Laser Welding vs MIG: Which Offers Better Precision?

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser and MIG Welding Evolution and Objectives

Welding technology has evolved significantly since its inception in the late 19th century. Metal Inert Gas (MIG) welding emerged in the 1940s as a revolutionary semi-automatic process, offering faster welding speeds and improved quality compared to traditional stick welding. This development marked a significant advancement in manufacturing capabilities, particularly during World War II when production efficiency became paramount. MIG welding quickly gained traction across various industries due to its versatility and relative ease of use.

Laser welding technology, by contrast, represents a more recent innovation, with practical industrial applications beginning in the 1970s. The technology underwent substantial refinement throughout the 1980s and 1990s as laser sources became more powerful, reliable, and cost-effective. The introduction of fiber lasers in the early 2000s further revolutionized the field, offering unprecedented precision and energy efficiency. This technological progression has enabled laser welding to transition from specialized applications to mainstream manufacturing processes.

The evolution of both technologies has been driven by consistent industry demands for greater precision, speed, and quality in joining materials. MIG welding has evolved through improvements in wire feeding mechanisms, shielding gas compositions, and power source technologies. Meanwhile, laser welding has progressed through advancements in beam quality, power density, and control systems. These parallel development paths reflect the different technical foundations of each approach but similar objectives in meeting manufacturing needs.

Current technological objectives for both welding methods center around several key areas. For MIG welding, objectives include reducing spatter, improving deposition rates, enhancing control over heat input, and expanding the range of materials that can be effectively joined. For laser welding, primary objectives include increasing processing speeds, improving energy efficiency, enhancing weld quality monitoring capabilities, and developing solutions for traditionally challenging materials like highly reflective metals and dissimilar material combinations.

Looking forward, both technologies are evolving toward greater automation and integration with Industry 4.0 principles. This includes the development of advanced sensing technologies, real-time quality monitoring systems, and adaptive control mechanisms. The ultimate technological goal for both welding methods is to achieve perfect precision, repeatability, and quality while minimizing energy consumption and maximizing production efficiency. However, the approaches to reaching these objectives differ significantly based on the fundamental physics and operational principles of each welding technology.

Laser welding technology, by contrast, represents a more recent innovation, with practical industrial applications beginning in the 1970s. The technology underwent substantial refinement throughout the 1980s and 1990s as laser sources became more powerful, reliable, and cost-effective. The introduction of fiber lasers in the early 2000s further revolutionized the field, offering unprecedented precision and energy efficiency. This technological progression has enabled laser welding to transition from specialized applications to mainstream manufacturing processes.

The evolution of both technologies has been driven by consistent industry demands for greater precision, speed, and quality in joining materials. MIG welding has evolved through improvements in wire feeding mechanisms, shielding gas compositions, and power source technologies. Meanwhile, laser welding has progressed through advancements in beam quality, power density, and control systems. These parallel development paths reflect the different technical foundations of each approach but similar objectives in meeting manufacturing needs.

Current technological objectives for both welding methods center around several key areas. For MIG welding, objectives include reducing spatter, improving deposition rates, enhancing control over heat input, and expanding the range of materials that can be effectively joined. For laser welding, primary objectives include increasing processing speeds, improving energy efficiency, enhancing weld quality monitoring capabilities, and developing solutions for traditionally challenging materials like highly reflective metals and dissimilar material combinations.

Looking forward, both technologies are evolving toward greater automation and integration with Industry 4.0 principles. This includes the development of advanced sensing technologies, real-time quality monitoring systems, and adaptive control mechanisms. The ultimate technological goal for both welding methods is to achieve perfect precision, repeatability, and quality while minimizing energy consumption and maximizing production efficiency. However, the approaches to reaching these objectives differ significantly based on the fundamental physics and operational principles of each welding technology.

Market Demand Analysis for Precision Welding Technologies

The precision welding market is experiencing significant growth driven by increasing demands across multiple industries for higher quality, more precise, and efficient joining solutions. The global precision welding market was valued at approximately $2.1 billion in 2022 and is projected to reach $3.5 billion by 2028, growing at a CAGR of 8.9% during the forecast period. This growth trajectory is primarily fueled by advancements in automotive manufacturing, aerospace applications, electronics production, and medical device fabrication.

In the automotive sector, the transition toward lightweight materials and electric vehicles has intensified the need for precision welding technologies. Manufacturers require joining solutions capable of handling dissimilar materials like aluminum alloys and high-strength steels while maintaining structural integrity. The aerospace industry similarly demands high-precision welding for critical components where failure is not an option, creating a premium segment within the market.

Electronics manufacturing represents another significant driver, with miniaturization trends necessitating increasingly precise micro-welding capabilities. The semiconductor industry alone accounts for approximately 18% of the precision welding market, with requirements for sub-micron accuracy in certain applications.

