Laser Welding vs Spot Welding: A Productivity Study

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Welding Technologies Evolution and Objectives

Welding technology has evolved significantly over the past century, transforming from rudimentary joining methods to sophisticated automated processes. The journey began with manual metal arc welding in the early 1900s, progressing through gas welding techniques, and eventually leading to the development of resistance spot welding in the automotive industry during the 1950s. This evolution marked a significant advancement in manufacturing efficiency, particularly for mass production environments.

The 1970s witnessed the emergence of laser welding technology, initially limited to specialized applications due to high equipment costs and technical complexity. As laser technology matured through the 1980s and 1990s, its precision, speed, and versatility began to challenge traditional welding methods across various industries. The parallel development of computer control systems further enhanced both spot and laser welding capabilities, enabling unprecedented levels of automation and quality control.

Recent decades have seen a convergence of welding technologies with Industry 4.0 principles, incorporating sensors, real-time monitoring, and data analytics to optimize welding processes. This integration has transformed welding from a purely mechanical operation to an information-rich manufacturing process capable of self-adjustment and quality verification. The automotive and aerospace sectors have been particularly influential in driving these technological advancements, demanding ever-higher standards of weld quality, consistency, and production efficiency.

The primary objective of modern welding technology development is to maximize productivity while maintaining or improving joint quality. This balance represents the central challenge in the comparison between laser and spot welding technologies. Productivity in this context encompasses not only cycle time and throughput but also considerations of energy efficiency, material utilization, and long-term reliability of the welded joints.

Additional objectives include reducing the environmental impact of welding processes, minimizing post-weld operations, and enhancing flexibility to accommodate diverse materials and joint configurations. As manufacturers face increasing pressure to reduce production costs while meeting stringent quality standards, the selection between laser and spot welding technologies has become a critical strategic decision with significant implications for competitive advantage.

The evolution trajectory suggests a continued trend toward hybrid welding solutions that combine the advantages of multiple technologies, alongside growing integration with digital manufacturing ecosystems. Understanding this evolutionary context is essential for evaluating the relative merits of laser and spot welding in contemporary manufacturing environments and anticipating future developments in joining technology.

The 1970s witnessed the emergence of laser welding technology, initially limited to specialized applications due to high equipment costs and technical complexity. As laser technology matured through the 1980s and 1990s, its precision, speed, and versatility began to challenge traditional welding methods across various industries. The parallel development of computer control systems further enhanced both spot and laser welding capabilities, enabling unprecedented levels of automation and quality control.

Recent decades have seen a convergence of welding technologies with Industry 4.0 principles, incorporating sensors, real-time monitoring, and data analytics to optimize welding processes. This integration has transformed welding from a purely mechanical operation to an information-rich manufacturing process capable of self-adjustment and quality verification. The automotive and aerospace sectors have been particularly influential in driving these technological advancements, demanding ever-higher standards of weld quality, consistency, and production efficiency.

The primary objective of modern welding technology development is to maximize productivity while maintaining or improving joint quality. This balance represents the central challenge in the comparison between laser and spot welding technologies. Productivity in this context encompasses not only cycle time and throughput but also considerations of energy efficiency, material utilization, and long-term reliability of the welded joints.

Additional objectives include reducing the environmental impact of welding processes, minimizing post-weld operations, and enhancing flexibility to accommodate diverse materials and joint configurations. As manufacturers face increasing pressure to reduce production costs while meeting stringent quality standards, the selection between laser and spot welding technologies has become a critical strategic decision with significant implications for competitive advantage.

The evolution trajectory suggests a continued trend toward hybrid welding solutions that combine the advantages of multiple technologies, alongside growing integration with digital manufacturing ecosystems. Understanding this evolutionary context is essential for evaluating the relative merits of laser and spot welding in contemporary manufacturing environments and anticipating future developments in joining technology.

Market Demand Analysis for Advanced Welding Solutions

The global welding industry is experiencing a significant shift towards advanced welding technologies, driven by increasing demands for higher productivity, precision, and quality in manufacturing processes. Market research indicates that the advanced welding solutions market, which includes both laser and resistance spot welding technologies, is projected to grow at a compound annual growth rate of 5.7% through 2028, reaching a market value of 49.5 billion USD globally.

