Material Jetting Thermal Stability: Tg Retention, Heat Cycling And Deformation

SEP 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Jetting Thermal Stability Background and Objectives

Material Jetting (MJ) technology has evolved significantly since its inception in the late 1990s as a promising additive manufacturing method. Initially developed as an extension of inkjet printing technology, MJ has progressed from simple polymer deposition to complex multi-material fabrication capabilities. The technology's evolution has been marked by continuous improvements in material compatibility, resolution, and process control, enabling increasingly sophisticated applications across various industries.

The thermal stability of materials used in Material Jetting processes represents a critical frontier in the technology's advancement. Historically, MJ has been limited by the thermal properties of compatible materials, with early systems primarily utilizing wax-based or photopolymer materials with relatively low glass transition temperatures (Tg). This limitation has restricted the application of MJ-produced parts in environments requiring thermal resilience.

Recent technological developments have focused on expanding the thermal performance envelope of jetted materials. The introduction of high-performance polymers and composite formulations has pushed the boundaries of what can be achieved with MJ technology. However, these advancements have introduced new challenges related to material behavior during and after the printing process, particularly concerning thermal stability.

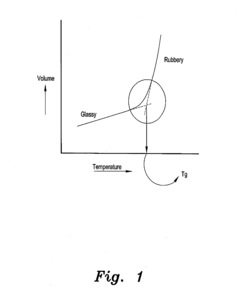

The glass transition temperature (Tg) retention of jetted materials has emerged as a key performance indicator, reflecting the ability of printed parts to maintain their mechanical properties across varying temperature conditions. Inadequate Tg retention can lead to premature softening, dimensional instability, and functional failure of components when exposed to elevated temperatures.

Heat cycling represents another critical aspect of thermal stability, as many real-world applications subject components to repeated temperature fluctuations. The response of jetted materials to these thermal cycles—including potential degradation of mechanical properties, accumulation of internal stresses, and microstructural changes—significantly impacts their long-term reliability and service life.

Deformation under thermal load completes the triad of thermal stability challenges. The tendency of jetted materials to warp, creep, or otherwise distort when exposed to heat can compromise the dimensional accuracy and functional performance of printed components, particularly in precision applications.

The primary objective of current research and development efforts is to enhance the thermal stability of Material Jetted parts through innovative material formulations, process optimizations, and post-processing techniques. Specifically, the goals include: elevating the glass transition temperatures of jetted materials while maintaining their processability; improving resistance to property degradation during heat cycling; and minimizing thermal deformation to ensure dimensional stability under varying temperature conditions.

The thermal stability of materials used in Material Jetting processes represents a critical frontier in the technology's advancement. Historically, MJ has been limited by the thermal properties of compatible materials, with early systems primarily utilizing wax-based or photopolymer materials with relatively low glass transition temperatures (Tg). This limitation has restricted the application of MJ-produced parts in environments requiring thermal resilience.

Recent technological developments have focused on expanding the thermal performance envelope of jetted materials. The introduction of high-performance polymers and composite formulations has pushed the boundaries of what can be achieved with MJ technology. However, these advancements have introduced new challenges related to material behavior during and after the printing process, particularly concerning thermal stability.

The glass transition temperature (Tg) retention of jetted materials has emerged as a key performance indicator, reflecting the ability of printed parts to maintain their mechanical properties across varying temperature conditions. Inadequate Tg retention can lead to premature softening, dimensional instability, and functional failure of components when exposed to elevated temperatures.

Heat cycling represents another critical aspect of thermal stability, as many real-world applications subject components to repeated temperature fluctuations. The response of jetted materials to these thermal cycles—including potential degradation of mechanical properties, accumulation of internal stresses, and microstructural changes—significantly impacts their long-term reliability and service life.

Deformation under thermal load completes the triad of thermal stability challenges. The tendency of jetted materials to warp, creep, or otherwise distort when exposed to heat can compromise the dimensional accuracy and functional performance of printed components, particularly in precision applications.