Regional analysis reveals that Asia-Pacific currently dominates the precision welding market with a 42% share, followed by North America (28%) and Europe (24%). China and South Korea are experiencing the fastest growth rates, primarily due to their expanding electronics manufacturing and automotive sectors.

Customer requirements are evolving toward more automated, flexible welding solutions that can be integrated into Industry 4.0 manufacturing environments. According to recent industry surveys, 76% of manufacturing executives consider precision and quality as the primary factors when selecting welding technologies, followed by production speed (68%) and operational costs (62%).

The comparison between laser welding and MIG (Metal Inert Gas) welding reflects broader market dynamics. Laser welding systems, despite higher initial investment costs, are gaining market share due to superior precision capabilities. The laser welding segment is growing at 12.3% annually, outpacing the overall market growth rate. Meanwhile, advanced MIG systems maintain strong demand in applications where cost-effectiveness and versatility outweigh the need for ultimate precision.

Market forecasts indicate that hybrid welding technologies combining laser and arc methods will see substantial growth in the coming years, as manufacturers seek to leverage the advantages of both approaches while minimizing their respective limitations. This trend aligns with the broader industry movement toward more adaptive and multi-capable manufacturing systems.

In the automotive sector, the transition toward lightweight materials and electric vehicles has intensified the need for precision welding technologies. Manufacturers require joining solutions capable of handling dissimilar materials like aluminum alloys and high-strength steels while maintaining structural integrity. The aerospace industry similarly demands high-precision welding for critical components where failure is not an option, creating a premium segment within the market.

Electronics manufacturing represents another significant driver, with miniaturization trends necessitating increasingly precise micro-welding capabilities. The semiconductor industry alone accounts for approximately 18% of the precision welding market, with requirements for sub-micron accuracy in certain applications.

Regional analysis reveals that Asia-Pacific currently dominates the precision welding market with a 42% share, followed by North America (28%) and Europe (24%). China and South Korea are experiencing the fastest growth rates, primarily due to their expanding electronics manufacturing and automotive sectors.

Customer requirements are evolving toward more automated, flexible welding solutions that can be integrated into Industry 4.0 manufacturing environments. According to recent industry surveys, 76% of manufacturing executives consider precision and quality as the primary factors when selecting welding technologies, followed by production speed (68%) and operational costs (62%).

The comparison between laser welding and MIG (Metal Inert Gas) welding reflects broader market dynamics. Laser welding systems, despite higher initial investment costs, are gaining market share due to superior precision capabilities. The laser welding segment is growing at 12.3% annually, outpacing the overall market growth rate. Meanwhile, advanced MIG systems maintain strong demand in applications where cost-effectiveness and versatility outweigh the need for ultimate precision.

Market forecasts indicate that hybrid welding technologies combining laser and arc methods will see substantial growth in the coming years, as manufacturers seek to leverage the advantages of both approaches while minimizing their respective limitations. This trend aligns with the broader industry movement toward more adaptive and multi-capable manufacturing systems.

Current Technological Landscape and Precision Challenges

The welding industry currently stands at a technological crossroads, with both Laser Welding and Metal Inert Gas (MIG) welding representing distinct approaches to precision joining. Laser welding technology has experienced significant advancement over the past decade, with fiber lasers increasingly replacing traditional CO2 systems due to their superior beam quality and energy efficiency. These systems now routinely achieve spot sizes below 0.1mm, enabling unprecedented precision in microelectronics and medical device manufacturing.

MIG welding, while considered a more conventional technology, has not remained static. Modern MIG systems incorporate sophisticated digital controls, pulsed power supplies, and advanced wire feeding mechanisms that have substantially improved their precision capabilities. However, even with these improvements, MIG welding typically produces weld beads no smaller than 2-3mm in width, creating a significant precision gap between the two technologies.

The precision challenges for laser welding primarily revolve around reflectivity issues with certain materials, particularly aluminum and copper alloys which are increasingly important in electric vehicle manufacturing. Thermal management also remains problematic, as the intense, concentrated heat can lead to distortion in thin materials. Additionally, the capital investment for industrial laser welding systems remains 3-5 times higher than comparable MIG setups, creating economic barriers to adoption.

For MIG welding, precision limitations stem from the inherent physics of the arc process. The broader heat-affected zone (HAZ) makes fine control difficult, particularly for materials under 1mm thickness. Spatter control continues to challenge manufacturers, with even advanced systems producing some level of weld spatter that requires post-processing. The manual skill component also introduces variability that automated laser systems largely eliminate.

Globally, laser welding technology development is concentrated in Germany, Japan, and the United States, with companies like IPG Photonics, Trumpf, and Coherent leading innovation. MIG technology development remains more distributed, with significant advancements coming from European, North American, and increasingly, Chinese manufacturers.

The precision gap between these technologies is narrowing in specific applications through hybrid laser-MIG systems that combine the penetration benefits of laser with the gap-bridging capabilities of MIG. These hybrid approaches represent a significant trend in addressing the limitations of both technologies, particularly for automotive and heavy equipment manufacturing where material thickness varies considerably.

