Lithium Hydroxide Handling In High-Humidity Environments

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Hydroxide Technology Background and Objectives

Lithium hydroxide (LiOH) has emerged as a critical material in the global transition toward sustainable energy systems, particularly in the lithium-ion battery industry. The compound's history dates back to the early 20th century, but its significance has grown exponentially in recent decades with the rise of electric vehicles and renewable energy storage solutions. The evolution of lithium hydroxide technology has been characterized by continuous improvements in production methods, from traditional brine extraction to more advanced spodumene conversion processes.

The hygroscopic nature of lithium hydroxide presents unique challenges in handling and storage, especially in high-humidity environments. This property, while intrinsic to its chemical structure, creates significant operational complexities across the supply chain. Historical approaches to managing these challenges have often relied on hermetic packaging and controlled environment facilities, which add substantial costs to production and logistics operations.

Current technological trends in lithium hydroxide handling are moving toward innovative material science solutions that can mitigate moisture absorption while maintaining the compound's essential properties for battery applications. These developments are crucial as the global battery industry expands into regions with varying climatic conditions, including high-humidity environments in Southeast Asia and other emerging manufacturing hubs.

The primary technical objective in this field is to develop cost-effective methods for handling lithium hydroxide that minimize degradation and contamination in high-humidity conditions without compromising production efficiency or end-product quality. This includes exploring novel coating technologies, advanced packaging materials, and process engineering solutions that can function reliably across diverse environmental conditions.

Another significant goal is to establish standardized protocols for humidity control during transportation, storage, and processing stages. These standards must balance practical implementation with the stringent purity requirements of high-performance battery applications, where even minor contamination can significantly impact cell performance and longevity.

Looking forward, the technology roadmap for lithium hydroxide handling must address the anticipated growth in global demand, which is projected to increase by over 300% by 2030. This expansion necessitates scalable solutions that can be implemented across different geographical regions and manufacturing environments while maintaining consistent quality standards.

The intersection of lithium hydroxide handling technology with broader sustainability goals also presents important objectives, including reducing energy consumption in climate-controlled storage facilities and developing recyclable or biodegradable packaging solutions that maintain effective moisture barriers. These environmental considerations are becoming increasingly central to technology development in this field.

The hygroscopic nature of lithium hydroxide presents unique challenges in handling and storage, especially in high-humidity environments. This property, while intrinsic to its chemical structure, creates significant operational complexities across the supply chain. Historical approaches to managing these challenges have often relied on hermetic packaging and controlled environment facilities, which add substantial costs to production and logistics operations.

Current technological trends in lithium hydroxide handling are moving toward innovative material science solutions that can mitigate moisture absorption while maintaining the compound's essential properties for battery applications. These developments are crucial as the global battery industry expands into regions with varying climatic conditions, including high-humidity environments in Southeast Asia and other emerging manufacturing hubs.

The primary technical objective in this field is to develop cost-effective methods for handling lithium hydroxide that minimize degradation and contamination in high-humidity conditions without compromising production efficiency or end-product quality. This includes exploring novel coating technologies, advanced packaging materials, and process engineering solutions that can function reliably across diverse environmental conditions.

Another significant goal is to establish standardized protocols for humidity control during transportation, storage, and processing stages. These standards must balance practical implementation with the stringent purity requirements of high-performance battery applications, where even minor contamination can significantly impact cell performance and longevity.

Looking forward, the technology roadmap for lithium hydroxide handling must address the anticipated growth in global demand, which is projected to increase by over 300% by 2030. This expansion necessitates scalable solutions that can be implemented across different geographical regions and manufacturing environments while maintaining consistent quality standards.

The intersection of lithium hydroxide handling technology with broader sustainability goals also presents important objectives, including reducing energy consumption in climate-controlled storage facilities and developing recyclable or biodegradable packaging solutions that maintain effective moisture barriers. These environmental considerations are becoming increasingly central to technology development in this field.

