Laser Welding vs Traditional Welding: Minimum Displacement Study

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Welding Technology Background and Objectives

Welding technology has evolved significantly over the past century, transitioning from traditional methods like gas and arc welding to advanced techniques such as laser welding. The development of laser technology began in the 1960s, with the first industrial laser welding applications emerging in the 1970s. Since then, laser welding has experienced continuous refinement, particularly with the introduction of high-power CO2 lasers, Nd:YAG lasers, fiber lasers, and most recently, direct diode lasers.

The evolution of laser welding technology has been driven by increasing demands for precision, efficiency, and quality in manufacturing processes across various industries. Traditional welding methods, while effective for many applications, introduce significant heat into workpieces, resulting in thermal distortion, residual stresses, and potential material property alterations. These limitations become particularly problematic in industries requiring high precision and minimal displacement, such as aerospace, electronics, medical device manufacturing, and automotive components.

Laser welding represents a paradigm shift in joining technology by offering a highly concentrated heat source that can be precisely controlled in terms of power density, spot size, and application duration. This concentrated energy delivery mechanism fundamentally changes the heat transfer dynamics during the welding process, potentially resulting in significantly reduced thermal distortion and workpiece displacement compared to traditional methods.

The primary technical objective of comparing laser welding with traditional welding in terms of minimum displacement is to quantify the advantages of laser-based processes in applications where dimensional stability is critical. This investigation aims to establish comprehensive performance metrics that can guide manufacturing decisions across different material types, thicknesses, and geometric configurations.

Current technological trends in this field include the development of hybrid laser welding systems, which combine laser technology with traditional methods to leverage the advantages of both approaches. Additionally, there is growing interest in real-time monitoring and adaptive control systems that can dynamically adjust welding parameters to minimize displacement during the process.

The advancement of simulation technologies has also enabled more accurate prediction of thermal effects and resulting displacements, allowing for optimization of welding parameters before physical implementation. This predictive capability is becoming increasingly important as manufacturers seek to reduce prototyping costs and accelerate product development cycles.

As industries continue to push the boundaries of material performance and design complexity, understanding the comparative advantages of laser welding in minimizing displacement becomes increasingly critical for maintaining competitive manufacturing capabilities and meeting ever-more-stringent quality requirements.

The evolution of laser welding technology has been driven by increasing demands for precision, efficiency, and quality in manufacturing processes across various industries. Traditional welding methods, while effective for many applications, introduce significant heat into workpieces, resulting in thermal distortion, residual stresses, and potential material property alterations. These limitations become particularly problematic in industries requiring high precision and minimal displacement, such as aerospace, electronics, medical device manufacturing, and automotive components.

Laser welding represents a paradigm shift in joining technology by offering a highly concentrated heat source that can be precisely controlled in terms of power density, spot size, and application duration. This concentrated energy delivery mechanism fundamentally changes the heat transfer dynamics during the welding process, potentially resulting in significantly reduced thermal distortion and workpiece displacement compared to traditional methods.

The primary technical objective of comparing laser welding with traditional welding in terms of minimum displacement is to quantify the advantages of laser-based processes in applications where dimensional stability is critical. This investigation aims to establish comprehensive performance metrics that can guide manufacturing decisions across different material types, thicknesses, and geometric configurations.

Current technological trends in this field include the development of hybrid laser welding systems, which combine laser technology with traditional methods to leverage the advantages of both approaches. Additionally, there is growing interest in real-time monitoring and adaptive control systems that can dynamically adjust welding parameters to minimize displacement during the process.

The advancement of simulation technologies has also enabled more accurate prediction of thermal effects and resulting displacements, allowing for optimization of welding parameters before physical implementation. This predictive capability is becoming increasingly important as manufacturers seek to reduce prototyping costs and accelerate product development cycles.

As industries continue to push the boundaries of material performance and design complexity, understanding the comparative advantages of laser welding in minimizing displacement becomes increasingly critical for maintaining competitive manufacturing capabilities and meeting ever-more-stringent quality requirements.

