials, may require more complex parameter optimization to achieve comparable results in these applications.

Electron beam welding, conversely, exhibits superior performance with high-density metals and refractory materials. It excels at welding materials like tungsten, molybdenum, and tantalum that typically present difficulties for other welding methods. The vacuum environment required for electron beam welding also provides significant advantages when working with reactive metals such as titanium and zirconium, as it prevents atmospheric contamination that could compromise weld integrity.

When considering material thickness, electron beam welding generally achieves deeper penetration capabilities, with single-pass welds possible in materials exceeding 50mm thickness. Laser welding traditionally operates more effectively with thinner materials, though advancements in high-power laser systems have expanded this range considerably in recent years.

Joint configuration compatibility also differs between these technologies. Laser welding typically requires precise fit-up with minimal gaps between components, generally less than 0.1mm. Electron beam welding can accommodate slightly larger tolerances but still demands careful joint preparation. Both technologies excel at producing autogenous welds (without filler material), though laser welding offers greater flexibility for incorporating filler materials when necessary.

Thermal conductivity characteristics of the target materials significantly impact weldability with both processes. Materials with high thermal conductivity, such as copper and aluminum, present challenges for laser welding due to rapid heat dissipation. Electron beam welding, with its higher energy density and vacuum environment, can often overcome these limitations more effectively.

Dissimilar material joining represents another important consideration. Laser welding demonstrates advantages for certain dissimilar metal combinations due to its precise heat input control, which minimizes the formation of brittle intermetallic compounds. Electron beam welding, while also capable of joining dissimilar materials, may require more complex parameter optimization to achieve comparable results in these applications.

Energy Efficiency and Environmental Impact Assessment

When comparing laser welding and electron beam welding technologies, energy efficiency and environmental impact considerations play crucial roles in determining their overall sustainability and operational costs. Laser welding systems typically operate with electrical efficiency ranging from 20-30%, with newer fiber and diode lasers reaching up to 40% efficiency. In contrast, electron beam welding systems generally achieve 60-70% electrical efficiency, making them significantly more energy-efficient in direct power conversion.

However, total energy consumption analysis reveals more complex patterns. Laser welding often requires less overall facility energy due to simpler vacuum requirements. Electron beam welding necessitates sophisticated vacuum systems that consume substantial energy during operation and maintenance, potentially offsetting its higher beam generation efficiency.

Heat management represents another significant environmental consideration. Laser welding generates more waste heat that must be dissipated through cooling systems, while electron beam processes contain heat more effectively within vacuum chambers. This difference impacts both energy consumption and workplace environmental conditions.

Carbon footprint assessments indicate that electron beam welding typically produces lower direct emissions during operation due to higher energy efficiency. However, when considering the entire lifecycle, including equipment manufacturing and maintenance requirements, the gap narrows considerably. Laser systems often feature longer operational lifespans with fewer specialized components requiring replacement.

Waste generation profiles differ markedly between technologies. Laser welding produces more fume emissions requiring filtration systems, while electron beam welding generates less airborne contamination but may produce more specialized waste from vacuum system maintenance. Modern laser systems increasingly incorporate recycling capabilities for cooling fluids and filter materials, reducing their environmental footprint.

Regulatory compliance considerations favor laser welding in many jurisdictions due to lower radiation shielding requirements. Electron beam systems must address more stringent safety protocols regarding X-ray emissions, necessitating additional materials and energy-intensive shielding structures that impact both initial and ongoing environmental costs.

Future sustainability improvements show promising trajectories for both technologies. Laser systems are benefiting from rapid advances in photonics efficiency, while electron beam systems are seeing innovations in vacuum technology that reduce energy requirements. The environmental advantage may ultimately depend on specific application requirements and ongoing technological developments in both fields.

However, total energy consumption analysis reveals more complex patterns. Laser welding often requires less overall facility energy due to simpler vacuum requirements. Electron beam welding necessitates sophisticated vacuum systems that consume substantial energy during operation and maintenance, potentially offsetting its higher beam generation efficiency.

Heat management represents another significant environmental consideration. Laser welding generates more waste heat that must be dissipated through cooling systems, while electron beam processes contain heat more effectively within vacuum chambers. This difference impacts both energy consumption and workplace environmental conditions.

Carbon footprint assessments indicate that electron beam welding typically produces lower direct emissions during operation due to higher energy efficiency. However, when considering the entire lifecycle, including equipment manufacturing and maintenance requirements, the gap narrows considerably. Laser systems often feature longer operational lifespans with fewer specialized components requiring replacement.

Waste generation profiles differ markedly between technologies. Laser welding produces more fume emissions requiring filtration systems, while electron beam welding generates less airborne contamination but may produce more specialized waste from vacuum system maintenance. Modern laser systems increasingly incorporate recycling capabilities for cooling fluids and filter materials, reducing their environmental footprint.

Regulatory compliance considerations favor laser welding in many jurisdictions due to lower radiation shielding requirements. Electron beam systems must address more stringent safety protocols regarding X-ray emissions, necessitating additional materials and energy-intensive shielding structures that impact both initial and ongoing environmental costs.

Future sustainability improvements show promising trajectories for both technologies. Laser systems are benefiting from rapid advances in photonics efficiency, while electron beam systems are seeing innovations in vacuum technology that reduce energy requirements. The environmental advantage may ultimately depend on specific application requirements and ongoing technological developments in both fields.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!