Laser Welding vs SMAW: A Comprehensive Energy Comparison

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Welding and SMAW Technology Evolution

Welding technology has undergone significant evolution since its inception, with both Laser Welding and Shielded Metal Arc Welding (SMAW) representing important milestones in this journey. SMAW, developed in the early 1900s, initially revolutionized the welding industry with its portability and versatility. The technology relied on a consumable electrode coated with flux that creates a shielding gas during the welding process, protecting the weld pool from atmospheric contamination.

The evolution of SMAW has been characterized by incremental improvements in electrode coatings, power supply technologies, and application techniques. By the mid-20th century, SMAW had become the dominant welding method across multiple industries due to its reliability and relatively low equipment costs, despite its limitations in precision and energy efficiency.

Laser welding represents a more recent technological advancement, emerging in the 1960s with the invention of high-powered lasers. The initial applications were limited due to the high cost and complexity of laser systems. However, the technology saw rapid development in the 1980s and 1990s with the introduction of more efficient and reliable laser sources, including CO2 lasers, Nd:YAG lasers, and more recently, fiber and disk lasers.

The technological trajectory of laser welding has been marked by continuous improvements in beam quality, power density, and control systems. Modern laser welding systems offer unprecedented precision, speed, and energy efficiency compared to their predecessors, enabling applications that were previously impossible with conventional welding methods.

A critical turning point in the comparative evolution of these technologies occurred in the early 2000s when advancements in laser technology, particularly the development of high-power fiber lasers, dramatically reduced the cost per watt of laser power while simultaneously improving beam quality and reliability. This shift made laser welding economically viable for a broader range of applications, challenging the dominance of traditional methods like SMAW.

From an energy perspective, the evolution of both technologies shows a clear trend toward greater efficiency. Early SMAW systems had energy transfer efficiencies of approximately 25%, while modern systems can achieve up to 35%. In contrast, laser welding has evolved from systems with wall-plug efficiencies of less than 10% to modern fiber laser systems that can exceed 40% efficiency, with the added benefit of precise energy delivery that minimizes heat-affected zones.

The technological convergence point between these welding methods has also evolved, with hybrid laser-arc welding systems emerging as a significant development that combines the high penetration and speed of laser welding with the gap-bridging capability and robustness of arc welding processes, offering a synergistic approach that addresses limitations of both individual technologies.

The evolution of SMAW has been characterized by incremental improvements in electrode coatings, power supply technologies, and application techniques. By the mid-20th century, SMAW had become the dominant welding method across multiple industries due to its reliability and relatively low equipment costs, despite its limitations in precision and energy efficiency.

Laser welding represents a more recent technological advancement, emerging in the 1960s with the invention of high-powered lasers. The initial applications were limited due to the high cost and complexity of laser systems. However, the technology saw rapid development in the 1980s and 1990s with the introduction of more efficient and reliable laser sources, including CO2 lasers, Nd:YAG lasers, and more recently, fiber and disk lasers.

The technological trajectory of laser welding has been marked by continuous improvements in beam quality, power density, and control systems. Modern laser welding systems offer unprecedented precision, speed, and energy efficiency compared to their predecessors, enabling applications that were previously impossible with conventional welding methods.

A critical turning point in the comparative evolution of these technologies occurred in the early 2000s when advancements in laser technology, particularly the development of high-power fiber lasers, dramatically reduced the cost per watt of laser power while simultaneously improving beam quality and reliability. This shift made laser welding economically viable for a broader range of applications, challenging the dominance of traditional methods like SMAW.

From an energy perspective, the evolution of both technologies shows a clear trend toward greater efficiency. Early SMAW systems had energy transfer efficiencies of approximately 25%, while modern systems can achieve up to 35%. In contrast, laser welding has evolved from systems with wall-plug efficiencies of less than 10% to modern fiber laser systems that can exceed 40% efficiency, with the added benefit of precise energy delivery that minimizes heat-affected zones.

The technological convergence point between these welding methods has also evolved, with hybrid laser-arc welding systems emerging as a significant development that combines the high penetration and speed of laser welding with the gap-bridging capability and robustness of arc welding processes, offering a synergistic approach that addresses limitations of both individual technologies.