Market Demand Analysis for Precision Welding Solutions

The precision welding market is experiencing significant growth driven by increasing demand for high-accuracy joining solutions across multiple industries. The global precision welding market was valued at approximately $2.3 billion in 2022 and is projected to reach $3.7 billion by 2028, growing at a CAGR of 8.2%. This growth is primarily fueled by the automotive, aerospace, electronics, and medical device manufacturing sectors, where minimal displacement during welding processes is critical for maintaining structural integrity and functionality.

In the automotive industry, the transition toward lightweight materials and electric vehicles has intensified the need for precision welding solutions that can join dissimilar materials with minimal thermal distortion. Manufacturers are seeking welding technologies that can maintain dimensional accuracy while joining advanced high-strength steels, aluminum alloys, and composite materials. The electric vehicle segment alone has seen a 43% increase in demand for precision welding solutions over the past three years.

The aerospace sector represents another significant market for precision welding technologies, with stringent requirements for structural components where even microscopic displacements can compromise safety and performance. Industry reports indicate that aerospace manufacturers are willing to invest 15-20% more in welding technologies that can demonstrate superior displacement control compared to conventional methods.

The electronics manufacturing industry is driving demand for micro-welding solutions capable of joining increasingly miniaturized components with near-zero displacement. As consumer electronics continue to shrink in size while increasing in functionality, the tolerance for welding-induced displacement has decreased to the micrometer range. This trend has created a specialized market segment estimated at $450 million annually.

Medical device manufacturing represents the fastest-growing segment for precision welding solutions, with a CAGR of 11.3%. The production of implantable devices, surgical instruments, and diagnostic equipment requires joining technologies that maintain precise dimensions while ensuring biocompatibility and sterility.

Regional analysis shows that Asia-Pacific dominates the market with a 42% share, followed by North America (28%) and Europe (23%). China and South Korea are experiencing the fastest growth rates due to rapid industrialization and increasing adoption of advanced manufacturing technologies.

Customer surveys reveal that key purchasing factors for precision welding solutions include displacement control (cited by 87% of respondents), process repeatability (82%), automation compatibility (76%), and total cost of ownership (71%). The market is increasingly demanding integrated solutions that combine advanced welding technologies with real-time monitoring and quality control systems to ensure consistent results with minimal displacement.

In the automotive industry, the transition toward lightweight materials and electric vehicles has intensified the need for precision welding solutions that can join dissimilar materials with minimal thermal distortion. Manufacturers are seeking welding technologies that can maintain dimensional accuracy while joining advanced high-strength steels, aluminum alloys, and composite materials. The electric vehicle segment alone has seen a 43% increase in demand for precision welding solutions over the past three years.

The aerospace sector represents another significant market for precision welding technologies, with stringent requirements for structural components where even microscopic displacements can compromise safety and performance. Industry reports indicate that aerospace manufacturers are willing to invest 15-20% more in welding technologies that can demonstrate superior displacement control compared to conventional methods.

The electronics manufacturing industry is driving demand for micro-welding solutions capable of joining increasingly miniaturized components with near-zero displacement. As consumer electronics continue to shrink in size while increasing in functionality, the tolerance for welding-induced displacement has decreased to the micrometer range. This trend has created a specialized market segment estimated at $450 million annually.

Medical device manufacturing represents the fastest-growing segment for precision welding solutions, with a CAGR of 11.3%. The production of implantable devices, surgical instruments, and diagnostic equipment requires joining technologies that maintain precise dimensions while ensuring biocompatibility and sterility.

Regional analysis shows that Asia-Pacific dominates the market with a 42% share, followed by North America (28%) and Europe (23%). China and South Korea are experiencing the fastest growth rates due to rapid industrialization and increasing adoption of advanced manufacturing technologies.

Customer surveys reveal that key purchasing factors for precision welding solutions include displacement control (cited by 87% of respondents), process repeatability (82%), automation compatibility (76%), and total cost of ownership (71%). The market is increasingly demanding integrated solutions that combine advanced welding technologies with real-time monitoring and quality control systems to ensure consistent results with minimal displacement.

