Laser Welding vs Friction Stir: Evaluating Joint Strength

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Welding Technologies Background and Objectives

Welding technology has evolved significantly over the past century, transitioning from traditional fusion-based methods to advanced solid-state and energy beam processes. The comparison between laser welding and friction stir welding represents a critical juncture in this evolution, highlighting the industry's shift toward precision, efficiency, and material optimization. Laser welding emerged in the 1960s following the invention of the first working laser, while friction stir welding was developed much later in 1991 at The Welding Institute (TWI) in the United Kingdom.

The technological trajectory of welding has been driven by increasing demands across aerospace, automotive, shipbuilding, and electronics manufacturing sectors, where joint strength and integrity are paramount considerations. Historical data indicates that conventional welding methods often introduce significant heat-affected zones that compromise material properties, creating a persistent challenge for engineers and materials scientists.

Recent market analyses suggest that the global advanced welding market is projected to reach $49.2 billion by 2027, with laser welding and friction stir welding representing the fastest-growing segments. This growth underscores the industrial significance of comparing these technologies specifically for joint strength evaluation.

The primary technical objective of this investigation is to establish a comprehensive comparative framework for assessing joint strength characteristics between laser welding and friction stir welding across various material combinations and thicknesses. This includes quantitative analysis of tensile strength, fatigue resistance, microstructural integrity, and long-term durability under diverse environmental conditions.

Secondary objectives include identifying the specific material-process relationships that optimize joint performance, determining the economic and operational thresholds where each technology demonstrates superior performance, and mapping potential hybrid approaches that might leverage the strengths of both technologies.

The technological evolution in this field has been characterized by three distinct waves: the initial development of basic process parameters, the subsequent refinement through computational modeling and simulation, and the current integration with real-time monitoring and adaptive control systems. Each wave has contributed to enhanced understanding of joint formation mechanisms and strength determinants.

Industry consortia and academic research centers have established standardized testing protocols for joint strength evaluation, though significant variations exist across different sectors. This investigation aims to synthesize these approaches into a unified methodology that enables direct comparison between laser and friction stir welding outcomes across multiple performance dimensions.

The technological trajectory of welding has been driven by increasing demands across aerospace, automotive, shipbuilding, and electronics manufacturing sectors, where joint strength and integrity are paramount considerations. Historical data indicates that conventional welding methods often introduce significant heat-affected zones that compromise material properties, creating a persistent challenge for engineers and materials scientists.

Recent market analyses suggest that the global advanced welding market is projected to reach $49.2 billion by 2027, with laser welding and friction stir welding representing the fastest-growing segments. This growth underscores the industrial significance of comparing these technologies specifically for joint strength evaluation.

The primary technical objective of this investigation is to establish a comprehensive comparative framework for assessing joint strength characteristics between laser welding and friction stir welding across various material combinations and thicknesses. This includes quantitative analysis of tensile strength, fatigue resistance, microstructural integrity, and long-term durability under diverse environmental conditions.

Secondary objectives include identifying the specific material-process relationships that optimize joint performance, determining the economic and operational thresholds where each technology demonstrates superior performance, and mapping potential hybrid approaches that might leverage the strengths of both technologies.

The technological evolution in this field has been characterized by three distinct waves: the initial development of basic process parameters, the subsequent refinement through computational modeling and simulation, and the current integration with real-time monitoring and adaptive control systems. Each wave has contributed to enhanced understanding of joint formation mechanisms and strength determinants.

Industry consortia and academic research centers have established standardized testing protocols for joint strength evaluation, though significant variations exist across different sectors. This investigation aims to synthesize these approaches into a unified methodology that enables direct comparison between laser and friction stir welding outcomes across multiple performance dimensions.

