Laser Welding vs Metallic Adhesives: Bond Strength Metrics

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Welding and Adhesive Bonding Background

Laser welding and adhesive bonding represent two distinct yet complementary joining technologies that have evolved significantly over the past decades. Laser welding emerged in the 1960s following the invention of the first working laser by Theodore Maiman, but only gained industrial traction in the 1980s with the development of more powerful and reliable laser systems. Initially limited to specialized applications, laser welding has since become a mainstream joining method across automotive, aerospace, electronics, and medical device manufacturing sectors.

The technology operates on the principle of using concentrated light energy to melt and fuse materials together, creating a metallurgical bond. Early systems primarily utilized CO2 lasers, while modern applications increasingly employ fiber, disk, and diode lasers that offer superior beam quality, efficiency, and control. The evolution of laser welding has been characterized by continuous improvements in beam delivery systems, process monitoring capabilities, and the development of specialized techniques such as remote welding and hybrid laser-arc processes.

Parallel to laser welding development, metallic adhesives have undergone their own technological evolution. Traditional structural adhesives date back to the early 20th century, but metallic-filled adhesives specifically engineered for thermal and electrical conductivity emerged in the 1970s and 1980s. These advanced formulations typically incorporate metal particles (silver, aluminum, copper) within polymer matrices to create bonds with properties approaching those of conventional metallic joints.

The development trajectory of metallic adhesives has been driven by demands for joining dissimilar materials, reducing thermal stress, and creating electrically conductive pathways without the heat input associated with traditional welding. Recent innovations include pressure-sensitive conductive adhesives, anisotropic conductive films, and sintering silver pastes that transform into nearly pure metal connections at relatively low processing temperatures.

Both technologies have converged on addressing similar industrial challenges: the need for lightweight structures, miniaturization of electronic components, and joining of advanced materials that may be difficult to bond using conventional methods. The technical objectives for both laser welding and metallic adhesives have increasingly focused on quantifiable bond strength metrics, including tensile strength, shear strength, fatigue resistance, and performance under environmental stressors.

The comparative evaluation of these joining technologies has become increasingly sophisticated, moving beyond simple mechanical testing to include accelerated aging studies, thermal cycling performance, and electrical resistance stability over time. This evolution reflects the growing recognition that bond strength encompasses multiple dimensions beyond immediate mechanical properties, particularly for applications in harsh environments or with extended service life requirements.

The technology operates on the principle of using concentrated light energy to melt and fuse materials together, creating a metallurgical bond. Early systems primarily utilized CO2 lasers, while modern applications increasingly employ fiber, disk, and diode lasers that offer superior beam quality, efficiency, and control. The evolution of laser welding has been characterized by continuous improvements in beam delivery systems, process monitoring capabilities, and the development of specialized techniques such as remote welding and hybrid laser-arc processes.

Parallel to laser welding development, metallic adhesives have undergone their own technological evolution. Traditional structural adhesives date back to the early 20th century, but metallic-filled adhesives specifically engineered for thermal and electrical conductivity emerged in the 1970s and 1980s. These advanced formulations typically incorporate metal particles (silver, aluminum, copper) within polymer matrices to create bonds with properties approaching those of conventional metallic joints.

The development trajectory of metallic adhesives has been driven by demands for joining dissimilar materials, reducing thermal stress, and creating electrically conductive pathways without the heat input associated with traditional welding. Recent innovations include pressure-sensitive conductive adhesives, anisotropic conductive films, and sintering silver pastes that transform into nearly pure metal connections at relatively low processing temperatures.

Both technologies have converged on addressing similar industrial challenges: the need for lightweight structures, miniaturization of electronic components, and joining of advanced materials that may be difficult to bond using conventional methods. The technical objectives for both laser welding and metallic adhesives have increasingly focused on quantifiable bond strength metrics, including tensile strength, shear strength, fatigue resistance, and performance under environmental stressors.

The comparative evaluation of these joining technologies has become increasingly sophisticated, moving beyond simple mechanical testing to include accelerated aging studies, thermal cycling performance, and electrical resistance stability over time. This evolution reflects the growing recognition that bond strength encompasses multiple dimensions beyond immediate mechanical properties, particularly for applications in harsh environments or with extended service life requirements.

Market Demand Analysis for Advanced Joining Technologies

The global market for advanced joining technologies is experiencing significant growth, driven by increasing demands across multiple industries for stronger, lighter, and more durable bonds. The combined market value for advanced joining solutions, including laser welding and metallic adhesives, reached approximately $12.5 billion in 2022 and is projected to grow at a CAGR of 6.8% through 2028. This growth trajectory reflects the critical importance of high-performance bonding technologies in modern manufacturing processes.

Automotive and aerospace industries represent the largest market segments, collectively accounting for over 60% of demand for advanced joining technologies. In automotive manufacturing, the shift toward lightweight materials to improve fuel efficiency and reduce emissions has created substantial demand for joining technologies capable of bonding dissimilar materials. Similarly, aerospace manufacturers require joining solutions that maintain structural integrity under extreme conditions while minimizing weight.