Manufacturing sectors such as automotive, aerospace, electronics, and medical devices are the primary drivers of this market expansion. The automotive industry, in particular, represents approximately 35% of the total demand for advanced welding solutions, as manufacturers seek to incorporate lightweight materials and complex designs while maintaining structural integrity and production efficiency.

Customer requirements have evolved significantly over the past decade, with manufacturers prioritizing welding solutions that offer reduced cycle times, minimal post-weld processing, and compatibility with automation systems. A recent industry survey revealed that 78% of manufacturing executives consider productivity improvements as the most critical factor when evaluating new welding technologies, followed by quality consistency (65%) and operational cost reduction (59%).

The market demand for laser welding has shown remarkable growth, particularly in high-precision applications. This growth is attributed to laser welding's ability to join dissimilar materials, create narrow and deep welds, and operate at significantly higher speeds compared to conventional methods. Industries requiring high aesthetic standards in final products show particular interest in laser welding due to its minimal distortion and clean finish characteristics.

Spot welding continues to maintain strong market presence due to its established infrastructure, lower initial investment costs, and proven reliability in certain applications. However, market analysis shows a gradual shift towards hybrid systems that combine the advantages of both technologies, especially in automotive body assembly lines where different joining requirements exist within the same production environment.

Regional market analysis reveals varying adoption rates of advanced welding technologies. While North America and Europe lead in laser welding implementation, emerging economies in Asia-Pacific are rapidly increasing their investment in these technologies as manufacturing capabilities advance. China, in particular, has doubled its consumption of industrial laser systems for welding applications over the past five years.

Customer feedback indicates growing interest in welding solutions that offer enhanced process monitoring capabilities, integration with Industry 4.0 platforms, and reduced environmental impact. Manufacturers are increasingly willing to invest in premium welding technologies that demonstrate clear productivity advantages and return on investment through reduced labor costs, improved quality, and decreased material waste.

Manufacturing sectors such as automotive, aerospace, electronics, and medical devices are the primary drivers of this market expansion. The automotive industry, in particular, represents approximately 35% of the total demand for advanced welding solutions, as manufacturers seek to incorporate lightweight materials and complex designs while maintaining structural integrity and production efficiency.

Customer requirements have evolved significantly over the past decade, with manufacturers prioritizing welding solutions that offer reduced cycle times, minimal post-weld processing, and compatibility with automation systems. A recent industry survey revealed that 78% of manufacturing executives consider productivity improvements as the most critical factor when evaluating new welding technologies, followed by quality consistency (65%) and operational cost reduction (59%).

The market demand for laser welding has shown remarkable growth, particularly in high-precision applications. This growth is attributed to laser welding's ability to join dissimilar materials, create narrow and deep welds, and operate at significantly higher speeds compared to conventional methods. Industries requiring high aesthetic standards in final products show particular interest in laser welding due to its minimal distortion and clean finish characteristics.

Spot welding continues to maintain strong market presence due to its established infrastructure, lower initial investment costs, and proven reliability in certain applications. However, market analysis shows a gradual shift towards hybrid systems that combine the advantages of both technologies, especially in automotive body assembly lines where different joining requirements exist within the same production environment.

Regional market analysis reveals varying adoption rates of advanced welding technologies. While North America and Europe lead in laser welding implementation, emerging economies in Asia-Pacific are rapidly increasing their investment in these technologies as manufacturing capabilities advance. China, in particular, has doubled its consumption of industrial laser systems for welding applications over the past five years.

Customer feedback indicates growing interest in welding solutions that offer enhanced process monitoring capabilities, integration with Industry 4.0 platforms, and reduced environmental impact. Manufacturers are increasingly willing to invest in premium welding technologies that demonstrate clear productivity advantages and return on investment through reduced labor costs, improved quality, and decreased material waste.