Market Demand Analysis for Advanced Joining Methods

The global market for advanced joining technologies is experiencing significant growth, driven by increasing demands across automotive, aerospace, electronics, and construction industries. The compound annual growth rate (CAGR) for advanced welding technologies is projected to reach 5.3% through 2028, with laser welding and friction stir welding representing two of the fastest-growing segments within this market.

Automotive manufacturing constitutes the largest application sector, accounting for approximately 32% of the advanced joining methods market. The industry's shift toward lightweight materials to improve fuel efficiency and reduce emissions has created substantial demand for joining technologies capable of effectively bonding dissimilar materials. Both laser welding and friction stir welding have gained traction in this sector due to their ability to join aluminum alloys, high-strength steels, and composite materials without compromising structural integrity.

Aerospace and defense sectors represent the second-largest market segment, with particularly strong demand for high-strength joints that can withstand extreme conditions. The need for precision joining of titanium alloys, aluminum-lithium alloys, and advanced composites has accelerated adoption of both laser and friction stir technologies. Market research indicates that aerospace applications of these advanced joining methods are growing at nearly 7% annually.

Consumer electronics manufacturing has emerged as a rapidly expanding market for precision joining technologies, particularly laser welding. The miniaturization trend in electronics requires increasingly precise and clean joining methods that minimize heat-affected zones and maintain the integrity of sensitive components. This sector is expected to represent the highest growth potential over the next five years.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 40% share, followed by North America and Europe. China and India are experiencing the fastest growth rates due to rapid industrialization and increasing manufacturing capabilities. However, North America and Europe maintain technological leadership in high-end applications requiring superior joint strength and quality control.

End-user surveys indicate that key purchasing factors include joint strength reliability, process speed, adaptability to different material combinations, and total cost of ownership. Laser welding is preferred where processing speed and precision are paramount, while friction stir welding is favored for applications requiring maximum joint strength and minimal thermal distortion. Market data suggests that manufacturers are increasingly seeking hybrid solutions that combine the advantages of both technologies to optimize joining processes for specific applications.

Automotive manufacturing constitutes the largest application sector, accounting for approximately 32% of the advanced joining methods market. The industry's shift toward lightweight materials to improve fuel efficiency and reduce emissions has created substantial demand for joining technologies capable of effectively bonding dissimilar materials. Both laser welding and friction stir welding have gained traction in this sector due to their ability to join aluminum alloys, high-strength steels, and composite materials without compromising structural integrity.

Aerospace and defense sectors represent the second-largest market segment, with particularly strong demand for high-strength joints that can withstand extreme conditions. The need for precision joining of titanium alloys, aluminum-lithium alloys, and advanced composites has accelerated adoption of both laser and friction stir technologies. Market research indicates that aerospace applications of these advanced joining methods are growing at nearly 7% annually.

Consumer electronics manufacturing has emerged as a rapidly expanding market for precision joining technologies, particularly laser welding. The miniaturization trend in electronics requires increasingly precise and clean joining methods that minimize heat-affected zones and maintain the integrity of sensitive components. This sector is expected to represent the highest growth potential over the next five years.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 40% share, followed by North America and Europe. China and India are experiencing the fastest growth rates due to rapid industrialization and increasing manufacturing capabilities. However, North America and Europe maintain technological leadership in high-end applications requiring superior joint strength and quality control.

End-user surveys indicate that key purchasing factors include joint strength reliability, process speed, adaptability to different material combinations, and total cost of ownership. Laser welding is preferred where processing speed and precision are paramount, while friction stir welding is favored for applications requiring maximum joint strength and minimal thermal distortion. Market data suggests that manufacturers are increasingly seeking hybrid solutions that combine the advantages of both technologies to optimize joining processes for specific applications.

Current State and Challenges in Welding Technologies

The global welding industry is currently experiencing a significant technological transition, with traditional welding methods being challenged by advanced techniques such as laser welding and friction stir welding. These technologies represent different approaches to material joining, each with distinct advantages and limitations when evaluating joint strength outcomes.