MIG welding, while considered a more conventional technology, has not remained static. Modern MIG systems incorporate sophisticated digital controls, pulsed power supplies, and advanced wire feeding mechanisms that have substantially improved their precision capabilities. However, even with these improvements, MIG welding typically produces weld beads no smaller than 2-3mm in width, creating a significant precision gap between the two technologies.

The precision challenges for laser welding primarily revolve around reflectivity issues with certain materials, particularly aluminum and copper alloys which are increasingly important in electric vehicle manufacturing. Thermal management also remains problematic, as the intense, concentrated heat can lead to distortion in thin materials. Additionally, the capital investment for industrial laser welding systems remains 3-5 times higher than comparable MIG setups, creating economic barriers to adoption.

For MIG welding, precision limitations stem from the inherent physics of the arc process. The broader heat-affected zone (HAZ) makes fine control difficult, particularly for materials under 1mm thickness. Spatter control continues to challenge manufacturers, with even advanced systems producing some level of weld spatter that requires post-processing. The manual skill component also introduces variability that automated laser systems largely eliminate.

Globally, laser welding technology development is concentrated in Germany, Japan, and the United States, with companies like IPG Photonics, Trumpf, and Coherent leading innovation. MIG technology development remains more distributed, with significant advancements coming from European, North American, and increasingly, Chinese manufacturers.

The precision gap between these technologies is narrowing in specific applications through hybrid laser-MIG systems that combine the penetration benefits of laser with the gap-bridging capabilities of MIG. These hybrid approaches represent a significant trend in addressing the limitations of both technologies, particularly for automotive and heavy equipment manufacturing where material thickness varies considerably.

Comparative Analysis of Laser and MIG Welding Solutions

01 Laser welding precision control techniques

Laser welding offers high precision through controlled heat input and focused energy delivery. Advanced control systems monitor and adjust parameters in real-time to maintain weld quality. These techniques include beam positioning systems, power modulation, and feedback mechanisms that respond to material conditions during the welding process. The precision of laser welding makes it suitable for applications requiring minimal heat-affected zones and fine detail work.- Laser welding precision control technologies: Laser welding offers high precision control through advanced beam manipulation technologies. These systems utilize precise positioning mechanisms, real-time monitoring, and feedback control to achieve accurate welds. The technology enables fine adjustment of parameters such as power density, focus position, and beam characteristics to maintain consistent weld quality even for complex geometries. These precision control systems significantly reduce defects and improve repeatability compared to conventional welding methods.

- MIG welding precision enhancement methods: Metal Inert Gas (MIG) welding precision can be enhanced through various technological improvements. These include advanced wire feeding systems, controlled short-circuit transfer mechanisms, and pulsed current technologies that provide better control over the welding process. Specialized MIG equipment incorporates digital control systems that regulate arc characteristics, wire feed speed, and shielding gas flow to achieve more precise welds. These enhancements allow MIG welding to achieve higher precision levels while maintaining its productivity advantages.

- Hybrid laser-MIG welding systems: Hybrid welding systems that combine laser and MIG technologies leverage the advantages of both methods to achieve superior precision and productivity. These systems use the laser for deep penetration and precise heat input while the MIG component provides additional filler material and improved gap bridging capability. The synergistic effect results in welds with excellent mechanical properties, reduced heat-affected zones, and higher processing speeds. Advanced control systems coordinate both processes to optimize weld quality across various materials and joint configurations.

- Automated precision welding equipment: Automated welding systems significantly improve precision for both laser and MIG processes through robotic manipulation and computer control. These systems incorporate vision systems, path planning algorithms, and adaptive control mechanisms to maintain consistent weld quality. Advanced sensors monitor critical parameters in real-time and make automatic adjustments to compensate for variations in material properties or joint geometry. The integration of artificial intelligence and machine learning further enhances the ability to optimize welding parameters for specific applications.

- Precision monitoring and quality control systems: Sophisticated monitoring and quality control systems are essential for achieving high precision in both laser and MIG welding applications. These systems employ various sensors including thermal cameras, spectroscopic analyzers, and acoustic monitors to detect deviations in real-time. Advanced signal processing algorithms analyze the collected data to identify potential defects before they become critical. Post-weld inspection technologies such as ultrasonic testing and radiographic examination verify weld integrity. These comprehensive quality control approaches ensure consistent precision across production runs.