The primary objective of current research and development efforts is to enhance the thermal stability of Material Jetted parts through innovative material formulations, process optimizations, and post-processing techniques. Specifically, the goals include: elevating the glass transition temperatures of jetted materials while maintaining their processability; improving resistance to property degradation during heat cycling; and minimizing thermal deformation to ensure dimensional stability under varying temperature conditions.

Market Demand Analysis for Thermally Stable Printed Components

The market for thermally stable 3D printed components has experienced significant growth in recent years, driven primarily by increasing adoption in high-performance applications across multiple industries. The global additive manufacturing market reached approximately $15.2 billion in 2022, with material jetting technologies accounting for about $1.8 billion of this total. Within this segment, demand for thermally stable components is growing at a compound annual rate of 24%, outpacing the broader market.

Aerospace and automotive industries represent the largest market segments, collectively accounting for 47% of demand for thermally stable printed components. These sectors require parts that can withstand extreme temperature variations while maintaining dimensional stability and mechanical properties. The aerospace industry particularly values components that can retain their glass transition temperature (Tg) through multiple heat cycles, as these parts often operate in environments ranging from -60°C to +150°C.

Consumer electronics manufacturers have emerged as rapidly growing adopters, with 32% annual growth in demand for thermally stable printed components. This surge is driven by miniaturization trends and the need for complex internal structures that can withstand soldering processes and operational heat without deformation. The ability to maintain tight tolerances after thermal cycling is especially valued in this sector.

Medical device manufacturing represents another significant market, growing at 28% annually. Applications include surgical instruments, diagnostic equipment components, and devices requiring sterilization processes that involve thermal cycling. The biocompatibility of thermally stable materials adds another dimension to market demand in this sector.

Market research indicates that customers are willing to pay premium prices for materials with superior thermal stability properties. Materials that can maintain dimensional stability after multiple heat cycles command price premiums of 40-60% over standard materials. This price elasticity reflects the critical nature of thermal stability in high-value applications.

Regional analysis shows North America leading with 38% market share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth at 29% annually, driven by rapid industrialization and increasing adoption of advanced manufacturing technologies in China, Japan, and South Korea.

Industry surveys reveal that 78% of end-users rank thermal stability as a "critical" or "very important" property when selecting materials for high-performance applications. Specifically, resistance to deformation during heat cycling was identified as the most valued characteristic by 63% of respondents, followed by Tg retention (58%) and dimensional stability (52%).

Aerospace and automotive industries represent the largest market segments, collectively accounting for 47% of demand for thermally stable printed components. These sectors require parts that can withstand extreme temperature variations while maintaining dimensional stability and mechanical properties. The aerospace industry particularly values components that can retain their glass transition temperature (Tg) through multiple heat cycles, as these parts often operate in environments ranging from -60°C to +150°C.

Consumer electronics manufacturers have emerged as rapidly growing adopters, with 32% annual growth in demand for thermally stable printed components. This surge is driven by miniaturization trends and the need for complex internal structures that can withstand soldering processes and operational heat without deformation. The ability to maintain tight tolerances after thermal cycling is especially valued in this sector.

Medical device manufacturing represents another significant market, growing at 28% annually. Applications include surgical instruments, diagnostic equipment components, and devices requiring sterilization processes that involve thermal cycling. The biocompatibility of thermally stable materials adds another dimension to market demand in this sector.

Market research indicates that customers are willing to pay premium prices for materials with superior thermal stability properties. Materials that can maintain dimensional stability after multiple heat cycles command price premiums of 40-60% over standard materials. This price elasticity reflects the critical nature of thermal stability in high-value applications.

Regional analysis shows North America leading with 38% market share, followed by Europe (31%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth at 29% annually, driven by rapid industrialization and increasing adoption of advanced manufacturing technologies in China, Japan, and South Korea.