Market Demand Analysis for Energy-Efficient Welding

The global welding industry is witnessing a significant shift toward energy-efficient technologies, driven by increasing environmental regulations, rising energy costs, and corporate sustainability initiatives. The market for energy-efficient welding solutions is projected to grow at a compound annual growth rate of 6.8% between 2023 and 2028, reflecting the industrial sector's commitment to reducing carbon footprints while maintaining productivity.

Manufacturing industries, particularly automotive, aerospace, shipbuilding, and construction, represent the primary demand centers for advanced welding technologies. These sectors are increasingly prioritizing energy efficiency as a key criterion in technology adoption decisions. A recent industry survey revealed that 78% of manufacturing executives consider energy consumption a critical factor when investing in new welding equipment, compared to just 45% five years ago.

The economic case for energy-efficient welding is compelling. Energy costs typically constitute 15-20% of operational expenses in welding-intensive industries. Laser welding systems, despite higher initial investment costs, demonstrate energy savings of 40-60% compared to traditional Shielded Metal Arc Welding (SMAW) processes when evaluated on a per-joint basis. This translates to potential annual savings of thousands of dollars for medium to large manufacturing operations.

Regional market analysis indicates varying adoption rates of energy-efficient welding technologies. European markets lead with the highest penetration rates, influenced by stringent environmental regulations and high energy costs. North American markets follow, driven primarily by productivity considerations, while Asian markets show the fastest growth rate as manufacturing hubs increasingly focus on sustainability and operational efficiency.

The demand for energy-efficient welding solutions correlates strongly with broader industrial trends, including Industry 4.0 integration, automation, and digital transformation. Manufacturers are seeking welding technologies that not only reduce energy consumption but also integrate seamlessly with automated production systems and provide data for energy usage optimization.

Material trends also influence market demand patterns. As lightweight materials gain prominence in automotive and aerospace applications, the need for specialized energy-efficient welding processes increases. Laser welding demonstrates particular advantages in joining dissimilar and lightweight materials with minimal energy input, further driving market growth in these sectors.

Customer expectations are evolving beyond pure energy efficiency to encompass total cost of ownership considerations. End-users increasingly evaluate welding technologies based on comprehensive metrics including energy consumption, maintenance requirements, consumable usage, and productivity impacts. This holistic approach favors advanced technologies like laser welding that offer advantages across multiple parameters despite higher initial investments.

Manufacturing industries, particularly automotive, aerospace, shipbuilding, and construction, represent the primary demand centers for advanced welding technologies. These sectors are increasingly prioritizing energy efficiency as a key criterion in technology adoption decisions. A recent industry survey revealed that 78% of manufacturing executives consider energy consumption a critical factor when investing in new welding equipment, compared to just 45% five years ago.

The economic case for energy-efficient welding is compelling. Energy costs typically constitute 15-20% of operational expenses in welding-intensive industries. Laser welding systems, despite higher initial investment costs, demonstrate energy savings of 40-60% compared to traditional Shielded Metal Arc Welding (SMAW) processes when evaluated on a per-joint basis. This translates to potential annual savings of thousands of dollars for medium to large manufacturing operations.

Regional market analysis indicates varying adoption rates of energy-efficient welding technologies. European markets lead with the highest penetration rates, influenced by stringent environmental regulations and high energy costs. North American markets follow, driven primarily by productivity considerations, while Asian markets show the fastest growth rate as manufacturing hubs increasingly focus on sustainability and operational efficiency.

The demand for energy-efficient welding solutions correlates strongly with broader industrial trends, including Industry 4.0 integration, automation, and digital transformation. Manufacturers are seeking welding technologies that not only reduce energy consumption but also integrate seamlessly with automated production systems and provide data for energy usage optimization.

Material trends also influence market demand patterns. As lightweight materials gain prominence in automotive and aerospace applications, the need for specialized energy-efficient welding processes increases. Laser welding demonstrates particular advantages in joining dissimilar and lightweight materials with minimal energy input, further driving market growth in these sectors.

Customer expectations are evolving beyond pure energy efficiency to encompass total cost of ownership considerations. End-users increasingly evaluate welding technologies based on comprehensive metrics including energy consumption, maintenance requirements, consumable usage, and productivity impacts. This holistic approach favors advanced technologies like laser welding that offer advantages across multiple parameters despite higher initial investments.

