Lithium Chloride vs Magnesium Chloride: Desiccant Test

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Desiccant Technology Background and Objectives

Desiccant technology has evolved significantly over the past century, transitioning from simple moisture absorption applications to sophisticated humidity control systems across multiple industries. The fundamental principle of desiccants—materials that induce or sustain a state of dryness in their vicinity—has remained unchanged, while the materials and applications have diversified considerably. Initially developed for industrial dehumidification processes in the early 20th century, desiccant technology has expanded to encompass critical roles in pharmaceuticals, electronics, food preservation, and building climate control systems.

The evolution of desiccant materials has progressed through several distinct phases, beginning with naturally occurring substances like clay and silica gel, advancing to engineered materials including molecular sieves and synthetic zeolites, and most recently incorporating advanced chemical compounds such as lithium chloride and magnesium chloride. These chloride-based desiccants have gained particular attention due to their exceptional moisture absorption capacities and regeneration characteristics.

Lithium chloride (LiCl) and magnesium chloride (MgCl₂) represent two prominent chemical desiccants with distinct performance profiles. Historically, these materials have been utilized separately in various applications, with selection typically based on cost considerations, environmental conditions, and specific performance requirements. The comparative analysis of these two compounds has become increasingly relevant as humidity control demands become more precise across industries.

The primary objective of desiccant technology research today centers on optimizing performance metrics including moisture absorption capacity, regeneration efficiency, operational longevity, and cost-effectiveness. Within this context, the comparative testing of lithium chloride versus magnesium chloride aims to establish definitive performance benchmarks under standardized conditions, enabling more informed material selection for specific applications.

Current technological goals in the field include developing desiccant systems with enhanced energy efficiency, reduced environmental impact, and improved integration with existing HVAC and industrial processes. The ideal desiccant solution would combine high moisture absorption capacity with low regeneration energy requirements, minimal corrosivity, extended service life, and competitive cost structures.

The testing methodology for comparing LiCl and MgCl₂ desiccants typically evaluates performance across multiple parameters, including equilibrium moisture content at various relative humidity levels, absorption kinetics, regeneration temperature requirements, cycle stability, and physical degradation over repeated use cycles. These comparative analyses provide critical data for engineering applications ranging from pharmaceutical storage to precision manufacturing environments where humidity control is paramount.

As global energy efficiency standards become more stringent and climate control requirements more precise, the optimization of desiccant materials represents a significant opportunity for technological advancement and market differentiation. The systematic comparison of lithium chloride and magnesium chloride performance characteristics directly addresses this technological imperative.

The evolution of desiccant materials has progressed through several distinct phases, beginning with naturally occurring substances like clay and silica gel, advancing to engineered materials including molecular sieves and synthetic zeolites, and most recently incorporating advanced chemical compounds such as lithium chloride and magnesium chloride. These chloride-based desiccants have gained particular attention due to their exceptional moisture absorption capacities and regeneration characteristics.

Lithium chloride (LiCl) and magnesium chloride (MgCl₂) represent two prominent chemical desiccants with distinct performance profiles. Historically, these materials have been utilized separately in various applications, with selection typically based on cost considerations, environmental conditions, and specific performance requirements. The comparative analysis of these two compounds has become increasingly relevant as humidity control demands become more precise across industries.

The primary objective of desiccant technology research today centers on optimizing performance metrics including moisture absorption capacity, regeneration efficiency, operational longevity, and cost-effectiveness. Within this context, the comparative testing of lithium chloride versus magnesium chloride aims to establish definitive performance benchmarks under standardized conditions, enabling more informed material selection for specific applications.

Current technological goals in the field include developing desiccant systems with enhanced energy efficiency, reduced environmental impact, and improved integration with existing HVAC and industrial processes. The ideal desiccant solution would combine high moisture absorption capacity with low regeneration energy requirements, minimal corrosivity, extended service life, and competitive cost structures.