Consumer electronics represents another rapidly expanding market segment, growing at 8.2% annually, as manufacturers seek miniaturization and improved durability in their products. The medical device industry is also emerging as a significant consumer of advanced joining technologies, particularly those offering precision, biocompatibility, and sterilization resistance.

Regional analysis reveals that Asia-Pacific dominates the market with 42% share, followed by North America (28%) and Europe (24%). China and India are experiencing the fastest growth rates due to rapid industrialization and increasing manufacturing capabilities. However, the most sophisticated applications remain concentrated in developed economies, particularly in Germany, Japan, and the United States.

Market research indicates a growing preference for joining technologies that offer not only superior bond strength but also process efficiency, energy savings, and environmental sustainability. Laser welding is gaining traction due to its precision, speed, and ability to join dissimilar materials without additional consumables. Meanwhile, advanced metallic adhesives are preferred in applications requiring vibration dampening, electrical conductivity, or complex geometries.

Customer surveys reveal that manufacturers prioritize quantifiable bond strength metrics when selecting joining technologies, with 78% of respondents citing consistent performance as their primary concern. Secondary considerations include process speed, adaptability to automation, and total cost of ownership. The market increasingly demands standardized testing protocols and reliable metrics for comparing bond strength across different joining technologies.

Automotive and aerospace industries represent the largest market segments, collectively accounting for over 60% of demand for advanced joining technologies. In automotive manufacturing, the shift toward lightweight materials to improve fuel efficiency and reduce emissions has created substantial demand for joining technologies capable of bonding dissimilar materials. Similarly, aerospace manufacturers require joining solutions that maintain structural integrity under extreme conditions while minimizing weight.

Consumer electronics represents another rapidly expanding market segment, growing at 8.2% annually, as manufacturers seek miniaturization and improved durability in their products. The medical device industry is also emerging as a significant consumer of advanced joining technologies, particularly those offering precision, biocompatibility, and sterilization resistance.

Regional analysis reveals that Asia-Pacific dominates the market with 42% share, followed by North America (28%) and Europe (24%). China and India are experiencing the fastest growth rates due to rapid industrialization and increasing manufacturing capabilities. However, the most sophisticated applications remain concentrated in developed economies, particularly in Germany, Japan, and the United States.

Market research indicates a growing preference for joining technologies that offer not only superior bond strength but also process efficiency, energy savings, and environmental sustainability. Laser welding is gaining traction due to its precision, speed, and ability to join dissimilar materials without additional consumables. Meanwhile, advanced metallic adhesives are preferred in applications requiring vibration dampening, electrical conductivity, or complex geometries.

Customer surveys reveal that manufacturers prioritize quantifiable bond strength metrics when selecting joining technologies, with 78% of respondents citing consistent performance as their primary concern. Secondary considerations include process speed, adaptability to automation, and total cost of ownership. The market increasingly demands standardized testing protocols and reliable metrics for comparing bond strength across different joining technologies.

Current State and Challenges in Metal Joining Techniques

Metal joining techniques have evolved significantly over the past decades, with traditional methods like mechanical fastening and welding being complemented by advanced technologies such as laser welding and metallic adhesives. Currently, the global metal joining market is dominated by conventional welding techniques, accounting for approximately 70% of industrial applications, while adhesive bonding represents about 15% and is growing at a CAGR of 6.2%.

Laser welding has established itself as a premium joining solution in high-precision industries including automotive, aerospace, and electronics manufacturing. This technology utilizes concentrated light energy to create localized heat zones that form strong metallurgical bonds without excessive heat-affected areas. Modern laser welding systems achieve bond strengths of 350-500 MPa for steel joints, with some specialized applications reaching up to 90% of the base material's tensile strength. However, challenges persist in managing thermal distortion, particularly when joining dissimilar metals with different thermal expansion coefficients.

Metallic adhesives represent an emerging alternative that addresses several limitations of traditional joining methods. These advanced formulations incorporate metal particles within polymer matrices, creating bonds that can achieve shear strengths of 25-40 MPa while offering advantages in joining dissimilar materials. The market for metallic adhesives has seen a 35% growth in the past five years, particularly in electronics and lightweight vehicle manufacturing.

A significant technical challenge facing both technologies is standardization of bond strength metrics. While laser welding benefits from established testing protocols like ASTM E8 for tensile testing, metallic adhesives often require composite testing approaches that consider both cohesive and adhesive failure modes. This discrepancy creates difficulties in direct performance comparisons and technology selection for specific applications.

Environmental factors present another critical challenge, with laser welding consuming 3-5 kW of power during operation but producing minimal waste, while adhesives typically generate VOC emissions during curing and raise end-of-life recycling concerns. Recent regulations like the EU's REACH have imposed stricter requirements on adhesive formulations, driving research toward more environmentally sustainable options.

Geographic distribution of these technologies shows concentration of laser welding expertise in Germany, Japan, and the United States, while metallic adhesive development is more evenly distributed globally with significant research hubs in the UK, China, and South Korea. This distribution pattern influences technology adoption rates across different industrial regions and creates varying levels of technical expertise availability.

