Laser Welding vs Plasma: Assessing Surface Finish

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser and Plasma Welding Technology Evolution

Welding technology has undergone significant evolution since its inception, with laser and plasma welding representing two major technological breakthroughs in the field. The journey began with traditional arc welding methods in the early 20th century, which laid the foundation for more advanced techniques. Plasma welding emerged in the 1950s as an extension of TIG (Tungsten Inert Gas) welding, utilizing a constricted arc that produces a high-temperature plasma jet. This innovation allowed for deeper penetration and faster welding speeds compared to conventional methods.

Laser welding technology followed a different evolutionary path, with the first industrial applications appearing in the 1970s after the invention of high-power CO2 lasers. The 1980s saw significant advancements with the development of Nd:YAG lasers, which offered better beam quality and the ability to transmit the beam through fiber optics, greatly enhancing flexibility in manufacturing settings.

The 1990s marked a period of rapid technological advancement for both methods. Plasma welding systems became more sophisticated with improved control systems and power sources, while laser welding benefited from the introduction of diode-pumped solid-state lasers, which offered higher efficiency and reliability. This decade also saw the beginning of hybrid welding techniques, combining laser with arc or plasma to leverage the advantages of both technologies.

The early 2000s witnessed the emergence of fiber and disk lasers, revolutionizing laser welding with higher beam quality, greater efficiency, and reduced maintenance requirements. These advancements significantly improved the surface finish quality achievable with laser welding, making it increasingly competitive with plasma welding for applications where aesthetics and precision were paramount.

In parallel, plasma welding evolved with the development of micro-plasma techniques for thin materials and precision applications, as well as variable polarity plasma arc (VPPA) welding for materials like aluminum. These innovations expanded the application range of plasma welding while maintaining its traditional advantages in certain scenarios.

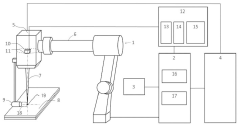

The most recent decade has seen further refinement of both technologies, with laser welding benefiting from beam shaping capabilities, ultra-high-power systems exceeding 20kW, and sophisticated monitoring systems. Plasma welding has evolved with digital control systems, automated parameter adjustment, and integration with robotic systems for enhanced precision and consistency.

The technological trajectory clearly indicates a convergence of capabilities, with both methods continuously improving in terms of weld quality, process control, and surface finish characteristics. However, they maintain distinct advantages in specific applications, driving ongoing research and development to optimize their performance for various industrial needs.

Laser welding technology followed a different evolutionary path, with the first industrial applications appearing in the 1970s after the invention of high-power CO2 lasers. The 1980s saw significant advancements with the development of Nd:YAG lasers, which offered better beam quality and the ability to transmit the beam through fiber optics, greatly enhancing flexibility in manufacturing settings.

The 1990s marked a period of rapid technological advancement for both methods. Plasma welding systems became more sophisticated with improved control systems and power sources, while laser welding benefited from the introduction of diode-pumped solid-state lasers, which offered higher efficiency and reliability. This decade also saw the beginning of hybrid welding techniques, combining laser with arc or plasma to leverage the advantages of both technologies.

The early 2000s witnessed the emergence of fiber and disk lasers, revolutionizing laser welding with higher beam quality, greater efficiency, and reduced maintenance requirements. These advancements significantly improved the surface finish quality achievable with laser welding, making it increasingly competitive with plasma welding for applications where aesthetics and precision were paramount.

In parallel, plasma welding evolved with the development of micro-plasma techniques for thin materials and precision applications, as well as variable polarity plasma arc (VPPA) welding for materials like aluminum. These innovations expanded the application range of plasma welding while maintaining its traditional advantages in certain scenarios.

The most recent decade has seen further refinement of both technologies, with laser welding benefiting from beam shaping capabilities, ultra-high-power systems exceeding 20kW, and sophisticated monitoring systems. Plasma welding has evolved with digital control systems, automated parameter adjustment, and integration with robotic systems for enhanced precision and consistency.

The technological trajectory clearly indicates a convergence of capabilities, with both methods continuously improving in terms of weld quality, process control, and surface finish characteristics. However, they maintain distinct advantages in specific applications, driving ongoing research and development to optimize their performance for various industrial needs.