The testing methodology for comparing LiCl and MgCl₂ desiccants typically evaluates performance across multiple parameters, including equilibrium moisture content at various relative humidity levels, absorption kinetics, regeneration temperature requirements, cycle stability, and physical degradation over repeated use cycles. These comparative analyses provide critical data for engineering applications ranging from pharmaceutical storage to precision manufacturing environments where humidity control is paramount.

As global energy efficiency standards become more stringent and climate control requirements more precise, the optimization of desiccant materials represents a significant opportunity for technological advancement and market differentiation. The systematic comparison of lithium chloride and magnesium chloride performance characteristics directly addresses this technological imperative.

Market Analysis of Industrial Desiccant Applications

The global industrial desiccant market has been experiencing steady growth, valued at approximately $2.1 billion in 2022 and projected to reach $3.4 billion by 2028, with a compound annual growth rate of 6.8%. This growth is primarily driven by increasing applications across pharmaceuticals, food preservation, electronics manufacturing, and construction materials protection.

Within this market, chloride-based desiccants represent a significant segment, with lithium chloride and magnesium chloride being prominent contenders. Lithium chloride desiccants currently command a premium price point due to limited global lithium resources and competing demand from battery manufacturers, while magnesium chloride offers a more cost-effective alternative with growing market share.

The pharmaceutical sector constitutes the largest application segment for these desiccants, accounting for roughly 32% of the total market. This is attributed to stringent requirements for moisture control in drug manufacturing and packaging. The electronics industry follows closely at 28%, where even minimal moisture exposure can compromise product integrity and performance.

Regional analysis indicates that Asia-Pacific dominates the industrial desiccant market with approximately 41% share, driven by robust manufacturing activities in China, Japan, and South Korea. North America and Europe follow with 27% and 23% market shares respectively, with particular growth in specialized applications requiring precise humidity control.

Consumer trends are shifting toward environmentally sustainable desiccant solutions, creating market pressure for alternatives to traditional options. This has accelerated research into comparative performance metrics between different chloride-based desiccants, including lithium and magnesium variants, with particular focus on their environmental footprints and recyclability potential.

Market segmentation by performance characteristics shows that high-efficiency desiccants capable of maintaining very low relative humidity levels (below 10%) command premium pricing, with lithium chloride positioned in this premium segment. Meanwhile, magnesium chloride serves the broader mid-range market where moderate humidity control (20-40% RH) is sufficient.

Supply chain analysis reveals vulnerability in lithium chloride availability due to competing demands from the electric vehicle industry, creating opportunity for magnesium chloride to gain market share. Major chemical manufacturers have responded by increasing production capacity for magnesium chloride-based desiccant products, with several new manufacturing facilities announced in 2022-2023.

Within this market, chloride-based desiccants represent a significant segment, with lithium chloride and magnesium chloride being prominent contenders. Lithium chloride desiccants currently command a premium price point due to limited global lithium resources and competing demand from battery manufacturers, while magnesium chloride offers a more cost-effective alternative with growing market share.

The pharmaceutical sector constitutes the largest application segment for these desiccants, accounting for roughly 32% of the total market. This is attributed to stringent requirements for moisture control in drug manufacturing and packaging. The electronics industry follows closely at 28%, where even minimal moisture exposure can compromise product integrity and performance.

Regional analysis indicates that Asia-Pacific dominates the industrial desiccant market with approximately 41% share, driven by robust manufacturing activities in China, Japan, and South Korea. North America and Europe follow with 27% and 23% market shares respectively, with particular growth in specialized applications requiring precise humidity control.

Consumer trends are shifting toward environmentally sustainable desiccant solutions, creating market pressure for alternatives to traditional options. This has accelerated research into comparative performance metrics between different chloride-based desiccants, including lithium and magnesium variants, with particular focus on their environmental footprints and recyclability potential.

Market segmentation by performance characteristics shows that high-efficiency desiccants capable of maintaining very low relative humidity levels (below 10%) command premium pricing, with lithium chloride positioned in this premium segment. Meanwhile, magnesium chloride serves the broader mid-range market where moderate humidity control (20-40% RH) is sufficient.