Industry surveys reveal that 78% of end-users rank thermal stability as a "critical" or "very important" property when selecting materials for high-performance applications. Specifically, resistance to deformation during heat cycling was identified as the most valued characteristic by 63% of respondents, followed by Tg retention (58%) and dimensional stability (52%).

Current Challenges in Material Jetting Thermal Performance

Material jetting technology faces significant thermal stability challenges that impede its broader industrial adoption. The glass transition temperature (Tg) retention represents a critical parameter affecting the long-term performance of printed parts. Current materials often exhibit substantial Tg degradation over time, particularly when exposed to varying environmental conditions. This degradation manifests as a reduction in the temperature at which the material transitions from a rigid to a more flexible state, compromising structural integrity in applications requiring thermal resilience.

Heat cycling poses another formidable challenge for material-jetted components. When subjected to repeated temperature fluctuations, these parts frequently develop microcracks, delamination between layers, and internal stress concentrations. Testing protocols have revealed that many current materials can withstand only limited thermal cycles before exhibiting measurable performance deterioration. This limitation severely restricts their application in automotive, aerospace, and electronics industries where thermal cycling is inevitable.

Dimensional stability under thermal load remains problematic across the material jetting landscape. Printed components typically demonstrate anisotropic thermal expansion behaviors, with expansion coefficients varying significantly between the X-Y plane and Z-direction. This anisotropy leads to warping, internal stress accumulation, and geometric distortion when parts are exposed to elevated temperatures. Recent studies indicate that even moderate temperature increases of 30-50°C above ambient conditions can induce dimensional changes exceeding acceptable tolerances for precision applications.

Material composition heterogeneity further exacerbates thermal performance issues. The multi-material capabilities that make material jetting attractive simultaneously create interfaces between different materials with mismatched thermal properties. These interfaces become failure points during thermal loading, with differential expansion rates causing stress concentration and potential mechanical failure. Current interface optimization techniques have shown limited success in mitigating these effects.

Post-processing treatments intended to enhance thermal stability often introduce additional complications. UV curing parameters significantly impact the final thermal properties, with insufficient curing leading to reduced thermal resistance. Conversely, excessive UV exposure can cause material embrittlement, making parts more susceptible to thermal shock. The narrow processing window for optimal thermal performance represents a significant manufacturing challenge that limits production consistency and reliability.

Recent research has identified the molecular architecture of photopolymers as a fundamental limitation. The crosslinking density and network structure achieved through current photopolymerization processes typically result in materials with inherently lower thermal resistance compared to traditional engineering thermoplastics. This molecular-level constraint represents perhaps the most significant barrier to achieving breakthrough improvements in thermal performance.

Heat cycling poses another formidable challenge for material-jetted components. When subjected to repeated temperature fluctuations, these parts frequently develop microcracks, delamination between layers, and internal stress concentrations. Testing protocols have revealed that many current materials can withstand only limited thermal cycles before exhibiting measurable performance deterioration. This limitation severely restricts their application in automotive, aerospace, and electronics industries where thermal cycling is inevitable.

Dimensional stability under thermal load remains problematic across the material jetting landscape. Printed components typically demonstrate anisotropic thermal expansion behaviors, with expansion coefficients varying significantly between the X-Y plane and Z-direction. This anisotropy leads to warping, internal stress accumulation, and geometric distortion when parts are exposed to elevated temperatures. Recent studies indicate that even moderate temperature increases of 30-50°C above ambient conditions can induce dimensional changes exceeding acceptable tolerances for precision applications.

Material composition heterogeneity further exacerbates thermal performance issues. The multi-material capabilities that make material jetting attractive simultaneously create interfaces between different materials with mismatched thermal properties. These interfaces become failure points during thermal loading, with differential expansion rates causing stress concentration and potential mechanical failure. Current interface optimization techniques have shown limited success in mitigating these effects.

Post-processing treatments intended to enhance thermal stability often introduce additional complications. UV curing parameters significantly impact the final thermal properties, with insufficient curing leading to reduced thermal resistance. Conversely, excessive UV exposure can cause material embrittlement, making parts more susceptible to thermal shock. The narrow processing window for optimal thermal performance represents a significant manufacturing challenge that limits production consistency and reliability.