Market Analysis for Humidity-Resistant Lithium Hydroxide

The global market for lithium hydroxide has experienced significant growth in recent years, primarily driven by the expanding electric vehicle (EV) industry. As a critical component in the production of high-nickel content cathode materials for lithium-ion batteries, lithium hydroxide demand is projected to reach 246,000 tons by 2025, representing a compound annual growth rate (CAGR) of 25.3% from 2020 levels.

Humidity-resistant lithium hydroxide represents an emerging segment within this market, addressing a crucial pain point in the supply chain. Traditional lithium hydroxide is highly hygroscopic, readily absorbing moisture from the air and forming monohydrate or solutions when exposed to humid environments. This property creates substantial challenges in storage, transportation, and handling, particularly in regions with high ambient humidity.

The market for humidity-resistant formulations is particularly strong in Southeast Asia, coastal China, and other high-humidity manufacturing hubs where battery production is concentrated. These regions typically experience relative humidity levels exceeding 70% throughout much of the year, creating significant operational challenges for battery manufacturers and material handlers.

Battery manufacturers represent the primary demand driver, accounting for approximately 80% of lithium hydroxide consumption. These companies face increased production costs due to the special handling requirements of conventional lithium hydroxide, including climate-controlled storage facilities, specialized packaging, and additional processing steps to remove absorbed moisture.

Market research indicates that battery producers are willing to pay a premium of 15-20% for humidity-resistant lithium hydroxide formulations that maintain stability in environments with relative humidity up to 85%. This premium pricing reflects the significant downstream cost savings in handling, storage, and processing.

The competitive landscape remains relatively underdeveloped, with few commercial solutions currently available. Major lithium producers including Albemarle, SQM, and Ganfeng Lithium have initiated research programs but have not yet brought comprehensive solutions to market at scale.

Market penetration for humidity-resistant formulations currently stands at less than 5% of total lithium hydroxide sales, indicating substantial growth potential. Early adopters have primarily been high-end battery manufacturers supplying the premium EV segment, where production efficiency and material consistency justify the higher material costs.

Regional analysis shows particularly strong demand growth in battery manufacturing hubs across China, South Korea, and emerging production centers in Southeast Asia. These markets are expected to drive initial adoption due to their challenging climatic conditions and high concentration of battery production facilities.

Humidity-resistant lithium hydroxide represents an emerging segment within this market, addressing a crucial pain point in the supply chain. Traditional lithium hydroxide is highly hygroscopic, readily absorbing moisture from the air and forming monohydrate or solutions when exposed to humid environments. This property creates substantial challenges in storage, transportation, and handling, particularly in regions with high ambient humidity.

The market for humidity-resistant formulations is particularly strong in Southeast Asia, coastal China, and other high-humidity manufacturing hubs where battery production is concentrated. These regions typically experience relative humidity levels exceeding 70% throughout much of the year, creating significant operational challenges for battery manufacturers and material handlers.

Battery manufacturers represent the primary demand driver, accounting for approximately 80% of lithium hydroxide consumption. These companies face increased production costs due to the special handling requirements of conventional lithium hydroxide, including climate-controlled storage facilities, specialized packaging, and additional processing steps to remove absorbed moisture.

Market research indicates that battery producers are willing to pay a premium of 15-20% for humidity-resistant lithium hydroxide formulations that maintain stability in environments with relative humidity up to 85%. This premium pricing reflects the significant downstream cost savings in handling, storage, and processing.

The competitive landscape remains relatively underdeveloped, with few commercial solutions currently available. Major lithium producers including Albemarle, SQM, and Ganfeng Lithium have initiated research programs but have not yet brought comprehensive solutions to market at scale.

Market penetration for humidity-resistant formulations currently stands at less than 5% of total lithium hydroxide sales, indicating substantial growth potential. Early adopters have primarily been high-end battery manufacturers supplying the premium EV segment, where production efficiency and material consistency justify the higher material costs.

Regional analysis shows particularly strong demand growth in battery manufacturing hubs across China, South Korea, and emerging production centers in Southeast Asia. These markets are expected to drive initial adoption due to their challenging climatic conditions and high concentration of battery production facilities.

