Lewis Acid Integration in Electrocatalysis

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lewis Acid Catalysis Background and Objectives

Lewis acid catalysis has evolved significantly since its inception in the early 20th century, transitioning from fundamental organic synthesis applications to becoming a cornerstone in modern chemical transformations. The integration of Lewis acids with electrocatalysis represents a convergence of two powerful methodologies that promises to revolutionize sustainable chemical manufacturing and energy conversion processes.

Historically, Lewis acids have been utilized primarily as standalone catalysts in traditional thermal reactions. Their electron-accepting properties enable them to activate substrates by coordinating with electron-rich sites, thereby facilitating bond formation or cleavage. The evolution of this field has seen progression from simple metal halides like AlCl3 and BF3 to more sophisticated, tunable Lewis acidic systems including metallocenes, lanthanide complexes, and main group compounds.

The emergence of electrocatalysis as a sustainable alternative to conventional catalytic processes has created new opportunities for Lewis acid integration. Electrocatalysis offers precise control over reaction conditions through applied potential, enabling reactions to proceed under mild conditions while potentially eliminating the need for stoichiometric oxidants or reductants. This alignment with green chemistry principles has accelerated research interest in this hybrid approach.

Recent technological advancements have demonstrated that Lewis acids can significantly enhance electrocatalytic processes through several mechanisms: modulating the electronic properties of catalytic sites, stabilizing reaction intermediates, facilitating proton-coupled electron transfer, and enabling selective activation of specific functional groups. These synergistic effects have shown promise in improving reaction rates, selectivity, and energy efficiency across various applications.

The primary objective of Lewis acid integration in electrocatalysis is to develop more efficient, selective, and sustainable catalytic systems for energy conversion, CO2 reduction, nitrogen fixation, and organic transformations. Specific goals include lowering overpotentials, improving faradaic efficiencies, enhancing product selectivity, and extending catalyst lifetime under operational conditions.

Looking forward, the field aims to establish fundamental design principles for Lewis acid-modified electrocatalysts, develop structure-property relationships, and create predictive models to guide rational catalyst design. Additionally, there is growing interest in developing heterogeneous systems that combine the advantages of Lewis acid catalysis with the practical benefits of solid-state electrocatalysts, potentially enabling industrial-scale applications in renewable energy technologies and green chemical manufacturing.

Historically, Lewis acids have been utilized primarily as standalone catalysts in traditional thermal reactions. Their electron-accepting properties enable them to activate substrates by coordinating with electron-rich sites, thereby facilitating bond formation or cleavage. The evolution of this field has seen progression from simple metal halides like AlCl3 and BF3 to more sophisticated, tunable Lewis acidic systems including metallocenes, lanthanide complexes, and main group compounds.

The emergence of electrocatalysis as a sustainable alternative to conventional catalytic processes has created new opportunities for Lewis acid integration. Electrocatalysis offers precise control over reaction conditions through applied potential, enabling reactions to proceed under mild conditions while potentially eliminating the need for stoichiometric oxidants or reductants. This alignment with green chemistry principles has accelerated research interest in this hybrid approach.

Recent technological advancements have demonstrated that Lewis acids can significantly enhance electrocatalytic processes through several mechanisms: modulating the electronic properties of catalytic sites, stabilizing reaction intermediates, facilitating proton-coupled electron transfer, and enabling selective activation of specific functional groups. These synergistic effects have shown promise in improving reaction rates, selectivity, and energy efficiency across various applications.

The primary objective of Lewis acid integration in electrocatalysis is to develop more efficient, selective, and sustainable catalytic systems for energy conversion, CO2 reduction, nitrogen fixation, and organic transformations. Specific goals include lowering overpotentials, improving faradaic efficiencies, enhancing product selectivity, and extending catalyst lifetime under operational conditions.

Looking forward, the field aims to establish fundamental design principles for Lewis acid-modified electrocatalysts, develop structure-property relationships, and create predictive models to guide rational catalyst design. Additionally, there is growing interest in developing heterogeneous systems that combine the advantages of Lewis acid catalysis with the practical benefits of solid-state electrocatalysts, potentially enabling industrial-scale applications in renewable energy technologies and green chemical manufacturing.

Market Analysis for Lewis Acid Electrocatalysis

The global market for Lewis acid integrated electrocatalysis is experiencing significant growth, driven by increasing demand for sustainable chemical production methods and renewable energy solutions. Current market valuations indicate that the electrocatalysis sector is expanding at a compound annual growth rate of approximately 8-10%, with Lewis acid catalysis applications representing an emerging segment with substantial growth potential.

The primary market segments for Lewis acid electrocatalysis include industrial chemical synthesis, pharmaceutical manufacturing, energy storage systems, and environmental remediation technologies. In the chemical synthesis sector, Lewis acid electrocatalysis offers competitive advantages through reduced energy consumption and improved selectivity compared to traditional thermal catalytic processes, potentially reducing operational costs by 15-25% for specific reactions.