Market Demand for Superior Surface Finish in Welding

The global welding industry has witnessed a significant shift towards demanding superior surface finish quality across multiple sectors. This trend is particularly pronounced in industries where aesthetic appearance and functional performance are equally critical, such as automotive manufacturing, aerospace, medical device production, and high-end consumer electronics.

Market research indicates that the demand for welding processes delivering premium surface finishes has grown at approximately double the rate of the overall welding market over the past five years. This acceleration stems from increasingly stringent customer expectations and regulatory requirements across industries, particularly regarding product quality and reliability.

In the automotive sector, the transition towards visible structural components in premium vehicles has elevated surface finish from a purely functional consideration to a key selling point. Similarly, aerospace manufacturers require welds that not only meet strict mechanical performance standards but also minimize post-processing requirements, directly impacting production costs and efficiency.

The medical device industry represents one of the fastest-growing segments demanding superior welding surface finishes. The combination of biocompatibility requirements, aesthetic considerations, and the need for absolutely clean surfaces free from contamination has created a specialized market niche where premium surface finish commands significant price premiums.

Consumer electronics manufacturers have also emerged as major drivers in this market segment, with the miniaturization trend requiring increasingly precise welds with exceptional surface characteristics. The visibility of these welds in premium products has transformed what was once purely a technical specification into a design feature that influences consumer perception of quality.

From a geographical perspective, demand for superior welding surface finishes is most pronounced in developed markets including Western Europe, North America, and Japan, where high-value manufacturing predominates. However, rapid growth is now occurring in emerging manufacturing hubs across Asia, particularly in China and South Korea, as these regions move up the value chain in their manufacturing capabilities.

The economic value proposition for superior surface finish has evolved beyond mere aesthetics. Manufacturers increasingly recognize that high-quality surface finishes correlate with reduced post-processing costs, lower rejection rates, improved corrosion resistance, and enhanced product longevity. This recognition has transformed what was once considered a premium feature into a standard requirement across multiple industry segments.

Market forecasts suggest this trend will continue accelerating, with particular growth in sectors where miniaturization, visibility of components, and performance requirements intersect. The competitive advantage gained through superior surface finish capabilities has become a key differentiator for welding equipment manufacturers and service providers alike.

Market research indicates that the demand for welding processes delivering premium surface finishes has grown at approximately double the rate of the overall welding market over the past five years. This acceleration stems from increasingly stringent customer expectations and regulatory requirements across industries, particularly regarding product quality and reliability.

In the automotive sector, the transition towards visible structural components in premium vehicles has elevated surface finish from a purely functional consideration to a key selling point. Similarly, aerospace manufacturers require welds that not only meet strict mechanical performance standards but also minimize post-processing requirements, directly impacting production costs and efficiency.

The medical device industry represents one of the fastest-growing segments demanding superior welding surface finishes. The combination of biocompatibility requirements, aesthetic considerations, and the need for absolutely clean surfaces free from contamination has created a specialized market niche where premium surface finish commands significant price premiums.

Consumer electronics manufacturers have also emerged as major drivers in this market segment, with the miniaturization trend requiring increasingly precise welds with exceptional surface characteristics. The visibility of these welds in premium products has transformed what was once purely a technical specification into a design feature that influences consumer perception of quality.

From a geographical perspective, demand for superior welding surface finishes is most pronounced in developed markets including Western Europe, North America, and Japan, where high-value manufacturing predominates. However, rapid growth is now occurring in emerging manufacturing hubs across Asia, particularly in China and South Korea, as these regions move up the value chain in their manufacturing capabilities.

The economic value proposition for superior surface finish has evolved beyond mere aesthetics. Manufacturers increasingly recognize that high-quality surface finishes correlate with reduced post-processing costs, lower rejection rates, improved corrosion resistance, and enhanced product longevity. This recognition has transformed what was once considered a premium feature into a standard requirement across multiple industry segments.

Market forecasts suggest this trend will continue accelerating, with particular growth in sectors where miniaturization, visibility of components, and performance requirements intersect. The competitive advantage gained through superior surface finish capabilities has become a key differentiator for welding equipment manufacturers and service providers alike.