Current Challenges in High-Humidity LiOH Storage

Lithium hydroxide (LiOH) storage in high-humidity environments presents significant technical challenges due to its hygroscopic nature and reactivity with moisture. When exposed to humid conditions, LiOH readily absorbs water from the atmosphere, forming lithium hydroxide monohydrate (LiOH·H₂O). This hydration process not only alters the chemical composition but also changes the physical properties of the material, leading to reduced purity, caking, and diminished effectiveness for its intended applications in battery production and other industrial processes.

Current industrial storage methods often prove inadequate in regions with relative humidity exceeding 40%. Traditional packaging materials such as polyethylene bags and standard metal containers fail to provide sufficient moisture barriers over extended periods. Tests conducted across various climate conditions show that even sealed containers can experience moisture ingress rates of 0.5-2% per month, depending on ambient conditions and container integrity.

The hydration reaction generates heat, creating potential safety hazards in large-scale storage facilities. Temperature increases of 10-15°C have been documented in improperly stored LiOH containers, which can accelerate further moisture absorption and potentially damage surrounding materials or equipment. This self-reinforcing degradation cycle represents a significant operational risk.

Material handling operations face additional complications as hydrated LiOH tends to form hard agglomerates that resist flow in processing equipment. These blockages necessitate frequent maintenance interventions, reducing production efficiency and increasing operational costs. Studies indicate that processing equipment handling partially hydrated LiOH requires maintenance cycles 30-40% more frequently than those handling properly preserved material.

Quality control becomes increasingly difficult as moisture content varies throughout stored material. This heterogeneity creates inconsistencies in downstream processes, particularly in battery cathode production where precise chemical compositions are critical for performance. Manufacturers report rejection rates increasing by 5-8% when using LiOH with variable hydration levels.

Economic implications are substantial, with degraded LiOH requiring either costly reprocessing or disposal. Reprocessing through dehydration consumes approximately 1.2-1.5 kWh of energy per kilogram of material, while disposal creates environmental concerns due to lithium's reactivity and potential groundwater impacts. The battery industry alone reports annual losses exceeding $50 million due to LiOH degradation during storage and transportation.

Regulatory compliance adds another layer of complexity, as transportation of partially hydrated LiOH may fall under different hazardous material classifications than anhydrous material. This regulatory uncertainty creates logistical challenges for global supply chains, particularly when shipping through regions with varying climate conditions and regulatory frameworks.

Current industrial storage methods often prove inadequate in regions with relative humidity exceeding 40%. Traditional packaging materials such as polyethylene bags and standard metal containers fail to provide sufficient moisture barriers over extended periods. Tests conducted across various climate conditions show that even sealed containers can experience moisture ingress rates of 0.5-2% per month, depending on ambient conditions and container integrity.

The hydration reaction generates heat, creating potential safety hazards in large-scale storage facilities. Temperature increases of 10-15°C have been documented in improperly stored LiOH containers, which can accelerate further moisture absorption and potentially damage surrounding materials or equipment. This self-reinforcing degradation cycle represents a significant operational risk.

Material handling operations face additional complications as hydrated LiOH tends to form hard agglomerates that resist flow in processing equipment. These blockages necessitate frequent maintenance interventions, reducing production efficiency and increasing operational costs. Studies indicate that processing equipment handling partially hydrated LiOH requires maintenance cycles 30-40% more frequently than those handling properly preserved material.

Quality control becomes increasingly difficult as moisture content varies throughout stored material. This heterogeneity creates inconsistencies in downstream processes, particularly in battery cathode production where precise chemical compositions are critical for performance. Manufacturers report rejection rates increasing by 5-8% when using LiOH with variable hydration levels.

Economic implications are substantial, with degraded LiOH requiring either costly reprocessing or disposal. Reprocessing through dehydration consumes approximately 1.2-1.5 kWh of energy per kilogram of material, while disposal creates environmental concerns due to lithium's reactivity and potential groundwater impacts. The battery industry alone reports annual losses exceeding $50 million due to LiOH degradation during storage and transportation.

