Management of High Matrix Samples in ICP-MS

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ICP-MS Matrix Challenges and Objectives

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) has evolved significantly since its commercial introduction in the 1980s, establishing itself as a cornerstone analytical technique for elemental analysis. The technology offers exceptional sensitivity, multi-element capabilities, and wide dynamic range, making it invaluable across industries including environmental monitoring, pharmaceuticals, food safety, and semiconductor manufacturing. However, despite these advantages, the analysis of high matrix samples remains one of the most persistent challenges in ICP-MS applications.

High matrix samples—those containing elevated levels of dissolved solids, organic compounds, or complex biological materials—present significant analytical obstacles. These matrices can cause physical interferences such as clogging of sample introduction components and deposition on interface cones, leading to signal drift and reduced instrument stability. Additionally, they introduce spectral interferences through polyatomic ion formation and non-spectral matrix effects that suppress or enhance analyte signals, compromising measurement accuracy and precision.

The evolution of ICP-MS technology has been largely driven by efforts to overcome these matrix-related challenges. Early systems struggled with total dissolved solids (TDS) limitations of approximately 0.1-0.2%, severely restricting their application to relatively clean samples. Modern systems aim to handle samples with TDS levels of 1-3% or higher, expanding the technique's utility across more complex sample types without extensive preparation.

Current technological objectives focus on developing robust solutions that maintain analytical performance while processing challenging matrices. Key goals include enhancing plasma robustness to resist matrix effects, improving interface designs to minimize deposition and clogging, and advancing collision/reaction cell technologies to eliminate polyatomic interferences. Additionally, there is significant interest in developing intelligent software algorithms that can automatically compensate for matrix-induced signal variations.

The industry is witnessing a paradigm shift from merely avoiding matrix effects to actively managing them. This transition reflects a deeper understanding of plasma physics, ion-molecule chemistry, and the complex interactions occurring within the ICP-MS system. Research efforts are increasingly directed toward predictive modeling of matrix behaviors and developing adaptive systems that can automatically optimize operating conditions based on sample characteristics.

As analytical demands grow more sophisticated across industries, particularly in pharmaceutical manufacturing, environmental monitoring, and clinical diagnostics, the ability to directly analyze high-matrix samples without extensive dilution or separation becomes increasingly valuable. This capability would significantly reduce sample preparation requirements, increase throughput, and enable more representative analyses of complex materials in their native state.

High matrix samples—those containing elevated levels of dissolved solids, organic compounds, or complex biological materials—present significant analytical obstacles. These matrices can cause physical interferences such as clogging of sample introduction components and deposition on interface cones, leading to signal drift and reduced instrument stability. Additionally, they introduce spectral interferences through polyatomic ion formation and non-spectral matrix effects that suppress or enhance analyte signals, compromising measurement accuracy and precision.

The evolution of ICP-MS technology has been largely driven by efforts to overcome these matrix-related challenges. Early systems struggled with total dissolved solids (TDS) limitations of approximately 0.1-0.2%, severely restricting their application to relatively clean samples. Modern systems aim to handle samples with TDS levels of 1-3% or higher, expanding the technique's utility across more complex sample types without extensive preparation.

Current technological objectives focus on developing robust solutions that maintain analytical performance while processing challenging matrices. Key goals include enhancing plasma robustness to resist matrix effects, improving interface designs to minimize deposition and clogging, and advancing collision/reaction cell technologies to eliminate polyatomic interferences. Additionally, there is significant interest in developing intelligent software algorithms that can automatically compensate for matrix-induced signal variations.

The industry is witnessing a paradigm shift from merely avoiding matrix effects to actively managing them. This transition reflects a deeper understanding of plasma physics, ion-molecule chemistry, and the complex interactions occurring within the ICP-MS system. Research efforts are increasingly directed toward predictive modeling of matrix behaviors and developing adaptive systems that can automatically optimize operating conditions based on sample characteristics.

As analytical demands grow more sophisticated across industries, particularly in pharmaceutical manufacturing, environmental monitoring, and clinical diagnostics, the ability to directly analyze high-matrix samples without extensive dilution or separation becomes increasingly valuable. This capability would significantly reduce sample preparation requirements, increase throughput, and enable more representative analyses of complex materials in their native state.