02 MIG welding precision enhancement methods

Metal Inert Gas (MIG) welding precision can be enhanced through various techniques including pulse control, wire feed optimization, and shielding gas composition adjustments. Advanced MIG systems incorporate digital controls to regulate arc characteristics and material transfer modes. Specialized fixtures and positioning equipment help maintain consistent standoff distances and travel speeds, which are critical factors in achieving precise MIG welds on various material thicknesses.Expand Specific Solutions03 Hybrid laser-MIG welding systems

Hybrid welding systems combine laser and MIG technologies to leverage the advantages of both processes. The laser provides deep penetration and precise heat input, while the MIG component adds filler material and improves gap bridging capability. These hybrid systems achieve higher welding speeds, better joint quality, and can handle thicker materials than either process alone. Synchronization between the laser and arc processes is critical for optimal performance in these hybrid systems.Expand Specific Solutions04 Automated precision welding equipment

Automated welding systems incorporate robotic arms, CNC controls, and vision systems to achieve high precision in both laser and MIG welding applications. These systems can maintain consistent travel speeds, torch angles, and standoff distances that would be difficult to achieve manually. Advanced sensors monitor weld parameters in real-time and make adjustments to ensure quality. Automation is particularly valuable for repetitive welding tasks requiring high precision and consistency across multiple parts.Expand Specific Solutions05 Precision welding for specialized materials

Achieving precision in welding specialized materials such as aluminum alloys, high-strength steels, and dissimilar metal combinations requires tailored approaches for both laser and MIG processes. Parameters must be carefully controlled to address challenges like thermal conductivity differences, melting point variations, and potential for intermetallic compound formation. Advanced techniques include pulsed power delivery, controlled preheating, and specialized filler materials designed for specific material combinations to ensure joint integrity and dimensional accuracy.Expand Specific Solutions

Leading Manufacturers and Industry Competition Analysis

The laser welding versus MIG welding precision competition is evolving in a rapidly growing market, currently transitioning from early adoption to mainstream implementation across manufacturing sectors. The global precision welding market is expanding at approximately 5-7% annually, driven by automotive and aerospace applications. Technologically, laser welding has reached higher maturity for precision applications, with companies like Illinois Tool Works, Air Liquide, and Kobe Steel leading innovation in high-precision laser systems. Meanwhile, MIG welding technology continues to evolve through advancements from ELCo Enterprises and Serimax SAS, focusing on improving precision capabilities while maintaining cost advantages. Automotive manufacturers like BMW and Honda are increasingly adopting laser welding for critical precision applications, while traditional MIG systems remain dominant in general manufacturing.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed proprietary laser welding technologies that deliver superior precision compared to traditional MIG welding. Their KOBELCO laser welding systems utilize fiber laser technology with power outputs ranging from 2kW to 10kW, achieving positioning accuracies of ±0.05mm. The company's hybrid laser-arc welding system combines the precision of laser with the gap-bridging capability of MIG, maintaining a heat-affected zone (HAZ) of less than 1mm while accommodating joint gaps up to 1mm. Their process control system monitors and adjusts parameters in real-time, maintaining consistent penetration depths with variations under 5%. For automotive applications, Kobe Steel's remote laser welding technology achieves speeds up to 15m/min with robot-guided mirrors, dramatically outpacing MIG welding's typical 0.5-2m/min while maintaining positional accuracy. Their specialized copper-aluminum joining technique uses controlled laser pulses to create metallurgical bonds without excessive intermetallic formation, solving a challenge that conventional MIG welding struggles with.

Strengths: Exceptional speed-to-precision ratio, minimal heat input reducing distortion, excellent for dissimilar metal joining, high automation potential with robotic integration. Weaknesses: Higher initial equipment investment, more sensitive to surface conditions and joint preparation, limited effectiveness in outdoor environments, requires more sophisticated process monitoring.

Honda Motor Co., Ltd.

Technical Solution: Honda Motor Co. has developed advanced laser welding technologies that significantly outperform MIG welding in precision applications across their automotive manufacturing processes. Their proprietary laser welding system employs 6kW fiber lasers with beam delivery systems achieving positional accuracy of ±0.1mm, compared to MIG's typical ±0.5-1mm tolerance. Honda's remote laser welding technology uses galvanometer scanners to position the beam with response times under 10ms, enabling complex weld patterns at speeds up to 10m/min while maintaining consistent quality. For body-in-white applications, their system produces welds with heat-affected zones averaging 0.4mm width, approximately 80% narrower than comparable MIG welds. Their process monitoring system employs multiple sensors including high-speed cameras and photodiodes to detect and compensate for variations in real-time, maintaining weld quality across production runs. Honda has also pioneered laser welding of aluminum components with specialized beam oscillation techniques that reduce porosity by up to 60% compared to conventional MIG processes, critical for lightweight vehicle structures.

Strengths: Superior precision for complex automotive assemblies, minimal heat distortion preserving material properties, high production speeds (5-10x faster than MIG for many applications), excellent for joining dissimilar materials. Weaknesses: Higher initial equipment investment, more sensitive to joint fit-up and preparation, limited effectiveness on certain highly reflective materials, requires more sophisticated process monitoring systems.