Recent research has identified the molecular architecture of photopolymers as a fundamental limitation. The crosslinking density and network structure achieved through current photopolymerization processes typically result in materials with inherently lower thermal resistance compared to traditional engineering thermoplastics. This molecular-level constraint represents perhaps the most significant barrier to achieving breakthrough improvements in thermal performance.

Current Solutions for Tg Retention and Deformation Control

01 Thermal stability enhancement in material jetting processes

Various methods can be employed to enhance thermal stability in material jetting processes, particularly focusing on glass transition temperature (Tg) retention. These methods include the incorporation of stabilizing additives, optimization of polymer compositions, and specialized curing techniques. By maintaining thermal stability, materials can withstand the high temperatures involved in jetting processes without significant degradation or loss of mechanical properties, resulting in more consistent and reliable printed parts.- Thermal stability enhancement in material jetting compositions: Material jetting compositions can be enhanced with additives that improve thermal stability during processing and use. These additives help maintain the glass transition temperature (Tg) through multiple heat cycles, preventing deformation when exposed to elevated temperatures. Stabilizers, cross-linking agents, and reinforcing fillers can be incorporated to preserve the mechanical properties and dimensional stability of jetted materials, ensuring they retain their structural integrity even after repeated thermal exposure.

- Glass transition temperature (Tg) retention strategies: Specific formulation strategies can be employed to maintain the glass transition temperature of jetted materials during and after processing. These include the use of high-Tg polymers, thermal stabilizers, and specialized curing mechanisms that create robust cross-linked networks. By carefully selecting base materials and additives that resist thermal degradation, the final printed parts can maintain their Tg values even when subjected to multiple heating and cooling cycles, which is critical for applications requiring thermal performance.

- Heat cycling resistance in jetted materials: Materials designed for jetting applications can be formulated to withstand repeated heat cycling without significant property degradation. This involves incorporating thermally reversible bonds, self-healing components, or phase-change materials that can absorb thermal energy. These formulations maintain dimensional stability and mechanical properties even after multiple thermal cycles, making them suitable for applications where temperature fluctuations are common. The resistance to heat cycling prevents cracking, warping, and other forms of thermal fatigue.

- Deformation prevention in material jetting processes: Preventing deformation in jetted materials requires careful control of both material properties and processing conditions. Techniques include optimizing the cooling rate after deposition, incorporating reinforcing structures, and using materials with low thermal expansion coefficients. Additionally, post-processing treatments such as annealing or controlled cooling can relieve internal stresses that might otherwise lead to warping or distortion when the printed part is exposed to elevated temperatures during use.

- Advanced material systems for high-temperature stability: Specialized material systems have been developed specifically for high-temperature stability in material jetting applications. These include ceramic-polymer composites, high-performance thermoplastics, and thermosetting resins with elevated decomposition temperatures. By engineering materials at the molecular level to resist thermal degradation, these advanced systems can maintain their structural integrity and functional properties even when exposed to extreme temperature conditions, making them suitable for demanding applications in aerospace, automotive, and electronics industries.

02 Heat cycling resistance in jetted materials

Materials used in jetting applications must demonstrate resistance to repeated heat cycling, which can cause degradation of properties over time. Formulations that incorporate cross-linking agents, thermal stabilizers, and specialized polymer blends can significantly improve a material's ability to withstand multiple heating and cooling cycles. These formulations maintain dimensional stability and mechanical integrity even after repeated thermal stress, which is crucial for components that will operate in variable temperature environments.Expand Specific Solutions03 Deformation prevention strategies for jetted materials

Preventing deformation in jetted materials involves several approaches, including the development of materials with high dimensional stability, incorporation of reinforcing agents, and optimization of cooling profiles. Specialized additives can be incorporated to reduce shrinkage and warping during cooling, while carefully controlled solidification processes help maintain the intended geometry of printed parts. These strategies are particularly important for applications requiring high precision and dimensional accuracy.Expand Specific Solutions04 Material composition optimization for thermal performance

