Limitations and Solutions in Lithium Iron Phosphate Battery Manufacturing

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Evolution and Objectives

Lithium Iron Phosphate (LFP) batteries have undergone significant evolution since their inception in the late 1990s. Initially developed as a safer alternative to traditional lithium-ion batteries, LFP technology has steadily improved in terms of energy density, cycle life, and manufacturing efficiency. The primary objective of LFP battery development has been to create a cost-effective, safe, and long-lasting energy storage solution for various applications, particularly in electric vehicles and renewable energy systems.

The evolution of LFP batteries can be traced through several key milestones. In the early 2000s, researchers focused on improving the cathode material's structure and composition to enhance its electrochemical performance. This led to the development of nano-sized LFP particles and carbon coating techniques, which significantly increased the battery's conductivity and power output. By the mid-2000s, LFP batteries began to see commercial adoption in electric bicycles and power tools.

As the demand for electric vehicles grew in the 2010s, LFP battery technology faced new challenges in terms of energy density and fast-charging capabilities. Manufacturers responded by developing advanced electrode designs and electrolyte formulations, pushing the boundaries of LFP performance. The introduction of cell-to-pack technology in recent years has further improved the overall energy density of LFP battery systems, making them increasingly competitive with other lithium-ion chemistries.

Looking ahead, the objectives for LFP battery technology are multifaceted. One primary goal is to continue increasing energy density without compromising safety or longevity. This involves exploring new cathode materials, such as lithium-rich phosphates, and optimizing electrode structures at the nanoscale. Another crucial objective is to enhance the fast-charging capabilities of LFP batteries, addressing a key limitation in electric vehicle applications.

Improving manufacturing processes is also a critical objective in LFP battery evolution. Researchers and manufacturers are working on developing more efficient and sustainable production methods, including water-based electrode processing and dry electrode manufacturing. These advancements aim to reduce production costs, minimize environmental impact, and scale up production to meet growing global demand.

Furthermore, the integration of LFP batteries into smart energy systems represents an emerging objective. This includes developing advanced battery management systems that can optimize performance, predict maintenance needs, and facilitate seamless integration with renewable energy sources. As the world transitions towards cleaner energy solutions, the continued evolution of LFP battery technology plays a crucial role in enabling this shift, with objectives focused on enhancing performance, sustainability, and cost-effectiveness.

The evolution of LFP batteries can be traced through several key milestones. In the early 2000s, researchers focused on improving the cathode material's structure and composition to enhance its electrochemical performance. This led to the development of nano-sized LFP particles and carbon coating techniques, which significantly increased the battery's conductivity and power output. By the mid-2000s, LFP batteries began to see commercial adoption in electric bicycles and power tools.

As the demand for electric vehicles grew in the 2010s, LFP battery technology faced new challenges in terms of energy density and fast-charging capabilities. Manufacturers responded by developing advanced electrode designs and electrolyte formulations, pushing the boundaries of LFP performance. The introduction of cell-to-pack technology in recent years has further improved the overall energy density of LFP battery systems, making them increasingly competitive with other lithium-ion chemistries.

Looking ahead, the objectives for LFP battery technology are multifaceted. One primary goal is to continue increasing energy density without compromising safety or longevity. This involves exploring new cathode materials, such as lithium-rich phosphates, and optimizing electrode structures at the nanoscale. Another crucial objective is to enhance the fast-charging capabilities of LFP batteries, addressing a key limitation in electric vehicle applications.

Improving manufacturing processes is also a critical objective in LFP battery evolution. Researchers and manufacturers are working on developing more efficient and sustainable production methods, including water-based electrode processing and dry electrode manufacturing. These advancements aim to reduce production costs, minimize environmental impact, and scale up production to meet growing global demand.

Furthermore, the integration of LFP batteries into smart energy systems represents an emerging objective. This includes developing advanced battery management systems that can optimize performance, predict maintenance needs, and facilitate seamless integration with renewable energy sources. As the world transitions towards cleaner energy solutions, the continued evolution of LFP battery technology plays a crucial role in enabling this shift, with objectives focused on enhancing performance, sustainability, and cost-effectiveness.