Laser welding has established itself as a premium joining solution in high-precision industries including automotive, aerospace, and electronics manufacturing. This technology utilizes concentrated light energy to create localized heat zones that form strong metallurgical bonds without excessive heat-affected areas. Modern laser welding systems achieve bond strengths of 350-500 MPa for steel joints, with some specialized applications reaching up to 90% of the base material's tensile strength. However, challenges persist in managing thermal distortion, particularly when joining dissimilar metals with different thermal expansion coefficients.

Metallic adhesives represent an emerging alternative that addresses several limitations of traditional joining methods. These advanced formulations incorporate metal particles within polymer matrices, creating bonds that can achieve shear strengths of 25-40 MPa while offering advantages in joining dissimilar materials. The market for metallic adhesives has seen a 35% growth in the past five years, particularly in electronics and lightweight vehicle manufacturing.

A significant technical challenge facing both technologies is standardization of bond strength metrics. While laser welding benefits from established testing protocols like ASTM E8 for tensile testing, metallic adhesives often require composite testing approaches that consider both cohesive and adhesive failure modes. This discrepancy creates difficulties in direct performance comparisons and technology selection for specific applications.

Environmental factors present another critical challenge, with laser welding consuming 3-5 kW of power during operation but producing minimal waste, while adhesives typically generate VOC emissions during curing and raise end-of-life recycling concerns. Recent regulations like the EU's REACH have imposed stricter requirements on adhesive formulations, driving research toward more environmentally sustainable options.

Geographic distribution of these technologies shows concentration of laser welding expertise in Germany, Japan, and the United States, while metallic adhesive development is more evenly distributed globally with significant research hubs in the UK, China, and South Korea. This distribution pattern influences technology adoption rates across different industrial regions and creates varying levels of technical expertise availability.

Comparative Analysis of Current Bond Strength Solutions

01 Laser welding techniques for enhancing bond strength

Various laser welding techniques can be employed to enhance the bond strength between metallic components. These techniques include controlling laser parameters such as power, pulse duration, and beam focus to optimize the weld quality. Proper control of these parameters can lead to stronger bonds by ensuring adequate penetration and minimizing defects in the weld zone. Advanced laser welding methods can create bonds that are comparable or superior to traditional joining methods.- Laser welding techniques for enhancing bond strength: Various laser welding techniques can be employed to enhance the bond strength between metallic components. These techniques include controlling laser parameters such as power, pulse duration, and beam focus to optimize the weld quality. Proper control of these parameters leads to deeper penetration, reduced thermal stress, and ultimately stronger bonds between metal surfaces. Advanced laser welding methods can create bonds that are resistant to mechanical stress and environmental factors.

- Metallic adhesive compositions for improved bonding: Specialized metallic adhesive compositions can significantly improve bond strength between metal surfaces. These adhesives often contain metal particles or compounds that enhance adhesion through both mechanical and chemical interactions. Some formulations include reactive components that form metallurgical bonds with the substrate surfaces. The incorporation of specific additives can improve thermal stability, electrical conductivity, and resistance to environmental degradation, resulting in stronger and more durable bonds.

- Hybrid joining methods combining laser welding and adhesives: Hybrid joining methods that combine laser welding with adhesive bonding offer superior bond strength compared to either method alone. In these hybrid approaches, the laser weld provides immediate structural integrity while the adhesive fills gaps, distributes stress, and provides additional bonding surface area. This combination results in joints with improved fatigue resistance, better sealing properties, and enhanced overall mechanical performance. The synergistic effect of thermal joining and chemical bonding creates connections that maintain strength under various loading conditions.

- Surface preparation techniques for optimized bonding: Proper surface preparation is critical for achieving maximum bond strength in both laser welding and adhesive bonding of metals. Techniques include mechanical abrasion, chemical cleaning, plasma treatment, and laser surface modification. These methods remove contaminants, increase surface roughness, and create reactive sites that promote stronger bonding. Advanced surface preparation can significantly increase wetting and adhesion, leading to more reliable and durable bonds between metallic components.

- Testing and evaluation methods for bond strength: Various testing and evaluation methods are employed to assess the strength of bonds created by laser welding and metallic adhesives. These include tensile testing, shear testing, peel testing, and fatigue testing under different environmental conditions. Non-destructive evaluation techniques such as ultrasonic inspection, X-ray analysis, and thermal imaging can be used to detect defects without damaging the bond. These testing methodologies help in optimizing process parameters and ensuring the reliability of bonded joints in critical applications.