Current State and Challenges in Industrial Welding

The welding industry is currently experiencing a significant technological transition, with traditional spot welding techniques being increasingly challenged by advanced laser welding technologies. Globally, industrial welding practices vary considerably across regions, with developed economies like Germany, Japan, and the United States leading in automation and adoption of laser-based solutions, while emerging markets still heavily rely on conventional spot welding methods.

Spot welding remains the dominant joining technology in many manufacturing sectors, particularly automotive, due to its established infrastructure, lower initial investment costs, and workforce familiarity. However, this mature technology faces inherent limitations in terms of heat-affected zone management, material compatibility, and precision control, especially when working with advanced high-strength steels and lightweight materials increasingly used in modern manufacturing.

Laser welding technologies have made remarkable progress in recent years, with fiber lasers, diode lasers, and hybrid systems showing particular promise. These systems offer superior precision, reduced heat input, and the ability to join dissimilar materials - critical advantages for industries pursuing lightweighting strategies. Despite these benefits, widespread adoption faces significant barriers including higher capital expenditure, specialized maintenance requirements, and the need for more sophisticated process controls.

A major technical challenge in the current welding landscape is the integration of advanced joining technologies into existing production lines without disrupting manufacturing flow or requiring complete facility redesign. This challenge is compounded by the shortage of skilled technicians who understand both traditional welding principles and the programming requirements of automated laser systems.

Quality assurance represents another significant hurdle, with real-time monitoring and defect detection systems still evolving for laser welding applications. While spot welding quality can be verified through relatively straightforward destructive and non-destructive testing methods, laser weld inspection often requires more sophisticated approaches including ultrasonic testing, thermography, and machine vision systems.

Energy efficiency considerations are increasingly influencing welding technology selection, with laser systems generally offering lower energy consumption per joint but requiring significant power during operation. This creates a complex cost-benefit analysis that varies based on production volume, duty cycle, and regional energy costs.

Material science developments are simultaneously enabling and constraining welding technology evolution, as new alloys and composites demand joining solutions that minimize thermal damage while maintaining structural integrity. This has accelerated research into controlled heat input methodologies and hybrid joining techniques that combine mechanical fastening with welding processes.

Spot welding remains the dominant joining technology in many manufacturing sectors, particularly automotive, due to its established infrastructure, lower initial investment costs, and workforce familiarity. However, this mature technology faces inherent limitations in terms of heat-affected zone management, material compatibility, and precision control, especially when working with advanced high-strength steels and lightweight materials increasingly used in modern manufacturing.

Laser welding technologies have made remarkable progress in recent years, with fiber lasers, diode lasers, and hybrid systems showing particular promise. These systems offer superior precision, reduced heat input, and the ability to join dissimilar materials - critical advantages for industries pursuing lightweighting strategies. Despite these benefits, widespread adoption faces significant barriers including higher capital expenditure, specialized maintenance requirements, and the need for more sophisticated process controls.

A major technical challenge in the current welding landscape is the integration of advanced joining technologies into existing production lines without disrupting manufacturing flow or requiring complete facility redesign. This challenge is compounded by the shortage of skilled technicians who understand both traditional welding principles and the programming requirements of automated laser systems.

Quality assurance represents another significant hurdle, with real-time monitoring and defect detection systems still evolving for laser welding applications. While spot welding quality can be verified through relatively straightforward destructive and non-destructive testing methods, laser weld inspection often requires more sophisticated approaches including ultrasonic testing, thermography, and machine vision systems.

Energy efficiency considerations are increasingly influencing welding technology selection, with laser systems generally offering lower energy consumption per joint but requiring significant power during operation. This creates a complex cost-benefit analysis that varies based on production volume, duty cycle, and regional energy costs.

Material science developments are simultaneously enabling and constraining welding technology evolution, as new alloys and composites demand joining solutions that minimize thermal damage while maintaining structural integrity. This has accelerated research into controlled heat input methodologies and hybrid joining techniques that combine mechanical fastening with welding processes.