Market Demand Analysis for LFP Batteries

The market demand for Lithium Iron Phosphate (LFP) batteries has been experiencing significant growth in recent years, driven by several key factors. The automotive industry, particularly the electric vehicle (EV) sector, has emerged as a primary driver of this demand. LFP batteries are increasingly favored by EV manufacturers due to their lower cost, improved safety features, and longer cycle life compared to other lithium-ion battery chemistries.

In the EV market, LFP batteries are gaining traction in mass-market models, where cost considerations are paramount. Major automakers have announced plans to incorporate LFP batteries into their product lines, signaling a shift in market preferences. This trend is particularly pronounced in China, the world's largest EV market, where LFP batteries have already captured a substantial market share.

Beyond the automotive sector, the energy storage system (ESS) market is another significant driver of LFP battery demand. Grid-scale energy storage applications, as well as residential and commercial energy storage systems, are increasingly adopting LFP batteries. The technology's safety profile and cost-effectiveness make it an attractive option for stationary storage applications, where energy density is less critical than in mobile applications.

The industrial and power tool sectors also contribute to the growing demand for LFP batteries. These applications benefit from the technology's robustness, safety, and ability to withstand frequent charging cycles. As industries continue to electrify their equipment and processes, the demand for LFP batteries in these sectors is expected to rise.

Market analysts project substantial growth in the LFP battery market over the coming years. The increasing focus on renewable energy integration and grid stability is expected to further boost demand for LFP batteries in energy storage applications. Additionally, as manufacturing processes improve and economies of scale are realized, the cost-competitiveness of LFP batteries is likely to increase, potentially expanding their market share in various applications.

However, the market demand for LFP batteries is not without challenges. Competition from other battery chemistries, particularly those offering higher energy density, remains a factor in certain applications. Additionally, the availability and pricing of raw materials, especially phosphate, could impact the market dynamics for LFP batteries.

In conclusion, the market demand for LFP batteries shows strong growth potential across multiple sectors, with the automotive and energy storage markets leading the way. As technology advances and manufacturing capabilities expand, LFP batteries are poised to play an increasingly significant role in the global energy transition and electrification efforts.

In the EV market, LFP batteries are gaining traction in mass-market models, where cost considerations are paramount. Major automakers have announced plans to incorporate LFP batteries into their product lines, signaling a shift in market preferences. This trend is particularly pronounced in China, the world's largest EV market, where LFP batteries have already captured a substantial market share.

Beyond the automotive sector, the energy storage system (ESS) market is another significant driver of LFP battery demand. Grid-scale energy storage applications, as well as residential and commercial energy storage systems, are increasingly adopting LFP batteries. The technology's safety profile and cost-effectiveness make it an attractive option for stationary storage applications, where energy density is less critical than in mobile applications.

The industrial and power tool sectors also contribute to the growing demand for LFP batteries. These applications benefit from the technology's robustness, safety, and ability to withstand frequent charging cycles. As industries continue to electrify their equipment and processes, the demand for LFP batteries in these sectors is expected to rise.

Market analysts project substantial growth in the LFP battery market over the coming years. The increasing focus on renewable energy integration and grid stability is expected to further boost demand for LFP batteries in energy storage applications. Additionally, as manufacturing processes improve and economies of scale are realized, the cost-competitiveness of LFP batteries is likely to increase, potentially expanding their market share in various applications.

However, the market demand for LFP batteries is not without challenges. Competition from other battery chemistries, particularly those offering higher energy density, remains a factor in certain applications. Additionally, the availability and pricing of raw materials, especially phosphate, could impact the market dynamics for LFP batteries.

In conclusion, the market demand for LFP batteries shows strong growth potential across multiple sectors, with the automotive and energy storage markets leading the way. As technology advances and manufacturing capabilities expand, LFP batteries are poised to play an increasingly significant role in the global energy transition and electrification efforts.