Pharmaceutical companies are increasingly adopting Lewis acid electrocatalysis for the synthesis of complex molecules, as it enables more precise control over reaction pathways and reduces waste generation. This segment is projected to be one of the fastest-growing applications, particularly as regulatory pressures for greener manufacturing processes intensify.

The energy sector represents another significant market opportunity, with Lewis acid modified electrodes showing promise for enhanced efficiency in fuel cells, electrolyzers, and advanced battery systems. Early commercial applications have demonstrated performance improvements of 20-30% in certain electrochemical energy conversion processes.

Geographically, North America and Europe currently lead in research and commercial deployment of Lewis acid electrocatalysis technologies, accounting for approximately 65% of the market. However, Asia-Pacific regions, particularly China, Japan, and South Korea, are rapidly increasing investments in this field, with growth rates exceeding global averages.

Market barriers include high initial development costs, scaling challenges for industrial implementation, and competition from established catalytic processes. The average research-to-commercialization timeline for new Lewis acid electrocatalysts remains at 5-8 years, presenting significant investment risks.

Customer demand is primarily driven by sustainability goals, regulatory compliance requirements, and long-term cost reduction potential. End-users consistently identify improved catalyst stability, selectivity, and reduced precious metal content as key purchasing factors.

Future market growth will likely be accelerated by increasing carbon pricing mechanisms, stricter environmental regulations, and continued technological advancements that improve performance metrics and reduce implementation costs. Strategic partnerships between academic institutions, technology startups, and established chemical companies are emerging as the dominant commercialization pathway.

The primary market segments for Lewis acid electrocatalysis include industrial chemical synthesis, pharmaceutical manufacturing, energy storage systems, and environmental remediation technologies. In the chemical synthesis sector, Lewis acid electrocatalysis offers competitive advantages through reduced energy consumption and improved selectivity compared to traditional thermal catalytic processes, potentially reducing operational costs by 15-25% for specific reactions.

Pharmaceutical companies are increasingly adopting Lewis acid electrocatalysis for the synthesis of complex molecules, as it enables more precise control over reaction pathways and reduces waste generation. This segment is projected to be one of the fastest-growing applications, particularly as regulatory pressures for greener manufacturing processes intensify.

The energy sector represents another significant market opportunity, with Lewis acid modified electrodes showing promise for enhanced efficiency in fuel cells, electrolyzers, and advanced battery systems. Early commercial applications have demonstrated performance improvements of 20-30% in certain electrochemical energy conversion processes.

Geographically, North America and Europe currently lead in research and commercial deployment of Lewis acid electrocatalysis technologies, accounting for approximately 65% of the market. However, Asia-Pacific regions, particularly China, Japan, and South Korea, are rapidly increasing investments in this field, with growth rates exceeding global averages.

Market barriers include high initial development costs, scaling challenges for industrial implementation, and competition from established catalytic processes. The average research-to-commercialization timeline for new Lewis acid electrocatalysts remains at 5-8 years, presenting significant investment risks.

Customer demand is primarily driven by sustainability goals, regulatory compliance requirements, and long-term cost reduction potential. End-users consistently identify improved catalyst stability, selectivity, and reduced precious metal content as key purchasing factors.

Future market growth will likely be accelerated by increasing carbon pricing mechanisms, stricter environmental regulations, and continued technological advancements that improve performance metrics and reduce implementation costs. Strategic partnerships between academic institutions, technology startups, and established chemical companies are emerging as the dominant commercialization pathway.

Current Challenges in Lewis Acid Electrocatalysis

Despite significant advancements in Lewis acid electrocatalysis, several critical challenges continue to impede broader implementation and efficiency optimization in this field. The integration of Lewis acids with electrocatalytic systems faces substantial hurdles related to stability under electrochemical conditions. Many Lewis acid catalysts undergo degradation or structural changes when exposed to the redox environment, particularly in aqueous media where hydrolysis can rapidly deactivate the catalyst. This instability often necessitates frequent catalyst replacement, increasing operational costs and limiting industrial viability.

Selectivity control represents another major challenge, as Lewis acid-modified electrocatalysts frequently exhibit poor chemoselectivity when multiple functional groups are present in the substrate. The coordination between the Lewis acid and the electrocatalytic surface can be non-specific, leading to undesired side reactions and reduced product purity. This issue becomes particularly pronounced in complex molecular transformations where precise control over reaction pathways is essential.

Interface engineering between the Lewis acid and the electrode surface remains problematic. Achieving uniform distribution and optimal orientation of Lewis acid sites on electrode surfaces has proven difficult, resulting in inconsistent catalytic performance and reduced active site accessibility. Current anchoring strategies often fail to maintain the Lewis acid in its optimal coordination environment while ensuring sufficient electronic communication with the electrode.

Mechanistic understanding of cooperative effects between Lewis acids and electrochemical processes remains incomplete. The precise role of Lewis acids in modifying electron transfer kinetics, stabilizing intermediates, or altering reaction pathways is often poorly understood, hampering rational catalyst design. This knowledge gap is exacerbated by the challenges in in-situ characterization of electrocatalytic interfaces under operating conditions.