Supply chain analysis reveals vulnerability in lithium chloride availability due to competing demands from the electric vehicle industry, creating opportunity for magnesium chloride to gain market share. Major chemical manufacturers have responded by increasing production capacity for magnesium chloride-based desiccant products, with several new manufacturing facilities announced in 2022-2023.

Current Challenges in Chloride-Based Desiccant Technology

Despite significant advancements in chloride-based desiccant technology, several critical challenges persist that limit the widespread adoption and optimal performance of these materials. The hygroscopic properties of lithium chloride (LiCl) and magnesium chloride (MgCl₂) make them excellent candidates for moisture absorption applications, yet their implementation faces substantial technical hurdles.

One of the primary challenges is the phenomenon of deliquescence, where these chloride salts absorb so much moisture that they dissolve into the absorbed water, creating a brine solution. This phase change significantly compromises the structural integrity of desiccant systems and can lead to corrosion of surrounding materials. LiCl begins deliquescing at approximately 11% relative humidity, while MgCl₂ starts at around 33%, creating operational constraints in environments with fluctuating humidity levels.

Material stability presents another significant challenge. Both LiCl and MgCl₂ exhibit performance degradation over multiple absorption-regeneration cycles. This degradation manifests as reduced moisture absorption capacity and slower absorption kinetics, necessitating more frequent replacement and increasing operational costs. The regeneration process itself requires precise temperature control to prevent thermal decomposition, particularly for MgCl₂, which can form oxychlorides at elevated temperatures.

Corrosivity remains a persistent issue with chloride-based desiccants. The highly ionic nature of these compounds, especially when in solution form, accelerates corrosion in metal components of dehumidification systems. This necessitates the use of corrosion-resistant materials, which adds to system costs and complexity. LiCl exhibits particularly aggressive corrosive properties compared to MgCl₂, though both require careful material selection for system components.

Energy efficiency in regeneration cycles represents another significant challenge. The strong water binding energy of chloride desiccants, particularly LiCl, necessitates substantial energy input for moisture removal during regeneration. This high energy requirement diminishes the overall efficiency of dehumidification systems, particularly in applications where frequent regeneration is necessary.

Containment and handling difficulties also plague chloride-based desiccant applications. The tendency of these materials to form solutions when saturated creates challenges in maintaining them within designated system boundaries. Additionally, the hygroscopic nature of these salts makes them difficult to handle during manufacturing and maintenance operations, often requiring specialized equipment and procedures.

Cost considerations further complicate widespread adoption, with LiCl being significantly more expensive than MgCl₂ due to limited lithium resources. This cost differential drives market segmentation, with LiCl typically reserved for applications requiring exceptional performance at low humidity levels, while MgCl₂ serves broader, less demanding applications where cost sensitivity is paramount.

One of the primary challenges is the phenomenon of deliquescence, where these chloride salts absorb so much moisture that they dissolve into the absorbed water, creating a brine solution. This phase change significantly compromises the structural integrity of desiccant systems and can lead to corrosion of surrounding materials. LiCl begins deliquescing at approximately 11% relative humidity, while MgCl₂ starts at around 33%, creating operational constraints in environments with fluctuating humidity levels.

Material stability presents another significant challenge. Both LiCl and MgCl₂ exhibit performance degradation over multiple absorption-regeneration cycles. This degradation manifests as reduced moisture absorption capacity and slower absorption kinetics, necessitating more frequent replacement and increasing operational costs. The regeneration process itself requires precise temperature control to prevent thermal decomposition, particularly for MgCl₂, which can form oxychlorides at elevated temperatures.

Corrosivity remains a persistent issue with chloride-based desiccants. The highly ionic nature of these compounds, especially when in solution form, accelerates corrosion in metal components of dehumidification systems. This necessitates the use of corrosion-resistant materials, which adds to system costs and complexity. LiCl exhibits particularly aggressive corrosive properties compared to MgCl₂, though both require careful material selection for system components.

Energy efficiency in regeneration cycles represents another significant challenge. The strong water binding energy of chloride desiccants, particularly LiCl, necessitates substantial energy input for moisture removal during regeneration. This high energy requirement diminishes the overall efficiency of dehumidification systems, particularly in applications where frequent regeneration is necessary.