Market Demand Analysis for Advanced ICP-MS Solutions

The global market for ICP-MS (Inductively Coupled Plasma Mass Spectrometry) solutions is experiencing robust growth, driven primarily by increasing demands for trace element analysis across multiple industries. Current market valuations indicate the global ICP-MS market reached approximately 1.2 billion USD in 2022, with projections suggesting a compound annual growth rate of 7.8% through 2028.

The pharmaceutical and biotechnology sectors represent the largest market segments, accounting for nearly 35% of the total demand. These industries require advanced ICP-MS solutions capable of handling high matrix samples for quality control, impurity profiling, and regulatory compliance. The stringent regulatory frameworks, particularly FDA and EMA guidelines regarding elemental impurities in drug products, have significantly accelerated market demand.

Environmental monitoring constitutes the second-largest market segment, representing approximately 28% of the total demand. Government agencies and environmental consulting firms increasingly rely on ICP-MS technology for analyzing complex environmental matrices including soil, sediment, and wastewater samples. The growing public concern regarding heavy metal contamination in drinking water has further stimulated market growth in this sector.

Food safety testing represents another rapidly expanding application area, with a projected growth rate of 9.2% annually. Consumer awareness regarding food contaminants and the implementation of stricter food safety regulations worldwide have created substantial demand for high-performance analytical instruments capable of handling complex food matrices.

Geographically, North America dominates the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate, driven by increasing industrialization, environmental concerns, and strengthening regulatory frameworks in countries like China and India.

End-users consistently express demand for several key improvements in ICP-MS technology for high matrix sample management: enhanced matrix tolerance without compromising detection limits; simplified sample preparation protocols; reduced maintenance requirements when processing complex matrices; and improved software solutions for matrix interference correction.

Market research indicates that laboratories are willing to invest 15-20% premium pricing for ICP-MS systems that effectively address high matrix sample challenges, demonstrating the significant market opportunity for advanced solutions in this space. Contract research organizations particularly value systems that can maintain high throughput while handling diverse sample matrices.

The pharmaceutical and biotechnology sectors represent the largest market segments, accounting for nearly 35% of the total demand. These industries require advanced ICP-MS solutions capable of handling high matrix samples for quality control, impurity profiling, and regulatory compliance. The stringent regulatory frameworks, particularly FDA and EMA guidelines regarding elemental impurities in drug products, have significantly accelerated market demand.

Environmental monitoring constitutes the second-largest market segment, representing approximately 28% of the total demand. Government agencies and environmental consulting firms increasingly rely on ICP-MS technology for analyzing complex environmental matrices including soil, sediment, and wastewater samples. The growing public concern regarding heavy metal contamination in drinking water has further stimulated market growth in this sector.

Food safety testing represents another rapidly expanding application area, with a projected growth rate of 9.2% annually. Consumer awareness regarding food contaminants and the implementation of stricter food safety regulations worldwide have created substantial demand for high-performance analytical instruments capable of handling complex food matrices.

Geographically, North America dominates the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate, driven by increasing industrialization, environmental concerns, and strengthening regulatory frameworks in countries like China and India.

End-users consistently express demand for several key improvements in ICP-MS technology for high matrix sample management: enhanced matrix tolerance without compromising detection limits; simplified sample preparation protocols; reduced maintenance requirements when processing complex matrices; and improved software solutions for matrix interference correction.

Market research indicates that laboratories are willing to invest 15-20% premium pricing for ICP-MS systems that effectively address high matrix sample challenges, demonstrating the significant market opportunity for advanced solutions in this space. Contract research organizations particularly value systems that can maintain high throughput while handling diverse sample matrices.

Current Limitations in High Matrix Sample Analysis

Despite significant advancements in ICP-MS technology, high matrix samples continue to present substantial analytical challenges. The primary limitation stems from matrix-induced signal suppression or enhancement, where high concentrations of dissolved solids interfere with analyte ionization efficiency in the plasma. This phenomenon creates unpredictable variations in signal intensity, compromising measurement accuracy and reproducibility, particularly when matrix composition differs between samples and calibration standards.