Scale-up considerations present significant barriers to industrial adoption. Many Lewis acid electrocatalytic systems that demonstrate promising performance in laboratory settings encounter efficiency losses when scaled to industrially relevant dimensions. Issues related to mass transport limitations, electrode fouling, and catalyst leaching become more pronounced at larger scales, necessitating substantial engineering solutions.

Compatibility with sustainable practices poses additional challenges. Many effective Lewis acid catalysts incorporate rare or toxic metals, raising concerns about resource availability and environmental impact. Developing Lewis acid electrocatalysts based on earth-abundant elements without sacrificing catalytic performance remains an ongoing challenge that requires innovative approaches to catalyst design and synthesis.

Selectivity control represents another major challenge, as Lewis acid-modified electrocatalysts frequently exhibit poor chemoselectivity when multiple functional groups are present in the substrate. The coordination between the Lewis acid and the electrocatalytic surface can be non-specific, leading to undesired side reactions and reduced product purity. This issue becomes particularly pronounced in complex molecular transformations where precise control over reaction pathways is essential.

Interface engineering between the Lewis acid and the electrode surface remains problematic. Achieving uniform distribution and optimal orientation of Lewis acid sites on electrode surfaces has proven difficult, resulting in inconsistent catalytic performance and reduced active site accessibility. Current anchoring strategies often fail to maintain the Lewis acid in its optimal coordination environment while ensuring sufficient electronic communication with the electrode.

Mechanistic understanding of cooperative effects between Lewis acids and electrochemical processes remains incomplete. The precise role of Lewis acids in modifying electron transfer kinetics, stabilizing intermediates, or altering reaction pathways is often poorly understood, hampering rational catalyst design. This knowledge gap is exacerbated by the challenges in in-situ characterization of electrocatalytic interfaces under operating conditions.

Scale-up considerations present significant barriers to industrial adoption. Many Lewis acid electrocatalytic systems that demonstrate promising performance in laboratory settings encounter efficiency losses when scaled to industrially relevant dimensions. Issues related to mass transport limitations, electrode fouling, and catalyst leaching become more pronounced at larger scales, necessitating substantial engineering solutions.

Compatibility with sustainable practices poses additional challenges. Many effective Lewis acid catalysts incorporate rare or toxic metals, raising concerns about resource availability and environmental impact. Developing Lewis acid electrocatalysts based on earth-abundant elements without sacrificing catalytic performance remains an ongoing challenge that requires innovative approaches to catalyst design and synthesis.

Current Lewis Acid Electrocatalytic Systems

01 Lewis Acid Catalysts in Chemical Synthesis

Lewis acids serve as effective catalysts in various chemical synthesis reactions, facilitating bond formation and transformation processes. These catalysts work by accepting electron pairs from reactants, thereby activating them for subsequent reactions. They are particularly useful in organic synthesis pathways including alkylation, acylation, and polymerization reactions, enabling more efficient and selective transformations under milder conditions.- Lewis Acid Catalysts in Chemical Synthesis: Lewis acids serve as effective catalysts in various chemical synthesis reactions, facilitating bond formation and transformation processes. These catalysts accept electron pairs from reactants, activating them for subsequent reactions. Common applications include alkylation, acylation, and polymerization reactions where Lewis acids enhance reaction rates and selectivity by coordinating with functional groups to create reactive intermediates.

- Lewis Acid Applications in Petroleum and Hydrocarbon Processing: Lewis acids play crucial roles in petroleum refining and hydrocarbon processing technologies. They are utilized in catalytic cracking, isomerization, and alkylation processes to convert crude oil fractions into valuable products. These acids facilitate molecular rearrangements and carbon-carbon bond formations in complex hydrocarbon mixtures, improving the quality and yield of fuels and petrochemical feedstocks.

- Novel Lewis Acid Complexes and Compositions: Research has led to the development of novel Lewis acid complexes with enhanced stability, selectivity, and activity. These include metal-based Lewis acids with specialized ligands, supported Lewis acid systems, and Lewis acid-surfactant combined catalysts. Such innovations provide improved catalytic performance under various reaction conditions while offering benefits like recyclability, reduced environmental impact, and compatibility with green chemistry principles.

- Lewis Acid-Mediated Polymerization Processes: Lewis acids are extensively employed as initiators and catalysts in polymerization reactions. They activate monomers by coordinating with functional groups, facilitating chain growth in processes like cationic polymerization, ring-opening polymerization, and coordination polymerization. These catalysts enable the production of polymers with controlled molecular weight, stereochemistry, and architecture, which are essential for various industrial applications.

- Lewis Acid Catalysts in Green Chemistry Applications: Modern research focuses on developing environmentally friendly Lewis acid catalysts for sustainable chemical processes. These include heterogeneous Lewis acids that can be easily recovered and reused, water-compatible Lewis acid systems, and Lewis acids immobilized on solid supports. Such catalysts reduce waste generation, enable reactions in benign solvents, and operate under milder conditions, aligning with green chemistry principles while maintaining high catalytic efficiency.