Comparative Analysis of Laser and Spot Welding Techniques

01 Laser welding process optimization for productivity

Laser welding productivity can be enhanced through process optimization techniques. These include optimizing laser power settings, controlling beam focus and spot size, and implementing advanced beam delivery systems. Proper parameter selection helps achieve faster welding speeds while maintaining quality. Automated parameter adjustment based on material thickness and type further improves efficiency and reduces cycle time in production environments.- Laser welding process optimization for productivity: Laser welding productivity can be enhanced through process optimization techniques. These include optimizing laser parameters such as power, speed, and focus position to achieve faster welding speeds while maintaining quality. Advanced beam shaping and control systems allow for precise energy distribution, reducing cycle times. Process monitoring and adaptive control systems can adjust parameters in real-time to maintain optimal welding conditions, minimizing defects and rework.

- Spot welding automation and robotics: Automation and robotics significantly improve spot welding productivity by enabling consistent, high-speed operation. Robotic welding systems can precisely position welding electrodes, maintain consistent pressure, and execute multiple welds in rapid succession. Advanced control systems optimize movement paths to minimize non-productive time between welds. Integration with material handling systems allows for continuous operation with minimal human intervention, reducing labor costs and increasing throughput.

- Multi-beam and hybrid welding technologies: Multi-beam laser configurations and hybrid welding technologies combine different welding methods to increase productivity. Systems that utilize multiple laser beams can process multiple parts simultaneously or create wider weld seams in a single pass. Hybrid laser-arc welding combines the deep penetration of laser welding with the gap-bridging capability of arc welding, allowing for higher speeds and better tolerance to fit-up issues. These approaches significantly reduce processing time while maintaining or improving weld quality.

- Advanced electrode designs for spot welding: Innovative electrode designs enhance spot welding productivity by improving heat distribution, extending electrode life, and enabling faster cycle times. Electrodes with specialized cooling systems maintain optimal temperature during high-volume production. Composite and coated electrodes resist wear and contamination, reducing the frequency of electrode maintenance and replacement. Shaped electrode tips optimize current density and pressure distribution, allowing for faster weld formation and shorter hold times.

- Real-time monitoring and quality control systems: Real-time monitoring and quality control systems improve welding productivity by reducing defects and minimizing post-weld inspection requirements. Sensors integrated into welding equipment collect data on critical parameters such as temperature, current, and material deformation. Advanced algorithms analyze this data to detect anomalies and predict potential defects before they occur. Automated inspection systems using vision technology, ultrasonic testing, or thermal imaging can verify weld quality immediately after welding, allowing for immediate corrective action and reducing rework.

02 Spot welding efficiency improvements

Productivity in spot welding can be increased through various technological improvements. These include optimized electrode designs that improve current distribution, advanced cooling systems that reduce electrode wear, and precise control of welding parameters such as current, pressure, and dwell time. Automated electrode maintenance and replacement systems minimize downtime, while real-time quality monitoring ensures consistent weld quality at higher production rates.Expand Specific Solutions03 Automation and robotics in welding systems

Integration of automation and robotics significantly enhances welding productivity. Robotic welding systems enable precise positioning and consistent movement speeds, resulting in uniform welds. Multi-axis robots can access complex geometries and perform welding operations in optimal orientations. Automated part handling, fixture systems, and tool changers reduce non-productive time. Advanced programming interfaces and offline simulation tools minimize setup time and maximize production throughput.Expand Specific Solutions04 Hybrid and multi-process welding technologies

Hybrid welding technologies that combine laser welding with other processes offer significant productivity advantages. Laser-arc hybrid welding combines the deep penetration of laser welding with the gap-bridging capability of arc welding. Multi-spot laser welding distributes energy more efficiently across the workpiece. Sequential spot welding strategies optimize energy usage and reduce cycle times. These hybrid approaches allow for faster welding speeds, better quality, and improved energy efficiency.Expand Specific Solutions05 Real-time monitoring and quality control systems

Advanced monitoring and quality control systems improve welding productivity by reducing defects and rework. Real-time sensors track critical parameters such as temperature, penetration depth, and weld pool dynamics. Machine learning algorithms analyze this data to detect anomalies and predict potential defects. Closed-loop control systems automatically adjust welding parameters to maintain optimal conditions. These technologies enable higher production speeds while ensuring consistent quality and reducing post-weld inspection requirements.Expand Specific Solutions