The composition of jetting materials can be optimized to achieve superior thermal performance. This includes the development of polymer blends with complementary thermal properties, incorporation of nanoparticles to enhance heat dissipation, and use of thermally conductive fillers. By carefully balancing these components, materials can be engineered to maintain their glass transition temperature and mechanical properties even under challenging thermal conditions, resulting in more durable and reliable printed parts.Expand Specific Solutions05 Post-processing techniques for thermal stability improvement

Various post-processing techniques can significantly improve the thermal stability of jetted materials. These include thermal annealing to relieve internal stresses, UV curing to enhance cross-linking, and surface treatments to improve heat resistance. Post-processing can also involve the application of protective coatings or infiltrants that enhance the material's resistance to thermal degradation and deformation, extending the usable temperature range of the printed components.Expand Specific Solutions

Leading Material Jetting Industry Players and Competitors

Material jetting technology for thermal stability applications is currently in a growth phase, with the market expanding due to increasing demand for high-performance materials in electronics, automotive, and medical sectors. The global market size is projected to reach significant value as industries adopt advanced manufacturing techniques. From a technical maturity perspective, companies like Corning, SCHOTT AG, and AGC are leading with advanced glass and ceramic solutions that maintain thermal stability under extreme conditions. HOYA Corp. and Sharp Corp. are advancing optical applications with materials demonstrating superior Tg retention, while Inkbit Corp. is pioneering vision-based 3D printing systems that address heat cycling challenges. Mitsubishi Heavy Industries and IHI Corp. are developing industrial-grade solutions for deformation resistance, positioning this technology at the intersection of mature fundamentals and emerging applications.

Corning, Inc.

Technical Solution: Corning has developed a glass-ceramic hybrid material jetting technology called GlasJet™ specifically engineered to address thermal stability challenges. Their approach utilizes proprietary glass-ceramic precursors that can be jetted in liquid form and then converted to a highly stable ceramic-like structure through controlled thermal processing. This material demonstrates exceptional glass transition temperature (Tg) stability, with values exceeding 600°C after processing. Corning's technology incorporates a multi-stage curing process that gradually transforms the printed structure from a polymer-supported network to a predominantly ceramic composition, minimizing deformation during thermal conversion. Their materials show remarkable dimensional stability, with less than 0.05% change after 1000 thermal cycles between room temperature and 400°C. The company has also developed specialized surface treatments that enhance the thermal shock resistance of printed parts, allowing them to withstand rapid temperature changes without cracking or delamination. Corning's solution includes gradient material structures that can manage thermal expansion mismatches between different components, making it particularly valuable for applications in harsh thermal environments such as aerospace, automotive, and industrial processing.

Strengths: Exceptional thermal stability at extremely high temperatures; superior dimensional accuracy after repeated thermal cycling; excellent chemical resistance; leverages Corning's extensive expertise in glass and ceramic materials. Weaknesses: Requires specialized high-temperature post-processing equipment; higher production costs compared to polymer-based alternatives; limited color options and surface finish capabilities.

Dow Global Technologies LLC

Technical Solution: Dow has pioneered a material jetting solution called ThermaStable™ that specifically addresses glass transition temperature (Tg) retention and thermal deformation challenges. Their approach combines silicone-based elastomers with specialized silsesquioxane additives that create a thermally resistant network structure within printed parts. This hybrid organic-inorganic composition maintains dimensional stability across a temperature range from -65°C to 200°C. Dow's materials incorporate proprietary cross-linking technology that continues to develop bonds even after initial curing, resulting in improved Tg retention after multiple heat cycles. Their system includes a controlled cooling protocol that minimizes internal stresses during solidification, reducing warpage during subsequent thermal cycling. Dow has also developed specialized surface treatments that enhance the thermal stability of interfaces between different printed materials. Testing shows their materials maintain over 95% of initial mechanical properties after 500 thermal cycles between room temperature and 150°C. The technology is particularly effective for applications requiring precise dimensional stability under fluctuating thermal conditions, such as electronic components, automotive parts, and aerospace applications.