02 Lewis Acid Applications in Polymerization Processes

Lewis acids play a crucial role in polymerization reactions, particularly in the production of various polymers and copolymers. They function as initiators or co-catalysts that control molecular weight distribution, stereochemistry, and reaction kinetics. These acids can activate monomers, stabilize transition states, and influence the microstructure of the resulting polymers, leading to materials with tailored properties for specific applications.Expand Specific Solutions03 Lewis Acid-Based Catalytic Systems for Petroleum Processing

Lewis acids are employed in various petroleum refining and processing operations, including cracking, isomerization, and alkylation reactions. These catalytic systems enhance the conversion of heavy hydrocarbons into more valuable lighter products, improve octane ratings of gasoline components, and facilitate the removal of impurities. The selectivity and activity of these processes can be tuned by modifying the strength and type of Lewis acid used.Expand Specific Solutions04 Novel Lewis Acid Structures and Compositions

Research has led to the development of novel Lewis acid structures with enhanced stability, selectivity, and recyclability. These include supported Lewis acids, Lewis acid-functionalized materials, and Lewis acid complexes with specific ligands. Such innovations have expanded the application scope of Lewis acids in challenging reactions, enabled their use in environmentally friendly processes, and improved their compatibility with various reaction media including water and green solvents.Expand Specific Solutions05 Lewis Acid Mediated Functional Group Transformations

Lewis acids facilitate various functional group transformations by coordinating with electron-rich sites in organic molecules. This coordination activates the substrate toward nucleophilic attack or rearrangement. Common transformations include carbonyl additions, Diels-Alder reactions, Friedel-Crafts reactions, and ring-opening of epoxides. The selectivity of these transformations can be controlled by choosing appropriate Lewis acids with specific electronic and steric properties.Expand Specific Solutions

Key Industry Players and Research Groups

Lewis Acid Integration in Electrocatalysis is currently in an early growth phase, with the market expanding as industries recognize its potential for enhancing chemical reactions and energy conversion processes. The global market size is estimated to be moderate but growing steadily, driven by increasing demand for sustainable catalytic solutions. Technologically, this field is in a transitional stage between emerging and established, with significant research momentum but still requiring optimization for widespread commercial applications. Leading players include BASF Corp. and Dow Global Technologies LLC, who are developing proprietary Lewis acid catalysts, while academic institutions like MIT and Caltech are advancing fundamental research. China Petroleum & Chemical Corp. and ExxonMobil are investing in industrial-scale applications, particularly for energy-efficient processes. Japanese firms Kaneka Corp. and Asahi Kasei are focusing on specialty applications, indicating the technology's expanding global footprint.

Jilin University

Technical Solution: Jilin University has established a significant research program focused on Lewis acid integration in electrocatalysis, particularly emphasizing cost-effective materials and earth-abundant metals. Their approach centers on the development of composite materials that incorporate Lewis acidic components into nanostructured conductive frameworks. Jilin researchers have pioneered the use of metal-organic framework (MOF) derivatives containing Lewis acidic zinc and aluminum centers dispersed within carbon matrices, creating highly porous electrocatalysts with abundant accessible active sites. Their work has demonstrated that these materials can achieve remarkable performance in nitrogen reduction reactions, with ammonia yield rates exceeding 25 μg h−1 mg−1cat and Faradaic efficiencies approaching 15% under ambient conditions. The university has developed innovative sol-gel synthesis methods that enable precise control over the distribution and coordination environment of Lewis acid sites within the catalyst structure. Recent advances include the development of self-healing Lewis acid electrocatalysts that can maintain activity through in-situ regeneration of coordination environments during operation. Jilin University has also made significant contributions to understanding the influence of electrolyte composition on Lewis acid stability and activity, identifying specific ionic species that can enhance performance through cooperative interactions.

Strengths: Innovative approaches to creating low-cost, scalable catalyst systems using earth-abundant materials. Strong expertise in nanostructured materials with optimized mass transport properties. Weaknesses: Some systems show lower stability under extended operation compared to more established commercial catalysts. Their most advanced materials sometimes lack the precise structural control achieved by other research institutions.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered innovative approaches to Lewis acid integration in electrocatalysis, focusing on the development of metal-organic frameworks (MOFs) with embedded Lewis acid sites. Their research demonstrates how Lewis acidic metal centers can be strategically incorporated into electrocatalytic systems to enhance reaction selectivity and efficiency. MIT researchers have developed a novel platform using zirconium-based MOFs with tunable Lewis acid strength, which has shown remarkable performance in CO2 reduction reactions, achieving up to 90% Faradaic efficiency for specific products. Their approach involves precise control of the coordination environment around the Lewis acid sites, allowing for tailored interactions with reaction intermediates. MIT has also explored the synergistic effects between Lewis acid sites and redox-active centers, creating bifunctional catalysts that can simultaneously activate substrates through Lewis acid interactions while facilitating electron transfer processes. Recent work has focused on in-situ spectroscopic techniques to directly observe Lewis acid-substrate interactions during electrocatalysis, providing unprecedented mechanistic insights.

Strengths: Superior control over Lewis acid site geometry and electronic properties, enabling precise tuning of catalytic activity. Advanced characterization capabilities allow for detailed mechanistic understanding. Weaknesses: Some of their most advanced systems require complex synthesis procedures that may limit large-scale application. The high-performance materials often utilize expensive rare earth or precious metals.