Laser welding technology has reached considerable maturity in industrial applications, particularly in automotive, aerospace, and electronics manufacturing. This non-contact welding method utilizes concentrated light energy to create precise, narrow welds with minimal heat-affected zones. Current laser welding systems predominantly employ fiber, CO2, or Nd:YAG lasers, with fiber lasers gaining significant market share due to their superior beam quality and energy efficiency.

Friction stir welding (FSW), developed in the early 1990s, has evolved into a viable solid-state joining process especially valuable for aluminum alloys and dissimilar materials. The technology has seen substantial adoption in aerospace, automotive, and shipbuilding industries where high-strength, defect-free joints are critical. Recent advancements in FSW tool materials and designs have expanded its application range to include harder materials like steel and titanium alloys.

Despite these advancements, both technologies face significant challenges. Laser welding struggles with reflective materials such as aluminum and copper, requiring higher power inputs or surface treatments. Joint fit-up requirements are extremely stringent, with gaps typically limited to less than 0.1mm to ensure weld quality. Additionally, the rapid cooling rates can lead to hardening and potential brittleness in certain materials, compromising joint strength under specific loading conditions.

Friction stir welding faces different obstacles, primarily related to equipment complexity and process limitations. The substantial forces required during the process necessitate rigid clamping systems and robust machinery, increasing capital investment. The relatively slow welding speeds compared to fusion methods limit productivity in high-volume manufacturing environments. Tool wear remains a significant concern when processing harder materials, affecting both economics and joint quality.

Geographically, laser welding technology development is concentrated in Germany, Japan, and the United States, with companies like TRUMPF, IPG Photonics, and Coherent leading innovation. Friction stir welding research and implementation are strongest in the United Kingdom, Norway, and Japan, with significant contributions from TWI (The Welding Institute), ESAB, and various aerospace manufacturers.

The evaluation of joint strength between these technologies reveals a complex picture dependent on material combinations, joint configurations, and loading conditions. Current research indicates that FSW often produces superior fatigue strength and ductility in aluminum alloys, while laser welding excels in precision applications and high-speed production environments where joint strength requirements are well-defined.

Laser welding technology has reached considerable maturity in industrial applications, particularly in automotive, aerospace, and electronics manufacturing. This non-contact welding method utilizes concentrated light energy to create precise, narrow welds with minimal heat-affected zones. Current laser welding systems predominantly employ fiber, CO2, or Nd:YAG lasers, with fiber lasers gaining significant market share due to their superior beam quality and energy efficiency.

Friction stir welding (FSW), developed in the early 1990s, has evolved into a viable solid-state joining process especially valuable for aluminum alloys and dissimilar materials. The technology has seen substantial adoption in aerospace, automotive, and shipbuilding industries where high-strength, defect-free joints are critical. Recent advancements in FSW tool materials and designs have expanded its application range to include harder materials like steel and titanium alloys.

Despite these advancements, both technologies face significant challenges. Laser welding struggles with reflective materials such as aluminum and copper, requiring higher power inputs or surface treatments. Joint fit-up requirements are extremely stringent, with gaps typically limited to less than 0.1mm to ensure weld quality. Additionally, the rapid cooling rates can lead to hardening and potential brittleness in certain materials, compromising joint strength under specific loading conditions.

Friction stir welding faces different obstacles, primarily related to equipment complexity and process limitations. The substantial forces required during the process necessitate rigid clamping systems and robust machinery, increasing capital investment. The relatively slow welding speeds compared to fusion methods limit productivity in high-volume manufacturing environments. Tool wear remains a significant concern when processing harder materials, affecting both economics and joint quality.

Geographically, laser welding technology development is concentrated in Germany, Japan, and the United States, with companies like TRUMPF, IPG Photonics, and Coherent leading innovation. Friction stir welding research and implementation are strongest in the United Kingdom, Norway, and Japan, with significant contributions from TWI (The Welding Institute), ESAB, and various aerospace manufacturers.