Critical Patents and Technical Advancements in Precision Welding

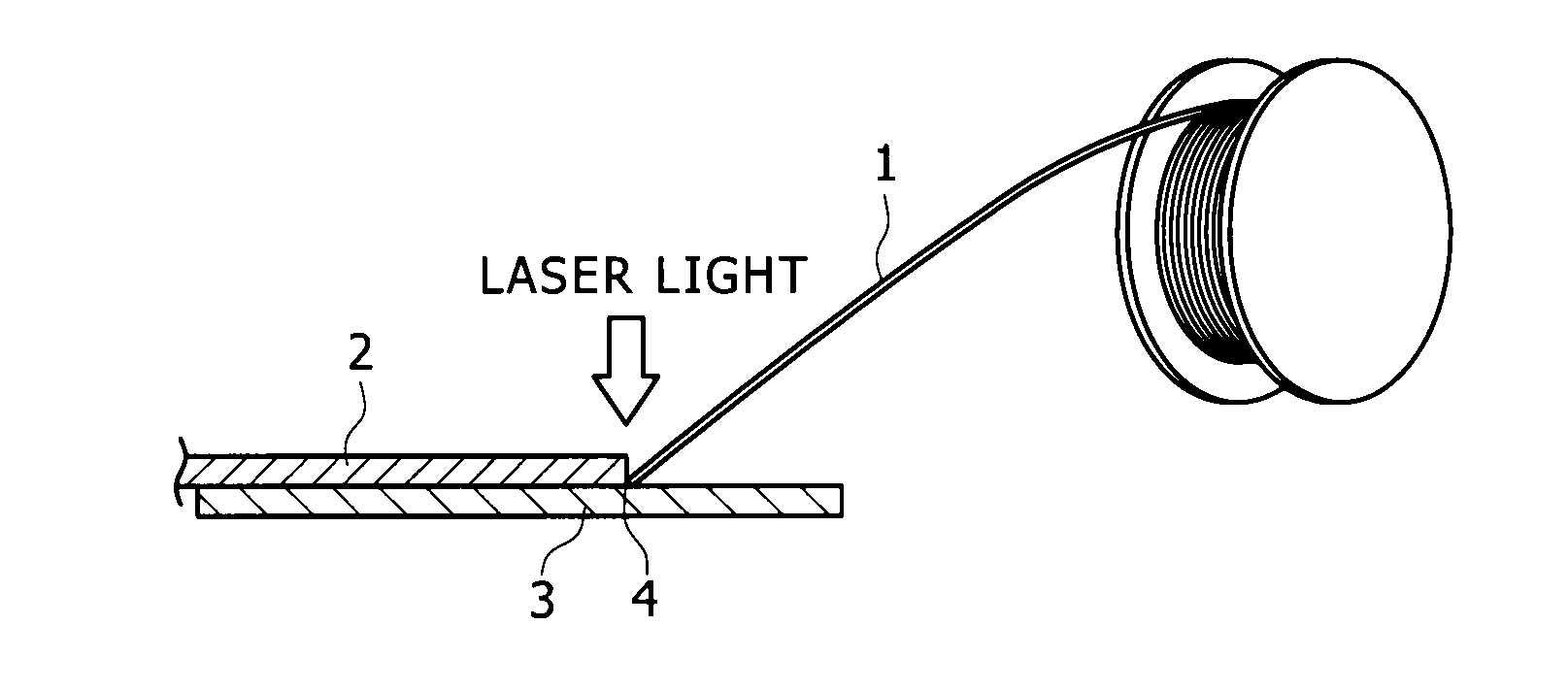

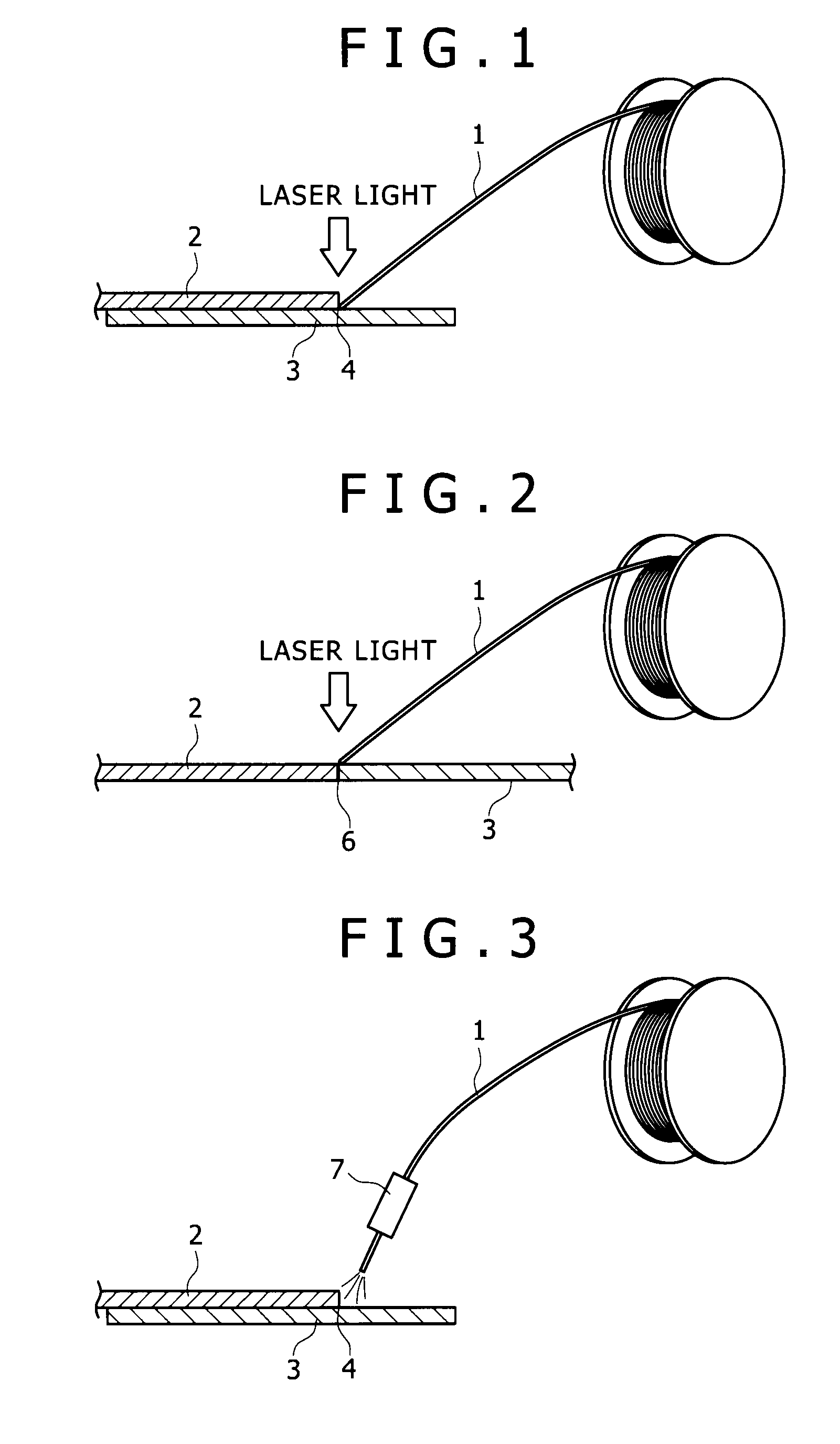

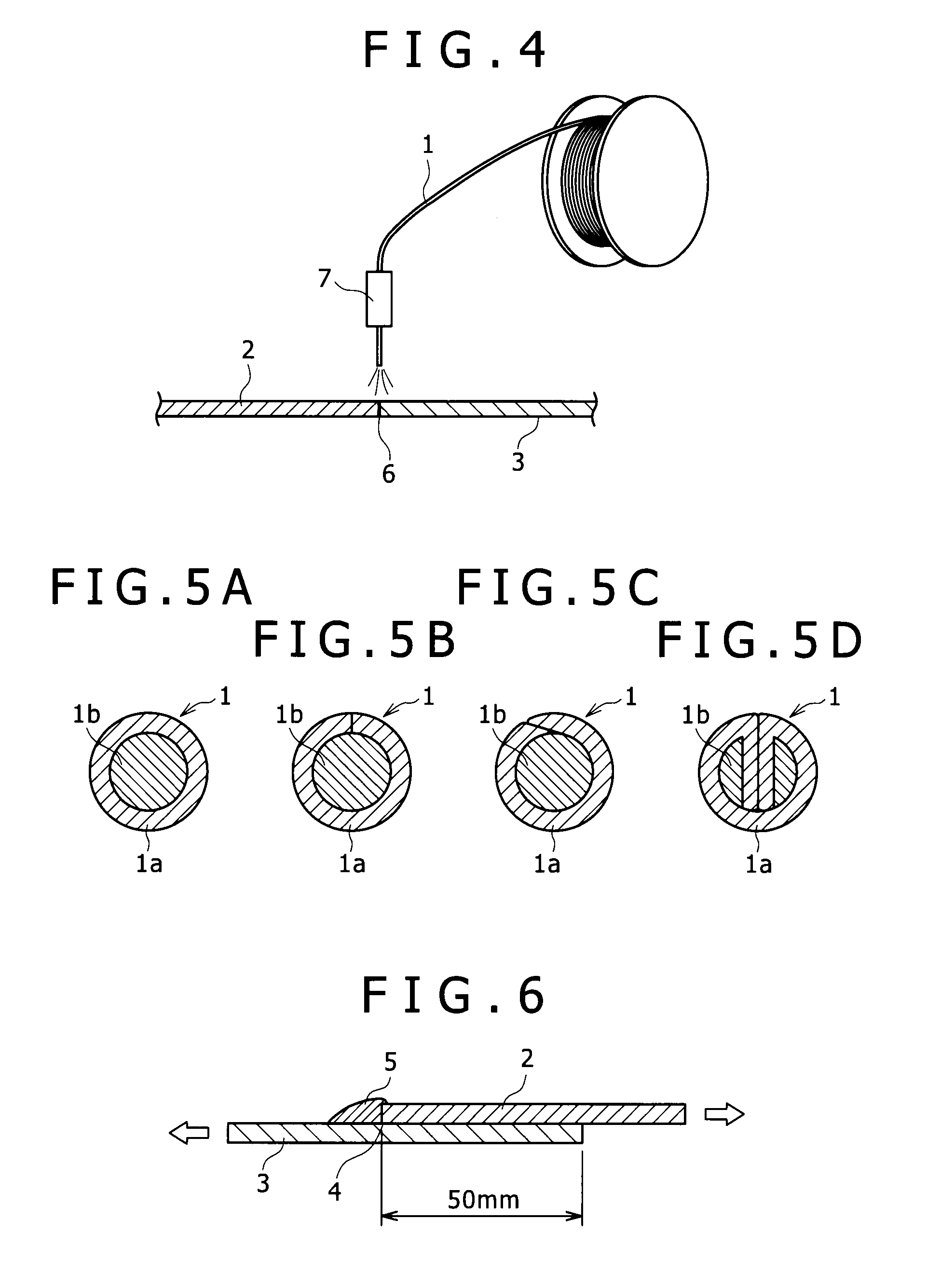

Flux-cored wire for welding different materials, method for laser welding of different materials and method for MIG welding of different materials

PatentActiveUS20120074111A1

Innovation

- A flux-cored wire with a specific composition of Si, Zr, and cesium fluoride, and AlF3 is used for laser and MIG welding, optimizing the flux packing fraction to suppress intermetallic compound formation, enhance bonding, and improve tensile shear and peeling strengths, while preventing cracks through grain refinement and surface oxide removal.

Glass welding through non-flat surface

PatentActiveUS20230069855A1

Innovation

- The use of a liquid optical medium with a refractive index matching that of the workpiece, combined with an optical guide that form-fits the curved surface, minimizes beam deviation and fills surface imperfections, allowing for effective laser welding through curved and rough surfaces, including edge-to-edge joints.

Material Compatibility and Application-Specific Considerations

Material compatibility represents a critical factor when choosing between laser welding and MIG processes for specific applications. Laser welding demonstrates superior performance with thin materials, particularly those below 6mm in thickness, offering exceptional precision for delicate components in electronics, medical devices, and aerospace applications. The focused energy beam creates minimal heat-affected zones, making it ideal for heat-sensitive materials and precision components.