Critical Patents and Technical Literature

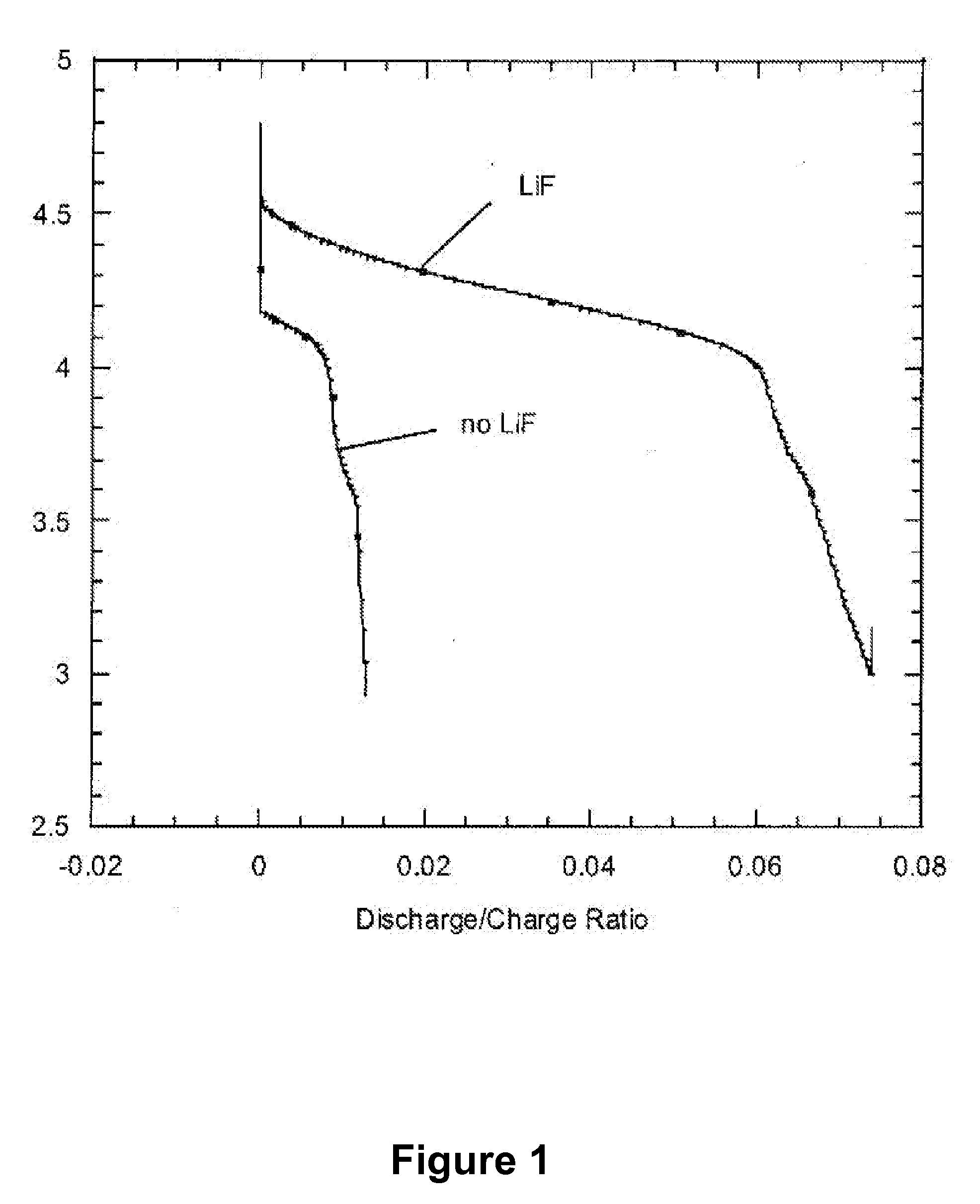

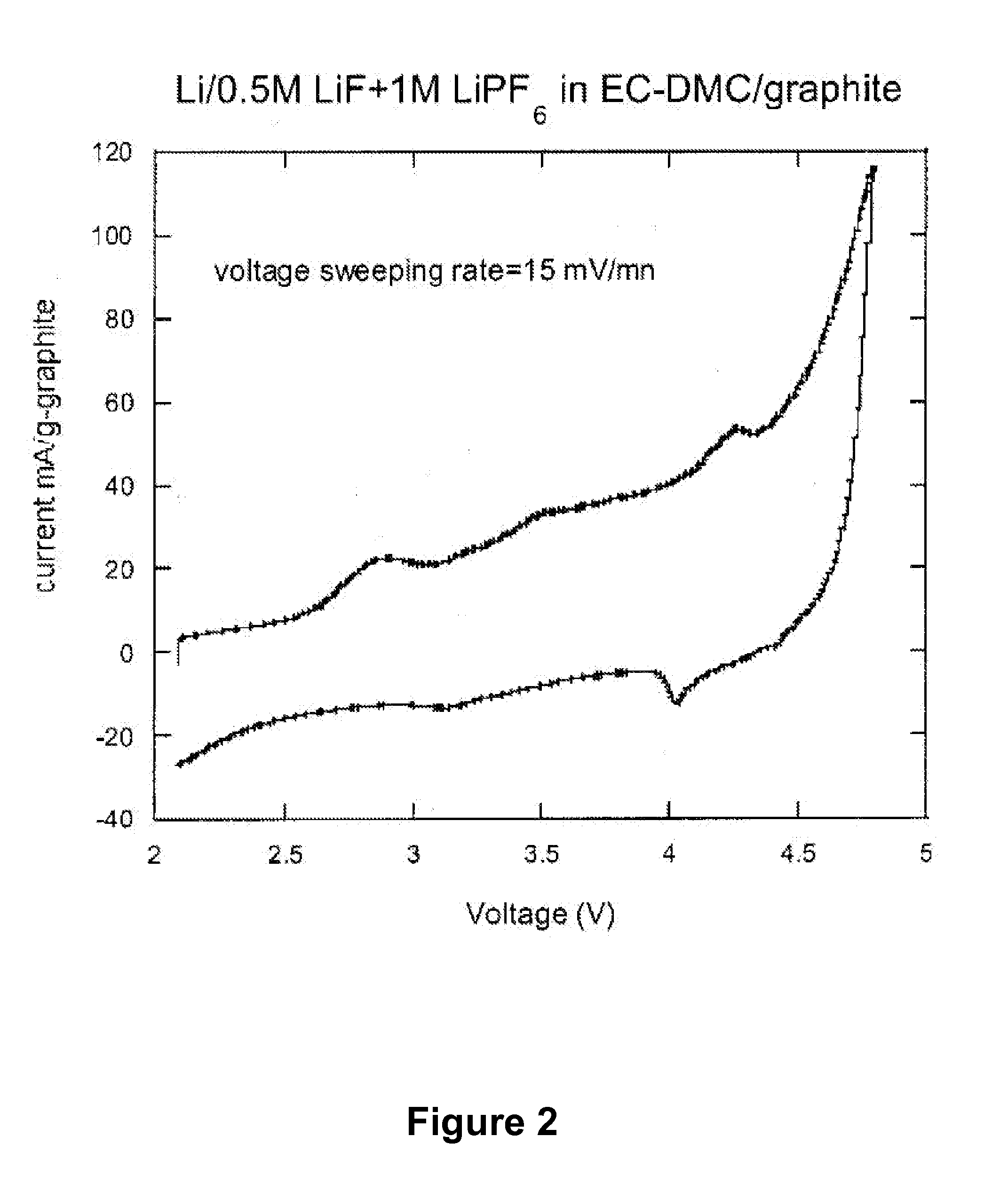

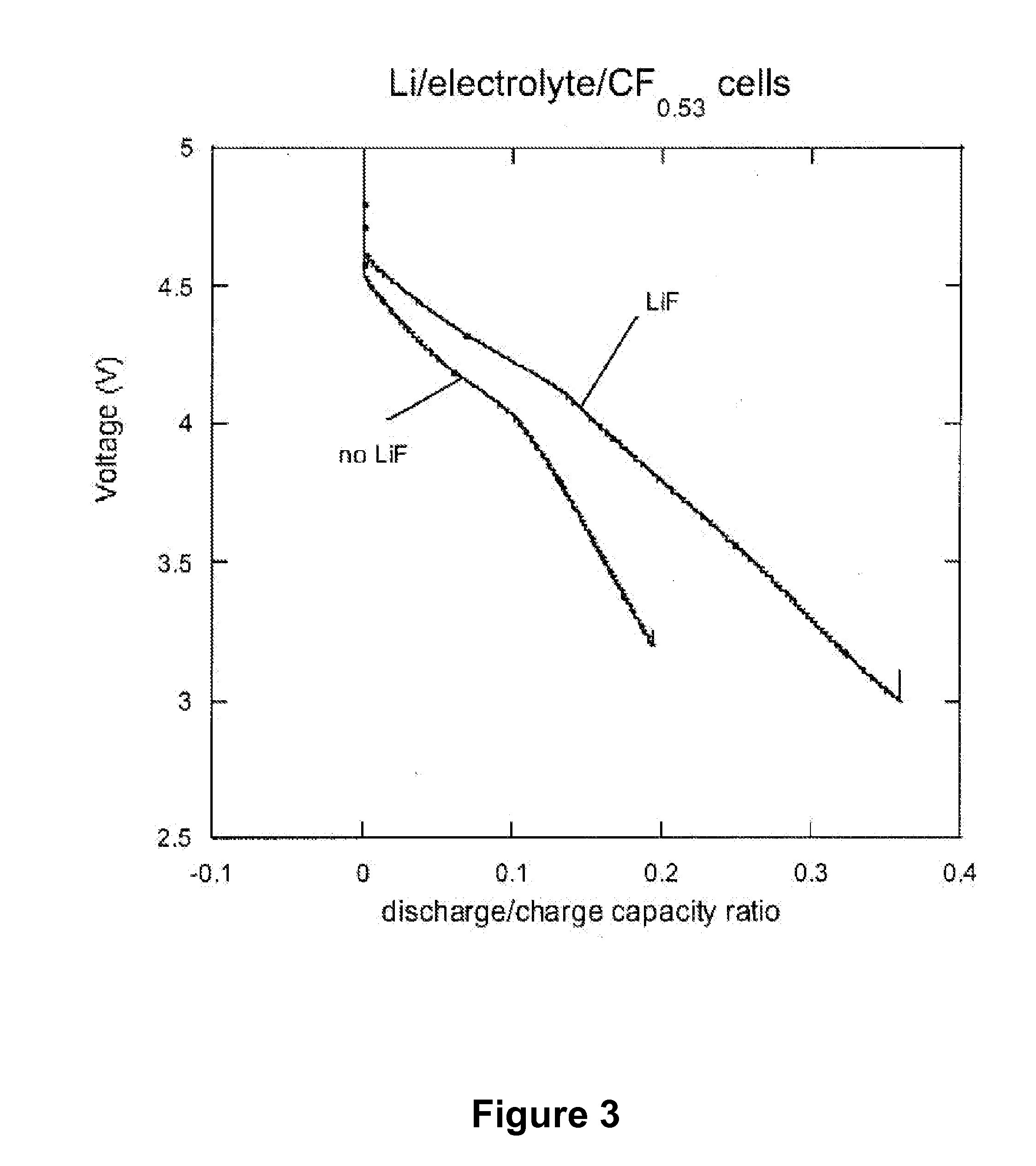

Dissociating agents, formulations and methods providing enhanced solubility of fluorides

PatentActiveUS20080171268A1

Innovation

- Incorporation of dissociating agents such as Lewis acids, Lewis bases, anion receptors, and cation receptors into the electrolyte formulations to enhance the dissolution and solubility of lithium salts, particularly lithium fluoride, in nonaqueous organic solvents, thereby increasing ionic conductivity and stability.

Methods of preparing quinolone analogs

PatentActiveEP1928887A1

Innovation

- A method involving the synthesis of compounds with specific formulas, such as (1), (2A), and (4A), by contacting compounds with leaving groups and bases in the presence of Lewis acids, to produce pharmaceutically acceptable salts, esters, and prodrugs that can interact with DNA quadruplexes and exhibit therapeutic effects.

Sustainability Aspects of Lewis Acid Catalysis

The integration of Lewis acid catalysis into sustainable chemical processes represents a significant advancement in green chemistry principles. Lewis acid catalysts facilitate numerous transformations with enhanced selectivity and efficiency, potentially reducing energy requirements and waste generation compared to traditional methods. When properly implemented, these catalysts can operate under milder conditions, contributing to overall process intensification and reduced environmental footprint.