The evaluation of joint strength between these technologies reveals a complex picture dependent on material combinations, joint configurations, and loading conditions. Current research indicates that FSW often produces superior fatigue strength and ductility in aluminum alloys, while laser welding excels in precision applications and high-speed production environments where joint strength requirements are well-defined.

Technical Comparison of Laser and Friction Stir Welding Methods

01 Friction stir welding techniques for improved joint strength

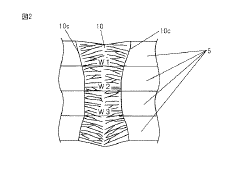

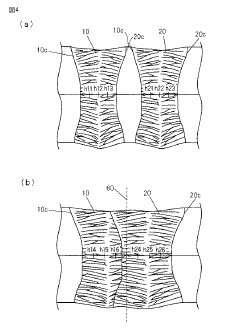

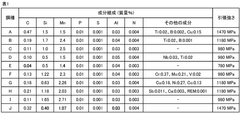

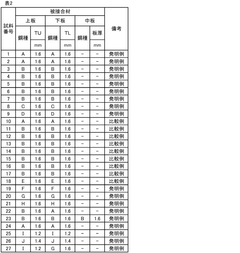

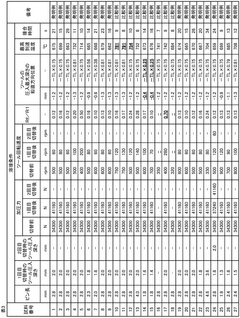

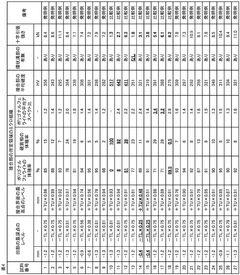

Friction stir welding (FSW) creates strong joints through mechanical stirring of materials in a solid state, avoiding issues associated with melting. The process involves a rotating tool that generates frictional heat and plastic deformation, creating a fine-grained microstructure that contributes to enhanced joint strength. Various tool designs and process parameters can be optimized to improve the mechanical properties of the welded joint, particularly for materials that are difficult to join using conventional fusion welding methods.- Friction Stir Welding Process Parameters for Enhanced Joint Strength: Friction stir welding (FSW) process parameters significantly impact joint strength. Key parameters include tool rotation speed, traverse speed, and axial force. Optimizing these parameters can lead to improved microstructure, reduced defects, and enhanced mechanical properties of the welded joint. The proper selection of tool geometry and design also plays a crucial role in achieving high-strength joints by controlling material flow and heat generation during the welding process.

- Laser Welding Techniques for Superior Joint Strength: Laser welding techniques offer precise control over heat input, resulting in narrow heat-affected zones and high-strength joints. Parameters such as laser power, welding speed, and beam focus significantly influence joint strength. Advanced laser welding methods include hybrid laser-arc welding, pulsed laser welding, and remote laser welding, each offering specific advantages for different materials and joint configurations. Proper surface preparation and shielding gas selection further enhance joint quality and strength in laser welding applications.

- Material Combinations and Joint Design for Welded Structures: The selection of compatible materials and appropriate joint designs significantly impacts the strength of welded connections. For dissimilar material joining, understanding the metallurgical compatibility and potential formation of intermetallic compounds is essential. Joint designs such as butt joints, lap joints, and T-joints each offer different strength characteristics depending on the loading conditions. Proper joint preparation, including cleaning, edge preparation, and fit-up, contributes to achieving optimal joint strength in both laser and friction stir welding processes.

- Post-Weld Treatments and Quality Assessment Methods: Post-weld treatments can significantly enhance joint strength in both laser and friction stir welded structures. Techniques include post-weld heat treatment, shot peening, and ultrasonic impact treatment to relieve residual stresses and improve microstructure. Non-destructive testing methods such as ultrasonic testing, radiography, and thermography help assess joint quality and detect defects that could compromise strength. Advanced monitoring systems during welding processes allow for real-time quality control and parameter adjustment to ensure consistent joint strength.