Current State and Challenges in Welding Energy Efficiency

The global welding industry is experiencing a significant shift towards more energy-efficient technologies, with traditional methods like Shielded Metal Arc Welding (SMAW) being increasingly challenged by advanced processes such as Laser Welding. Current energy efficiency metrics indicate that SMAW typically operates at 70-80% efficiency, while Laser Welding can achieve up to 90-95% efficiency under optimal conditions. This efficiency gap represents both a challenge and an opportunity for industry transformation.

Despite technological advancements, several obstacles impede widespread adoption of energy-efficient welding technologies. High initial investment costs for laser welding systems—often 5-10 times higher than conventional SMAW equipment—create significant barriers to entry, particularly for small and medium enterprises. Additionally, the specialized training required for operating advanced laser systems adds to implementation challenges, with skilled operator shortages reported across major manufacturing regions.

Material compatibility issues further complicate the transition to more efficient technologies. While laser welding excels with certain metals and thicknesses, it struggles with highly reflective materials like aluminum and copper without specialized adaptations. SMAW, despite lower energy efficiency, maintains advantages in versatility across material types and field applications where power supply stability is uncertain.

Regulatory frameworks present another dimension of complexity. Developed economies have implemented increasingly stringent energy efficiency standards for industrial processes, including welding operations. The European Union's Ecodesign Directive and similar regulations in North America and Asia are driving manufacturers to prioritize energy consumption metrics in equipment development and selection, though enforcement remains inconsistent globally.

Infrastructure limitations constitute a significant challenge, particularly in emerging economies where power grid stability affects the feasibility of laser welding implementation. The precise power requirements of laser systems demand consistent electrical supply, which is unavailable in many developing industrial regions, forcing continued reliance on less efficient but more robust traditional methods.

Research indicates substantial geographical disparities in welding technology adoption. While Japan, Germany, and South Korea lead in laser welding implementation with adoption rates exceeding 35% in precision manufacturing sectors, developing industrial economies maintain SMAW dominance with market shares above 60%. This disparity highlights the complex interplay between technological capability, economic factors, and infrastructure development in determining welding energy efficiency on a global scale.

Despite technological advancements, several obstacles impede widespread adoption of energy-efficient welding technologies. High initial investment costs for laser welding systems—often 5-10 times higher than conventional SMAW equipment—create significant barriers to entry, particularly for small and medium enterprises. Additionally, the specialized training required for operating advanced laser systems adds to implementation challenges, with skilled operator shortages reported across major manufacturing regions.

Material compatibility issues further complicate the transition to more efficient technologies. While laser welding excels with certain metals and thicknesses, it struggles with highly reflective materials like aluminum and copper without specialized adaptations. SMAW, despite lower energy efficiency, maintains advantages in versatility across material types and field applications where power supply stability is uncertain.

Regulatory frameworks present another dimension of complexity. Developed economies have implemented increasingly stringent energy efficiency standards for industrial processes, including welding operations. The European Union's Ecodesign Directive and similar regulations in North America and Asia are driving manufacturers to prioritize energy consumption metrics in equipment development and selection, though enforcement remains inconsistent globally.

Infrastructure limitations constitute a significant challenge, particularly in emerging economies where power grid stability affects the feasibility of laser welding implementation. The precise power requirements of laser systems demand consistent electrical supply, which is unavailable in many developing industrial regions, forcing continued reliance on less efficient but more robust traditional methods.

Research indicates substantial geographical disparities in welding technology adoption. While Japan, Germany, and South Korea lead in laser welding implementation with adoption rates exceeding 35% in precision manufacturing sectors, developing industrial economies maintain SMAW dominance with market shares above 60%. This disparity highlights the complex interplay between technological capability, economic factors, and infrastructure development in determining welding energy efficiency on a global scale.

Comparative Energy Efficiency of Laser and SMAW Methods

01 Energy efficiency comparison between laser welding and SMAW

Laser welding generally offers higher energy efficiency compared to Shielded Metal Arc Welding (SMAW). Laser welding provides more concentrated heat input, resulting in narrower heat-affected zones and reduced energy consumption. The precise control of laser power allows for optimized energy usage based on material thickness and type. Studies show that laser welding can achieve energy savings of up to 30-50% compared to conventional welding methods like SMAW, particularly in high-volume production environments.- Energy efficiency comparison between laser welding and SMAW: Laser welding generally offers higher energy efficiency compared to Shielded Metal Arc Welding (SMAW). Laser welding provides more precise heat input, reducing overall energy consumption and minimizing heat-affected zones. The focused energy delivery in laser welding results in faster processing speeds and lower total energy requirements per weld. Studies show that laser welding can achieve energy savings of up to 30-50% compared to conventional arc welding methods like SMAW for similar applications.