Regulatory compliance adds another layer of complexity, as transportation of partially hydrated LiOH may fall under different hazardous material classifications than anhydrous material. This regulatory uncertainty creates logistical challenges for global supply chains, particularly when shipping through regions with varying climate conditions and regulatory frameworks.

Existing Moisture Protection Solutions for LiOH

01 Safe handling and storage procedures for lithium hydroxide

Lithium hydroxide requires specific handling and storage procedures due to its corrosive nature. These include using appropriate personal protective equipment, maintaining controlled environmental conditions, implementing proper ventilation systems, and utilizing specialized containers resistant to corrosion. Safety protocols should address emergency procedures for spills or exposure incidents, and regular training for personnel handling this hazardous material is essential.- Safe handling and storage procedures: Lithium hydroxide requires specific handling and storage procedures due to its corrosive nature. These include using appropriate personal protective equipment, maintaining controlled storage conditions, implementing proper ventilation systems, and following established safety protocols to minimize exposure risks. Proper containment systems and specialized equipment are essential for handling this caustic material safely in industrial settings.

- Processing methods for lithium hydroxide production: Various processing methods are employed for the production of lithium hydroxide from different lithium sources. These methods include precipitation techniques, ion exchange processes, electrolysis, and conversion from lithium carbonate. The processing methods focus on optimizing yield, purity, and energy efficiency while minimizing waste generation and environmental impact during manufacturing operations.

- Transportation and packaging solutions: Specialized transportation and packaging solutions are required for lithium hydroxide to ensure safety during transit. These include using UN-approved containers, implementing proper labeling and documentation, utilizing moisture-resistant packaging materials, and following hazardous material transport regulations. The packaging must prevent contact with incompatible materials and protect against environmental factors that could compromise the integrity of the material.

- Environmental and waste management considerations: Environmental and waste management considerations for lithium hydroxide handling include neutralization procedures for spills, proper disposal methods for contaminated materials, wastewater treatment processes, and recycling opportunities. These practices aim to minimize environmental impact, comply with regulatory requirements, and implement sustainable approaches to lithium hydroxide waste management throughout its lifecycle.

- Quality control and purification techniques: Quality control and purification techniques for lithium hydroxide involve analytical testing methods, impurity removal processes, crystallization techniques, and filtration systems. These approaches ensure that the lithium hydroxide meets required specifications for various applications, particularly for battery-grade material. Advanced purification methods help achieve the high purity levels necessary for use in lithium-ion battery production and other specialized applications.

02 Processing methods for lithium hydroxide production

Various processing methods are employed for lithium hydroxide production, including precipitation techniques, electrolysis, and conversion from lithium carbonate. These methods involve specific reaction conditions, temperature control, and purification steps to achieve desired product quality. Advanced processing techniques focus on improving yield, reducing impurities, and optimizing energy consumption during production.Expand Specific Solutions03 Equipment and machinery for lithium hydroxide handling

Specialized equipment and machinery are required for handling lithium hydroxide throughout its lifecycle. This includes corrosion-resistant pumps, valves, and transfer systems, automated packaging equipment designed to minimize exposure risks, and monitoring systems that detect potential leaks or environmental releases. Equipment design considerations focus on minimizing maintenance requirements and preventing contamination of the product.Expand Specific Solutions04 Environmental and waste management considerations

Handling lithium hydroxide requires comprehensive environmental and waste management strategies. These include containment systems to prevent environmental release, wastewater treatment processes to neutralize alkaline effluents, and recycling protocols for production waste. Environmental monitoring programs track potential impacts, while disposal methods comply with hazardous waste regulations to minimize ecological footprint.Expand Specific Solutions05 Quality control and purity standards for lithium hydroxide

Maintaining quality control and purity standards is crucial when handling lithium hydroxide for industrial applications. This involves implementing analytical testing protocols, establishing specification limits for impurities, and conducting regular sampling throughout the production process. Quality management systems ensure consistency across batches, while certification procedures verify compliance with industry standards and customer requirements.Expand Specific Solutions