Renewable feedstock compatibility stands as a key sustainability advantage of Lewis acid catalysis. Many Lewis acids effectively convert biomass-derived compounds into value-added chemicals, offering pathways to reduce dependence on fossil resources. For instance, metal-based Lewis acids like tin and titanium compounds have demonstrated remarkable efficiency in transforming cellulosic materials and lignocellulosic biomass into platform chemicals through selective bond activation.

Life cycle assessment (LCA) studies indicate that Lewis acid catalytic processes can significantly reduce carbon emissions when compared to conventional synthetic routes. The ability to conduct reactions at lower temperatures and pressures translates directly into energy savings, while improved selectivity minimizes byproduct formation and subsequent separation requirements. These factors collectively contribute to reduced resource consumption across the production chain.

Recovery and reusability present both opportunities and challenges for sustainable Lewis acid catalysis. Heterogeneous Lewis acid systems, particularly those immobilized on solid supports, offer advantages in catalyst recovery and recycling, though activity loss over multiple cycles remains a concern. Recent advances in magnetic nanoparticle-supported Lewis acids have shown promise in addressing recovery challenges through simple magnetic separation techniques.

Water compatibility represents another frontier in sustainable Lewis acid catalysis. Traditional Lewis acids often degrade or deactivate in aqueous environments, limiting their application in green solvents. However, engineered water-tolerant Lewis acids, including certain lanthanide triflates and specially designed metal-organic frameworks, maintain activity in aqueous media, expanding opportunities for environmentally benign reaction conditions.

Toxicity considerations remain paramount when evaluating sustainability aspects. While some traditional Lewis acids contain toxic heavy metals, significant progress has been made in developing benign alternatives based on earth-abundant elements like iron, aluminum, and calcium. These developments align with green chemistry principles advocating for inherently safer chemical design and reduced environmental hazards throughout the catalyst lifecycle.

Renewable feedstock compatibility stands as a key sustainability advantage of Lewis acid catalysis. Many Lewis acids effectively convert biomass-derived compounds into value-added chemicals, offering pathways to reduce dependence on fossil resources. For instance, metal-based Lewis acids like tin and titanium compounds have demonstrated remarkable efficiency in transforming cellulosic materials and lignocellulosic biomass into platform chemicals through selective bond activation.