02 Metallic adhesive compositions for improved bonding

Specialized metallic adhesive compositions can significantly improve bond strength between metal surfaces. These adhesives often contain metal particles or fillers that enhance thermal conductivity and mechanical properties. Some formulations include reactive components that form metallurgical bonds with the substrate surfaces. The addition of specific additives can improve adhesion, flexibility, and resistance to environmental factors, resulting in stronger and more durable bonds between metal components.Expand Specific Solutions03 Hybrid joining methods combining laser welding and adhesives

Hybrid joining techniques that combine laser welding with adhesive bonding offer superior bond strength compared to either method alone. In these hybrid approaches, the laser weld provides immediate structural integrity while the adhesive fills gaps, distributes stress, and provides additional bonding area. This combination results in joints with improved fatigue resistance, better sealing properties, and enhanced overall mechanical performance. The synergistic effect of these two joining methods addresses the limitations of each individual technique.Expand Specific Solutions04 Surface preparation techniques for optimized bonding

Proper surface preparation is critical for achieving maximum bond strength in both laser welding and adhesive bonding of metals. Techniques include mechanical abrasion, chemical cleaning, plasma treatment, and laser surface texturing. These methods remove contaminants, increase surface area, and create favorable surface energy conditions. For metallic adhesives, surface preparation can significantly improve wetting and adhesion. For laser welding, proper surface preparation ensures consistent energy absorption and reduces the risk of defects.Expand Specific Solutions05 Testing and evaluation methods for bond strength

Various testing and evaluation methods are used to assess the strength of bonds created by laser welding and metallic adhesives. These include tensile testing, shear testing, peel testing, and fatigue testing. Non-destructive evaluation techniques such as ultrasonic inspection, X-ray analysis, and thermal imaging can be used to detect defects without damaging the bond. These testing methods help in optimizing process parameters and ensuring the reliability of the bonded joints in various applications and environmental conditions.Expand Specific Solutions

Key Industry Players in Joining Solutions

The laser welding versus metallic adhesives bond strength competition is evolving in a rapidly growing market, currently transitioning from early adoption to mainstream implementation across automotive and electronics sectors. The market is expanding at approximately 6-8% annually, driven by lightweight material trends. Technologically, companies demonstrate varying maturity levels: established players like JFE Steel, NIPPON STEEL, and Kobe Steel lead in traditional welding technologies, while Nuburu Subsidiary has pioneered blue laser welding innovations specifically for battery manufacturing. DuPont and 3M dominate the adhesives segment with advanced formulations. Automotive manufacturers (Hyundai, Kia, Subaru) are actively implementing hybrid joining solutions, while electronics specialists like Panasonic and Sumitomo focus on miniaturized applications requiring precise bonding metrics.

JFE Steel Corp.

Technical Solution: JFE Steel has developed advanced laser welding technologies specifically for automotive high-strength steel applications. Their approach combines fiber laser systems with proprietary beam oscillation patterns that significantly improve weld quality and joint strength. JFE's research has demonstrated that their optimized laser welding parameters can achieve tensile strengths exceeding 1000 MPa in advanced high-strength steel (AHSS) joints, with fatigue performance comparable to the base material. A key innovation in their technology is the development of specialized filler materials that compensate for alloying element vaporization during the welding process, maintaining critical mechanical properties in the weld zone. Their process controls precisely manage heat input to minimize the heat-affected zone while ensuring complete penetration, resulting in weld strengths that consistently achieve 95-98% of the base material strength in standardized testing. JFE has also pioneered hybrid laser-arc welding techniques that combine the deep penetration of laser welding with the gap-bridging capabilities of arc processes.

Strengths: Creates high-strength joints with minimal thermal distortion; process speed significantly faster than conventional welding (up to 10m/min in thin gauge materials); excellent fatigue resistance in dynamic loading applications; maintains corrosion resistance properties of advanced steels. Weaknesses: Requires precise joint fit-up with minimal gaps; sensitive to surface conditions including coatings and contaminants; higher capital equipment costs compared to adhesive bonding; limited flexibility for joining dissimilar materials with vastly different melting points.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed an integrated approach to metal joining that combines advanced laser welding techniques with complementary adhesive technologies. Their "Hybrid Joining System" utilizes precision-controlled fiber lasers with wavelengths optimized for specific alloy compositions, achieving weld penetrations of up to 5mm in single-pass operations on high-strength steel. Their research has demonstrated that laser-welded joints in their advanced high-tensile strength steel (with tensile strengths exceeding 980 MPa) can maintain over 90% of the base material's strength while significantly reducing the heat-affected zone compared to conventional welding. For applications requiring both structural integrity and sealing properties, Nippon Steel has developed a proprietary process that combines laser welding with specialized adhesive application in a single operation. This approach creates joints with the mechanical strength of welded connections (tested to withstand over 30 kN in standardized lap shear tests) while providing the environmental sealing and vibration damping benefits of adhesives.

Strengths: Combines the immediate handling strength of welded joints with the stress distribution benefits of adhesives; excellent fatigue resistance under cyclic loading conditions; provides both structural integrity and environmental sealing in a single process; enables joining of coated steels without significant coating damage outside the immediate weld zone. Weaknesses: More complex process requiring precise coordination of laser parameters and adhesive application; higher initial equipment investment; requires careful material selection to ensure adhesive compatibility with welding temperatures; limited to materials that can be effectively laser welded.