Key Industry Players in Lithium Hydroxide Production

The lithium hydroxide handling in high-humidity environments market is in a growth phase, driven by expanding lithium-ion battery production for electric vehicles and energy storage systems. The global market size is projected to increase significantly as demand for high-purity lithium compounds rises. Technologically, the field is moderately mature but faces ongoing challenges in humidity control. Leading players include Ganfeng Lithium and Tianqi Lithium, who have developed advanced handling systems, while companies like PolyPlus Battery and BASF are innovating with protective technologies for moisture-sensitive materials. SK Innovation and Sumitomo Metal Mining are investing in improved processing methods, while research institutions like Qinghai Institute of Salt Lakes and Pukyong National University are advancing fundamental solutions for humidity-related degradation issues.

Ganfeng Lithium Group Co., Ltd.

Technical Solution: Ganfeng Lithium has developed a proprietary encapsulation technology for lithium hydroxide that utilizes hydrophobic polymer coatings to create a moisture-resistant barrier around LiOH particles. Their system incorporates specialized silane coupling agents that bond to the hydroxide surface while presenting hydrophobic groups outward. This technology maintains material integrity in environments with relative humidity up to 85% without significant degradation. Additionally, Ganfeng has implemented controlled atmosphere processing lines that maintain humidity below 5% during production and packaging phases. Their sealed drum technology incorporates desiccant liners and oxygen scavengers, extending shelf life in high-humidity regions. For industrial applications, they've developed specialized handling equipment with integrated dehumidification systems that create localized dry zones during material transfer operations.

Strengths: Superior moisture protection allowing for safer handling in tropical environments; integrated production-to-packaging solution minimizes exposure risks. Weaknesses: Higher production costs compared to standard lithium hydroxide; encapsulation process adds complexity to downstream processing in battery manufacturing.

BASF Corp.

Technical Solution: BASF has engineered an advanced lithium hydroxide handling system specifically designed for high-humidity environments called HydroShield™. This comprehensive solution combines material science and engineering controls to address moisture sensitivity challenges. The core technology involves a multi-layer protection approach where lithium hydroxide particles are treated with proprietary surface modifiers that create a temporary hydrophobic barrier without affecting electrochemical performance. BASF's system includes specialized packaging with humidity indicators and multi-layer moisture barriers that can maintain internal relative humidity below 10% even when external conditions exceed 90% RH. For processing facilities, they've developed modular dry rooms with redundant dehumidification systems that can maintain dewpoints below -40°C while accommodating personnel and material movement. Their automated handling equipment incorporates nitrogen purging systems that create protective atmospheres during transfer operations, effectively preventing moisture ingress during the most vulnerable handling phases.

Strengths: Comprehensive end-to-end solution from production to application; surface modification technology doesn't compromise material purity. Weaknesses: Requires significant capital investment for full implementation; system complexity necessitates specialized training for operational personnel.

Critical Patents in Hygroscopic Material Handling

Method for manufacturing lithium hydroxide powder, method for manufacturing positive electrode active material for lithium secondary cell, and package

PatentWO2019168110A1

Innovation

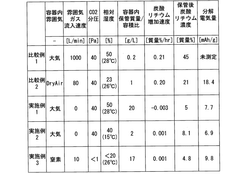

- A method involving the pulverization of lithium hydroxide to produce powder with controlled particle size, followed by storage in an airtight container with low carbon dioxide partial pressure and relative humidity, and using a package with low oxygen permeability to minimize carbonation, ensuring the lithium hydroxide powder has a low lithium carbonate content.

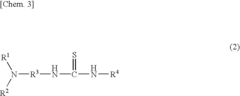

Method for stabilizing carbodiimide derivative and stabilized composition thereof

PatentInactiveUS20100016634A1

Innovation

- Maintaining carbodiimide derivatives in an atmosphere with a molecular oxygen concentration of 3 vol % or less and co-presence of antioxidants, N-oxyl compounds, sulfur compounds, amines, or Lewis acids to enhance stability, allowing for effective handling and storage on a commercial scale.