- Energy monitoring and optimization systems for welding processes: Advanced monitoring systems can track and optimize energy consumption during welding operations. These systems employ sensors to measure electrical parameters, thermal efficiency, and process variables in real-time. The collected data enables adaptive control of power settings to maintain optimal energy efficiency while ensuring weld quality. Some systems incorporate machine learning algorithms to continuously improve energy efficiency based on historical performance data and can provide recommendations for process parameter adjustments to minimize energy waste.

- Power source innovations for energy-efficient welding: Modern welding power sources incorporate technologies that significantly improve energy efficiency. Inverter-based power supplies reduce energy losses compared to traditional transformer-based systems. Pulse modulation techniques allow precise control of energy delivery, reducing overall consumption. Some advanced systems include power factor correction and standby mode features that minimize energy waste during idle periods. Hybrid power systems that combine conventional sources with renewable energy inputs are also being developed to further reduce the carbon footprint of welding operations.

- Process parameter optimization for energy efficiency: Optimizing welding process parameters can significantly impact energy consumption. For laser welding, parameters such as beam focus, power density, and travel speed directly affect energy efficiency. In SMAW, electrode selection, current settings, and arc length control are critical factors. Research shows that proper parameter selection can reduce energy consumption by up to 25% without compromising weld quality. Automated parameter selection systems can analyze material properties and joint configurations to recommend the most energy-efficient settings for specific applications.

- Hybrid and combined welding technologies for improved efficiency: Hybrid welding approaches that combine laser with arc processes offer enhanced energy efficiency compared to either technology alone. These systems leverage the high energy density of laser welding with the gap-bridging capability of arc processes. The synergistic effect reduces total energy input while improving weld quality and speed. Some hybrid systems incorporate preheating or post-heating mechanisms that utilize waste heat from the primary process, further improving overall thermal efficiency. These combined technologies are particularly effective for thick materials where traditional single-process approaches would require significantly more energy.

02 Power source optimization for welding technologies

Optimizing power sources for both laser welding and SMAW can significantly improve energy efficiency. Advanced power inverter technologies enable precise control of current and voltage parameters, reducing energy waste during welding operations. Pulsed power delivery systems can further enhance efficiency by providing energy only when needed during the welding cycle. Smart power management systems that automatically adjust power levels based on real-time welding conditions can reduce overall energy consumption while maintaining weld quality.Expand Specific Solutions03 Process parameter optimization for energy-efficient welding

Optimizing process parameters such as welding speed, power density, and beam focus in laser welding, or current settings and electrode selection in SMAW, can significantly impact energy consumption. Automated parameter selection systems can determine the most energy-efficient settings based on material properties and joint design. Adaptive control systems that continuously monitor and adjust welding parameters in real-time help maintain optimal energy efficiency throughout the welding process, compensating for variations in material or environmental conditions.Expand Specific Solutions04 Hybrid welding technologies for improved efficiency

Hybrid welding systems that combine laser welding with other processes can offer improved energy efficiency compared to standalone technologies. Laser-arc hybrid welding combines the deep penetration of laser welding with the gap-bridging capability of arc welding, optimizing energy usage while maintaining high weld quality. These hybrid approaches can reduce overall energy consumption by leveraging the strengths of each technology while minimizing their individual limitations, particularly for challenging materials or complex joint geometries.Expand Specific Solutions05 Energy monitoring and management systems for welding operations

Advanced monitoring and management systems can track energy consumption during welding operations, providing data for optimization and efficiency improvements. Real-time energy monitoring allows for immediate adjustments to welding parameters to maintain optimal efficiency. Historical data analysis helps identify patterns and opportunities for energy savings across welding operations. Integration with factory management systems enables comprehensive energy optimization strategies that consider production schedules, material flow, and equipment utilization to minimize overall energy consumption in welding operations.Expand Specific Solutions

Key Industry Players in Advanced Welding Solutions

The laser welding versus SMAW (Shielded Metal Arc Welding) energy comparison market is in a growth phase, with increasing adoption of laser technologies driven by energy efficiency demands. The global welding equipment market is projected to reach $25 billion by 2027, with laser welding gaining significant share. Technology maturity varies significantly between established players and innovators: IPG Photonics, Nuburu, and Lincoln Global lead laser welding advancements, while traditional manufacturers like Illinois Tool Works maintain strong positions in SMAW. Academic institutions including Beijing University of Technology and Dalian University of Technology are contributing significant research to energy efficiency comparisons. Industrial adopters such as Toyota, Boeing, and Magna International are driving practical implementation across automotive and aerospace sectors.