LFP Manufacturing Challenges

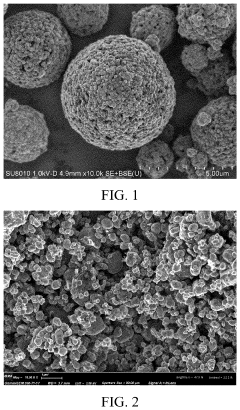

Lithium Iron Phosphate (LFP) battery manufacturing faces several significant challenges that impact production efficiency, cost-effectiveness, and overall battery performance. One of the primary limitations is the complexity of the synthesis process for LFP cathode materials. The traditional solid-state reaction method often results in non-uniform particle size distribution and poor crystallinity, leading to suboptimal electrochemical properties.

Another major challenge lies in the low electronic conductivity of LFP materials. This inherent characteristic necessitates additional processing steps, such as carbon coating or doping with conductive materials, to enhance the battery's power density and rate capability. However, these processes can be difficult to control precisely, potentially affecting the consistency of battery performance across production batches.

The energy density of LFP batteries is also a concern when compared to other lithium-ion chemistries. Manufacturers struggle to increase the energy density without compromising the safety and stability advantages that LFP batteries are known for. This limitation often requires trade-offs in battery design and application suitability.

Production scalability presents another significant hurdle. As demand for LFP batteries grows, manufacturers face difficulties in scaling up production while maintaining quality and cost-effectiveness. The need for specialized equipment and precise control over manufacturing conditions can lead to bottlenecks in high-volume production scenarios.

Environmental considerations also pose challenges in LFP manufacturing. The synthesis of LFP materials typically involves high-temperature processes, which are energy-intensive and can have a substantial carbon footprint. Developing more energy-efficient and environmentally friendly production methods remains an ongoing challenge for the industry.

Quality control and consistency in LFP battery production are critical yet challenging aspects. Variations in raw material quality, processing conditions, and assembly techniques can lead to inconsistencies in battery performance and lifespan. Implementing robust quality control measures throughout the manufacturing process is essential but can be complex and resource-intensive.

To address these challenges, manufacturers are exploring various solutions. Advanced synthesis techniques, such as hydrothermal or sol-gel methods, are being developed to improve particle morphology and crystallinity. Innovative approaches to carbon coating and doping are being investigated to enhance conductivity more effectively. Research into novel cathode compositions and structures aims to increase energy density while maintaining the inherent safety of LFP chemistry.

Another major challenge lies in the low electronic conductivity of LFP materials. This inherent characteristic necessitates additional processing steps, such as carbon coating or doping with conductive materials, to enhance the battery's power density and rate capability. However, these processes can be difficult to control precisely, potentially affecting the consistency of battery performance across production batches.

The energy density of LFP batteries is also a concern when compared to other lithium-ion chemistries. Manufacturers struggle to increase the energy density without compromising the safety and stability advantages that LFP batteries are known for. This limitation often requires trade-offs in battery design and application suitability.

Production scalability presents another significant hurdle. As demand for LFP batteries grows, manufacturers face difficulties in scaling up production while maintaining quality and cost-effectiveness. The need for specialized equipment and precise control over manufacturing conditions can lead to bottlenecks in high-volume production scenarios.

Environmental considerations also pose challenges in LFP manufacturing. The synthesis of LFP materials typically involves high-temperature processes, which are energy-intensive and can have a substantial carbon footprint. Developing more energy-efficient and environmentally friendly production methods remains an ongoing challenge for the industry.

Quality control and consistency in LFP battery production are critical yet challenging aspects. Variations in raw material quality, processing conditions, and assembly techniques can lead to inconsistencies in battery performance and lifespan. Implementing robust quality control measures throughout the manufacturing process is essential but can be complex and resource-intensive.

To address these challenges, manufacturers are exploring various solutions. Advanced synthesis techniques, such as hydrothermal or sol-gel methods, are being developed to improve particle morphology and crystallinity. Innovative approaches to carbon coating and doping are being investigated to enhance conductivity more effectively. Research into novel cathode compositions and structures aims to increase energy density while maintaining the inherent safety of LFP chemistry.

Current LFP Production Methods

01 Electrode material composition and preparation

Lithium iron phosphate (LiFePO4) is a key cathode material for lithium-ion batteries. The composition and preparation methods of this material significantly impact battery performance. Techniques such as doping, coating, and nanostructuring are employed to enhance conductivity, stability, and capacity of the electrode material.- Electrode material composition and preparation: Lithium iron phosphate (LiFePO4) is a key cathode material for LFP batteries. The composition and preparation methods of this material significantly impact battery performance. Techniques include doping with other elements, controlling particle size and morphology, and optimizing synthesis conditions to enhance conductivity and capacity.