Key Industry Players and Manufacturers Analysis

The laser welding versus spot welding productivity landscape is currently in a growth phase, with the global market expanding as manufacturers seek more efficient joining technologies. The market is projected to reach significant scale as automotive and electronics industries increasingly adopt laser welding for its precision and speed advantages. Technologically, the field shows varying maturity levels among key players. Industry leaders like IPG Photonics and FANUC have established advanced laser welding capabilities, while automotive manufacturers including Toyota, Volkswagen, and Renault are integrating these technologies into production lines. Companies like Sciaky and Corelase represent specialized innovation in specific welding applications, while academic institutions such as Huazhong University contribute to fundamental research advancing both technologies.

IPG Photonics Corp.

Technical Solution: IPG Photonics has developed advanced fiber laser welding systems that deliver high-power, high-brightness laser beams for precision welding applications. Their technology utilizes single-mode and multi-mode fiber lasers with power ranges from 1kW to 100kW, enabling deep penetration welding with minimal heat-affected zones. IPG's YLS series fiber lasers achieve welding speeds up to 10 times faster than conventional spot welding, with documented production line improvements of 30-40% in automotive applications. Their proprietary beam delivery systems incorporate real-time monitoring and closed-loop control, ensuring consistent weld quality across variable material thicknesses. IPG's systems also feature programmable beam shaping technology that can be optimized for different materials, reducing spatter by up to 90% compared to conventional laser welding approaches. Recent advancements include multi-focal point technology that addresses traditional challenges with reflective materials like aluminum and copper.

Strengths: Superior beam quality and power efficiency (>30% wall-plug efficiency) compared to other laser technologies; highly flexible beam delivery through fiber optics; minimal maintenance requirements with >100,000 hours diode lifetime. Weaknesses: Higher initial capital investment compared to resistance spot welding; requires more precise part fit-up and positioning; more complex integration with existing manufacturing systems.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a hybrid welding approach that strategically combines laser welding and spot welding technologies in their vehicle manufacturing processes. Their Toyota New Global Architecture (TNGA) platform utilizes laser screw welding technology that increases body rigidity by 30-65% compared to conventional spot welding alone. Toyota's process incorporates over 120 meters of laser welding per vehicle body, focusing on structural joints that benefit most from the continuous weld characteristics. Their manufacturing system employs in-line laser welding stations with adaptive control systems that automatically adjust parameters based on material thickness and composition. Toyota has documented a 10% reduction in overall body weight while improving crash performance through strategic placement of laser welds in high-stress areas. Their production data shows cycle time improvements of approximately 25% and energy consumption reduction of 30% compared to traditional all-spot-welded body assembly lines. Toyota's approach maintains compatibility with existing assembly processes by combining both technologies rather than complete replacement.

Strengths: Optimized balance between weld strength, production speed, and capital investment; improved structural performance without complete process redesign; reduced energy consumption compared to conventional methods. Weaknesses: More complex production planning required to determine optimal weld type placement; requires maintenance of two different welding technologies; higher initial investment than pure spot welding approaches.

Technical Innovations in Modern Welding Processes

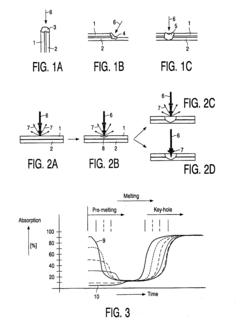

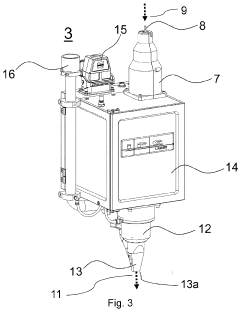

Method and a device for laser spot welding

PatentInactiveUS20060249487A1

Innovation

- Implementing a monitoring system that uses infrared sensors to detect the surface temperature of the weld spot during and after the welding process, allowing for feedback control of the laser beam power based on temperature measurements to ensure a consistent and high-quality weld.