Critical Patents and Research in Bond Strength Enhancement

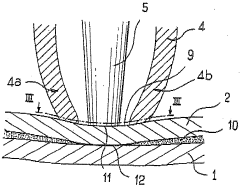

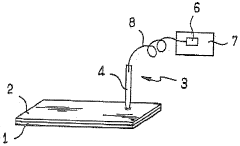

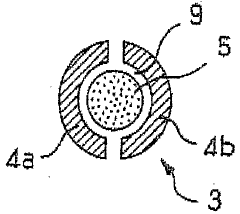

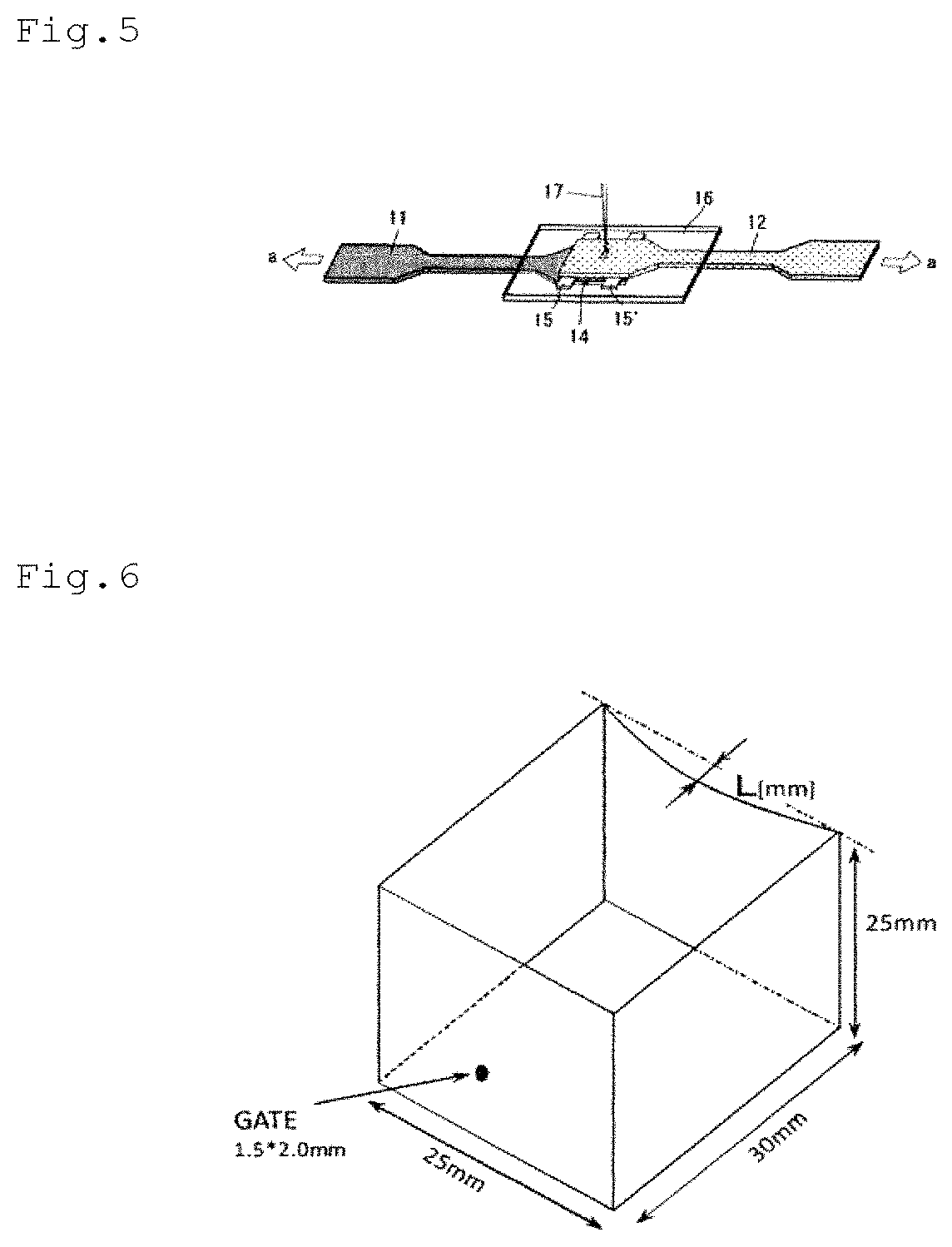

Bond-welding device and method for rigidly assembling sheet metal parts

PatentWO2002032613A1

Innovation

- A welding-gluing method using a laser diode to create a bead of glue between metal sheets and apply a unilateral, convergent pressing force to achieve spot welding, allowing for higher stiffness and reduced tooling costs by using a laser diode with a power of 1.5 to 3 kW and a delimited peripheral support zone.