Physical interferences represent another critical limitation. High matrix samples frequently cause clogging of sample introduction components, including nebulizers, spray chambers, and torch injectors. This leads to signal drift, reduced instrument stability, and increased maintenance requirements. The gradual deposition of matrix components on sampler and skimmer cones further exacerbates these issues, causing progressive sensitivity deterioration during analytical runs.

Spectral interferences pose significant challenges in high matrix analysis. Complex samples generate numerous polyatomic species that overlap with analyte masses, complicating accurate quantification. While collision/reaction cell technologies have improved interference management, they remain insufficient for extremely complex matrices where multiple interference mechanisms may operate simultaneously.

Sample preparation limitations also constrain high matrix analysis capabilities. Traditional dilution approaches reduce matrix effects but simultaneously diminish analyte concentrations, potentially pushing target elements below detection limits. Matrix separation techniques like chelation, precipitation, or extraction add complexity, time requirements, and potential contamination risks to analytical workflows.

Calibration challenges persist when analyzing high matrix samples. Matrix-matched calibration, while theoretically ideal, requires extensive preparation of multiple standards that precisely mirror sample compositions—often impractical for variable or unknown matrices. Internal standardization provides only partial compensation for matrix effects, particularly when matrix components affect different elements to varying degrees.

The dynamic range limitations of ICP-MS detectors create additional complications. High matrix samples often contain major elements at percentage levels alongside trace elements at ppb or ppt concentrations. This concentration spread exceeds the linear dynamic range of most detectors, necessitating multiple dilutions or analytical runs to capture all elements of interest.

Finally, quality control becomes exceptionally challenging with high matrix samples. Reference materials matching complex matrices are limited in availability and scope, complicating method validation and uncertainty estimation. The variable nature of matrix effects also makes it difficult to establish consistent performance metrics and detection limits across diverse sample types.

Physical interferences represent another critical limitation. High matrix samples frequently cause clogging of sample introduction components, including nebulizers, spray chambers, and torch injectors. This leads to signal drift, reduced instrument stability, and increased maintenance requirements. The gradual deposition of matrix components on sampler and skimmer cones further exacerbates these issues, causing progressive sensitivity deterioration during analytical runs.

Spectral interferences pose significant challenges in high matrix analysis. Complex samples generate numerous polyatomic species that overlap with analyte masses, complicating accurate quantification. While collision/reaction cell technologies have improved interference management, they remain insufficient for extremely complex matrices where multiple interference mechanisms may operate simultaneously.

Sample preparation limitations also constrain high matrix analysis capabilities. Traditional dilution approaches reduce matrix effects but simultaneously diminish analyte concentrations, potentially pushing target elements below detection limits. Matrix separation techniques like chelation, precipitation, or extraction add complexity, time requirements, and potential contamination risks to analytical workflows.

Calibration challenges persist when analyzing high matrix samples. Matrix-matched calibration, while theoretically ideal, requires extensive preparation of multiple standards that precisely mirror sample compositions—often impractical for variable or unknown matrices. Internal standardization provides only partial compensation for matrix effects, particularly when matrix components affect different elements to varying degrees.

The dynamic range limitations of ICP-MS detectors create additional complications. High matrix samples often contain major elements at percentage levels alongside trace elements at ppb or ppt concentrations. This concentration spread exceeds the linear dynamic range of most detectors, necessitating multiple dilutions or analytical runs to capture all elements of interest.

Finally, quality control becomes exceptionally challenging with high matrix samples. Reference materials matching complex matrices are limited in availability and scope, complicating method validation and uncertainty estimation. The variable nature of matrix effects also makes it difficult to establish consistent performance metrics and detection limits across diverse sample types.