In contrast, MIG welding excels with thicker materials and is particularly effective for structural steel applications where material thickness exceeds 6mm. Its higher heat input and filler material addition make it more suitable for applications requiring gap bridging capabilities and higher structural strength, such as heavy machinery manufacturing and construction.

Material composition significantly influences welding method selection. Laser welding performs exceptionally well with reflective materials like aluminum and copper when using appropriate wavelength lasers (fiber or disk lasers). It also maintains high precision with dissimilar material combinations, creating clean, narrow welds with minimal thermal distortion. This capability is particularly valuable in automotive lightweighting strategies where joining aluminum to steel is required.

MIG welding demonstrates greater versatility across common structural materials but faces challenges with highly reflective or heat-sensitive materials. Its strength lies in applications where weld appearance is less critical than structural integrity, such as general fabrication and repair work.

Application-specific considerations extend beyond material properties to production requirements. Laser welding offers significant advantages in high-volume automated production environments, delivering consistent quality with minimal post-processing requirements. Its non-contact nature enables welding in hard-to-reach areas and complex geometries, making it preferred for intricate assemblies in consumer electronics and medical implants.

MIG welding maintains relevance in applications requiring field repairs, where portability and adaptability to varying environmental conditions are essential. Its lower equipment cost and simpler setup make it more accessible for small-scale operations and repair services where the ultimate precision of laser welding may not justify its higher implementation costs.

The selection between these technologies ultimately depends on a comprehensive evaluation of material properties, production volumes, quality requirements, and economic factors specific to each application context. Industries requiring the highest precision in thin-material applications increasingly favor laser welding, while those prioritizing versatility and cost-effectiveness across thicker materials continue to rely on MIG processes.

In contrast, MIG welding excels with thicker materials and is particularly effective for structural steel applications where material thickness exceeds 6mm. Its higher heat input and filler material addition make it more suitable for applications requiring gap bridging capabilities and higher structural strength, such as heavy machinery manufacturing and construction.

Material composition significantly influences welding method selection. Laser welding performs exceptionally well with reflective materials like aluminum and copper when using appropriate wavelength lasers (fiber or disk lasers). It also maintains high precision with dissimilar material combinations, creating clean, narrow welds with minimal thermal distortion. This capability is particularly valuable in automotive lightweighting strategies where joining aluminum to steel is required.

MIG welding demonstrates greater versatility across common structural materials but faces challenges with highly reflective or heat-sensitive materials. Its strength lies in applications where weld appearance is less critical than structural integrity, such as general fabrication and repair work.