Environmental Impact Assessment of LiOH Storage Methods

The environmental impact of lithium hydroxide storage methods is a critical consideration for industries utilizing this compound, particularly in high-humidity environments where special handling precautions are necessary. Traditional storage methods often involve plastic or metal containers that, while effective for short-term storage, may contribute to environmental degradation through microplastic pollution or metal contamination when improperly disposed of.

Storage facilities for lithium hydroxide typically require climate-controlled environments to prevent moisture absorption, necessitating significant energy consumption for dehumidification and temperature regulation. This energy demand contributes to greenhouse gas emissions, especially in regions where power generation relies heavily on fossil fuels. Studies indicate that a medium-sized LiOH storage facility can consume approximately 25-30% more energy in high-humidity regions compared to arid environments.

Water usage represents another environmental concern, as some storage methods incorporate water barriers or water-based cooling systems. In high-humidity environments, these systems may require more frequent maintenance and water replacement, potentially leading to increased water consumption and wastewater generation containing trace amounts of lithium compounds.

Land use impacts vary significantly depending on storage method selection. Hermetically sealed storage systems typically require smaller footprints but more sophisticated infrastructure, while bulk storage methods may require larger areas with specialized containment systems to prevent environmental contamination. The construction of these facilities often involves land clearing and habitat disruption, particularly concerning when facilities are located near sensitive ecosystems.

Risk assessment studies have identified potential contamination scenarios from improper LiOH storage, including soil alkalinization and disruption of local aquatic ecosystems through pH alterations. These risks are amplified in high-humidity environments where the reactive nature of lithium hydroxide with moisture increases the likelihood of accidental releases.

Recent innovations in storage technology have focused on reducing environmental footprints through biodegradable packaging materials, energy-efficient climate control systems, and closed-loop water management. Life cycle assessments of these newer storage methods indicate potential reductions in environmental impact by 15-20% compared to conventional approaches, though implementation costs remain a barrier to widespread adoption.

Regulatory frameworks governing LiOH storage vary globally, with more stringent environmental protection measures typically found in Europe and North America. These regulations increasingly emphasize sustainable storage practices, including requirements for environmental impact assessments prior to facility construction and regular monitoring of potential environmental contaminants.

Storage facilities for lithium hydroxide typically require climate-controlled environments to prevent moisture absorption, necessitating significant energy consumption for dehumidification and temperature regulation. This energy demand contributes to greenhouse gas emissions, especially in regions where power generation relies heavily on fossil fuels. Studies indicate that a medium-sized LiOH storage facility can consume approximately 25-30% more energy in high-humidity regions compared to arid environments.

Water usage represents another environmental concern, as some storage methods incorporate water barriers or water-based cooling systems. In high-humidity environments, these systems may require more frequent maintenance and water replacement, potentially leading to increased water consumption and wastewater generation containing trace amounts of lithium compounds.

Land use impacts vary significantly depending on storage method selection. Hermetically sealed storage systems typically require smaller footprints but more sophisticated infrastructure, while bulk storage methods may require larger areas with specialized containment systems to prevent environmental contamination. The construction of these facilities often involves land clearing and habitat disruption, particularly concerning when facilities are located near sensitive ecosystems.

Risk assessment studies have identified potential contamination scenarios from improper LiOH storage, including soil alkalinization and disruption of local aquatic ecosystems through pH alterations. These risks are amplified in high-humidity environments where the reactive nature of lithium hydroxide with moisture increases the likelihood of accidental releases.

Recent innovations in storage technology have focused on reducing environmental footprints through biodegradable packaging materials, energy-efficient climate control systems, and closed-loop water management. Life cycle assessments of these newer storage methods indicate potential reductions in environmental impact by 15-20% compared to conventional approaches, though implementation costs remain a barrier to widespread adoption.

Regulatory frameworks governing LiOH storage vary globally, with more stringent environmental protection measures typically found in Europe and North America. These regulations increasingly emphasize sustainable storage practices, including requirements for environmental impact assessments prior to facility construction and regular monitoring of potential environmental contaminants.