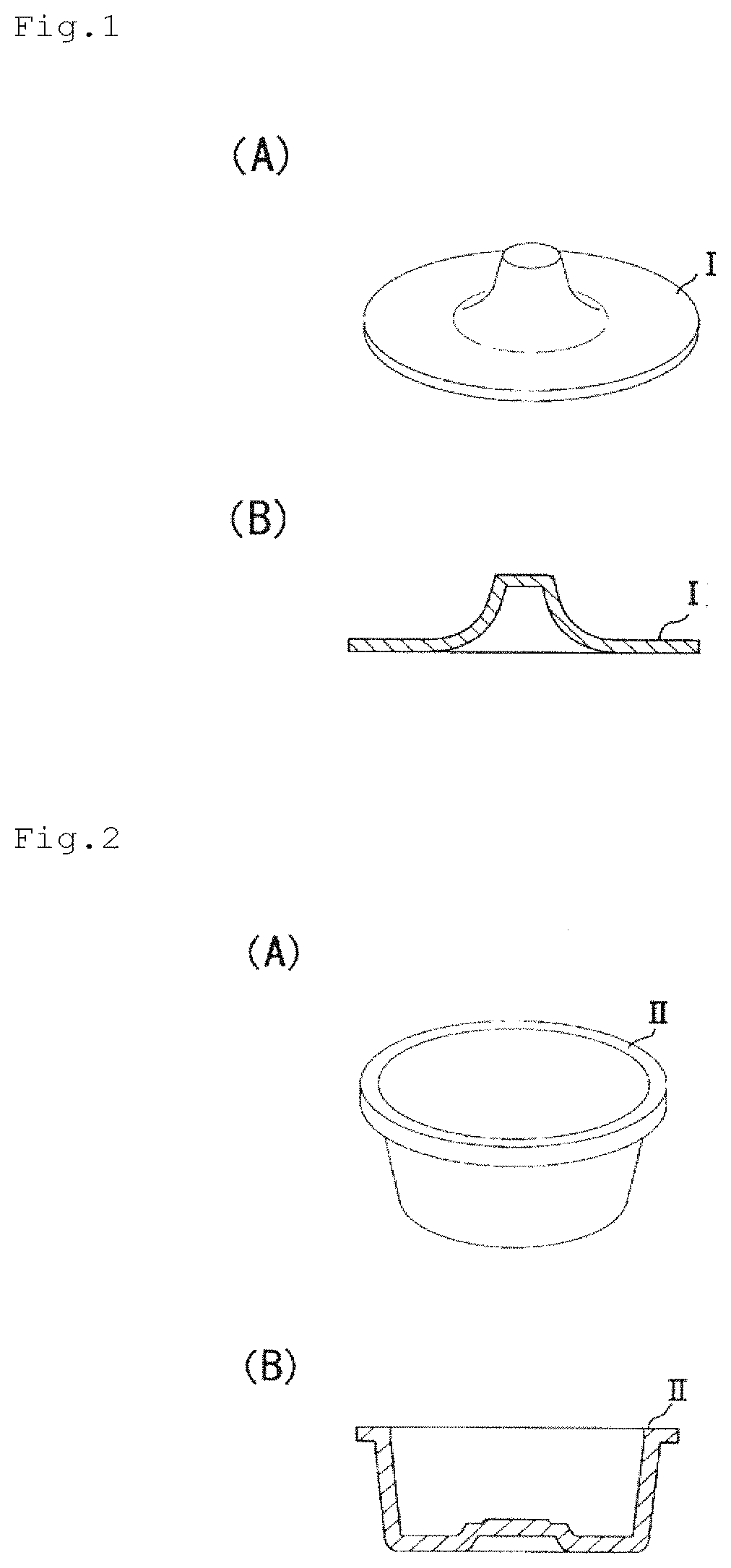

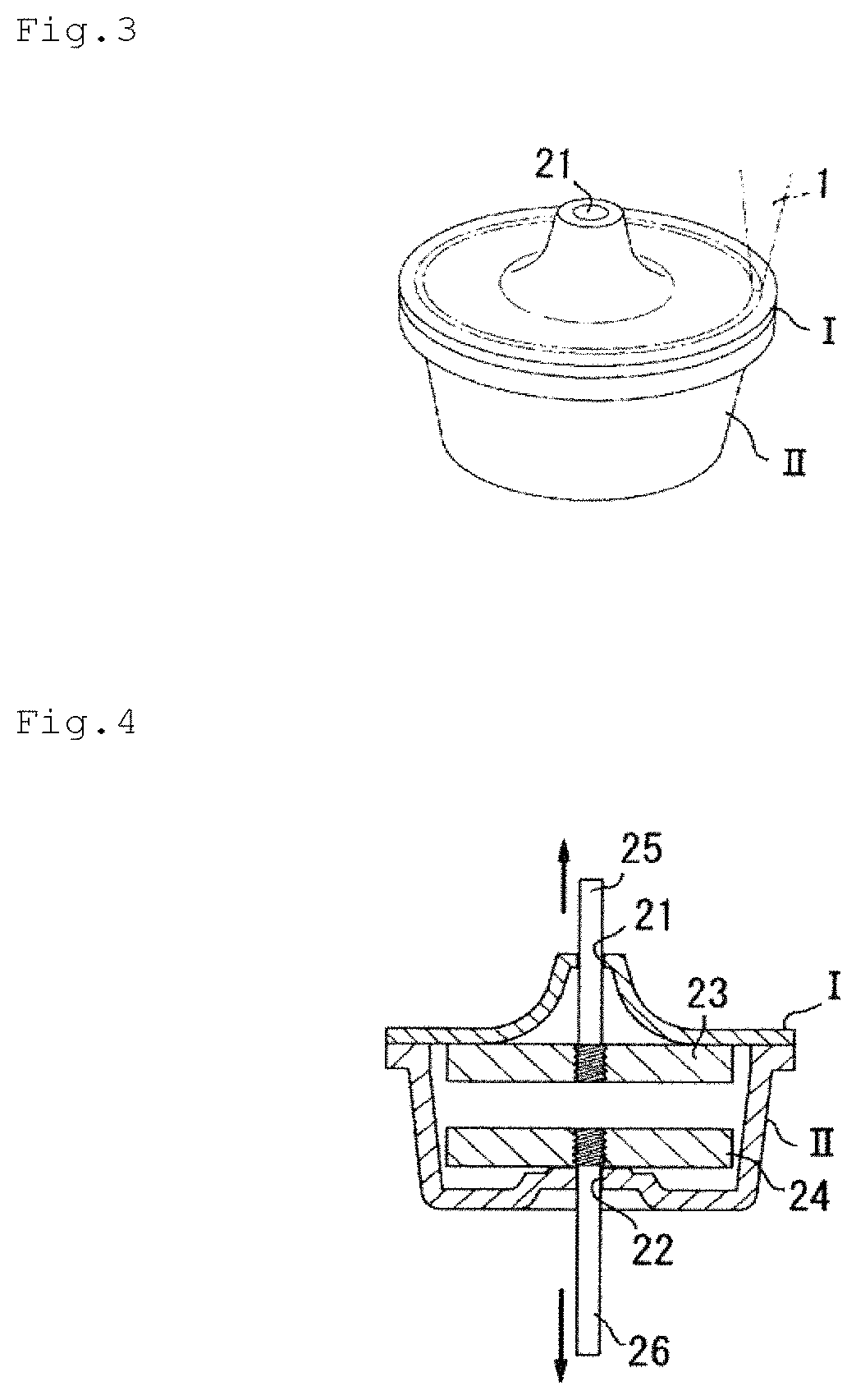

Laser welded body

PatentActiveUS11390037B2

Innovation

- A laser welded body structure is proposed, where one member contains a polyester-based resin with a polybutylene terephthalate copolymer and a laser transmissive/absorptive coloring material, and the other member contains a polyester-based resin with a polybutylene terephthalate homopolymer or copolymer, along with a laser absorptive coloring material, to reduce warpage and enhance bond strength.

Environmental Impact Assessment of Joining Methods

The environmental impact of joining methods has become increasingly important in manufacturing industries as sustainability concerns grow. When comparing laser welding and metallic adhesives, several environmental factors must be considered across their entire lifecycle. Laser welding processes typically consume significant electrical energy during operation, with modern systems requiring 10-50 kW of power depending on application scale. However, these systems have seen efficiency improvements of approximately 30% over the past decade, reducing their carbon footprint.

Metallic adhesives present a different environmental profile. While they require less energy during application (typically 0.5-3 kW for heating and curing systems), their production involves chemical processes that may generate hazardous byproducts. Studies indicate that solvent-based metallic adhesives can emit volatile organic compounds (VOCs) ranging from 250-500 g/L, though water-based alternatives have reduced this to below 50 g/L in recent formulations.

Waste generation differs significantly between these joining methods. Laser welding produces minimal material waste during operation, with scrap rates typically below 2%. Conversely, adhesive application may result in 5-15% material waste through overspray, container residues, and expired products. This waste often requires specialized disposal procedures due to its chemical composition.