- Battery structure and assembly: The design and assembly of LFP batteries play a crucial role in their performance and safety. This includes innovations in cell packaging, electrode stacking or winding, electrolyte formulation, and separator design. Advanced manufacturing techniques are employed to improve energy density and reduce internal resistance.

- Thermal management and safety features: LFP batteries require effective thermal management to maintain optimal performance and ensure safety. This involves the development of cooling systems, heat-resistant materials, and safety mechanisms to prevent thermal runaway. Innovations in this area focus on improving heat dissipation and implementing fail-safe features.

- Battery management systems: Advanced battery management systems (BMS) are crucial for optimizing LFP battery performance and longevity. These systems monitor and control various parameters such as voltage, current, and temperature. Innovations in BMS include improved algorithms for state-of-charge estimation, cell balancing, and predictive maintenance.

- Recycling and sustainability: As LFP batteries become more widespread, there is increasing focus on recycling and sustainable production methods. This includes developing efficient processes for recovering and reusing materials from spent batteries, as well as exploring more environmentally friendly manufacturing techniques and materials sourcing.

02 Electrolyte formulations

The electrolyte plays a crucial role in lithium iron phosphate batteries. Research focuses on developing novel electrolyte formulations to improve ionic conductivity, thermal stability, and electrochemical performance. This includes the use of additives, ionic liquids, and solid electrolytes to enhance battery safety and longevity.Expand Specific Solutions03 Battery cell design and assembly

Innovations in cell design and assembly techniques aim to optimize the performance of lithium iron phosphate batteries. This includes advancements in electrode stacking, current collector design, and packaging methods to improve energy density, power output, and thermal management of the battery cells.Expand Specific Solutions04 Battery management systems

Advanced battery management systems are crucial for optimizing the performance and lifespan of lithium iron phosphate batteries. These systems monitor and control various parameters such as voltage, current, and temperature to ensure safe and efficient operation, as well as to implement advanced charging and discharging strategies.Expand Specific Solutions05 Recycling and sustainability

As the adoption of lithium iron phosphate batteries increases, focus on recycling and sustainable production methods is growing. Research in this area includes developing efficient recycling processes to recover valuable materials, as well as exploring more environmentally friendly production techniques to reduce the overall carbon footprint of battery manufacturing.Expand Specific Solutions

Key LFP Battery Manufacturers

The lithium iron phosphate (LFP) battery manufacturing industry is in a growth phase, driven by increasing demand for electric vehicles and energy storage systems. The global market size for LFP batteries is projected to expand significantly in the coming years. Technologically, LFP batteries are relatively mature, with ongoing improvements in energy density and cost reduction. Key players like BYD, CATL, and A123 Systems are leading innovation in this space. Emerging companies such as Nano One Materials and Guoxuan High-Tech are developing advanced manufacturing processes to enhance LFP battery performance. Research institutions like Tsinghua University and Central South University are contributing to fundamental advancements in LFP technology. The competitive landscape is characterized by a mix of established battery manufacturers and innovative startups, with a focus on overcoming limitations in energy density and production efficiency.

BYD Co., Ltd.

Technical Solution: BYD has developed a revolutionary Blade Battery technology for LFP batteries, addressing key limitations in energy density and safety. The Blade Battery uses a novel cell-to-pack design, eliminating the need for module housing[1]. This approach increases energy density by 50% compared to traditional LFP batteries[2]. BYD's manufacturing process involves single-crystal technology and large-format cells, reducing internal resistance and improving thermal management[3]. The company has also implemented advanced automation in production, with over 100 robots used in key processes, enhancing consistency and reducing manufacturing defects[4].

Strengths: High energy density, improved safety, and cost-effective production. Weaknesses: Initial high capital investment for manufacturing setup and potential supply chain dependencies for specialized materials.

Nano One Materials Corp.