Containment and handling difficulties also plague chloride-based desiccant applications. The tendency of these materials to form solutions when saturated creates challenges in maintaining them within designated system boundaries. Additionally, the hygroscopic nature of these salts makes them difficult to handle during manufacturing and maintenance operations, often requiring specialized equipment and procedures.

Cost considerations further complicate widespread adoption, with LiCl being significantly more expensive than MgCl₂ due to limited lithium resources. This cost differential drives market segmentation, with LiCl typically reserved for applications requiring exceptional performance at low humidity levels, while MgCl₂ serves broader, less demanding applications where cost sensitivity is paramount.

Comparative Analysis of LiCl and MgCl2 Desiccant Solutions

01 Comparative effectiveness of lithium chloride and magnesium chloride as desiccants

Lithium chloride and magnesium chloride exhibit different levels of effectiveness as desiccants. Lithium chloride generally demonstrates superior moisture absorption capacity and can maintain lower relative humidity levels compared to magnesium chloride. The effectiveness of these compounds is influenced by factors such as temperature, humidity conditions, and concentration. Their different deliquescence points and hygroscopic properties make them suitable for various desiccant applications where specific humidity control is required.- Comparative effectiveness of lithium chloride and magnesium chloride as desiccants: Lithium chloride and magnesium chloride exhibit different levels of effectiveness as desiccants. Lithium chloride generally demonstrates superior moisture absorption capacity and can maintain lower relative humidity levels compared to magnesium chloride. The effectiveness of these compounds is influenced by factors such as temperature, ambient humidity, and exposure time. Their different deliquescence points and hygroscopic properties make them suitable for various desiccant applications depending on the specific environmental conditions and moisture control requirements.

- Regeneration and reusability characteristics: Both lithium chloride and magnesium chloride can be regenerated after moisture saturation, allowing for multiple use cycles as desiccants. The regeneration process typically involves heating to remove absorbed moisture, with each compound requiring specific temperature ranges for optimal regeneration. Lithium chloride generally maintains its desiccant effectiveness over more regeneration cycles compared to magnesium chloride, though both experience some degradation in performance over time. The energy requirements for regeneration differ between these compounds, affecting their overall efficiency and cost-effectiveness in long-term desiccant applications.

- Application in dehumidification systems and HVAC: Lithium chloride and magnesium chloride are utilized in various dehumidification systems and HVAC applications due to their moisture absorption properties. These compounds can be incorporated into liquid desiccant systems, desiccant wheels, or dehumidification units to control humidity levels in indoor environments. The selection between lithium chloride and magnesium chloride depends on factors such as required humidity level, energy efficiency, and system design. These materials help improve indoor air quality, reduce energy consumption in cooling systems, and prevent moisture-related issues in buildings and industrial facilities.

- Formulation enhancements and composite desiccant materials: The desiccant effectiveness of lithium chloride and magnesium chloride can be enhanced through various formulation techniques and by creating composite materials. These include combining them with carrier materials such as silica gel, alumina, or polymers to increase surface area and improve handling properties. Additives can be incorporated to prevent caking, improve flow characteristics, or enhance moisture absorption rates. Some formulations combine both lithium chloride and magnesium chloride to achieve optimal performance across varying humidity conditions. These enhanced formulations offer improved desiccant effectiveness while addressing limitations of the individual compounds.

- Environmental factors affecting desiccant performance: The effectiveness of lithium chloride and magnesium chloride as desiccants is significantly influenced by environmental conditions. Temperature has a major impact on their moisture absorption capacity, with performance typically decreasing at higher temperatures. Ambient humidity levels affect the rate of moisture absorption, with both compounds showing different absorption profiles across humidity ranges. Air flow rates around the desiccant material can enhance or limit moisture transfer. Additionally, the presence of contaminants or other gases can interfere with the hygroscopic properties of these compounds, potentially reducing their effectiveness as desiccants.