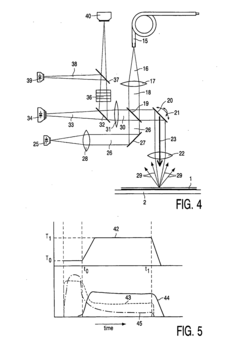

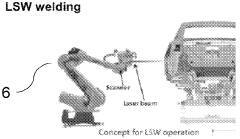

Laser welding system and laser welding method

PatentWO2023203516A1

Innovation

- A laser welding system and method, known as the laser seam pointer (LSP), which enables fast, contact welding of metal sheets without surface damage, using a compact design with a mechanical shaft for pressure application and advanced beam guidance, allowing for reduced movement cycles and improved accessibility.

Cost-Benefit Analysis of Welding Methods

The economic comparison between laser welding and spot welding reveals significant differences in initial investment, operational costs, and long-term financial benefits. Laser welding systems typically require a substantially higher initial capital expenditure, with equipment costs ranging from $150,000 to $500,000 depending on power requirements and automation levels. In contrast, spot welding equipment generally costs between $30,000 and $100,000, representing a considerably lower barrier to entry for manufacturers.

Operational expenses also differ markedly between these technologies. Laser welding demonstrates superior energy efficiency, consuming approximately 30-40% less electricity than comparable spot welding operations. Additionally, laser welding's precision reduces material waste by 15-25% and minimizes the need for post-weld finishing, resulting in material cost savings of up to 20% for high-volume production environments.

Maintenance requirements present another significant cost differential. Spot welding electrodes require frequent replacement, typically after 5,000-8,000 welds, with associated labor costs and production downtime. Laser systems, while having higher-cost components, offer extended maintenance intervals, with major service requirements typically occurring only every 8,000-10,000 operating hours.

Production throughput analysis indicates that laser welding can achieve processing speeds up to five times faster than spot welding for certain applications, particularly in thin-gauge materials. This speed advantage translates to higher production capacity and reduced labor costs per unit. Furthermore, laser welding's flexibility allows for rapid changeover between different product specifications, reducing setup times by an average of 65% compared to reconfiguring spot welding equipment.

Return on investment calculations demonstrate that despite higher initial costs, laser welding systems typically achieve break-even points within 18-24 months for high-volume manufacturing operations. This ROI timeline shortens considerably in applications requiring complex joint geometries or when working with advanced materials where laser welding's precision significantly reduces rework and scrap rates.

Quality-related costs also favor laser welding in many applications. The reduced heat-affected zone and minimal distortion result in rejection rates approximately 40-60% lower than spot welding for precision components. This quality advantage becomes particularly significant in industries with stringent quality requirements, where rework and warranty costs can substantially impact overall production economics.

Operational expenses also differ markedly between these technologies. Laser welding demonstrates superior energy efficiency, consuming approximately 30-40% less electricity than comparable spot welding operations. Additionally, laser welding's precision reduces material waste by 15-25% and minimizes the need for post-weld finishing, resulting in material cost savings of up to 20% for high-volume production environments.

Maintenance requirements present another significant cost differential. Spot welding electrodes require frequent replacement, typically after 5,000-8,000 welds, with associated labor costs and production downtime. Laser systems, while having higher-cost components, offer extended maintenance intervals, with major service requirements typically occurring only every 8,000-10,000 operating hours.

Production throughput analysis indicates that laser welding can achieve processing speeds up to five times faster than spot welding for certain applications, particularly in thin-gauge materials. This speed advantage translates to higher production capacity and reduced labor costs per unit. Furthermore, laser welding's flexibility allows for rapid changeover between different product specifications, reducing setup times by an average of 65% compared to reconfiguring spot welding equipment.

Return on investment calculations demonstrate that despite higher initial costs, laser welding systems typically achieve break-even points within 18-24 months for high-volume manufacturing operations. This ROI timeline shortens considerably in applications requiring complex joint geometries or when working with advanced materials where laser welding's precision significantly reduces rework and scrap rates.

Quality-related costs also favor laser welding in many applications. The reduced heat-affected zone and minimal distortion result in rejection rates approximately 40-60% lower than spot welding for precision components. This quality advantage becomes particularly significant in industries with stringent quality requirements, where rework and warranty costs can substantially impact overall production economics.