Current State and Challenges in Welding Displacement Control

The global welding industry is currently experiencing a significant shift towards precision manufacturing, with displacement control emerging as a critical factor in ensuring structural integrity and product quality. Traditional welding methods, including arc welding, resistance welding, and gas welding, have historically dominated the industry but face inherent limitations in controlling thermal distortion and material displacement during the joining process.

Current displacement control in traditional welding relies heavily on pre-weld fixture design, post-weld correction techniques, and operator expertise. These approaches often result in inconsistent outcomes, particularly in high-precision applications. Statistical analysis indicates that traditional welding methods typically produce displacement variations of 0.5-2.0 mm, which exceeds tolerance requirements in aerospace, medical device manufacturing, and microelectronics industries.

Laser welding technology has emerged as a promising alternative, offering significantly improved displacement control capabilities. Recent studies demonstrate that laser welding can reduce material displacement by 60-80% compared to traditional methods, with some advanced systems achieving displacement control within 0.05-0.1 mm range. This precision stems from laser welding's concentrated heat input, reduced heat-affected zone, and faster processing speeds.

Despite these advancements, several technical challenges persist in welding displacement control. Material-specific challenges remain prominent, as different alloys and composites exhibit varying thermal expansion coefficients and phase transformation behaviors during welding. Particularly problematic are high-strength aluminum alloys, titanium-based materials, and advanced high-strength steels used in lightweight structural applications.

Measurement and real-time monitoring systems represent another significant challenge. Current in-process monitoring technologies often lack the resolution and speed required for effective closed-loop control of displacement during welding. Most systems operate at sampling rates insufficient to capture rapid thermal events occurring in millisecond timeframes.

Computational modeling capabilities, while advancing rapidly, still struggle with accurately predicting complex multi-physics interactions during welding processes. Current models typically achieve 70-85% accuracy in displacement prediction, leaving a significant margin for error in high-precision applications.

Geographical distribution of welding displacement control technology shows concentration in industrial hubs across Germany, Japan, the United States, and increasingly China. European research institutions lead in fundamental research, while Asian manufacturers excel in implementation and process optimization. This global disparity creates challenges in technology transfer and standardization efforts.

Regulatory and standardization frameworks have not kept pace with technological advancements, creating barriers to widespread adoption of improved displacement control techniques. Current international standards provide limited guidance on displacement control methodologies specific to advanced welding processes, leaving manufacturers to develop proprietary approaches.

Current displacement control in traditional welding relies heavily on pre-weld fixture design, post-weld correction techniques, and operator expertise. These approaches often result in inconsistent outcomes, particularly in high-precision applications. Statistical analysis indicates that traditional welding methods typically produce displacement variations of 0.5-2.0 mm, which exceeds tolerance requirements in aerospace, medical device manufacturing, and microelectronics industries.

Laser welding technology has emerged as a promising alternative, offering significantly improved displacement control capabilities. Recent studies demonstrate that laser welding can reduce material displacement by 60-80% compared to traditional methods, with some advanced systems achieving displacement control within 0.05-0.1 mm range. This precision stems from laser welding's concentrated heat input, reduced heat-affected zone, and faster processing speeds.

Despite these advancements, several technical challenges persist in welding displacement control. Material-specific challenges remain prominent, as different alloys and composites exhibit varying thermal expansion coefficients and phase transformation behaviors during welding. Particularly problematic are high-strength aluminum alloys, titanium-based materials, and advanced high-strength steels used in lightweight structural applications.

Measurement and real-time monitoring systems represent another significant challenge. Current in-process monitoring technologies often lack the resolution and speed required for effective closed-loop control of displacement during welding. Most systems operate at sampling rates insufficient to capture rapid thermal events occurring in millisecond timeframes.

Computational modeling capabilities, while advancing rapidly, still struggle with accurately predicting complex multi-physics interactions during welding processes. Current models typically achieve 70-85% accuracy in displacement prediction, leaving a significant margin for error in high-precision applications.