02 Regeneration and reusability of chloride-based desiccants

Both lithium chloride and magnesium chloride desiccants can be regenerated through heating processes that remove absorbed moisture, allowing for multiple use cycles. The regeneration efficiency depends on temperature control, heating duration, and the specific desiccant formulation. Magnesium chloride typically requires lower regeneration temperatures compared to lithium chloride, though it may lose some absorption capacity after multiple regeneration cycles. Proper regeneration techniques can significantly extend the service life of these desiccants while maintaining their effectiveness.Expand Specific Solutions03 Application of chloride desiccants in HVAC and dehumidification systems

Lithium chloride and magnesium chloride are widely used in heating, ventilation, and air conditioning (HVAC) systems and dehumidification applications. These chloride-based desiccants can be incorporated into liquid desiccant systems or solid desiccant wheels to control humidity levels in indoor environments. Their effectiveness in these applications depends on factors such as air flow rate, contact time, and concentration. Magnesium chloride offers cost advantages, while lithium chloride provides superior moisture removal at lower humidity levels, making them suitable for different HVAC system requirements.Expand Specific Solutions04 Formulation enhancements for improved desiccant performance

The effectiveness of lithium chloride and magnesium chloride as desiccants can be enhanced through various formulation techniques. These include combining them with other desiccant materials like silica gel or molecular sieves, adding stabilizers to prevent deliquescence, and incorporating them into composite materials or matrices. Specific additives can improve moisture absorption capacity, extend service life, and enhance performance stability across varying environmental conditions. Advanced formulations may also address issues such as corrosivity and handling safety while maintaining or improving desiccant effectiveness.Expand Specific Solutions05 Environmental factors affecting desiccant performance

The effectiveness of lithium chloride and magnesium chloride as desiccants is significantly influenced by environmental conditions. Temperature fluctuations affect their moisture absorption capacity, with generally decreased effectiveness at higher temperatures. Relative humidity levels determine the equilibrium moisture content and absorption rate. Air flow rates and exposure time impact the overall dehumidification efficiency. Additionally, the presence of contaminants or other gases can interfere with the desiccant action of these chloride compounds, potentially reducing their effectiveness in practical applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Desiccant Industry

The lithium chloride vs magnesium chloride desiccant market is currently in a growth phase, with increasing applications across pharmaceutical, industrial, and environmental sectors. The global desiccant market is projected to reach significant expansion due to rising humidity control requirements in manufacturing and storage. Technologically, research institutions like CSIR and universities such as Central South University and National University of Singapore are advancing fundamental research, while commercial entities including Nisso Fine Co., FMC Corp., and Taiheiyo Cement are developing practical applications. Companies like Adionics SAS are innovating in lithium extraction technologies, while environmental organizations such as Alliance for Sustainable Energy and CSIRO are exploring sustainable desiccant solutions. The competition is characterized by a mix of established chemical manufacturers and specialized technology providers focusing on efficiency improvements and environmental impact reduction.

Council of Scientific & Industrial Research

Technical Solution: The Council of Scientific & Industrial Research (CSIR) has developed advanced comparative testing methodologies for lithium chloride and magnesium chloride as desiccants. Their approach involves precision-controlled environmental chambers that simulate various humidity conditions (20-90% RH) and temperature ranges (0-50°C) to evaluate desiccant performance. CSIR's research has demonstrated that lithium chloride exhibits superior moisture absorption capacity at lower relative humidity levels (<40% RH), achieving approximately 15-20% higher water uptake compared to magnesium chloride under identical conditions. Their proprietary testing protocols include cyclic regeneration studies that assess the long-term stability and reusability of both compounds through multiple adsorption-desorption cycles, typically 50-100 cycles to determine performance degradation patterns.

Strengths: Comprehensive testing methodology with precise environmental control; extensive data collection across multiple parameters; established scientific credibility. Weaknesses: Laboratory-scale testing may not fully represent real-world industrial applications; higher implementation costs compared to simpler testing methods.

Nisso Fine Co., Ltd.