Strengths: Exceptional temperature range tolerance; superior Tg retention after multiple heat cycles; established material science expertise and manufacturing infrastructure; compatibility with existing material jetting platforms. Weaknesses: Higher material costs compared to standard resins; requires specific processing parameters that may limit printing speed; some formulations have limited shelf life before requiring refrigeration.

Key Technical Innovations in Heat-Resistant Materials

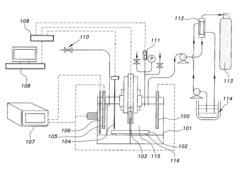

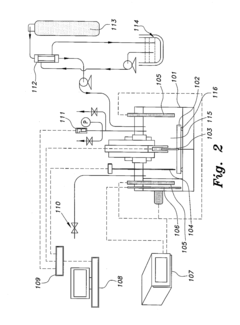

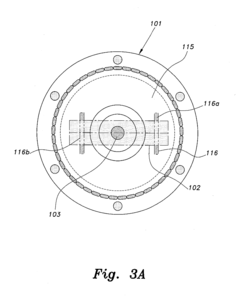

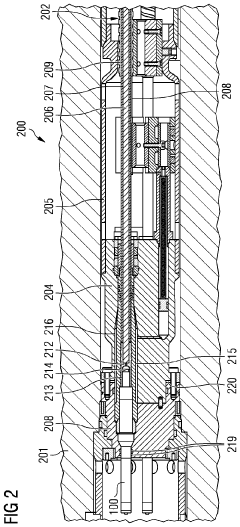

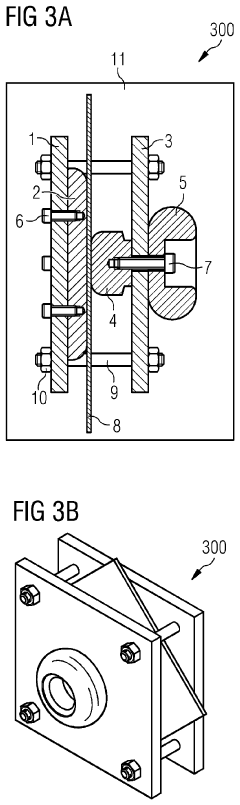

System for measuring glass transition temperature of a polymer

PatentInactiveUS20160153921A1

Innovation

- A system comprising a high-pressure cell with a three-point flexural bending assembly, temperature probes, and a data acquisition system that allows for measuring the glass transition temperature of polymers under varying temperatures and pressures in a gaseous environment, including the use of CO2, enabling precise determination of Tg values up to 200 bar and 300°C.

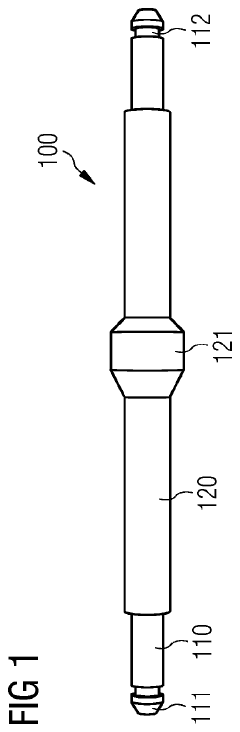

An electrical connector

PatentActiveUS20230344166A1

Innovation

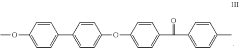

- High glass transition temperature (Tg) polymeric material (180°C to 220°C) for enhanced thermal stability in material jetting applications.

- Standardized DSC methodology for precise determination of thermal properties (Tg, Tm, and ΔHm) with specific heating/cooling cycles and hold times.

- Quantitative crystallization level determination method using heat of fusion measurements relative to a fully crystalline polymer reference.

