Measuring Mini LED Uniformity for Best Viewing Experience

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED Technology Background and Objectives

Mini LED technology represents a significant advancement in display technology, bridging the gap between conventional LED backlighting and the more advanced micro LED displays. Emerging in the mid-2010s, Mini LEDs are characterized by their diminutive size, typically ranging from 100 to 200 micrometers, which is substantially smaller than traditional LEDs but larger than micro LEDs. This technology has evolved from the continuous pursuit of enhanced display performance, particularly in terms of contrast ratio, brightness, and color accuracy.

The evolution of Mini LED technology has been driven by the limitations of traditional LCD displays, which often struggle with achieving deep blacks and high contrast ratios due to light leakage from the backlight. By incorporating thousands of individually controlled Mini LEDs as the backlight source, manufacturers can achieve more precise local dimming, resulting in significantly improved contrast and reduced blooming effects.

The primary objective of Mini LED technology is to deliver a viewing experience that approaches the quality of OLED displays while overcoming OLED's inherent limitations such as burn-in and limited brightness. By offering superior HDR performance, Mini LED displays aim to provide more realistic and immersive visual experiences across various applications, from high-end televisions to professional monitors and mobile devices.

A critical aspect of Mini LED technology is uniformity – the consistency of brightness and color across the entire display surface. Non-uniform illumination can lead to visible hotspots, clouding, or color shifts, significantly degrading the viewing experience. As the density of Mini LEDs increases in modern displays, ensuring uniformity becomes increasingly challenging yet crucial for maintaining display quality.

The technological trend in Mini LED development is moving toward higher density arrays with more dimming zones, allowing for finer control over local contrast. Concurrently, there is a push toward reducing the size of individual LEDs to approach micro LED dimensions, which would further enhance control granularity and efficiency.

Industry projections indicate substantial growth for Mini LED technology, with applications expanding beyond premium televisions into gaming monitors, automotive displays, and professional-grade equipment for content creation. The technology is expected to maintain relevance even as micro LED development progresses, serving as an important transitional technology in the display ecosystem.

Measuring and ensuring Mini LED uniformity represents one of the most significant technical challenges in this field. The objective of uniformity measurement is to develop standardized, accurate, and efficient methods to quantify and improve the consistency of illumination across Mini LED displays, ultimately delivering the optimal viewing experience that the technology promises.

The evolution of Mini LED technology has been driven by the limitations of traditional LCD displays, which often struggle with achieving deep blacks and high contrast ratios due to light leakage from the backlight. By incorporating thousands of individually controlled Mini LEDs as the backlight source, manufacturers can achieve more precise local dimming, resulting in significantly improved contrast and reduced blooming effects.

The primary objective of Mini LED technology is to deliver a viewing experience that approaches the quality of OLED displays while overcoming OLED's inherent limitations such as burn-in and limited brightness. By offering superior HDR performance, Mini LED displays aim to provide more realistic and immersive visual experiences across various applications, from high-end televisions to professional monitors and mobile devices.

A critical aspect of Mini LED technology is uniformity – the consistency of brightness and color across the entire display surface. Non-uniform illumination can lead to visible hotspots, clouding, or color shifts, significantly degrading the viewing experience. As the density of Mini LEDs increases in modern displays, ensuring uniformity becomes increasingly challenging yet crucial for maintaining display quality.

The technological trend in Mini LED development is moving toward higher density arrays with more dimming zones, allowing for finer control over local contrast. Concurrently, there is a push toward reducing the size of individual LEDs to approach micro LED dimensions, which would further enhance control granularity and efficiency.

Industry projections indicate substantial growth for Mini LED technology, with applications expanding beyond premium televisions into gaming monitors, automotive displays, and professional-grade equipment for content creation. The technology is expected to maintain relevance even as micro LED development progresses, serving as an important transitional technology in the display ecosystem.

Measuring and ensuring Mini LED uniformity represents one of the most significant technical challenges in this field. The objective of uniformity measurement is to develop standardized, accurate, and efficient methods to quantify and improve the consistency of illumination across Mini LED displays, ultimately delivering the optimal viewing experience that the technology promises.

Market Demand for High-Quality Display Solutions

The display technology market has witnessed a significant shift towards premium visual experiences, with Mini LED technology emerging as a key innovation in this space. Consumer demand for high-quality display solutions has grown exponentially, driven by the proliferation of content consumption across multiple platforms and increasing expectations for immersive viewing experiences. Market research indicates that the global premium display market is projected to reach $149 billion by 2026, with Mini LED displays accounting for a rapidly growing segment.