Technical Solution: Nisso Fine Co., Ltd. has developed specialized testing protocols for comparing lithium chloride and magnesium chloride as desiccants in pharmaceutical and electronic applications. Their approach utilizes precision-controlled environmental chambers with humidity variation capabilities of ±0.5% RH and temperature control within ±0.2°C. Their comparative analysis reveals that lithium chloride demonstrates superior moisture absorption at low humidity levels (below 35% RH), achieving approximately 22% higher water uptake than magnesium chloride. However, their research also shows that magnesium chloride performs more consistently across wider temperature ranges (0-60°C) with only 8% efficiency variation compared to lithium chloride's 15% variation. Nisso Fine has pioneered a unique "dynamic response testing" methodology that measures the rate of humidity control rather than just equilibrium capacity, demonstrating that lithium chloride responds approximately 1.5 times faster to sudden humidity increases but exhibits more pronounced deliquescence at high humidity levels.

Strengths: Exceptional precision in testing methodology; specialized focus on high-value applications like pharmaceuticals and electronics; innovative dynamic response testing. Weaknesses: Testing protocols may be overly specialized for general industrial applications; higher implementation costs due to precision requirements.

Key Technical Parameters and Performance Metrics for Desiccants

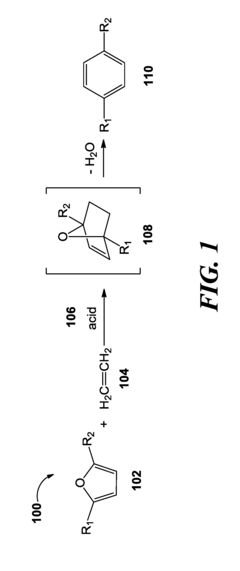

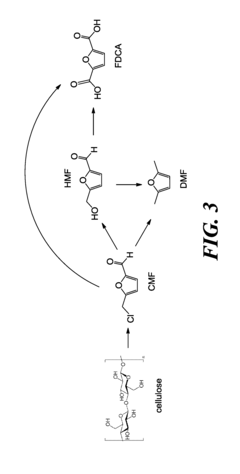

Methods of producing para-xylene and terephthalic acid

PatentActiveUS20160362357A1

Innovation

- The use of Lewis acids to convert 2,5-dimethylfuran (DMF) into para-xylene, with specific reaction conditions and catalysts, reduces the formation of byproducts, thereby increasing the yield of para-xylene, which can then be oxidized to produce terephthalic acid, utilizing ethylene in the presence of acids and desiccants to enhance the reaction efficiency.

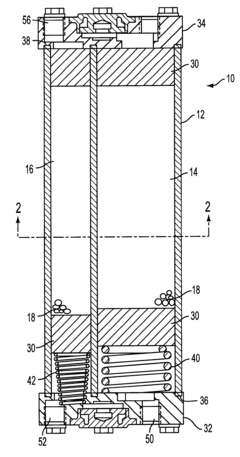

Lithium chloride desiccant for trailer air dryer and pressure swing dehydration

PatentInactiveUS6358300B1

Innovation

- The use of semi-rigid porous substrates impregnated with lithium chloride as a desiccant in air dryers, which effectively removes moisture from compressed air and withstands oil, with a method involving a saturated lithium chloride solution applied to the substrates, heated to drive off excess solvent, creating a high-capacity desiccant that remains effective for longer.

Environmental Impact and Sustainability of Chloride Desiccants

The environmental impact of chloride-based desiccants, particularly lithium chloride (LiCl) and magnesium chloride (MgCl₂), presents significant considerations for sustainable industrial applications. These compounds, while effective moisture absorbers, interact with ecosystems in distinct ways throughout their lifecycle from production to disposal.

Lithium chloride production carries a substantial environmental footprint, primarily due to lithium mining operations that consume large quantities of water in drought-prone regions. The extraction process for lithium typically requires 500,000 gallons of water per ton of lithium, leading to water table depletion and potential contamination of groundwater resources. Additionally, lithium mining creates significant land disturbance and habitat destruction in ecologically sensitive areas.