Current Matrix Management Techniques in ICP-MS

01 Automated sample preparation systems for ICP-MS

Automated systems for sample preparation in ICP-MS analysis improve efficiency and reduce human error. These systems include robotic sample handling, automated dilution, and integrated workflow management. Automation helps maintain sample integrity, ensures consistent preparation protocols, and increases throughput for high-volume testing environments. These systems often incorporate intelligent scheduling and can handle various sample types while maintaining precision.- Automated sample preparation systems for ICP-MS: Automated systems for sample preparation in ICP-MS analysis improve efficiency and reduce human error. These systems include robotic sample handling, automated dilution, and integrated sample introduction mechanisms. Automation helps maintain consistency in sample preparation, which is critical for accurate ICP-MS measurements, and allows for higher throughput in analytical laboratories.

- Sample introduction and nebulization techniques: Various sample introduction methods and nebulization techniques are employed to optimize ICP-MS analysis. These include specialized nebulizers, spray chambers, and sample introduction systems designed to handle different sample types and volumes. Improvements in nebulization efficiency and aerosol generation lead to better sensitivity and stability in ICP-MS measurements, particularly for challenging sample matrices.

- Sample pretreatment and digestion methods: Effective sample pretreatment and digestion methods are crucial for accurate ICP-MS analysis. These include acid digestion, microwave-assisted digestion, and specialized dissolution techniques for different sample matrices. Proper sample preparation ensures complete dissolution of analytes and minimizes matrix interferences, leading to more reliable quantitative results in trace element analysis.

- Quality control and calibration systems: Quality control procedures and calibration systems are essential for reliable ICP-MS analysis. These include the use of internal standards, certified reference materials, and drift correction methods. Systematic approaches to quality control ensure measurement accuracy and precision, while robust calibration strategies help compensate for matrix effects and instrument drift during analysis.

- Specialized sample handling for challenging matrices: Specialized techniques for handling challenging sample matrices in ICP-MS analysis address issues such as high salt content, organic matrices, and limited sample volumes. These include dilution protocols, matrix matching, separation techniques, and specialized sample introduction systems. These approaches help overcome matrix interferences and enhance detection limits for trace elements in complex samples like biological fluids, environmental samples, and industrial materials.

02 Sample introduction and nebulization techniques

Specialized sample introduction systems for ICP-MS enhance analytical performance by optimizing how samples enter the plasma. These include various nebulizer designs, spray chambers, and desolvation systems that improve sample transport efficiency and stability. Advanced nebulization techniques reduce matrix effects, minimize clogging, and handle difficult sample types such as high-salt or organic matrices. These innovations help achieve lower detection limits and better precision in elemental analysis.Expand Specific Solutions03 Sample pretreatment methods for complex matrices

Specialized pretreatment methods for complex sample matrices in ICP-MS analysis include digestion techniques, extraction procedures, and matrix elimination strategies. These methods address challenges like high dissolved solids, organic content, or interfering elements. Approaches include microwave digestion, chemical separation, chelation, and dilution protocols tailored to specific sample types. Effective pretreatment ensures accurate quantification by reducing matrix effects and spectral interferences.Expand Specific Solutions04 Quality control and calibration systems

Quality control and calibration systems for ICP-MS ensure measurement accuracy and reliability. These include internal standardization methods, drift correction algorithms, and automated calibration verification. Systems may incorporate reference materials, spike recovery tests, and statistical process control. Advanced quality management approaches use real-time monitoring of instrument performance parameters and automated flagging of anomalous results to maintain data integrity throughout analytical sessions.Expand Specific Solutions05 Integrated sample tracking and data management

Integrated sample tracking and data management systems for ICP-MS provide comprehensive chain-of-custody documentation and results processing. These systems include barcode or RFID sample identification, centralized databases for sample information, and automated data processing workflows. They enable traceability from sample collection through analysis and reporting, with features for data validation, trend analysis, and regulatory compliance. Advanced systems incorporate machine learning for anomaly detection and predictive maintenance.Expand Specific Solutions

Key Industry Players in ICP-MS Instrumentation

The management of high matrix samples in ICP-MS is currently in a mature development phase, with a global market estimated at $1.5-2 billion annually. The technology has evolved from early research applications to widespread industrial adoption across pharmaceutical, environmental, and nuclear sectors. Leading companies like Thermo Fisher Scientific and Agilent Technologies dominate the market with comprehensive solutions for matrix interference challenges, while Elemental Scientific and PerkinElmer offer specialized sample introduction systems. Academic institutions such as ETH Zurich and EPFL collaborate with industry to advance fundamental research. The competitive landscape features established players focusing on automation and high-throughput capabilities, with emerging innovations in sample preparation techniques and specialized software algorithms for complex matrix compensation.