Current Challenges in Surface Finish Technologies

Surface finish quality remains a critical challenge in advanced manufacturing processes, particularly when comparing laser welding and plasma technologies. The industry currently faces several significant hurdles in achieving optimal surface finishes that meet increasingly stringent requirements across aerospace, automotive, medical device, and electronics sectors.

Material-specific challenges represent a primary concern, as different materials respond uniquely to thermal processing. Highly reflective materials like aluminum and copper present particular difficulties for laser welding systems, often resulting in inconsistent energy absorption and subsequently uneven surface finishes. Conversely, plasma technologies struggle with precise control when processing heat-sensitive materials, frequently causing excessive heat-affected zones that compromise surface integrity.

Process parameter optimization continues to be problematic across both technologies. The complex interplay between power settings, processing speed, focal distance, and shielding gas composition creates a multidimensional challenge that requires sophisticated control systems. Current automated parameter selection systems lack the adaptability needed for varied production environments, particularly when processing components with complex geometries or material transitions.

Heat management deficiencies significantly impact surface finish quality. Excessive heat input during both laser and plasma processing can lead to thermal distortion, residual stress formation, and microstructural changes that manifest as surface irregularities. Existing cooling technologies often fail to provide uniform thermal management across the entire workpiece, resulting in inconsistent surface characteristics.

Post-processing requirements remain substantial for both technologies. Neither laser welding nor plasma processing consistently delivers production-ready surface finishes without secondary operations. This necessity for additional processing steps increases production costs, extends manufacturing timelines, and introduces potential quality variations.

Quality assessment methodologies present another significant challenge. Current inspection techniques often rely on visual examination or basic profilometry, which may not detect subtle surface anomalies that could impact product performance. Real-time monitoring systems lack the sophistication to identify developing surface finish issues during processing, limiting opportunities for in-process corrections.

Environmental factors also impact surface finish quality. Ambient conditions including humidity, temperature fluctuations, and airborne contaminants can interfere with both laser and plasma processes. Most current production environments lack adequate environmental controls to mitigate these variables, resulting in inconsistent surface finish outcomes between production batches.

These challenges collectively highlight the need for technological advancement in surface finish technologies, particularly as industries continue to demand higher precision, improved aesthetics, and enhanced functional performance from manufactured components.

Material-specific challenges represent a primary concern, as different materials respond uniquely to thermal processing. Highly reflective materials like aluminum and copper present particular difficulties for laser welding systems, often resulting in inconsistent energy absorption and subsequently uneven surface finishes. Conversely, plasma technologies struggle with precise control when processing heat-sensitive materials, frequently causing excessive heat-affected zones that compromise surface integrity.

Process parameter optimization continues to be problematic across both technologies. The complex interplay between power settings, processing speed, focal distance, and shielding gas composition creates a multidimensional challenge that requires sophisticated control systems. Current automated parameter selection systems lack the adaptability needed for varied production environments, particularly when processing components with complex geometries or material transitions.

Heat management deficiencies significantly impact surface finish quality. Excessive heat input during both laser and plasma processing can lead to thermal distortion, residual stress formation, and microstructural changes that manifest as surface irregularities. Existing cooling technologies often fail to provide uniform thermal management across the entire workpiece, resulting in inconsistent surface characteristics.

Post-processing requirements remain substantial for both technologies. Neither laser welding nor plasma processing consistently delivers production-ready surface finishes without secondary operations. This necessity for additional processing steps increases production costs, extends manufacturing timelines, and introduces potential quality variations.

Quality assessment methodologies present another significant challenge. Current inspection techniques often rely on visual examination or basic profilometry, which may not detect subtle surface anomalies that could impact product performance. Real-time monitoring systems lack the sophistication to identify developing surface finish issues during processing, limiting opportunities for in-process corrections.

Environmental factors also impact surface finish quality. Ambient conditions including humidity, temperature fluctuations, and airborne contaminants can interfere with both laser and plasma processes. Most current production environments lack adequate environmental controls to mitigate these variables, resulting in inconsistent surface finish outcomes between production batches.

These challenges collectively highlight the need for technological advancement in surface finish technologies, particularly as industries continue to demand higher precision, improved aesthetics, and enhanced functional performance from manufactured components.