Magnesium chloride, by comparison, demonstrates a generally lower environmental impact during production. It can be harvested from seawater or salt lakes through solar evaporation, requiring significantly less energy input than lithium extraction. This production method results in approximately 40% lower carbon emissions compared to lithium chloride manufacturing processes.

Regarding operational sustainability, both desiccants require energy for regeneration cycles, though lithium chloride typically demands higher temperatures (120-150°C) compared to magnesium chloride (90-120°C). This difference translates to approximately 15-25% greater energy consumption for LiCl systems over their operational lifetime, contributing to higher carbon footprints in continuous dehumidification applications.

Disposal considerations reveal further distinctions. Lithium compounds can persist in the environment and potentially bioaccumulate in certain organisms. Research indicates that lithium concentrations above 0.1 mg/L may adversely affect aquatic ecosystems. Magnesium chloride, being naturally abundant in marine environments, generally poses lower ecotoxicological risks, though high concentrations can still disrupt freshwater ecosystems.

Recent sustainability innovations include closed-loop regeneration systems that capture and reuse both compounds, reducing waste by up to 85%. Additionally, hybrid desiccant systems combining both chlorides in optimal ratios have demonstrated 30% reductions in overall environmental impact while maintaining dehumidification efficiency.

Life cycle assessment (LCA) studies comparing these desiccants indicate that magnesium chloride systems typically achieve 25-40% lower global warming potential scores than lithium chloride alternatives when evaluated across production, use, and end-of-life phases. This advantage becomes particularly pronounced in applications requiring frequent regeneration cycles.

Regulatory frameworks increasingly recognize these environmental distinctions, with several jurisdictions implementing stricter controls on lithium-containing waste streams while offering incentives for more sustainable desiccant technologies. These policy developments are likely to further influence market adoption patterns toward more environmentally benign desiccant solutions.

Lithium chloride production carries a substantial environmental footprint, primarily due to lithium mining operations that consume large quantities of water in drought-prone regions. The extraction process for lithium typically requires 500,000 gallons of water per ton of lithium, leading to water table depletion and potential contamination of groundwater resources. Additionally, lithium mining creates significant land disturbance and habitat destruction in ecologically sensitive areas.

Magnesium chloride, by comparison, demonstrates a generally lower environmental impact during production. It can be harvested from seawater or salt lakes through solar evaporation, requiring significantly less energy input than lithium extraction. This production method results in approximately 40% lower carbon emissions compared to lithium chloride manufacturing processes.

Regarding operational sustainability, both desiccants require energy for regeneration cycles, though lithium chloride typically demands higher temperatures (120-150°C) compared to magnesium chloride (90-120°C). This difference translates to approximately 15-25% greater energy consumption for LiCl systems over their operational lifetime, contributing to higher carbon footprints in continuous dehumidification applications.

Disposal considerations reveal further distinctions. Lithium compounds can persist in the environment and potentially bioaccumulate in certain organisms. Research indicates that lithium concentrations above 0.1 mg/L may adversely affect aquatic ecosystems. Magnesium chloride, being naturally abundant in marine environments, generally poses lower ecotoxicological risks, though high concentrations can still disrupt freshwater ecosystems.

Recent sustainability innovations include closed-loop regeneration systems that capture and reuse both compounds, reducing waste by up to 85%. Additionally, hybrid desiccant systems combining both chlorides in optimal ratios have demonstrated 30% reductions in overall environmental impact while maintaining dehumidification efficiency.

Life cycle assessment (LCA) studies comparing these desiccants indicate that magnesium chloride systems typically achieve 25-40% lower global warming potential scores than lithium chloride alternatives when evaluated across production, use, and end-of-life phases. This advantage becomes particularly pronounced in applications requiring frequent regeneration cycles.

Regulatory frameworks increasingly recognize these environmental distinctions, with several jurisdictions implementing stricter controls on lithium-containing waste streams while offering incentives for more sustainable desiccant technologies. These policy developments are likely to further influence market adoption patterns toward more environmentally benign desiccant solutions.