- Hybrid and Advanced Welding Approaches for Strength Optimization: Hybrid and advanced welding approaches combine the advantages of multiple welding techniques to optimize joint strength. Hybrid laser-friction stir welding processes leverage the benefits of both methods, resulting in joints with improved mechanical properties. Other innovations include the use of filler materials, interlayers, and surface modifications to enhance joint strength. Computational modeling and simulation tools help predict joint behavior and optimize process parameters before physical implementation, leading to stronger and more reliable welded connections.

02 Laser welding techniques for high-strength joints

Laser welding provides precise, high-energy density heat input that creates strong joints with minimal heat-affected zones. The focused energy allows for deep penetration welds with high aspect ratios, resulting in narrow, strong joints. Various laser types (CO2, Nd:YAG, fiber, etc.) can be employed depending on the material and application requirements. The process parameters such as laser power, welding speed, and focal position significantly influence the joint strength and can be optimized for specific material combinations.Expand Specific Solutions03 Hybrid and combined welding approaches for enhanced joint strength

Combining laser welding with friction stir welding or other welding techniques creates hybrid processes that leverage the advantages of each method. These hybrid approaches can overcome limitations of individual techniques and produce joints with superior mechanical properties. For example, laser-assisted friction stir welding uses laser preheating to reduce the forces required during FSW while maintaining or improving joint strength. Similarly, combining laser welding with arc welding can increase penetration depth and welding speed while enhancing joint quality.Expand Specific Solutions04 Material-specific welding techniques for optimized joint strength

Different materials require specific welding approaches to achieve optimal joint strength. For aluminum alloys, friction stir welding often produces stronger joints than fusion welding methods due to the avoidance of solidification defects. For dissimilar material combinations, specialized techniques such as modified tool designs in FSW or controlled power modulation in laser welding can be employed to manage the formation of brittle intermetallic compounds that would otherwise compromise joint strength. Advanced process monitoring and control systems help maintain consistent joint quality across various material combinations.Expand Specific Solutions05 Post-weld treatments and joint design for strength enhancement

Various post-weld treatments can significantly improve the strength of welded joints. These include heat treatments to relieve residual stresses, mechanical processing to refine grain structure, and surface treatments to enhance fatigue resistance. Additionally, joint design plays a crucial role in determining the final strength of welded connections. Optimized joint geometries that consider stress distribution, material flow (in FSW), or beam focusing (in laser welding) can substantially increase joint performance. Computational modeling and simulation tools help predict and optimize joint behavior under various loading conditions.Expand Specific Solutions

Key Industry Players and Manufacturers Analysis

The laser welding versus friction stir welding competition landscape is currently in a mature development phase, with a global market valued at approximately $2.5 billion. Major aerospace corporations like Boeing and Airbus Defence & Space are driving innovation in laser welding for lightweight structures, while automotive manufacturers including Nissan and Magna International are advancing friction stir applications for high-strength aluminum joints. Research institutions such as Harbin Institute of Technology and Beihang University are developing hybrid techniques combining both methods. Steel manufacturers like Kobe Steel and JFE Steel are focusing on improving joint strength for high-performance applications. The technology maturity varies by sector, with aerospace applications being most advanced, while automotive implementations are rapidly evolving toward mass production capabilities.

The Boeing Co.