Thermo Fisher Scientific (Bremen) GmbH

Technical Solution: Thermo Fisher Scientific has developed advanced collision/reaction cell technology for their ICP-MS systems to manage high matrix samples. Their iCAP RQ ICP-MS platform incorporates Kinetic Energy Discrimination (KED) with helium gas to reduce polyatomic interferences from complex matrices. The system features their proprietary QCell technology with flatapole design that maintains sensitivity while removing matrix-based interferences. For extremely challenging high-matrix samples, they've implemented Triple Quadrupole (TQ-ICP-MS) technology in their iCAP TQ system, allowing controlled chemical reactions in the collision cell to convert problematic interferences into different species or neutralize them entirely. Their High Matrix Introduction (HMI) technology dilutes samples aerodynamically at the interface, reducing matrix loading without physical dilution of samples[1][3]. Additionally, their Discrete Sampling System (DSS) minimizes sample uptake and washout times, reducing matrix effects between samples.

Strengths: Superior interference removal capabilities through triple quadrupole technology; integrated aerosol dilution reduces maintenance requirements; comprehensive software for automated optimization of high-matrix methods. Weaknesses: Higher acquisition costs compared to single-quad systems; more complex operation requiring additional training; increased gas consumption with collision/reaction cell technologies.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has pioneered several innovative approaches for managing high matrix samples in ICP-MS analysis. Their 7900 and 8900 ICP-MS systems feature the High Matrix Introduction (HMI) system that uses aerosol dilution to reduce matrix loading on the plasma, allowing direct analysis of samples containing up to 3% total dissolved solids without physical dilution[2]. For interference management, Agilent employs their Octopole Reaction System (ORS) technology, which provides effective collision/reaction capabilities in helium mode for polyatomic interference removal. The 8900 Triple Quadrupole ICP-MS takes this further with MS/MS capability, enabling precise control over reaction chemistry for challenging matrices. Agilent's Ultra High Matrix Introduction (UHMI) technology extends tolerance up to 25% dissolved solids for specialized applications[4]. Their systems also incorporate the Advanced Electron Beam Ion Source (AEBIS) that maintains plasma stability even with fluctuating matrix loads, and intelligent rinse functions that reduce carryover between high matrix samples.

Strengths: Industry-leading matrix tolerance with UHMI technology; excellent long-term stability for high-salt matrices; comprehensive interference management through triple-quad capabilities. Weaknesses: Premium pricing structure compared to some competitors; complex method development may be required for novel matrix types; higher argon gas consumption when operating with high matrix introduction systems.

Critical Innovations in High Matrix Tolerance

inductively coupled plasma mass spectrometer

PatentActiveDE102007032176A1

Innovation

- An ICP-MS device with a control system that adjusts the amount of liquid droplets, carrier gas flow rate, RF power output, and plasma torch-to-interface distance to maintain sensitivity ratios of at least 10:1, allowing for continuous analysis of samples with varying matrix concentrations without manual dilution.

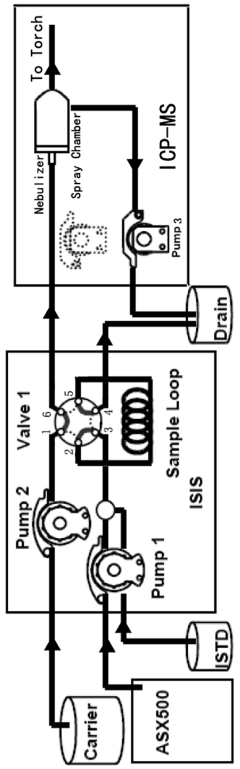

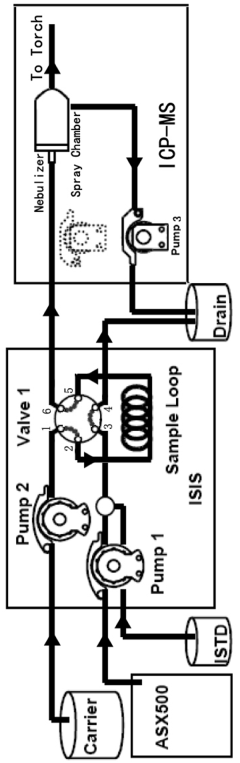

ICP-ms method for multi-element determination by direct sample injection of high salt water