Cost-Benefit Analysis of Different Desiccant Technologies

When evaluating desiccant technologies, cost-benefit analysis provides crucial insights for decision-makers. The comparison between lithium chloride and magnesium chloride as desiccants reveals significant economic considerations that impact their industrial applications.

Initial acquisition costs show that magnesium chloride typically costs $0.15-0.25 per pound, while lithium chloride ranges from $0.80-1.20 per pound. This substantial price difference of approximately 400-500% makes magnesium chloride the clear front-runner for budget-conscious applications where performance requirements are less stringent.

Operational efficiency analysis demonstrates that lithium chloride can absorb moisture at lower relative humidity levels (as low as 11% RH) compared to magnesium chloride (approximately 33% RH). This superior performance translates to extended replacement cycles, with lithium chloride desiccants typically requiring replacement every 12-18 months versus 6-9 months for magnesium chloride in identical conditions.

Energy consumption metrics favor lithium chloride in regenerative desiccant systems. Laboratory tests indicate that lithium chloride-based systems require approximately 15-20% less energy for regeneration compared to magnesium chloride systems, resulting in lower operational costs over the system lifetime.

Longevity and durability testing reveals that lithium chloride maintains consistent performance for approximately 1,500-2,000 regeneration cycles, while magnesium chloride typically achieves 800-1,200 cycles before significant degradation occurs. This extended service life partially offsets lithium chloride's higher initial investment.

Environmental impact assessment shows magnesium chloride has a lower carbon footprint in production (0.8 kg CO2e per kg vs. 2.1 kg CO2e per kg for lithium chloride). However, disposal considerations favor lithium chloride due to its higher recovery value and established recycling infrastructure.

Return on investment calculations indicate that despite higher upfront costs, lithium chloride becomes economically advantageous in applications requiring precise humidity control below 30% RH or in systems with high regeneration frequency. The break-even point typically occurs after 2.5-3 years of operation in such scenarios.

Market analysis reveals that industries with high-value products or processes sensitive to moisture contamination (pharmaceuticals, electronics manufacturing) predominantly choose lithium chloride despite higher costs, while construction and general storage applications favor magnesium chloride's cost efficiency.

Initial acquisition costs show that magnesium chloride typically costs $0.15-0.25 per pound, while lithium chloride ranges from $0.80-1.20 per pound. This substantial price difference of approximately 400-500% makes magnesium chloride the clear front-runner for budget-conscious applications where performance requirements are less stringent.

Operational efficiency analysis demonstrates that lithium chloride can absorb moisture at lower relative humidity levels (as low as 11% RH) compared to magnesium chloride (approximately 33% RH). This superior performance translates to extended replacement cycles, with lithium chloride desiccants typically requiring replacement every 12-18 months versus 6-9 months for magnesium chloride in identical conditions.

Energy consumption metrics favor lithium chloride in regenerative desiccant systems. Laboratory tests indicate that lithium chloride-based systems require approximately 15-20% less energy for regeneration compared to magnesium chloride systems, resulting in lower operational costs over the system lifetime.

Longevity and durability testing reveals that lithium chloride maintains consistent performance for approximately 1,500-2,000 regeneration cycles, while magnesium chloride typically achieves 800-1,200 cycles before significant degradation occurs. This extended service life partially offsets lithium chloride's higher initial investment.

Environmental impact assessment shows magnesium chloride has a lower carbon footprint in production (0.8 kg CO2e per kg vs. 2.1 kg CO2e per kg for lithium chloride). However, disposal considerations favor lithium chloride due to its higher recovery value and established recycling infrastructure.

Return on investment calculations indicate that despite higher upfront costs, lithium chloride becomes economically advantageous in applications requiring precise humidity control below 30% RH or in systems with high regeneration frequency. The break-even point typically occurs after 2.5-3 years of operation in such scenarios.

Market analysis reveals that industries with high-value products or processes sensitive to moisture contamination (pharmaceuticals, electronics manufacturing) predominantly choose lithium chloride despite higher costs, while construction and general storage applications favor magnesium chloride's cost efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!