Material Characterization Methods for Thermal Performance

The comprehensive assessment of thermal performance in material jetting processes requires sophisticated characterization methods that can accurately measure and predict material behavior under various thermal conditions. Differential Scanning Calorimetry (DSC) stands as a primary analytical technique, enabling precise determination of glass transition temperature (Tg), melting points, and crystallization behavior. DSC measurements reveal critical information about phase transitions and thermal stability, particularly important for understanding how jetted materials maintain their Tg characteristics after processing.

Dynamic Mechanical Analysis (DMA) complements DSC by evaluating viscoelastic properties across temperature ranges. This technique measures storage modulus, loss modulus, and tan delta, providing insights into material stiffness and damping characteristics during thermal cycling. For material jetting applications, DMA helps predict how printed components will respond to mechanical stresses at varying temperatures, essential for parts subjected to thermal fluctuations in service.

Thermomechanical Analysis (TMA) specifically addresses dimensional stability by measuring thermal expansion coefficients and dimensional changes during heating and cooling cycles. This method proves invaluable for quantifying deformation tendencies in jetted materials, particularly for applications requiring tight dimensional tolerances under thermal loading conditions.

Thermogravimetric Analysis (TGA) evaluates material degradation by measuring weight changes during controlled temperature programs. For jetted materials, TGA identifies thermal decomposition thresholds and stability limits, helping establish safe operating temperature ranges and predicting long-term performance under elevated temperature conditions.

Advanced imaging techniques, including Hot-Stage Microscopy and Thermal Infrared Imaging, provide visual confirmation of thermal behavior. These methods allow direct observation of physical changes during heating and cooling cycles, revealing phenomena like warping, cracking, or delamination that might occur in jetted components.

Rheological characterization under temperature variation offers critical insights into flow behavior changes, particularly relevant for understanding how material jetting feedstocks perform during processing. Measuring viscosity changes across temperature ranges helps optimize printing parameters and predict material behavior during deposition and solidification phases.

Accelerated aging tests simulate long-term thermal exposure effects, enabling prediction of thermal stability over extended periods. These protocols typically involve cycling between temperature extremes to evaluate cumulative effects on mechanical properties, dimensional stability, and overall performance degradation rates in jetted materials.

Dynamic Mechanical Analysis (DMA) complements DSC by evaluating viscoelastic properties across temperature ranges. This technique measures storage modulus, loss modulus, and tan delta, providing insights into material stiffness and damping characteristics during thermal cycling. For material jetting applications, DMA helps predict how printed components will respond to mechanical stresses at varying temperatures, essential for parts subjected to thermal fluctuations in service.

Thermomechanical Analysis (TMA) specifically addresses dimensional stability by measuring thermal expansion coefficients and dimensional changes during heating and cooling cycles. This method proves invaluable for quantifying deformation tendencies in jetted materials, particularly for applications requiring tight dimensional tolerances under thermal loading conditions.

Thermogravimetric Analysis (TGA) evaluates material degradation by measuring weight changes during controlled temperature programs. For jetted materials, TGA identifies thermal decomposition thresholds and stability limits, helping establish safe operating temperature ranges and predicting long-term performance under elevated temperature conditions.

Advanced imaging techniques, including Hot-Stage Microscopy and Thermal Infrared Imaging, provide visual confirmation of thermal behavior. These methods allow direct observation of physical changes during heating and cooling cycles, revealing phenomena like warping, cracking, or delamination that might occur in jetted components.

Rheological characterization under temperature variation offers critical insights into flow behavior changes, particularly relevant for understanding how material jetting feedstocks perform during processing. Measuring viscosity changes across temperature ranges helps optimize printing parameters and predict material behavior during deposition and solidification phases.

Accelerated aging tests simulate long-term thermal exposure effects, enabling prediction of thermal stability over extended periods. These protocols typically involve cycling between temperature extremes to evaluate cumulative effects on mechanical properties, dimensional stability, and overall performance degradation rates in jetted materials.