Safety Protocols for Reactive Material Handling

Handling lithium hydroxide in high-humidity environments requires stringent safety protocols due to its reactive nature. The compound reacts vigorously with water, generating heat and potentially creating hazardous conditions. Personnel must wear appropriate personal protective equipment (PPE) including chemical-resistant gloves, safety goggles, face shields, and respiratory protection with particulate filters designed for alkaline materials.

Storage protocols must be rigorously enforced, keeping lithium hydroxide in hermetically sealed containers made of compatible materials such as high-density polyethylene or polypropylene. These containers should be stored in climate-controlled environments with humidity levels maintained below 40% to prevent moisture absorption. Temperature monitoring systems should be implemented to detect any exothermic reactions that might indicate water contamination.

Specialized handling procedures must be established for transfer operations. These include using dry inert gas purging systems when opening containers and implementing closed-system transfer mechanisms to minimize exposure to ambient air. Powder transfer should utilize vacuum systems with appropriate filtration rather than manual scooping or pouring methods that increase dust generation and exposure risks.

Emergency response protocols specific to lithium hydroxide incidents must be developed and regularly practiced. These should include procedures for containing spills using dry absorbents (never water), neutralization techniques using appropriate acidic solutions, and evacuation plans for cases where significant reactions occur. Specialized fire suppression agents must be readily available, as water-based extinguishers are contraindicated for lithium hydroxide fires.

Environmental monitoring represents another critical safety component. Real-time humidity sensors should be installed in handling areas with automated alarm systems that trigger when conditions exceed safe thresholds. Airborne particulate monitoring should also be implemented to detect fugitive emissions before they reach hazardous concentrations.

Training programs must be comprehensive and recurring, covering chemical properties of lithium hydroxide, recognition of reaction hazards, proper use of PPE, spill response procedures, and first aid for chemical exposures. Simulation exercises should be conducted quarterly to ensure response readiness, with particular emphasis on the unique challenges presented by high-humidity environments where reaction risks are elevated.

Documentation systems must track all handling events, near-misses, and incidents to facilitate continuous improvement of safety protocols. Regular audits should evaluate protocol compliance and effectiveness, with findings incorporated into updated procedures to address emerging risks or technological advances in handling methodologies.

Storage protocols must be rigorously enforced, keeping lithium hydroxide in hermetically sealed containers made of compatible materials such as high-density polyethylene or polypropylene. These containers should be stored in climate-controlled environments with humidity levels maintained below 40% to prevent moisture absorption. Temperature monitoring systems should be implemented to detect any exothermic reactions that might indicate water contamination.

Specialized handling procedures must be established for transfer operations. These include using dry inert gas purging systems when opening containers and implementing closed-system transfer mechanisms to minimize exposure to ambient air. Powder transfer should utilize vacuum systems with appropriate filtration rather than manual scooping or pouring methods that increase dust generation and exposure risks.

Emergency response protocols specific to lithium hydroxide incidents must be developed and regularly practiced. These should include procedures for containing spills using dry absorbents (never water), neutralization techniques using appropriate acidic solutions, and evacuation plans for cases where significant reactions occur. Specialized fire suppression agents must be readily available, as water-based extinguishers are contraindicated for lithium hydroxide fires.

Environmental monitoring represents another critical safety component. Real-time humidity sensors should be installed in handling areas with automated alarm systems that trigger when conditions exceed safe thresholds. Airborne particulate monitoring should also be implemented to detect fugitive emissions before they reach hazardous concentrations.

Training programs must be comprehensive and recurring, covering chemical properties of lithium hydroxide, recognition of reaction hazards, proper use of PPE, spill response procedures, and first aid for chemical exposures. Simulation exercises should be conducted quarterly to ensure response readiness, with particular emphasis on the unique challenges presented by high-humidity environments where reaction risks are elevated.

Documentation systems must track all handling events, near-misses, and incidents to facilitate continuous improvement of safety protocols. Regular audits should evaluate protocol compliance and effectiveness, with findings incorporated into updated procedures to address emerging risks or technological advances in handling methodologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!