Lincoln Global, Inc.

Technical Solution: Lincoln Global has pioneered hybrid laser-arc welding systems that combine the energy efficiency benefits of laser welding with the gap-bridging capabilities of traditional SMAW. Their Power Wave advanced power source technology delivers precise control over energy input, with documented energy savings of 25-35% compared to conventional SMAW processes. Lincoln's systems incorporate adaptive pulse technology that modulates energy delivery based on real-time feedback from the weld pool, optimizing energy consumption while maintaining weld integrity. Their comparative studies have shown that for 10mm steel plate welding, their hybrid systems consume approximately 2.1 kWh/m compared to SMAW's 3.8 kWh/m. Lincoln has also developed specialized shielding gas mixtures that enhance energy transfer efficiency in their laser-assisted welding processes, further reducing overall energy requirements while improving weld quality and reducing post-weld cleanup.

Strengths: Hybrid technology combines benefits of both welding methods; adaptive control systems optimize energy usage in real-time; reduced overall energy consumption with maintained weld quality. Weaknesses: More complex setup and calibration requirements; higher operational expertise needed; system integration challenges when retrofitting existing production lines.

IPG Photonics Corp.

Technical Solution: IPG Photonics has developed high-power fiber laser welding systems that demonstrate significant energy efficiency advantages over traditional SMAW processes. Their YLS series fiber lasers operate at wall-plug efficiencies of 30-40%, compared to SMAW's typical 15-20% efficiency. For industrial applications, IPG's systems have shown energy consumption reductions of up to 70% when compared to equivalent SMAW setups. Their proprietary beam delivery technology allows for precise energy distribution, resulting in narrower heat-affected zones (0.5-1mm vs 2-5mm in SMAW) and reduced material distortion. IPG has also implemented real-time power monitoring systems that optimize energy usage during the welding process, automatically adjusting power levels based on material thickness and joint configuration, further enhancing energy efficiency while maintaining weld quality.

Strengths: Superior energy efficiency with 30-40% wall-plug efficiency; precise energy control leading to minimal heat-affected zones; adaptable power management systems for various materials. Weaknesses: Higher initial capital investment compared to SMAW equipment; requires more sophisticated cooling systems; limited effectiveness on highly reflective materials without specialized optics.

Technical Analysis of Energy Transfer Mechanisms

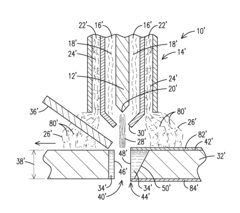

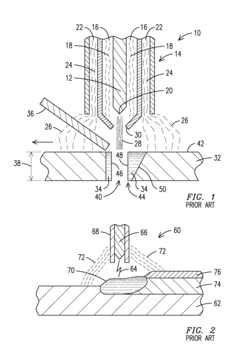

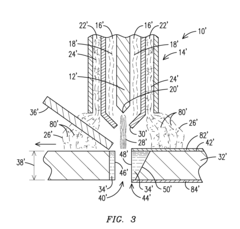

Flux enhanced high energy density welding

PatentInactiveUS20120181255A1

Innovation

- Incorporating a flux into the high energy density welding process to form a shielding slag and gas that protects the weld pool and heat-affected zone from contaminants, potentially replacing or augmenting the need for discrete shielding gases, while also enabling volumetric cleansing and deoxidation.