PatentActiveNL2033445A

Innovation

- A Discrete Flow Injection Sampling (DFIS) method using a six-way valve and peristaltic pumps to directly inject seawater samples into an ICP-MS system, optimizing parameters like sample loop diameter, carrier acidity, and pumping speed to minimize salt deposition and ensure stable sample delivery, allowing simultaneous analysis of multiple elements.

Environmental Regulations Impact on ICP-MS Methods

Environmental regulations worldwide have significantly shaped the development and application of ICP-MS methods for high matrix sample analysis. The increasing stringency of environmental protection laws has driven analytical laboratories to adopt more sensitive and accurate techniques for monitoring toxic elements in various matrices. In the United States, the Environmental Protection Agency (EPA) has established Method 6020 specifically for ICP-MS analysis, which includes detailed protocols for handling high matrix samples and sets strict quality control requirements for environmental monitoring.

The European Union's Water Framework Directive and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations have similarly influenced ICP-MS methodologies by mandating lower detection limits for toxic elements in environmental samples. These regulations have necessitated the development of advanced sample preparation techniques and interference reduction strategies to achieve the required analytical performance in complex matrices.

In Asia, particularly China and Japan, rapid industrialization has led to the implementation of stringent environmental monitoring programs. These countries have established their own regulatory frameworks that often require analysis of high matrix samples such as industrial effluents, contaminated soils, and urban dust. The regulatory limits for heavy metals in these matrices have been progressively lowered, challenging laboratories to enhance their ICP-MS capabilities.

Global harmonization efforts, such as ISO standards for environmental testing, have further standardized ICP-MS methods for high matrix samples. ISO 17294-2, which specifies ICP-MS determination of selected elements in water samples, has become a reference method for many national regulatory frameworks, promoting consistency in analytical approaches across borders.

The regulatory focus on emerging contaminants has expanded the application scope of ICP-MS. Rare earth elements, previously unregulated, are now monitored in environmental samples due to their increasing use in technology and potential ecological impacts. This has prompted the development of specialized ICP-MS methods capable of distinguishing between naturally occurring and anthropogenic sources of these elements in complex matrices.

Compliance with evolving regulations has driven innovation in ICP-MS technology, particularly in collision/reaction cell systems that effectively eliminate polyatomic interferences common in environmental samples. These technological advances have enabled laboratories to meet increasingly stringent regulatory requirements while maintaining analytical efficiency when processing high matrix samples.

The European Union's Water Framework Directive and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations have similarly influenced ICP-MS methodologies by mandating lower detection limits for toxic elements in environmental samples. These regulations have necessitated the development of advanced sample preparation techniques and interference reduction strategies to achieve the required analytical performance in complex matrices.

In Asia, particularly China and Japan, rapid industrialization has led to the implementation of stringent environmental monitoring programs. These countries have established their own regulatory frameworks that often require analysis of high matrix samples such as industrial effluents, contaminated soils, and urban dust. The regulatory limits for heavy metals in these matrices have been progressively lowered, challenging laboratories to enhance their ICP-MS capabilities.

Global harmonization efforts, such as ISO standards for environmental testing, have further standardized ICP-MS methods for high matrix samples. ISO 17294-2, which specifies ICP-MS determination of selected elements in water samples, has become a reference method for many national regulatory frameworks, promoting consistency in analytical approaches across borders.

The regulatory focus on emerging contaminants has expanded the application scope of ICP-MS. Rare earth elements, previously unregulated, are now monitored in environmental samples due to their increasing use in technology and potential ecological impacts. This has prompted the development of specialized ICP-MS methods capable of distinguishing between naturally occurring and anthropogenic sources of these elements in complex matrices.