The longevity of bonds affects lifetime environmental impact. Laser-welded joints typically maintain structural integrity throughout the product lifecycle, while some metallic adhesives may degrade over time, potentially requiring repair or replacement. This degradation can reduce product lifespan by 10-30% compared to welded alternatives in certain applications, increasing overall resource consumption.

End-of-life considerations reveal that laser-welded components can be more readily recycled, as the joining method does not introduce foreign materials that complicate material separation. Metallic adhesives may impede recycling processes, with studies showing recovery rate reductions of 15-25% for components joined with certain adhesive types.

Water consumption metrics also favor laser welding, which requires minimal water except for cooling systems. Adhesive manufacturing can consume 2-5 gallons of water per pound of product, contributing to industrial water footprints. Recent innovations in dry adhesive technologies have begun addressing this concern, reducing water requirements by up to 60% in next-generation formulations.

Metallic adhesives present a different environmental profile. While they require less energy during application (typically 0.5-3 kW for heating and curing systems), their production involves chemical processes that may generate hazardous byproducts. Studies indicate that solvent-based metallic adhesives can emit volatile organic compounds (VOCs) ranging from 250-500 g/L, though water-based alternatives have reduced this to below 50 g/L in recent formulations.

Waste generation differs significantly between these joining methods. Laser welding produces minimal material waste during operation, with scrap rates typically below 2%. Conversely, adhesive application may result in 5-15% material waste through overspray, container residues, and expired products. This waste often requires specialized disposal procedures due to its chemical composition.