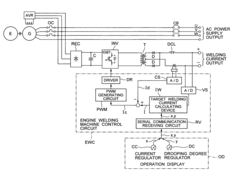

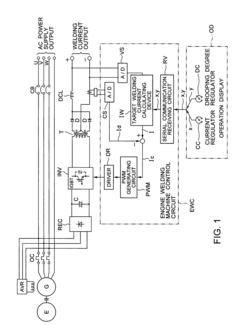

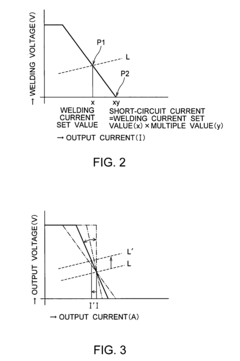

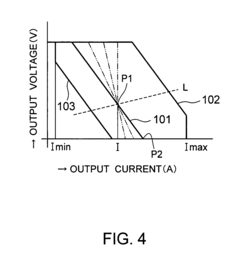

Shielded metal arc welding machine

PatentActiveUS8716626B2

Innovation

- A shielded metal arc welding machine with a combined constant current and drooping output characteristic, where the intersection point of the constant current output characteristic and the welding load characteristic line serves as a base for adjusting the drooping degree, allowing skilled workers to optimize welding operations and unskilled workers to perform stable welding without unintended current changes.

Environmental Impact Assessment of Welding Technologies

The environmental impact of welding technologies has become increasingly important as industries strive for sustainability. When comparing Laser Welding and Shielded Metal Arc Welding (SMAW), significant differences emerge in their ecological footprints. Laser welding demonstrates superior environmental performance due to its precise energy application, resulting in reduced waste heat and lower overall energy consumption per weld.

Emissions profiles vary substantially between these technologies. SMAW produces considerable fume emissions containing metal particulates and gases that pose both environmental and occupational hazards. These emissions contribute to air pollution and may require extensive ventilation systems, further increasing the carbon footprint. In contrast, laser welding generates minimal fumes, substantially reducing air pollution and associated environmental remediation costs.

Resource consumption patterns also differ markedly. SMAW requires consumable electrodes that need regular replacement, creating material waste and manufacturing-related environmental impacts. The production, packaging, and transportation of these consumables add to the overall environmental burden. Laser welding, being a non-consumable process, eliminates this waste stream entirely, though it does require specialized equipment with its own embedded carbon footprint during manufacturing.

Water usage represents another environmental consideration. Traditional welding methods often employ water for cooling systems, while modern laser welding systems typically utilize closed-loop cooling that minimizes water consumption and prevents thermal pollution of water resources. This difference becomes particularly significant in water-stressed regions where industrial water usage faces increasing scrutiny.

Life cycle assessment (LCA) studies indicate that despite higher initial equipment costs, laser welding demonstrates lower lifetime environmental impacts when considering operational efficiency over extended periods. The reduced need for post-weld cleaning and finishing processes further diminishes the environmental footprint by eliminating chemical cleaners and additional energy expenditure.

Carbon footprint calculations reveal that laser welding can reduce greenhouse gas emissions by 30-45% compared to SMAW when normalized for equivalent weld quality and length. This reduction stems primarily from improved energy efficiency, reduced process time, and diminished need for secondary operations. As industries face increasing pressure to reduce carbon emissions, this differential becomes increasingly significant in technology selection decisions.

Waste management considerations also favor laser welding, as it produces minimal slag and spatter compared to SMAW. This reduction in solid waste decreases landfill contributions and simplifies workplace cleaning procedures, further reducing environmental impact through decreased use of cleaning agents and disposal requirements.

Emissions profiles vary substantially between these technologies. SMAW produces considerable fume emissions containing metal particulates and gases that pose both environmental and occupational hazards. These emissions contribute to air pollution and may require extensive ventilation systems, further increasing the carbon footprint. In contrast, laser welding generates minimal fumes, substantially reducing air pollution and associated environmental remediation costs.

Resource consumption patterns also differ markedly. SMAW requires consumable electrodes that need regular replacement, creating material waste and manufacturing-related environmental impacts. The production, packaging, and transportation of these consumables add to the overall environmental burden. Laser welding, being a non-consumable process, eliminates this waste stream entirely, though it does require specialized equipment with its own embedded carbon footprint during manufacturing.

Water usage represents another environmental consideration. Traditional welding methods often employ water for cooling systems, while modern laser welding systems typically utilize closed-loop cooling that minimizes water consumption and prevents thermal pollution of water resources. This difference becomes particularly significant in water-stressed regions where industrial water usage faces increasing scrutiny.

Life cycle assessment (LCA) studies indicate that despite higher initial equipment costs, laser welding demonstrates lower lifetime environmental impacts when considering operational efficiency over extended periods. The reduced need for post-weld cleaning and finishing processes further diminishes the environmental footprint by eliminating chemical cleaners and additional energy expenditure.