Environmental Impact and Sustainability Considerations

The environmental impact of welding processes has become increasingly important as industries strive for more sustainable manufacturing practices. Laser welding demonstrates significant environmental advantages over traditional spot welding techniques. Energy consumption analysis reveals that laser welding systems typically consume 30-40% less electricity per weld joint compared to resistance spot welding, primarily due to their higher energy efficiency and reduced heat-affected zone.

Emissions profiles of both processes show marked differences. Spot welding generates considerable electromagnetic fields and produces more airborne particulates, including metal fumes containing zinc, copper, and other potentially hazardous materials. Laser welding, by contrast, produces fewer airborne contaminants and can be more easily contained with localized extraction systems, reducing workplace exposure and environmental release.

Material conservation represents another sustainability advantage for laser welding. The precision of laser systems allows for narrower weld seams and reduced overlap requirements, resulting in material savings of up to 15% in certain applications. Additionally, laser welding enables the joining of thinner materials without distortion, supporting lightweight design strategies that contribute to downstream energy savings in transportation applications.

Waste generation metrics favor laser welding processes. The reduced need for consumables such as electrode tips (which require regular replacement in spot welding) translates to less solid waste. Studies from automotive manufacturing facilities indicate that transitioning from spot to laser welding can reduce welding-related waste by approximately 25-30% over equipment lifecycle.

Life cycle assessment (LCA) comparisons between the two technologies reveal that while laser welding equipment typically has a higher initial carbon footprint during manufacturing, this is offset by operational efficiencies within 3-5 years of regular industrial use. The longer service life of laser welding equipment (typically 15-20 years versus 10-12 years for spot welding systems) further enhances its sustainability profile.

Water usage presents another environmental consideration. Spot welding requires significant cooling water circulation, with industrial systems consuming 5-10 gallons per minute during operation. Advanced laser welding systems have reduced cooling requirements, with some fiber laser configurations using closed-loop cooling systems that minimize water consumption by up to 80% compared to conventional resistance welding.

Regulatory compliance is increasingly favoring laser technology as environmental standards become more stringent. Laser welding more readily meets emerging carbon reduction targets and workplace exposure limits for metallic fumes, positioning it as the more future-proof technology from a regulatory perspective.

Emissions profiles of both processes show marked differences. Spot welding generates considerable electromagnetic fields and produces more airborne particulates, including metal fumes containing zinc, copper, and other potentially hazardous materials. Laser welding, by contrast, produces fewer airborne contaminants and can be more easily contained with localized extraction systems, reducing workplace exposure and environmental release.

Material conservation represents another sustainability advantage for laser welding. The precision of laser systems allows for narrower weld seams and reduced overlap requirements, resulting in material savings of up to 15% in certain applications. Additionally, laser welding enables the joining of thinner materials without distortion, supporting lightweight design strategies that contribute to downstream energy savings in transportation applications.

Waste generation metrics favor laser welding processes. The reduced need for consumables such as electrode tips (which require regular replacement in spot welding) translates to less solid waste. Studies from automotive manufacturing facilities indicate that transitioning from spot to laser welding can reduce welding-related waste by approximately 25-30% over equipment lifecycle.

Life cycle assessment (LCA) comparisons between the two technologies reveal that while laser welding equipment typically has a higher initial carbon footprint during manufacturing, this is offset by operational efficiencies within 3-5 years of regular industrial use. The longer service life of laser welding equipment (typically 15-20 years versus 10-12 years for spot welding systems) further enhances its sustainability profile.

Water usage presents another environmental consideration. Spot welding requires significant cooling water circulation, with industrial systems consuming 5-10 gallons per minute during operation. Advanced laser welding systems have reduced cooling requirements, with some fiber laser configurations using closed-loop cooling systems that minimize water consumption by up to 80% compared to conventional resistance welding.

Regulatory compliance is increasingly favoring laser technology as environmental standards become more stringent. Laser welding more readily meets emerging carbon reduction targets and workplace exposure limits for metallic fumes, positioning it as the more future-proof technology from a regulatory perspective.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!