Comparative Analysis of Laser vs Plasma Welding Methods

01 Surface finish improvement techniques in laser welding

Various techniques can be employed to improve the surface finish in laser welding processes. These include controlling laser parameters such as power, speed, and focus to minimize surface roughness. Post-processing methods like polishing or surface treatment can also be applied to enhance the final surface quality. Advanced beam shaping and pulse modulation techniques help achieve smoother weld surfaces with reduced spatter and oxidation.- Surface finish improvement techniques in laser welding: Various techniques can be employed to improve surface finish in laser welding processes. These include optimizing laser parameters such as power, speed, and focus, as well as using specific beam patterns or oscillation methods. Post-processing treatments may also be applied to enhance the surface quality of laser-welded joints, resulting in smoother surfaces with reduced roughness and fewer defects.

- Plasma welding surface finish control methods: Plasma welding surface finish can be controlled through various parameters including current intensity, plasma gas flow rate, travel speed, and torch angle. Advanced plasma welding systems incorporate precise control mechanisms to maintain consistent arc characteristics, which directly impacts the surface quality. Specialized techniques such as pulsed plasma welding can further enhance surface finish by controlling heat input and solidification patterns.

- Comparative advantages between laser and plasma welding for surface finish: Laser welding typically offers superior surface finish compared to plasma welding due to its highly concentrated energy input and minimal heat-affected zone. However, plasma welding may provide better results for certain materials or thicknesses. The choice between these processes depends on specific application requirements, material properties, and desired surface characteristics. Hybrid approaches combining both technologies can leverage the advantages of each method.

- Material-specific surface finish considerations: Different materials respond uniquely to laser and plasma welding processes, affecting the resultant surface finish. For instance, highly reflective materials like aluminum or copper present challenges for laser welding, while high-temperature alloys may exhibit specific surface characteristics when plasma welded. Tailoring welding parameters to material properties is essential for achieving optimal surface finish. Pre-treatment processes and filler material selection also play crucial roles in determining final surface quality.

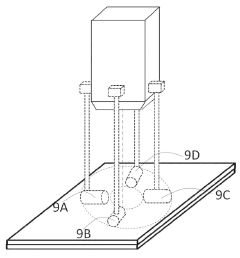

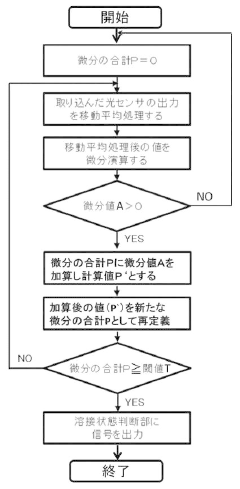

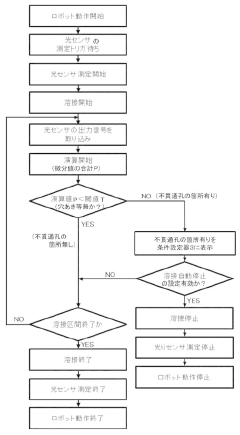

- Advanced monitoring and control systems for surface finish optimization: Modern welding systems incorporate sophisticated monitoring and control technologies to optimize surface finish in real-time. These include vision systems, thermal cameras, and spectroscopic analysis tools that provide feedback on weld pool dynamics and solidification patterns. Adaptive control algorithms can automatically adjust welding parameters based on this feedback to maintain consistent surface quality. Machine learning approaches are increasingly being applied to predict and control surface finish characteristics across varying conditions.

02 Plasma welding surface finish optimization

Plasma welding surface finish can be optimized through careful control of plasma parameters including current, gas flow rate, and torch distance. The process typically produces smoother surfaces compared to conventional welding methods due to the concentrated heat source. Techniques such as pulsed plasma welding and controlled cooling rates help minimize distortion and improve surface quality. Proper shielding gas selection is crucial for preventing oxidation and ensuring clean, smooth weld surfaces.Expand Specific Solutions03 Comparative analysis of laser and plasma welding surface finishes