Geographical distribution of welding displacement control technology shows concentration in industrial hubs across Germany, Japan, the United States, and increasingly China. European research institutions lead in fundamental research, while Asian manufacturers excel in implementation and process optimization. This global disparity creates challenges in technology transfer and standardization efforts.

Regulatory and standardization frameworks have not kept pace with technological advancements, creating barriers to widespread adoption of improved displacement control techniques. Current international standards provide limited guidance on displacement control methodologies specific to advanced welding processes, leaving manufacturers to develop proprietary approaches.

Current Displacement Minimization Techniques Comparison

01 Laser welding displacement control techniques

Laser welding technologies employ precise displacement control mechanisms to ensure accurate positioning of the laser beam relative to the workpiece. These systems often utilize advanced sensors and feedback controls to monitor and adjust the position in real-time, compensating for any thermal distortion or movement during the welding process. The precision displacement control in laser welding contributes to higher quality welds with minimal defects, particularly important in applications requiring high accuracy such as automotive and aerospace industries.- Laser welding displacement control mechanisms: Laser welding technologies employ precise displacement control mechanisms to ensure accurate positioning of the laser beam relative to the workpiece. These mechanisms include servo motors, piezoelectric actuators, and optical positioning systems that can adjust the laser focus point with micrometer precision. Advanced feedback systems monitor the welding process in real-time, allowing for dynamic adjustments to compensate for thermal expansion or material deformation during welding, resulting in higher quality welds with minimal distortion.

- Comparative displacement characteristics between laser and traditional welding: Laser welding typically produces significantly less workpiece displacement compared to traditional welding methods due to its concentrated heat input and smaller heat-affected zone. Traditional welding techniques such as arc welding often cause greater thermal distortion and residual stress in materials, leading to more substantial displacement issues. The difference in displacement characteristics influences material selection, fixture design, and post-welding processing requirements. Understanding these differences is crucial for selecting the appropriate welding technology based on dimensional accuracy requirements and material properties.

- Displacement measurement and monitoring systems: Advanced displacement measurement systems are essential for both laser and traditional welding processes to ensure quality control. These systems include optical sensors, laser interferometers, and digital image correlation techniques that can detect sub-millimeter displacements during and after welding. Real-time monitoring allows for process adjustments to minimize unwanted displacement, while post-weld measurement helps verify compliance with dimensional specifications. Integration of these measurement systems with automated welding equipment enables closed-loop control for consistent results across production runs.

- Displacement compensation techniques: Various techniques have been developed to compensate for displacement in both laser and traditional welding processes. These include pre-distortion of components, adaptive fixturing systems, and programmed welding sequences designed to balance thermal stresses. For laser welding, beam manipulation strategies such as oscillation patterns and power modulation can distribute heat more evenly to reduce warping. In traditional welding, techniques such as back-stepping and intermittent welding help control displacement by managing heat input. Computer modeling and simulation tools enable prediction of displacement patterns before actual welding begins.

- Hybrid welding technologies for displacement reduction: Hybrid welding technologies combine laser welding with traditional methods to optimize displacement control while maintaining productivity. These approaches leverage the precision and low heat input of laser welding with the gap-bridging capabilities and robustness of traditional processes. Examples include laser-arc hybrid welding, laser-MIG hybrid systems, and sequential multi-process welding. The synergistic effects of combined technologies can result in reduced overall displacement compared to either method used alone, while also improving weld quality and process stability across a wider range of materials and joint configurations.