Application-specific considerations extend beyond material properties to production requirements. Laser welding offers significant advantages in high-volume automated production environments, delivering consistent quality with minimal post-processing requirements. Its non-contact nature enables welding in hard-to-reach areas and complex geometries, making it preferred for intricate assemblies in consumer electronics and medical implants.

MIG welding maintains relevance in applications requiring field repairs, where portability and adaptability to varying environmental conditions are essential. Its lower equipment cost and simpler setup make it more accessible for small-scale operations and repair services where the ultimate precision of laser welding may not justify its higher implementation costs.

The selection between these technologies ultimately depends on a comprehensive evaluation of material properties, production volumes, quality requirements, and economic factors specific to each application context. Industries requiring the highest precision in thin-material applications increasingly favor laser welding, while those prioritizing versatility and cost-effectiveness across thicker materials continue to rely on MIG processes.

Energy Efficiency and Environmental Impact Assessment

When comparing laser welding and MIG (Metal Inert Gas) welding technologies from an energy efficiency and environmental impact perspective, several critical factors emerge that influence industrial decision-making processes.

Laser welding demonstrates superior energy efficiency with conversion rates typically ranging between 30-50%, significantly higher than MIG welding's 15-25% efficiency. This translates to approximately 40-60% less energy consumption per unit weld length in laser applications. The focused energy delivery system of laser welding minimizes heat-affected zones and reduces overall energy requirements, particularly beneficial in high-volume manufacturing environments.

Power consumption metrics reveal that laser welding systems operate at 10-30 kW for industrial applications, while comparable MIG systems require 5-15 kW. However, when factoring in actual processing time, laser welding's faster operation speed (typically 5-10 meters per minute versus MIG's 1-3 meters per minute) results in lower total energy consumption per completed weld.

From an environmental standpoint, laser welding produces minimal fume emissions—approximately 80-90% less than MIG welding. This reduction significantly decreases workplace hazards and environmental pollution, reducing the need for extensive ventilation and filtration systems. The absence of consumable electrodes in laser welding further reduces material waste and associated environmental impacts.

Carbon footprint analysis indicates that laser welding operations generate approximately 0.5-0.8 kg CO₂ equivalent per meter of weld, compared to MIG welding's 0.9-1.4 kg CO₂ equivalent. This difference becomes particularly significant in large-scale manufacturing operations where thousands of meters are welded daily.

Material utilization rates also favor laser technology, with material efficiency reaching 95-98% compared to MIG's 85-90%. The precision of laser welding minimizes over-welding and reduces the need for post-weld finishing processes, further decreasing energy consumption and waste generation in the overall manufacturing process.

Lifecycle assessment studies indicate that while laser welding equipment requires higher initial energy investment during manufacturing and has more complex end-of-life recycling requirements, these factors are typically offset by operational efficiency gains within 3-5 years of industrial use. The longer service life of laser equipment (typically 15-20 years versus 8-12 years for MIG systems) further enhances its environmental credentials when evaluated on a complete lifecycle basis.

Laser welding demonstrates superior energy efficiency with conversion rates typically ranging between 30-50%, significantly higher than MIG welding's 15-25% efficiency. This translates to approximately 40-60% less energy consumption per unit weld length in laser applications. The focused energy delivery system of laser welding minimizes heat-affected zones and reduces overall energy requirements, particularly beneficial in high-volume manufacturing environments.

Power consumption metrics reveal that laser welding systems operate at 10-30 kW for industrial applications, while comparable MIG systems require 5-15 kW. However, when factoring in actual processing time, laser welding's faster operation speed (typically 5-10 meters per minute versus MIG's 1-3 meters per minute) results in lower total energy consumption per completed weld.

From an environmental standpoint, laser welding produces minimal fume emissions—approximately 80-90% less than MIG welding. This reduction significantly decreases workplace hazards and environmental pollution, reducing the need for extensive ventilation and filtration systems. The absence of consumable electrodes in laser welding further reduces material waste and associated environmental impacts.

Carbon footprint analysis indicates that laser welding operations generate approximately 0.5-0.8 kg CO₂ equivalent per meter of weld, compared to MIG welding's 0.9-1.4 kg CO₂ equivalent. This difference becomes particularly significant in large-scale manufacturing operations where thousands of meters are welded daily.

Material utilization rates also favor laser technology, with material efficiency reaching 95-98% compared to MIG's 85-90%. The precision of laser welding minimizes over-welding and reduces the need for post-weld finishing processes, further decreasing energy consumption and waste generation in the overall manufacturing process.

Lifecycle assessment studies indicate that while laser welding equipment requires higher initial energy investment during manufacturing and has more complex end-of-life recycling requirements, these factors are typically offset by operational efficiency gains within 3-5 years of industrial use. The longer service life of laser equipment (typically 15-20 years versus 8-12 years for MIG systems) further enhances its environmental credentials when evaluated on a complete lifecycle basis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!