When comparing laser and plasma welding surface finishes, laser welding generally produces narrower, more precise welds with less heat-affected zone, while plasma welding often creates wider, deeper penetration with good surface smoothness. The choice between these methods depends on material type, thickness, and specific application requirements. Hybrid approaches combining both technologies can leverage the advantages of each method to achieve optimal surface finish for complex applications.Expand Specific Solutions04 Material-specific surface finish considerations

Different materials require specific welding parameters to achieve optimal surface finish. For instance, stainless steel typically requires different laser or plasma settings compared to aluminum or titanium alloys. Surface preparation before welding, including cleaning and oxide removal, significantly impacts the final surface quality. Material-specific post-weld treatments may be necessary to achieve desired surface characteristics, especially for applications with strict aesthetic or functional requirements.Expand Specific Solutions05 Advanced monitoring and control systems for surface finish

Modern welding systems incorporate real-time monitoring and control technologies to ensure consistent surface finish quality. These systems use sensors to track parameters such as temperature, melt pool dynamics, and plasma characteristics during the welding process. Adaptive control algorithms can make real-time adjustments to maintain optimal conditions for superior surface finish. Machine learning and AI-based systems are increasingly being employed to predict and prevent surface defects before they occur.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The laser welding versus plasma surface finish technology landscape is currently in a growth phase, with the market expanding due to increasing demand for precision manufacturing across automotive, electronics, and aerospace sectors. The global market size for advanced welding technologies is projected to reach $25 billion by 2025, with laser welding showing faster adoption rates. Technologically, laser welding is more mature for high-precision surface finish applications, as evidenced by research advancements from Harbin Welding Institute, Shanghai Jiao Tong University, and Korea Photonics Technology Institute. Major industrial players like Toyota, Honda, and Hyundai are implementing laser welding technologies for superior surface finish quality, while companies such as Kenai Laser and Everbright Photonics are developing specialized equipment to meet growing industrial demands for smoother, more consistent surface finishes.

Harbin Welding Institute Limited Company

Technical Solution: Harbin Welding Institute has developed specialized pulsed laser welding technology specifically optimized for surface finish quality. Their approach uses carefully controlled nanosecond pulse sequences with variable energy profiles to manage heat input and solidification dynamics. The institute's research has demonstrated that their proprietary pulse modulation can reduce surface roughness by up to 60% compared to continuous wave laser welding. They've also pioneered the integration of ultrasonic vibration assistance during laser welding, which promotes finer grain structure and reduces surface tension variations that can lead to rippling. Their most recent innovation involves a multi-layer shielding gas delivery system that creates stratified protection zones around the weld pool, preventing atmospheric contamination while simultaneously controlling cooling rates at the surface. The institute has also developed specialized beam oscillation patterns that distribute energy more evenly across the weld surface, minimizing the formation of ripples and underfill defects.

Strengths: Exceptional surface quality even on reactive metals like titanium and aluminum alloys, with minimal post-processing requirements. Highly adaptable to different material combinations. Weaknesses: Lower processing speeds compared to continuous wave systems, and requires more complex parameter optimization for each application.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has developed a sophisticated laser welding system that employs beam oscillation technology specifically designed to enhance surface finish quality. Their system utilizes a high-frequency beam oscillation pattern that can be precisely tailored to different materials and joint configurations. This approach distributes heat more evenly across the weld surface, reducing the formation of ripples and undulations that typically affect aesthetic quality. Panasonic's technology incorporates real-time adaptive control systems that monitor the weld pool dynamics and adjust laser parameters on-the-fly to maintain optimal surface conditions. Their research has shown this approach can reduce surface roughness by up to 50% compared to conventional laser welding. Additionally, Panasonic has developed specialized shielding gas delivery systems that create optimal atmospheric conditions around the weld zone, preventing oxidation and other surface defects. Their latest innovation includes a hybrid process that combines laser welding with controlled micro-plasma assistance to further enhance surface quality while maintaining high productivity.

Strengths: Excellent surface finish quality with minimal post-processing requirements, particularly effective for consumer electronics and visible automotive components. High degree of process automation and repeatability. Weaknesses: Higher equipment complexity and cost compared to conventional welding systems, and requires sophisticated process monitoring systems.