02 Traditional welding displacement monitoring systems

Traditional welding methods incorporate displacement monitoring systems to track the movement and deformation of materials during the welding process. These systems typically use mechanical or optical sensors to measure displacement changes, helping operators maintain proper welding parameters. The monitoring systems are crucial for preventing excessive distortion and ensuring structural integrity of the welded components. By continuously tracking displacement, these systems allow for adjustments to be made during the welding process, improving overall quality and reducing the need for post-weld corrections.Expand Specific Solutions03 Comparative displacement characteristics between laser and traditional welding

Laser welding generally produces significantly less displacement and distortion compared to traditional welding methods due to its concentrated heat input and faster processing speed. Traditional welding techniques typically cause greater thermal expansion and subsequent contraction, resulting in more pronounced displacement of the workpiece. The difference in displacement characteristics influences material selection, fixture design, and post-welding processing requirements. Understanding these differences is essential for engineers when selecting the appropriate welding technology for specific applications, particularly where dimensional stability is critical.Expand Specific Solutions04 Displacement compensation mechanisms in welding equipment

Advanced welding equipment incorporates displacement compensation mechanisms to counteract unwanted movement during the welding process. These mechanisms may include predictive modeling software, adaptive control systems, and specialized fixtures designed to anticipate and neutralize displacement effects. For laser welding, high-precision galvanometer systems enable rapid beam positioning adjustments, while traditional welding may employ mechanical tensioning devices to manage displacement. These compensation technologies are particularly valuable in automated welding systems where consistent quality must be maintained across large production volumes.Expand Specific Solutions05 Displacement measurement and analysis in welding processes

Sophisticated measurement and analysis techniques are employed to quantify displacement in both laser and traditional welding processes. These include digital image correlation, laser interferometry, and strain gauge systems that provide real-time data on material movement during welding. The collected displacement data helps in optimizing welding parameters, validating simulation models, and developing improved welding procedures. Advanced analysis software can predict potential displacement issues before production, allowing for proactive adjustments to welding sequences and parameters to minimize unwanted deformation.Expand Specific Solutions

Key Industry Players in Advanced Welding Technologies

Laser welding technology is currently in a growth phase within the manufacturing sector, with the market expected to reach $3.5 billion by 2027. The competitive landscape features established industrial equipment manufacturers like TRUMPF, Coherent, and IPG Photonics leading technological innovation, particularly in minimizing displacement during welding processes. Major automotive companies including Toyota, Volkswagen, and Honda are driving adoption through implementation in high-precision manufacturing applications. The technology has reached moderate maturity in automotive and electronics sectors, but continues to evolve with research contributions from institutions like Fraunhofer-Gesellschaft and Harbin Institute of Technology. Competitive differentiation now centers on precision control, material compatibility, and integration with automated production systems, with displacement minimization becoming a critical performance metric.

TRUMPF Laser- und Systemtechnik GmbH

Technical Solution: TRUMPF has developed advanced laser welding technologies specifically designed to minimize displacement during welding processes. Their TruLaser Weld system incorporates precise beam control and real-time monitoring to achieve minimal thermal distortion. The company's ColdMetal Transfer (CMT) laser welding technology combines controlled heat input with sophisticated beam oscillation patterns to reduce the heat-affected zone by up to 70% compared to traditional welding methods. TRUMPF's systems utilize predictive thermal modeling software that anticipates material displacement and adjusts parameters accordingly, achieving displacement reductions of up to 85% in thin sheet metal applications. Their PrecisionWeld technology employs ultra-short pulse durations (nanosecond to picosecond range) that significantly limit heat transfer to surrounding material, resulting in near-zero displacement for precision components. Additionally, TRUMPF has pioneered hybrid laser-MIG welding systems that optimize energy distribution to maintain structural integrity while minimizing distortion.

Strengths: Superior precision control with displacement reduction up to 85% in thin materials; comprehensive thermal modeling capabilities; versatile application across various material types including high-strength steels and aluminum alloys. Weaknesses: Higher initial investment costs compared to traditional welding equipment; requires specialized operator training; limited effectiveness for very thick materials (>15mm) without supplementary processes.

Coherent, Inc.