Carbon footprint calculations reveal that laser welding can reduce greenhouse gas emissions by 30-45% compared to SMAW when normalized for equivalent weld quality and length. This reduction stems primarily from improved energy efficiency, reduced process time, and diminished need for secondary operations. As industries face increasing pressure to reduce carbon emissions, this differential becomes increasingly significant in technology selection decisions.

Waste management considerations also favor laser welding, as it produces minimal slag and spatter compared to SMAW. This reduction in solid waste decreases landfill contributions and simplifies workplace cleaning procedures, further reducing environmental impact through decreased use of cleaning agents and disposal requirements.

Cost-Benefit Analysis of Energy Investment in Welding

When evaluating the economic viability of welding technologies, particularly comparing Laser Welding and Shielded Metal Arc Welding (SMAW), energy investment represents a critical factor in the overall cost structure. Initial capital expenditure for laser welding systems typically ranges from $150,000 to $500,000, significantly higher than SMAW equipment costs of $2,000 to $5,000. However, this substantial difference in upfront investment must be analyzed against long-term operational economics.

Energy consumption patterns reveal striking differences between these technologies. Laser welding operates at higher energy efficiency, typically converting 20-30% of input energy into useful welding energy, compared to SMAW's 10-15% efficiency. For industrial applications, this translates to approximately 15-40 kWh per meter of weld for laser systems versus 30-60 kWh for SMAW, representing potential energy savings of 30-50% in direct production costs.

Return on investment calculations indicate that laser welding systems typically achieve breakeven within 2-4 years in high-volume production environments. This calculation factors in not only direct energy costs but also associated expenses such as reduced material waste (5-10% for laser versus 15-25% for SMAW) and decreased post-weld processing requirements.

Sensitivity analysis demonstrates that energy cost fluctuations impact SMAW operations more severely. A 10% increase in energy costs typically results in a 4-6% increase in total SMAW operational expenses, while the same increase affects laser welding total costs by only 2-3%, creating greater cost stability for laser-based operations.

Life-cycle cost assessment reveals that while laser systems require higher maintenance expenditure (approximately $10,000-$25,000 annually), their extended operational lifespan of 15-20 years compared to 5-8 years for SMAW equipment offsets this disadvantage. Additionally, laser systems demonstrate superior energy performance under continuous operation, maintaining consistent efficiency levels even after 8+ hours of operation, whereas SMAW efficiency typically decreases by 5-10% during extended use periods.

Environmental cost considerations further favor laser technology, with carbon emissions approximately 30-40% lower than equivalent SMAW operations. As carbon pricing mechanisms become more prevalent globally, this represents an increasingly significant economic advantage, potentially adding $5-15 per ton of production to SMAW costs in regulated markets.

Energy consumption patterns reveal striking differences between these technologies. Laser welding operates at higher energy efficiency, typically converting 20-30% of input energy into useful welding energy, compared to SMAW's 10-15% efficiency. For industrial applications, this translates to approximately 15-40 kWh per meter of weld for laser systems versus 30-60 kWh for SMAW, representing potential energy savings of 30-50% in direct production costs.

Return on investment calculations indicate that laser welding systems typically achieve breakeven within 2-4 years in high-volume production environments. This calculation factors in not only direct energy costs but also associated expenses such as reduced material waste (5-10% for laser versus 15-25% for SMAW) and decreased post-weld processing requirements.

Sensitivity analysis demonstrates that energy cost fluctuations impact SMAW operations more severely. A 10% increase in energy costs typically results in a 4-6% increase in total SMAW operational expenses, while the same increase affects laser welding total costs by only 2-3%, creating greater cost stability for laser-based operations.

Life-cycle cost assessment reveals that while laser systems require higher maintenance expenditure (approximately $10,000-$25,000 annually), their extended operational lifespan of 15-20 years compared to 5-8 years for SMAW equipment offsets this disadvantage. Additionally, laser systems demonstrate superior energy performance under continuous operation, maintaining consistent efficiency levels even after 8+ hours of operation, whereas SMAW efficiency typically decreases by 5-10% during extended use periods.

Environmental cost considerations further favor laser technology, with carbon emissions approximately 30-40% lower than equivalent SMAW operations. As carbon pricing mechanisms become more prevalent globally, this represents an increasingly significant economic advantage, potentially adding $5-15 per ton of production to SMAW costs in regulated markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!