Environmental Impact of High-Temperature Material Jetting Applications

The environmental implications of high-temperature material jetting applications extend beyond mere manufacturing considerations, encompassing broader ecological concerns. As material jetting technologies increasingly incorporate thermally stable polymers capable of withstanding elevated temperatures, their environmental footprint becomes a critical factor for sustainable industrial development.

The production of high-temperature resistant materials often requires energy-intensive processes and specialized chemical compounds. These materials typically contain advanced polymer formulations with complex additives that enhance thermal stability while maintaining glass transition temperature (Tg) properties. The synthesis of these compounds frequently involves petroleum-derived precursors and energy-intensive manufacturing, contributing significantly to carbon emissions and resource depletion.

During the operational phase, high-temperature material jetting applications demonstrate mixed environmental effects. On one hand, the enhanced thermal stability reduces waste generation from heat-induced deformation failures, extending product lifecycles and decreasing replacement frequency. This durability aspect represents a positive environmental contribution through resource conservation and waste reduction. Conversely, the energy consumption required to maintain elevated processing temperatures creates a substantial operational carbon footprint.

End-of-life considerations present particular challenges for thermally stable materials. Their inherent resistance to degradation—the very property that makes them valuable in high-temperature applications—often renders them less biodegradable and more persistent in natural environments. Recycling processes for these specialized materials frequently require higher energy inputs and more complex separation techniques compared to conventional polymers, creating additional environmental burdens.

Recent life cycle assessments of high-temperature material jetting applications reveal that the environmental impact varies significantly based on specific material formulations and processing parameters. Materials engineered to maintain dimensional stability through heat cycling often incorporate flame retardants and thermal stabilizers that may present toxicity concerns if improperly managed at disposal. However, innovations in bio-based high-temperature resistant polymers show promising developments toward reducing environmental impact while maintaining thermal performance.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns, with particular focus on recyclability requirements and restrictions on persistent organic pollutants often found in high-performance materials. Industry leaders are responding with green chemistry initiatives aimed at developing thermally stable materials with reduced environmental footprints, including biodegradable alternatives and materials designed for easier recycling pathways.

The production of high-temperature resistant materials often requires energy-intensive processes and specialized chemical compounds. These materials typically contain advanced polymer formulations with complex additives that enhance thermal stability while maintaining glass transition temperature (Tg) properties. The synthesis of these compounds frequently involves petroleum-derived precursors and energy-intensive manufacturing, contributing significantly to carbon emissions and resource depletion.

During the operational phase, high-temperature material jetting applications demonstrate mixed environmental effects. On one hand, the enhanced thermal stability reduces waste generation from heat-induced deformation failures, extending product lifecycles and decreasing replacement frequency. This durability aspect represents a positive environmental contribution through resource conservation and waste reduction. Conversely, the energy consumption required to maintain elevated processing temperatures creates a substantial operational carbon footprint.

End-of-life considerations present particular challenges for thermally stable materials. Their inherent resistance to degradation—the very property that makes them valuable in high-temperature applications—often renders them less biodegradable and more persistent in natural environments. Recycling processes for these specialized materials frequently require higher energy inputs and more complex separation techniques compared to conventional polymers, creating additional environmental burdens.

Recent life cycle assessments of high-temperature material jetting applications reveal that the environmental impact varies significantly based on specific material formulations and processing parameters. Materials engineered to maintain dimensional stability through heat cycling often incorporate flame retardants and thermal stabilizers that may present toxicity concerns if improperly managed at disposal. However, innovations in bio-based high-temperature resistant polymers show promising developments toward reducing environmental impact while maintaining thermal performance.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns, with particular focus on recyclability requirements and restrictions on persistent organic pollutants often found in high-performance materials. Industry leaders are responding with green chemistry initiatives aimed at developing thermally stable materials with reduced environmental footprints, including biodegradable alternatives and materials designed for easier recycling pathways.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!