Technical Solution: Coherent has developed specialized laser welding solutions focused on minimizing workpiece displacement through advanced beam control technologies. Their ExactWeld system utilizes proprietary SmartBeam technology that dynamically adjusts the laser's spatial energy distribution during the welding process, reducing thermal gradients by up to 65% compared to traditional welding methods. Coherent's pulse-shaping capabilities allow for precise control of energy delivery timing, with rise and fall times as short as 5 microseconds, significantly limiting heat accumulation in sensitive materials. The company's HighLight FL-ARM (Adjustable Ring Mode) fiber laser technology features a unique dual-beam delivery system that preheats the material with an outer ring while the central beam performs the actual welding, resulting in measured displacement reductions of 40-60% in aluminum and stainless steel applications. Their systems incorporate advanced galvanometer scanning technology capable of complex beam path manipulation at speeds up to 10m/s, enabling sophisticated heat distribution strategies that minimize overall thermal input while maintaining weld strength. Coherent has also pioneered ultra-short pulse laser welding for micro-applications, achieving sub-micron precision with virtually no measurable displacement in thin materials.

Strengths: Exceptional beam quality control with industry-leading pulse shaping capabilities; versatile application across diverse materials including dissimilar metal combinations; comprehensive process monitoring and quality assurance systems. Weaknesses: Premium pricing positions products at the higher end of the market; complex systems require specialized maintenance expertise; limited penetration depth compared to some competing technologies for very thick materials.

Core Technical Innovations in Laser Welding Precision

Laser welding process

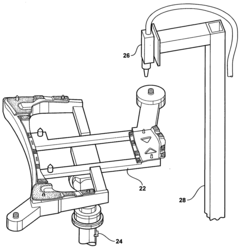

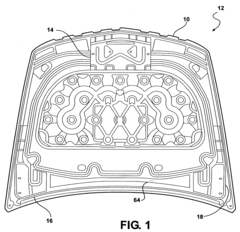

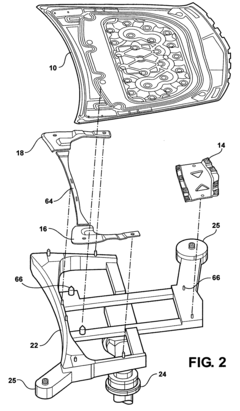

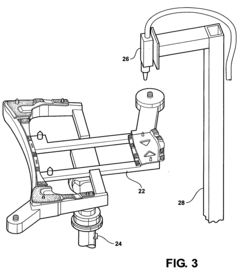

PatentInactiveUS20090179013A1

Innovation

- A robotic system equipped with a pressure pad/anvil and localized laser welding holes allows for the use of a long focal length laser, enabling accurate clamping and welding of automotive panel assemblies using a clamping mechanism that provides continuous pressure along the panel flange, with optional integration of a wire brush motor for cleaning weld flash.

Laser welding method for steel plates and profile steel welded by laser welding

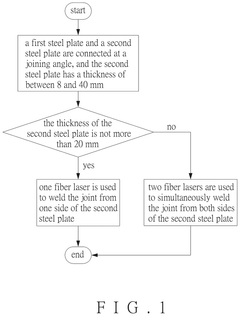

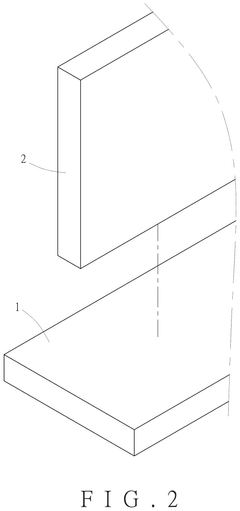

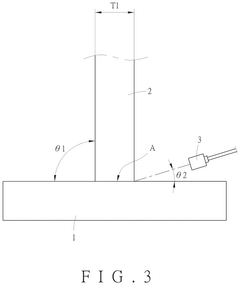

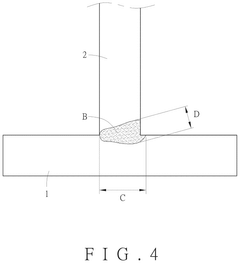

PatentPendingUS20250114867A1

Innovation

- A laser welding method utilizing a high-power laser (between 10,000 and 25,000 watts) with a diameter of 0.1 to 0.5 mm, welding at a speed of 5 to 30 mm/s and an angle of 5 to 20 degrees, to penetrate and join steel plates with thicknesses between 8 and 40 mm without deformation.