Compliance with evolving regulations has driven innovation in ICP-MS technology, particularly in collision/reaction cell systems that effectively eliminate polyatomic interferences common in environmental samples. These technological advances have enabled laboratories to meet increasingly stringent regulatory requirements while maintaining analytical efficiency when processing high matrix samples.

Sample Preparation Strategies for Complex Matrices

Sample preparation represents a critical step in the analytical workflow for ICP-MS analysis of high matrix samples. Complex matrices such as seawater, geological materials, biological tissues, and industrial waste present significant challenges due to their high dissolved solid content, which can cause signal suppression, spectral interferences, and instrument contamination. Effective sample preparation strategies must address these challenges while maintaining analytical accuracy and precision.

Dilution remains one of the simplest and most widely employed approaches for managing high matrix samples. Serial dilution techniques can reduce total dissolved solids (TDS) to acceptable levels (<0.2% for most ICP-MS systems), though this approach inevitably raises detection limits and may compromise sensitivity for trace elements. Modern instruments with collision/reaction cell technology can tolerate slightly higher TDS levels, allowing for less extreme dilution factors.

Acid digestion procedures represent another fundamental approach, with various protocols optimized for specific matrix types. Open vessel digestion using hotplates offers simplicity but risks contamination and volatile element loss. Closed vessel microwave-assisted digestion systems provide more efficient decomposition of resistant matrices while minimizing volatile element losses and contamination risks. For particularly resistant materials like silicates, high-pressure digestion bombs utilizing HF may be necessary.

Matrix separation techniques have gained prominence for particularly challenging samples. Solid phase extraction (SPE) using specialized resins enables selective retention of analytes while matrix components are washed away. Chelating resins containing iminodiacetic acid groups have proven especially effective for seawater analysis. Precipitation methods can also remove matrix elements through selective precipitation of either interfering components or analytes of interest.

Chromatographic separation approaches, including ion chromatography and HPLC when coupled with ICP-MS, provide powerful tools for both matrix removal and speciation analysis. These hyphenated techniques allow for separation of analytes from matrix components prior to introduction to the plasma, significantly reducing interferences.

Field-flow fractionation represents an emerging technique for size-based separation of nanoparticles and colloids in complex environmental and biological samples. This approach enables characterization of particle size distribution alongside elemental composition when coupled with ICP-MS, providing valuable insights for environmental monitoring and nanoparticle research applications.

Dilution remains one of the simplest and most widely employed approaches for managing high matrix samples. Serial dilution techniques can reduce total dissolved solids (TDS) to acceptable levels (<0.2% for most ICP-MS systems), though this approach inevitably raises detection limits and may compromise sensitivity for trace elements. Modern instruments with collision/reaction cell technology can tolerate slightly higher TDS levels, allowing for less extreme dilution factors.

Acid digestion procedures represent another fundamental approach, with various protocols optimized for specific matrix types. Open vessel digestion using hotplates offers simplicity but risks contamination and volatile element loss. Closed vessel microwave-assisted digestion systems provide more efficient decomposition of resistant matrices while minimizing volatile element losses and contamination risks. For particularly resistant materials like silicates, high-pressure digestion bombs utilizing HF may be necessary.

Matrix separation techniques have gained prominence for particularly challenging samples. Solid phase extraction (SPE) using specialized resins enables selective retention of analytes while matrix components are washed away. Chelating resins containing iminodiacetic acid groups have proven especially effective for seawater analysis. Precipitation methods can also remove matrix elements through selective precipitation of either interfering components or analytes of interest.

Chromatographic separation approaches, including ion chromatography and HPLC when coupled with ICP-MS, provide powerful tools for both matrix removal and speciation analysis. These hyphenated techniques allow for separation of analytes from matrix components prior to introduction to the plasma, significantly reducing interferences.

Field-flow fractionation represents an emerging technique for size-based separation of nanoparticles and colloids in complex environmental and biological samples. This approach enables characterization of particle size distribution alongside elemental composition when coupled with ICP-MS, providing valuable insights for environmental monitoring and nanoparticle research applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!