Technical Solution: Boeing has developed advanced laser beam welding (LBW) technologies specifically for aerospace applications, focusing on joining aluminum alloys used in aircraft structures. Their proprietary system combines fiber laser technology with sophisticated beam control mechanisms to achieve precise welds on complex geometries. Boeing's approach includes adaptive power control systems that adjust laser parameters in real-time based on material feedback, ensuring consistent penetration and minimizing heat-affected zones. For friction stir welding (FSW), Boeing has pioneered self-reacting FSW tools that eliminate the need for backing anvils, allowing welding of enclosed structures like fuel tanks. Their FSW implementation includes advanced process monitoring with force feedback control and thermal imaging to maintain optimal welding conditions across varying material thicknesses. Boeing has extensively compared both technologies, finding that FSW produces joints with superior fatigue resistance (up to 30% improvement over laser welding) for primary aircraft structures, while laser welding offers significant advantages in speed and flexibility for secondary structures.

Strengths: Boeing's dual-technology approach allows optimal joining selection based on specific requirements. FSW produces superior mechanical properties with minimal distortion for critical load-bearing structures, while laser welding offers higher production rates for less critical components. Weaknesses: Their FSW implementation requires substantial capital investment and has limited application for complex 3D geometries, while their laser welding systems still face challenges with highly reflective aluminum alloys and thickness limitations.

Hitachi Ltd.

Technical Solution: Hitachi has developed hybrid laser-arc welding systems that combine the advantages of both laser welding and traditional arc welding processes. Their technology utilizes high-power fiber lasers (up to 10kW) working in tandem with conventional arc welding to achieve deeper penetration and higher welding speeds than either process alone. For thick-section materials, Hitachi's system can achieve single-pass welds up to 12mm in thickness with minimal distortion. In the friction stir welding domain, Hitachi has created specialized FSW tools with advanced cooling systems and wear-resistant materials that extend tool life by approximately 300% compared to conventional tools. Their FSW technology incorporates real-time monitoring systems that track axial force, torque, and temperature distribution to ensure consistent weld quality. Hitachi's comparative studies between these technologies have demonstrated that their hybrid laser welding achieves joint efficiencies of 85-95% of base material strength, while their FSW process consistently achieves 95-98% joint efficiency, particularly important for high-stress applications in transportation and energy sectors.

Strengths: Hitachi's hybrid laser welding technology offers exceptional versatility across material types and thicknesses, with production speeds up to 5 times faster than conventional welding. Their FSW technology produces superior metallurgical bonds with minimal defects and excellent fatigue properties. Weaknesses: The hybrid laser system requires precise alignment and calibration, making it less adaptable to field conditions, while their FSW equipment demands significant capital investment and has limited application for complex joint geometries.

Joint Strength Evaluation Methodologies and Standards

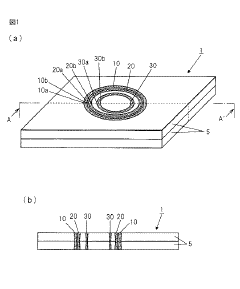

Laser welding joint excellent in joint strength and method for manufacturing the same

PatentActiveJP2012240086A

Innovation

- A laser welding method that forms a closed-loop main bead with a tempered bead and a compressive strain-inducing bead, positioned and timed to offset tensile strain, with specific hardness and spatial relationships to prevent cracking and enhance joint strength.

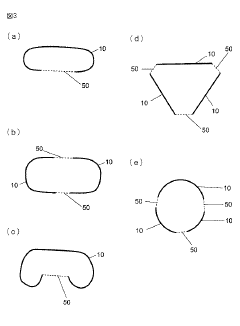

Friction-stir-spot-welded joint, production method for same, and friction stir spot welding method

PatentWO2023032514A1

Innovation

- A friction stir spot welding method that involves forming an annular groove on the joint surface, controlling the microstructure and hardness of the joint to achieve a specific volume fraction of polygonal ferrite and hard phase, and adjusting the tool's rotational speed and press-fitting depth to optimize the bonding interface, ensuring a maximum temperature between 600°C and 750°C and a rotational speed ratio of Rf/R1 ≤ 0.60.