Material Science Considerations in Precision Welding

Material selection plays a critical role in determining the success of both laser and traditional welding processes, particularly when minimum displacement is a key requirement. The inherent properties of materials significantly influence their behavior during welding operations, affecting thermal conductivity, melting points, and structural integrity under heat stress.

For laser welding applications, materials with high reflectivity such as aluminum and copper present unique challenges due to their tendency to reflect laser energy rather than absorb it. This necessitates higher power requirements or specialized wavelength selection to achieve effective fusion. Conversely, materials with lower reflectivity like steel and titanium typically respond more favorably to laser welding techniques, allowing for more precise energy delivery and minimal heat-affected zones.

Traditional welding methods demonstrate different material compatibility profiles. Arc welding processes generally perform well with ferrous materials but may introduce excessive heat input, leading to greater thermal expansion and subsequent contraction during cooling. This thermal cycling can result in significant displacement, particularly in thin sections or precision components.

The crystalline structure of materials undergoes substantial transformation during the welding process. In laser welding, the rapid heating and cooling cycles can produce finer grain structures in the weld zone, potentially enhancing mechanical properties while minimizing distortion. Traditional methods typically produce larger heat-affected zones with coarser grain structures, which may contribute to increased displacement.

Alloying elements within materials significantly impact weldability across both methodologies. Elements such as carbon, sulfur, and phosphorus can promote cracking in traditional welds, while elements like manganese and silicon may improve weld pool fluidity and reduce displacement. For laser welding, the presence of volatile elements can lead to porosity issues due to the high energy density and rapid solidification rates.

Surface preparation requirements differ substantially between the two approaches. Laser welding demands exceptionally clean, precisely fitted surfaces to achieve optimal results with minimal displacement. Traditional welding can often accommodate greater fit-up tolerances but may require more extensive pre-weld preparation such as beveling or groove preparation, which can influence the final dimensional stability of the welded assembly.

Advanced material developments, including tailored alloys and composites specifically designed for welding applications, continue to emerge. These materials often incorporate elements that enhance beam absorption for laser processes or improve flow characteristics for traditional methods, ultimately contributing to reduced displacement outcomes in precision welding applications.

For laser welding applications, materials with high reflectivity such as aluminum and copper present unique challenges due to their tendency to reflect laser energy rather than absorb it. This necessitates higher power requirements or specialized wavelength selection to achieve effective fusion. Conversely, materials with lower reflectivity like steel and titanium typically respond more favorably to laser welding techniques, allowing for more precise energy delivery and minimal heat-affected zones.

Traditional welding methods demonstrate different material compatibility profiles. Arc welding processes generally perform well with ferrous materials but may introduce excessive heat input, leading to greater thermal expansion and subsequent contraction during cooling. This thermal cycling can result in significant displacement, particularly in thin sections or precision components.

The crystalline structure of materials undergoes substantial transformation during the welding process. In laser welding, the rapid heating and cooling cycles can produce finer grain structures in the weld zone, potentially enhancing mechanical properties while minimizing distortion. Traditional methods typically produce larger heat-affected zones with coarser grain structures, which may contribute to increased displacement.

Alloying elements within materials significantly impact weldability across both methodologies. Elements such as carbon, sulfur, and phosphorus can promote cracking in traditional welds, while elements like manganese and silicon may improve weld pool fluidity and reduce displacement. For laser welding, the presence of volatile elements can lead to porosity issues due to the high energy density and rapid solidification rates.

Surface preparation requirements differ substantially between the two approaches. Laser welding demands exceptionally clean, precisely fitted surfaces to achieve optimal results with minimal displacement. Traditional welding can often accommodate greater fit-up tolerances but may require more extensive pre-weld preparation such as beveling or groove preparation, which can influence the final dimensional stability of the welded assembly.