Technical Solution: Nano One has developed a patented One-Pot process for manufacturing LFP cathode materials, addressing issues of cost and environmental impact. Their technology uses a unique aqueous process that combines all input materials in a single reaction[5]. This method reduces the number of steps in LFP production from 4-5 to just 1, cutting costs by up to 50%[6]. The process also produces a coated single-crystal cathode powder, improving battery performance and longevity. Nano One's method reduces water consumption by 60-80% compared to traditional methods and eliminates wastewater[7], addressing a significant environmental concern in LFP manufacturing.

Strengths: Cost-effective, environmentally friendly, and produces high-performance cathode materials. Weaknesses: Scaling up production to meet industry demands and potential resistance from established manufacturers using traditional methods.

Innovative LFP Synthesis Techniques

Method for preparing lithium iron phosphate positive electrode material, positive electrode pole piece and lithium ion battery

PatentPendingUS20240128452A1

Innovation

- A method to prepare lithium iron phosphate positive electrode materials by regulating sintering temperature and time for two materials with different morphologies, achieving a higher compaction density through a specific mass ratio and processing steps, including grinding, spray-drying, and crushing, to enhance fill rate and packing efficiency.

Method for preparing lithium iron phosphate as a positive electrode active material for a lithium ion secondary battery

PatentWO2008145034A1

Innovation

- A method involving the use of ferric oxide as the iron source and phosphoric acid as the phosphorus source, mixed with a lithium source and carbon in a solvent, followed by drying and sintering, to form a precursor with small and uniform particle size distribution, enhancing the electrochemical properties of lithium iron phosphate.

Environmental Impact of LFP Production

The production of Lithium Iron Phosphate (LFP) batteries has significant environmental implications that warrant careful consideration. The manufacturing process involves the extraction and processing of raw materials, which can lead to habitat disruption and resource depletion. Mining activities for lithium, iron, and phosphate often result in land degradation and potential water pollution if not properly managed.

Energy consumption during LFP battery production is a major environmental concern. The synthesis of cathode materials and the assembly of battery cells require substantial amounts of electricity, often sourced from fossil fuels in many regions. This contributes to greenhouse gas emissions and exacerbates climate change issues. However, the long-term environmental benefits of LFP batteries in enabling clean energy storage and electric mobility must be weighed against these production-phase impacts.

Water usage in LFP manufacturing is another critical environmental factor. The production process demands large quantities of water for material processing, cooling, and cleaning operations. In water-stressed regions, this can lead to competition with local communities and ecosystems for scarce water resources. Implementing water recycling and efficient use technologies in manufacturing facilities is crucial to mitigate this impact.

Chemical waste generation during LFP production poses potential risks to soil and water systems if not properly handled. The use of solvents, binders, and other chemical additives in the manufacturing process can result in hazardous waste streams. Stringent waste management protocols and investment in advanced treatment technologies are essential to minimize environmental contamination.

Air quality is also affected by LFP production, primarily through the release of particulate matter and volatile organic compounds during various stages of manufacturing. These emissions can contribute to local air pollution and associated health risks for nearby communities. Installation of state-of-the-art air filtration systems and adoption of cleaner production techniques are necessary to address this concern.

Despite these challenges, ongoing research and technological advancements are focused on developing more environmentally friendly LFP production methods. Innovations in green chemistry, recycling technologies, and renewable energy integration in manufacturing processes hold promise for reducing the overall environmental footprint of LFP battery production. As the industry matures, it is expected that more sustainable practices will be adopted, balancing the need for large-scale energy storage solutions with environmental preservation.

Energy consumption during LFP battery production is a major environmental concern. The synthesis of cathode materials and the assembly of battery cells require substantial amounts of electricity, often sourced from fossil fuels in many regions. This contributes to greenhouse gas emissions and exacerbates climate change issues. However, the long-term environmental benefits of LFP batteries in enabling clean energy storage and electric mobility must be weighed against these production-phase impacts.

Water usage in LFP manufacturing is another critical environmental factor. The production process demands large quantities of water for material processing, cooling, and cleaning operations. In water-stressed regions, this can lead to competition with local communities and ecosystems for scarce water resources. Implementing water recycling and efficient use technologies in manufacturing facilities is crucial to mitigate this impact.