Material Compatibility and Limitations Assessment

Material compatibility represents a critical factor in determining the appropriate welding technique between laser welding and friction stir welding (FSW). Laser welding demonstrates exceptional versatility with metals including steel, aluminum, titanium, and various alloys, but faces significant limitations with highly reflective materials such as copper and brass, which can reflect laser energy and reduce process efficiency. Additionally, materials with low melting points or high thermal conductivity present challenges due to heat management issues during the laser welding process.

Friction stir welding exhibits particular strength in joining aluminum alloys, where it creates joints with minimal defects and excellent mechanical properties. However, FSW encounters substantial limitations when working with high-temperature materials like steel and titanium, which cause accelerated tool wear and reduced process efficiency. The technique requires specialized tooling materials such as tungsten carbide or polycrystalline cubic boron nitride to withstand the extreme mechanical stresses and temperatures generated during the welding process.

Material thickness represents another significant compatibility factor. Laser welding excels with thin materials (0.5-6mm) but struggles with thicker sections due to limited penetration depth, while FSW performs optimally with medium to thick materials (3-50mm) but faces challenges with very thin sections where the mechanical forces can cause distortion.

Joint configuration compatibility also differs significantly between these technologies. Laser welding accommodates various joint designs including butt, lap, and fillet joints, offering flexibility in design applications. FSW primarily works with butt and lap joints, with limited capability for complex geometries due to tool access requirements and the mechanical nature of the process.

Dissimilar material joining represents a particular area where these technologies diverge in capability. Laser welding can join certain dissimilar metals but often produces brittle intermetallic compounds at the joint interface. FSW demonstrates superior performance in joining dissimilar materials, particularly aluminum to copper or aluminum to steel combinations, as the solid-state nature of the process minimizes intermetallic formation and associated joint weakening.

Environmental considerations also impact material compatibility, with laser welding requiring stringent surface cleanliness and often necessitating shielding gases to prevent oxidation. FSW demonstrates greater tolerance for surface contaminants but requires robust fixturing to counteract the substantial mechanical forces generated during the process.

Friction stir welding exhibits particular strength in joining aluminum alloys, where it creates joints with minimal defects and excellent mechanical properties. However, FSW encounters substantial limitations when working with high-temperature materials like steel and titanium, which cause accelerated tool wear and reduced process efficiency. The technique requires specialized tooling materials such as tungsten carbide or polycrystalline cubic boron nitride to withstand the extreme mechanical stresses and temperatures generated during the welding process.

Material thickness represents another significant compatibility factor. Laser welding excels with thin materials (0.5-6mm) but struggles with thicker sections due to limited penetration depth, while FSW performs optimally with medium to thick materials (3-50mm) but faces challenges with very thin sections where the mechanical forces can cause distortion.

Joint configuration compatibility also differs significantly between these technologies. Laser welding accommodates various joint designs including butt, lap, and fillet joints, offering flexibility in design applications. FSW primarily works with butt and lap joints, with limited capability for complex geometries due to tool access requirements and the mechanical nature of the process.

Dissimilar material joining represents a particular area where these technologies diverge in capability. Laser welding can join certain dissimilar metals but often produces brittle intermetallic compounds at the joint interface. FSW demonstrates superior performance in joining dissimilar materials, particularly aluminum to copper or aluminum to steel combinations, as the solid-state nature of the process minimizes intermetallic formation and associated joint weakening.

Environmental considerations also impact material compatibility, with laser welding requiring stringent surface cleanliness and often necessitating shielding gases to prevent oxidation. FSW demonstrates greater tolerance for surface contaminants but requires robust fixturing to counteract the substantial mechanical forces generated during the process.

Energy Efficiency and Environmental Impact Considerations

When comparing laser welding and friction stir welding (FSW) technologies, energy efficiency and environmental impact considerations play crucial roles in determining their industrial applicability and sustainability. Laser welding typically consumes significant electrical energy to generate high-intensity laser beams, with energy efficiency ranging from 10% to 30% depending on the laser type. Modern fiber and diode lasers have substantially improved this efficiency compared to older CO2 or Nd:YAG systems, reducing overall energy consumption by up to 40%.