Advanced material developments, including tailored alloys and composites specifically designed for welding applications, continue to emerge. These materials often incorporate elements that enhance beam absorption for laser processes or improve flow characteristics for traditional methods, ultimately contributing to reduced displacement outcomes in precision welding applications.

Quality Assurance Methods for High-Precision Welding

Quality assurance in high-precision welding environments requires rigorous methodologies to ensure consistent results, particularly when comparing laser welding with traditional welding techniques in minimum displacement studies. The implementation of comprehensive quality control systems becomes essential for maintaining precision standards across manufacturing processes.

Non-destructive testing (NDT) methods form the cornerstone of quality assurance protocols for high-precision welding. Ultrasonic testing enables detection of internal defects without compromising the structural integrity of welded joints, providing critical data on potential displacement issues. X-ray radiography offers detailed visualization of weld penetration depth and internal structure, allowing engineers to identify microscopic displacement variations between laser and traditional welding techniques.

Real-time monitoring systems have revolutionized quality assurance in precision welding applications. Advanced thermal imaging cameras track heat distribution patterns during both laser and traditional welding processes, enabling immediate detection of thermal gradient anomalies that may lead to displacement. Spectroscopic analysis of the plasma plume during laser welding provides valuable data on material composition changes and potential contamination that could affect dimensional stability.

Statistical process control (SPC) methodologies have been adapted specifically for high-precision welding environments. Control charts tracking key parameters such as power density, travel speed, and focal position help maintain process stability and minimize displacement variation. Capability indices (Cpk and Ppk) are calculated to quantify process performance relative to specification limits, with laser welding typically demonstrating superior capability indices in displacement control studies.

Digital twin technology represents the cutting edge of quality assurance for precision welding. Virtual models simulate welding processes before physical implementation, predicting potential displacement issues and optimizing parameters. Machine learning algorithms analyze historical welding data to identify patterns and correlations between process variables and displacement outcomes, continuously refining predictive models.

Standardized certification and documentation procedures ensure traceability and compliance with industry specifications. Welding procedure specifications (WPS) document precise parameters for both laser and traditional welding methods, while welder qualification records verify operator competency in executing these procedures with minimal displacement. Comprehensive material certification ensures that base materials and filler metals meet required specifications for dimensional stability applications.

Non-destructive testing (NDT) methods form the cornerstone of quality assurance protocols for high-precision welding. Ultrasonic testing enables detection of internal defects without compromising the structural integrity of welded joints, providing critical data on potential displacement issues. X-ray radiography offers detailed visualization of weld penetration depth and internal structure, allowing engineers to identify microscopic displacement variations between laser and traditional welding techniques.

Real-time monitoring systems have revolutionized quality assurance in precision welding applications. Advanced thermal imaging cameras track heat distribution patterns during both laser and traditional welding processes, enabling immediate detection of thermal gradient anomalies that may lead to displacement. Spectroscopic analysis of the plasma plume during laser welding provides valuable data on material composition changes and potential contamination that could affect dimensional stability.

Statistical process control (SPC) methodologies have been adapted specifically for high-precision welding environments. Control charts tracking key parameters such as power density, travel speed, and focal position help maintain process stability and minimize displacement variation. Capability indices (Cpk and Ppk) are calculated to quantify process performance relative to specification limits, with laser welding typically demonstrating superior capability indices in displacement control studies.

Digital twin technology represents the cutting edge of quality assurance for precision welding. Virtual models simulate welding processes before physical implementation, predicting potential displacement issues and optimizing parameters. Machine learning algorithms analyze historical welding data to identify patterns and correlations between process variables and displacement outcomes, continuously refining predictive models.

Standardized certification and documentation procedures ensure traceability and compliance with industry specifications. Welding procedure specifications (WPS) document precise parameters for both laser and traditional welding methods, while welder qualification records verify operator competency in executing these procedures with minimal displacement. Comprehensive material certification ensures that base materials and filler metals meet required specifications for dimensional stability applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!