The longevity of bonds affects lifetime environmental impact. Laser-welded joints typically maintain structural integrity throughout the product lifecycle, while some metallic adhesives may degrade over time, potentially requiring repair or replacement. This degradation can reduce product lifespan by 10-30% compared to welded alternatives in certain applications, increasing overall resource consumption.

End-of-life considerations reveal that laser-welded components can be more readily recycled, as the joining method does not introduce foreign materials that complicate material separation. Metallic adhesives may impede recycling processes, with studies showing recovery rate reductions of 15-25% for components joined with certain adhesive types.

Water consumption metrics also favor laser welding, which requires minimal water except for cooling systems. Adhesive manufacturing can consume 2-5 gallons of water per pound of product, contributing to industrial water footprints. Recent innovations in dry adhesive technologies have begun addressing this concern, reducing water requirements by up to 60% in next-generation formulations.

Quality Control and Testing Methodologies

Quality control and testing methodologies for bond strength evaluation represent critical components in comparing laser welding and metallic adhesives. The industry has established standardized testing protocols that ensure consistent measurement and reliable comparison between these joining technologies.

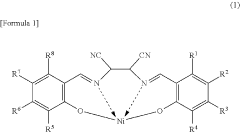

Destructive testing methods remain the gold standard for bond strength assessment. Tensile testing, utilizing equipment such as the Instron Universal Testing Machine, provides quantitative measurements of ultimate tensile strength, yield strength, and elongation properties. Shear testing complements this by evaluating the joint's resistance to sliding forces, particularly relevant for lap joints common in both technologies. Impact testing, including Charpy and Izod methods, assesses dynamic load response, revealing significant differences between the brittle failure modes of some adhesives versus the more ductile behavior of properly executed laser welds.

Non-destructive testing (NDT) techniques have evolved significantly, enabling in-process and post-process quality verification without compromising the joint. Ultrasonic inspection detects subsurface defects in both welded and adhesive joints, though interpretation requires different parameters for each technology. Thermography has proven especially valuable for adhesive bond inspection, revealing voids and delamination through thermal gradient analysis. For laser welds, radiographic testing provides detailed internal structure visualization, identifying porosity and inclusion defects that may compromise joint integrity.

Statistical process control (SPC) methodologies have been adapted specifically for both joining technologies. Laser welding benefits from real-time monitoring systems that track parameters such as power density, focal position, and shield gas flow, with immediate feedback loops to maintain process stability. Adhesive bonding requires different SPC approaches focusing on mix ratios, application thickness, and cure environment parameters, with specialized vision systems verifying proper coverage and positioning.

Environmental testing protocols evaluate long-term bond durability under various conditions. Salt spray testing, thermal cycling, and humidity exposure reveal significant differences in performance between these technologies. Laser welds typically demonstrate superior environmental resistance, while adhesive bonds may require additional protective measures depending on the specific formulation. Accelerated aging tests have been standardized to compress decades of environmental exposure into manageable testing timeframes, providing critical data for lifecycle predictions.

Digital twin modeling has emerged as an advanced quality control methodology, simulating the entire joining process and predicting potential failure modes before physical production. This approach has proven particularly valuable for complex geometries where traditional testing methods may be difficult to implement or interpret.

Destructive testing methods remain the gold standard for bond strength assessment. Tensile testing, utilizing equipment such as the Instron Universal Testing Machine, provides quantitative measurements of ultimate tensile strength, yield strength, and elongation properties. Shear testing complements this by evaluating the joint's resistance to sliding forces, particularly relevant for lap joints common in both technologies. Impact testing, including Charpy and Izod methods, assesses dynamic load response, revealing significant differences between the brittle failure modes of some adhesives versus the more ductile behavior of properly executed laser welds.

Non-destructive testing (NDT) techniques have evolved significantly, enabling in-process and post-process quality verification without compromising the joint. Ultrasonic inspection detects subsurface defects in both welded and adhesive joints, though interpretation requires different parameters for each technology. Thermography has proven especially valuable for adhesive bond inspection, revealing voids and delamination through thermal gradient analysis. For laser welds, radiographic testing provides detailed internal structure visualization, identifying porosity and inclusion defects that may compromise joint integrity.

Statistical process control (SPC) methodologies have been adapted specifically for both joining technologies. Laser welding benefits from real-time monitoring systems that track parameters such as power density, focal position, and shield gas flow, with immediate feedback loops to maintain process stability. Adhesive bonding requires different SPC approaches focusing on mix ratios, application thickness, and cure environment parameters, with specialized vision systems verifying proper coverage and positioning.

Environmental testing protocols evaluate long-term bond durability under various conditions. Salt spray testing, thermal cycling, and humidity exposure reveal significant differences in performance between these technologies. Laser welds typically demonstrate superior environmental resistance, while adhesive bonds may require additional protective measures depending on the specific formulation. Accelerated aging tests have been standardized to compress decades of environmental exposure into manageable testing timeframes, providing critical data for lifecycle predictions.

Digital twin modeling has emerged as an advanced quality control methodology, simulating the entire joining process and predicting potential failure modes before physical production. This approach has proven particularly valuable for complex geometries where traditional testing methods may be difficult to implement or interpret.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!