Chemical waste generation during LFP production poses potential risks to soil and water systems if not properly handled. The use of solvents, binders, and other chemical additives in the manufacturing process can result in hazardous waste streams. Stringent waste management protocols and investment in advanced treatment technologies are essential to minimize environmental contamination.

Air quality is also affected by LFP production, primarily through the release of particulate matter and volatile organic compounds during various stages of manufacturing. These emissions can contribute to local air pollution and associated health risks for nearby communities. Installation of state-of-the-art air filtration systems and adoption of cleaner production techniques are necessary to address this concern.

Despite these challenges, ongoing research and technological advancements are focused on developing more environmentally friendly LFP production methods. Innovations in green chemistry, recycling technologies, and renewable energy integration in manufacturing processes hold promise for reducing the overall environmental footprint of LFP battery production. As the industry matures, it is expected that more sustainable practices will be adopted, balancing the need for large-scale energy storage solutions with environmental preservation.

LFP Battery Safety Standards

Safety standards play a crucial role in the manufacturing and deployment of Lithium Iron Phosphate (LFP) batteries. These standards are designed to ensure the safe production, transportation, and use of LFP batteries across various applications. The primary focus of these standards is to mitigate potential risks associated with thermal runaway, short circuits, and other safety hazards.

One of the key safety standards for LFP batteries is the UN38.3 certification, which is mandatory for the transportation of lithium-ion batteries. This standard involves a series of tests, including altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge. These tests are designed to simulate various conditions that batteries may encounter during transportation and use.

In addition to UN38.3, the IEC 62133 standard is widely recognized for safety requirements for portable sealed secondary cells and batteries. This standard covers aspects such as construction, design, and safety performance under both normal and abnormal operating conditions. It includes tests for electrical, mechanical, and environmental safety.

For automotive applications, the SAE J2464 standard is particularly relevant. This standard provides guidelines for electric and hybrid vehicle battery systems, including safety criteria and test procedures. It addresses issues such as electrical isolation, thermal management, and crash safety.

The UL 1642 standard is another important safety benchmark for lithium batteries. It outlines requirements for testing and evaluating the safety of lithium batteries used in various products. This standard includes tests for electrical, mechanical, and environmental safety, as well as abuse conditions.

In the manufacturing process, adherence to ISO 9001 quality management standards is essential. While not specific to LFP batteries, this standard ensures consistent quality control throughout the production process, which is critical for battery safety.

As the technology evolves, safety standards are continuously updated to address new challenges and improvements in battery technology. For instance, recent updates have focused on enhancing safety measures for high-capacity batteries and fast-charging technologies. Manufacturers must stay abreast of these evolving standards to ensure compliance and maintain the highest safety levels in their LFP battery production.

One of the key safety standards for LFP batteries is the UN38.3 certification, which is mandatory for the transportation of lithium-ion batteries. This standard involves a series of tests, including altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge. These tests are designed to simulate various conditions that batteries may encounter during transportation and use.

In addition to UN38.3, the IEC 62133 standard is widely recognized for safety requirements for portable sealed secondary cells and batteries. This standard covers aspects such as construction, design, and safety performance under both normal and abnormal operating conditions. It includes tests for electrical, mechanical, and environmental safety.

For automotive applications, the SAE J2464 standard is particularly relevant. This standard provides guidelines for electric and hybrid vehicle battery systems, including safety criteria and test procedures. It addresses issues such as electrical isolation, thermal management, and crash safety.

The UL 1642 standard is another important safety benchmark for lithium batteries. It outlines requirements for testing and evaluating the safety of lithium batteries used in various products. This standard includes tests for electrical, mechanical, and environmental safety, as well as abuse conditions.

In the manufacturing process, adherence to ISO 9001 quality management standards is essential. While not specific to LFP batteries, this standard ensures consistent quality control throughout the production process, which is critical for battery safety.

As the technology evolves, safety standards are continuously updated to address new challenges and improvements in battery technology. For instance, recent updates have focused on enhancing safety measures for high-capacity batteries and fast-charging technologies. Manufacturers must stay abreast of these evolving standards to ensure compliance and maintain the highest safety levels in their LFP battery production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!