In contrast, friction stir welding operates on mechanical energy principles, converting rotational force into frictional heat. This direct energy conversion pathway typically results in higher energy efficiency rates of 80-90% in optimal conditions. Studies from manufacturing sectors indicate FSW can reduce energy consumption by 60-70% compared to traditional fusion welding methods for certain aluminum applications.

From an environmental perspective, laser welding produces minimal direct emissions during operation but generates indirect environmental impacts through electricity consumption. The carbon footprint varies significantly based on the regional electricity generation mix. However, laser welding eliminates the need for filler materials and shielding gases in many applications, reducing resource consumption and associated environmental impacts.

Friction stir welding demonstrates superior environmental performance with near-zero direct emissions and minimal consumables. The solid-state nature of FSW eliminates spatter, fumes, and radiation hazards common in fusion welding processes. Life cycle assessments indicate FSW can reduce greenhouse gas emissions by 35-50% compared to conventional welding methods for similar joint configurations.

Material waste considerations also favor FSW, which typically generates minimal waste during operation. Laser welding may produce more waste through vaporization and spatter, though advanced beam control systems have significantly reduced these losses. Both technologies enable precise control that minimizes post-weld machining requirements, further reducing material waste and energy consumption in finishing operations.

Water usage presents another environmental consideration, with laser systems often requiring closed-loop cooling systems. While water-intensive during installation, these systems minimize ongoing consumption. FSW typically requires less cooling but may consume more lubricants, creating different environmental trade-offs.

When evaluating joint strength in relation to environmental impact, it's noteworthy that both technologies can produce high-strength joints with minimal environmental compromise. However, FSW generally achieves superior joint strength in aluminum alloys while consuming less energy, presenting an environmentally advantageous option for these materials. Laser welding maintains advantages in speed and versatility across diverse materials, offering environmental benefits through production efficiency despite higher energy demands.

In contrast, friction stir welding operates on mechanical energy principles, converting rotational force into frictional heat. This direct energy conversion pathway typically results in higher energy efficiency rates of 80-90% in optimal conditions. Studies from manufacturing sectors indicate FSW can reduce energy consumption by 60-70% compared to traditional fusion welding methods for certain aluminum applications.

From an environmental perspective, laser welding produces minimal direct emissions during operation but generates indirect environmental impacts through electricity consumption. The carbon footprint varies significantly based on the regional electricity generation mix. However, laser welding eliminates the need for filler materials and shielding gases in many applications, reducing resource consumption and associated environmental impacts.

Friction stir welding demonstrates superior environmental performance with near-zero direct emissions and minimal consumables. The solid-state nature of FSW eliminates spatter, fumes, and radiation hazards common in fusion welding processes. Life cycle assessments indicate FSW can reduce greenhouse gas emissions by 35-50% compared to conventional welding methods for similar joint configurations.

Material waste considerations also favor FSW, which typically generates minimal waste during operation. Laser welding may produce more waste through vaporization and spatter, though advanced beam control systems have significantly reduced these losses. Both technologies enable precise control that minimizes post-weld machining requirements, further reducing material waste and energy consumption in finishing operations.

Water usage presents another environmental consideration, with laser systems often requiring closed-loop cooling systems. While water-intensive during installation, these systems minimize ongoing consumption. FSW typically requires less cooling but may consume more lubricants, creating different environmental trade-offs.

When evaluating joint strength in relation to environmental impact, it's noteworthy that both technologies can produce high-strength joints with minimal environmental compromise. However, FSW generally achieves superior joint strength in aluminum alloys while consuming less energy, presenting an environmentally advantageous option for these materials. Laser welding maintains advantages in speed and versatility across diverse materials, offering environmental benefits through production efficiency despite higher energy demands.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!