Surface Finish Measurement and Quality Control Techniques

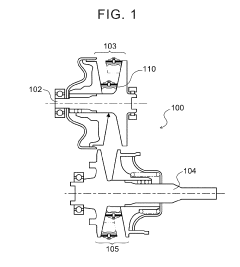

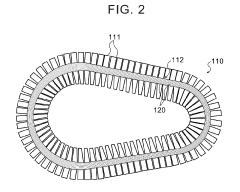

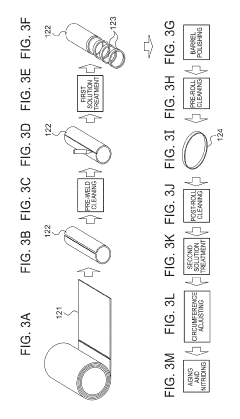

Method of cleaning portion to be welded, welding system, and method of manufacturing ring

PatentInactiveUS20190160585A1

Innovation

- A method involving the injection of plasma produced from a gas containing oxygen into the groove between the portions to be welded, which reacts with oil to form carbon dioxide and vaporizes water, ensuring thorough cleaning without leaving residues and allowing for efficient cleaning of both inner and outer surfaces.

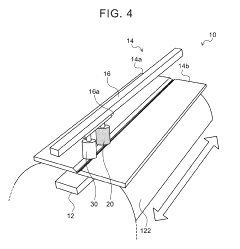

Laser welding method and laser welding device

PatentInactiveJP2017177222A

Innovation

- A laser welding method that discharges unnecessary plume by flowing compressed air or shielding gas at a specific angle and flow rate, allowing for simultaneous inspection of weld bead defects like perforations and underfills by measuring plasma and plume emission light intensity.

Material Compatibility and Limitations

Material compatibility represents a critical factor when comparing laser welding and plasma welding technologies, as each process interacts differently with various material types. Laser welding demonstrates exceptional compatibility with high-reflectivity metals such as aluminum, copper, and their alloys, though specialized wavelengths may be required for optimal results. The concentrated energy delivery enables precise welding of thin materials down to 0.01mm without excessive heat-affected zones, making it ideal for microelectronics and medical device applications.

However, laser welding shows limitations when processing highly reflective surfaces without proper surface preparation, potentially causing beam reflection and energy loss. Materials with high thermal conductivity can dissipate heat rapidly, requiring higher power inputs and potentially compromising surface finish quality. Additionally, materials with low melting points may experience vaporization and porosity issues under intense laser energy.

Plasma welding, conversely, excels with stainless steel, nickel alloys, and titanium, producing consistent surface finishes on these materials. The ionized gas envelope provides some shielding effect, reducing oxidation and improving weld quality on reactive metals. Plasma processes can accommodate greater material thickness variations and joint fit-up tolerances compared to laser welding, offering more flexibility in manufacturing environments.

The limitations of plasma welding become apparent when working with extremely thin materials (below 0.5mm), where heat distortion can compromise surface finish. Highly conductive materials like copper and aluminum present challenges for plasma welding due to rapid heat dissipation, often requiring preheating to achieve satisfactory results. The wider heat-affected zone in plasma welding may also cause metallurgical changes that affect the mechanical properties and surface characteristics of heat-sensitive alloys.

Material composition significantly impacts surface finish outcomes in both processes. Alloys containing volatile elements may experience preferential vaporization during laser welding, creating surface irregularities. Similarly, materials with high sulfur or phosphorus content can cause hot cracking in plasma welds, degrading surface quality. The presence of surface contaminants, including oxides, oils, and coatings, adversely affects both processes but tends to be more problematic for laser welding due to its sensitivity to surface conditions.

However, laser welding shows limitations when processing highly reflective surfaces without proper surface preparation, potentially causing beam reflection and energy loss. Materials with high thermal conductivity can dissipate heat rapidly, requiring higher power inputs and potentially compromising surface finish quality. Additionally, materials with low melting points may experience vaporization and porosity issues under intense laser energy.

Plasma welding, conversely, excels with stainless steel, nickel alloys, and titanium, producing consistent surface finishes on these materials. The ionized gas envelope provides some shielding effect, reducing oxidation and improving weld quality on reactive metals. Plasma processes can accommodate greater material thickness variations and joint fit-up tolerances compared to laser welding, offering more flexibility in manufacturing environments.