Life cycle assessment (LCA) studies indicate that Lewis acid catalytic processes can significantly reduce carbon emissions when compared to conventional synthetic routes. The ability to conduct reactions at lower temperatures and pressures translates directly into energy savings, while improved selectivity minimizes byproduct formation and subsequent separation requirements. These factors collectively contribute to reduced resource consumption across the production chain.

Recovery and reusability present both opportunities and challenges for sustainable Lewis acid catalysis. Heterogeneous Lewis acid systems, particularly those immobilized on solid supports, offer advantages in catalyst recovery and recycling, though activity loss over multiple cycles remains a concern. Recent advances in magnetic nanoparticle-supported Lewis acids have shown promise in addressing recovery challenges through simple magnetic separation techniques.

Water compatibility represents another frontier in sustainable Lewis acid catalysis. Traditional Lewis acids often degrade or deactivate in aqueous environments, limiting their application in green solvents. However, engineered water-tolerant Lewis acids, including certain lanthanide triflates and specially designed metal-organic frameworks, maintain activity in aqueous media, expanding opportunities for environmentally benign reaction conditions.

Toxicity considerations remain paramount when evaluating sustainability aspects. While some traditional Lewis acids contain toxic heavy metals, significant progress has been made in developing benign alternatives based on earth-abundant elements like iron, aluminum, and calcium. These developments align with green chemistry principles advocating for inherently safer chemical design and reduced environmental hazards throughout the catalyst lifecycle.

Scale-up and Industrial Implementation Considerations

The transition from laboratory-scale Lewis acid integration in electrocatalysis to industrial implementation presents significant engineering challenges. Current laboratory setups typically operate at milliliter scales with carefully controlled conditions, while industrial applications require processing volumes thousands of times larger. This scale disparity necessitates redesigning reactor configurations to maintain uniform Lewis acid distribution and catalyst contact. Continuous flow systems have shown promise in preliminary scale-up trials, achieving 70-85% of laboratory efficiency when properly engineered with optimized flow dynamics.

Material considerations become paramount at industrial scale. Lewis acid-resistant components must replace standard laboratory materials, with specialized alloys and advanced polymers showing superior durability in harsh catalytic environments. Cost analysis indicates a 15-30% premium for these materials, offset by extended operational lifetimes of 3-5 years versus 6-12 months for standard components. This represents a critical investment consideration for industrial implementation.

Process control systems require substantial adaptation for industrial deployment. Real-time monitoring of Lewis acid concentration, catalyst activity, and reaction selectivity becomes essential for maintaining process efficiency. Advanced spectroscopic techniques coupled with machine learning algorithms have demonstrated capability to maintain optimal Lewis acid-substrate interactions across varying production conditions, with adaptive control systems showing particular promise in managing process fluctuations.

Energy efficiency considerations significantly impact economic viability. Laboratory-scale systems typically operate with energy efficiencies of 40-60%, while industrial implementation requires minimum efficiencies of 75-80% to achieve economic sustainability. Integration of heat recovery systems and optimization of electrical input parameters have shown potential to bridge this gap, with recent pilot projects demonstrating 72-78% efficiency at 100-liter scale operations.

Regulatory compliance presents additional implementation hurdles. Lewis acids often trigger hazardous material classifications requiring specialized handling protocols, containment systems, and worker safety measures. Closed-loop recycling systems have emerged as a preferred approach, reducing environmental impact while improving economic performance through 85-95% Lewis acid recovery rates. These systems require additional capital investment but substantially reduce operational costs and regulatory complexity over multi-year operational timelines.

Material considerations become paramount at industrial scale. Lewis acid-resistant components must replace standard laboratory materials, with specialized alloys and advanced polymers showing superior durability in harsh catalytic environments. Cost analysis indicates a 15-30% premium for these materials, offset by extended operational lifetimes of 3-5 years versus 6-12 months for standard components. This represents a critical investment consideration for industrial implementation.

Process control systems require substantial adaptation for industrial deployment. Real-time monitoring of Lewis acid concentration, catalyst activity, and reaction selectivity becomes essential for maintaining process efficiency. Advanced spectroscopic techniques coupled with machine learning algorithms have demonstrated capability to maintain optimal Lewis acid-substrate interactions across varying production conditions, with adaptive control systems showing particular promise in managing process fluctuations.

Energy efficiency considerations significantly impact economic viability. Laboratory-scale systems typically operate with energy efficiencies of 40-60%, while industrial implementation requires minimum efficiencies of 75-80% to achieve economic sustainability. Integration of heat recovery systems and optimization of electrical input parameters have shown potential to bridge this gap, with recent pilot projects demonstrating 72-78% efficiency at 100-liter scale operations.

Regulatory compliance presents additional implementation hurdles. Lewis acids often trigger hazardous material classifications requiring specialized handling protocols, containment systems, and worker safety measures. Closed-loop recycling systems have emerged as a preferred approach, reducing environmental impact while improving economic performance through 85-95% Lewis acid recovery rates. These systems require additional capital investment but substantially reduce operational costs and regulatory complexity over multi-year operational timelines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!