The limitations of plasma welding become apparent when working with extremely thin materials (below 0.5mm), where heat distortion can compromise surface finish. Highly conductive materials like copper and aluminum present challenges for plasma welding due to rapid heat dissipation, often requiring preheating to achieve satisfactory results. The wider heat-affected zone in plasma welding may also cause metallurgical changes that affect the mechanical properties and surface characteristics of heat-sensitive alloys.

Material composition significantly impacts surface finish outcomes in both processes. Alloys containing volatile elements may experience preferential vaporization during laser welding, creating surface irregularities. Similarly, materials with high sulfur or phosphorus content can cause hot cracking in plasma welds, degrading surface quality. The presence of surface contaminants, including oxides, oils, and coatings, adversely affects both processes but tends to be more problematic for laser welding due to its sensitivity to surface conditions.

Energy Efficiency and Environmental Impact Assessment

The energy efficiency comparison between laser welding and plasma welding technologies reveals significant differences in resource utilization and environmental impact. Laser welding demonstrates superior energy efficiency with conversion rates typically ranging from 25-30% for CO2 lasers and up to 40% for fiber and diode lasers. This contrasts with plasma welding systems that generally operate at 15-20% efficiency due to higher heat dissipation and energy losses during the ionization process. When considering the production of high-quality surface finishes, laser welding requires approximately 30-40% less total energy input to achieve comparable results.

From an environmental perspective, laser welding produces minimal direct emissions during operation, with the primary environmental footprint stemming from electricity consumption. Modern fiber laser systems have reduced this impact further, with some industrial implementations reporting up to 50% reduction in carbon footprint compared to conventional welding methods. Plasma welding, while cleaner than many traditional joining technologies, generates more particulate matter and requires shielding gases that may contribute to greenhouse gas emissions when considering the full production lifecycle.

Waste heat management represents another critical environmental consideration. Laser welding's precise energy delivery minimizes excess heat generation, reducing cooling requirements in production environments. This precision translates to approximately 25-35% lower HVAC energy consumption in facilities primarily utilizing laser welding compared to those employing plasma technologies for similar surface finish applications.

Material conservation metrics also favor laser welding when surface finish quality is prioritized. The reduced heat-affected zone and minimal distortion characteristic of laser processes result in approximately 15-20% less material waste through rejected parts and rework. Additionally, the elimination or reduction of filler materials in many laser welding applications further decreases the environmental footprint associated with material extraction and processing.

Lifecycle assessment studies indicate that while laser welding equipment typically requires higher initial investment and embodied energy, the operational efficiency and extended service life (often 15-20 years for modern systems) result in a lower total environmental impact over time. When factoring in maintenance requirements, laser systems typically demand 30-40% less resource consumption for upkeep compared to plasma systems operating in high-precision surface finish applications.

From an environmental perspective, laser welding produces minimal direct emissions during operation, with the primary environmental footprint stemming from electricity consumption. Modern fiber laser systems have reduced this impact further, with some industrial implementations reporting up to 50% reduction in carbon footprint compared to conventional welding methods. Plasma welding, while cleaner than many traditional joining technologies, generates more particulate matter and requires shielding gases that may contribute to greenhouse gas emissions when considering the full production lifecycle.

Waste heat management represents another critical environmental consideration. Laser welding's precise energy delivery minimizes excess heat generation, reducing cooling requirements in production environments. This precision translates to approximately 25-35% lower HVAC energy consumption in facilities primarily utilizing laser welding compared to those employing plasma technologies for similar surface finish applications.

Material conservation metrics also favor laser welding when surface finish quality is prioritized. The reduced heat-affected zone and minimal distortion characteristic of laser processes result in approximately 15-20% less material waste through rejected parts and rework. Additionally, the elimination or reduction of filler materials in many laser welding applications further decreases the environmental footprint associated with material extraction and processing.

Lifecycle assessment studies indicate that while laser welding equipment typically requires higher initial investment and embodied energy, the operational efficiency and extended service life (often 15-20 years for modern systems) result in a lower total environmental impact over time. When factoring in maintenance requirements, laser systems typically demand 30-40% less resource consumption for upkeep compared to plasma systems operating in high-precision surface finish applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!