This surge in demand stems from several converging factors. First, the entertainment industry's transition to higher resolution content, including 4K and 8K, has created consumer expectations for displays that can faithfully reproduce this content. Streaming platforms like Netflix, Amazon Prime, and Disney+ have invested heavily in high-quality content production, further driving consumer demand for displays that can render these productions with optimal visual fidelity.

The gaming sector represents another significant market driver, with gamers increasingly seeking displays that offer superior brightness, contrast ratios, and color accuracy. The competitive gaming and e-sports segments particularly value uniform brightness and minimal motion blur, features where Mini LED technology excels. Gaming monitor sales featuring premium display technologies have grown by 27% annually since 2020.

Professional markets, including content creation, medical imaging, and industrial design, also demonstrate strong demand for high-uniformity displays. These sectors require precise color reproduction and consistent brightness across the entire screen to ensure accurate visualization of critical information. The professional display market segment has shown a compound annual growth rate of 18% over the past five years.

Consumer electronics manufacturers have recognized this market opportunity, with major brands including Samsung, LG, Apple, and TCL incorporating Mini LED technology into their flagship products. This has created a competitive landscape where display quality, particularly uniformity, has become a key differentiator. Market analysis shows that consumers are willing to pay a premium of 15-30% for displays with superior uniformity and visual performance.

Regional analysis reveals that North America and Asia-Pacific lead in adoption of premium display technologies, with Europe showing accelerated growth. China has emerged as both a major consumer market and manufacturing hub for Mini LED technology, with significant investments in production capacity and research facilities.

The sustainability aspect also influences market demand, with energy-efficient display technologies gaining preference among environmentally conscious consumers. Mini LED technology offers improved energy efficiency compared to traditional LCD displays, aligning with this market trend and regulatory requirements for reduced power consumption in consumer electronics.

This surge in demand stems from several converging factors. First, the entertainment industry's transition to higher resolution content, including 4K and 8K, has created consumer expectations for displays that can faithfully reproduce this content. Streaming platforms like Netflix, Amazon Prime, and Disney+ have invested heavily in high-quality content production, further driving consumer demand for displays that can render these productions with optimal visual fidelity.

The gaming sector represents another significant market driver, with gamers increasingly seeking displays that offer superior brightness, contrast ratios, and color accuracy. The competitive gaming and e-sports segments particularly value uniform brightness and minimal motion blur, features where Mini LED technology excels. Gaming monitor sales featuring premium display technologies have grown by 27% annually since 2020.

Professional markets, including content creation, medical imaging, and industrial design, also demonstrate strong demand for high-uniformity displays. These sectors require precise color reproduction and consistent brightness across the entire screen to ensure accurate visualization of critical information. The professional display market segment has shown a compound annual growth rate of 18% over the past five years.

Consumer electronics manufacturers have recognized this market opportunity, with major brands including Samsung, LG, Apple, and TCL incorporating Mini LED technology into their flagship products. This has created a competitive landscape where display quality, particularly uniformity, has become a key differentiator. Market analysis shows that consumers are willing to pay a premium of 15-30% for displays with superior uniformity and visual performance.

Regional analysis reveals that North America and Asia-Pacific lead in adoption of premium display technologies, with Europe showing accelerated growth. China has emerged as both a major consumer market and manufacturing hub for Mini LED technology, with significant investments in production capacity and research facilities.

The sustainability aspect also influences market demand, with energy-efficient display technologies gaining preference among environmentally conscious consumers. Mini LED technology offers improved energy efficiency compared to traditional LCD displays, aligning with this market trend and regulatory requirements for reduced power consumption in consumer electronics.

Current Challenges in Mini LED Uniformity Measurement

Despite significant advancements in Mini LED technology, the industry continues to face substantial challenges in accurately measuring and ensuring display uniformity. The primary obstacle lies in the inherent complexity of Mini LED arrays, which can contain thousands of individual light sources, each potentially exhibiting slight variations in brightness, color, and performance characteristics. These variations, while subtle individually, can collectively create noticeable uniformity issues that detract from the viewing experience.

Current measurement methodologies struggle with the scale and precision required for comprehensive Mini LED uniformity assessment. Traditional imaging colorimeters and spectroradiometers, while effective for conventional displays, often lack the resolution and dynamic range necessary to capture the subtle variations across thousands of Mini LEDs simultaneously. This creates a fundamental measurement gap that impacts quality control processes.

Another significant challenge is the multi-dimensional nature of uniformity issues in Mini LED displays. Uniformity must be assessed across brightness levels, viewing angles, and over time as the display ages. The industry lacks standardized testing protocols that address all these dimensions comprehensively, leading to inconsistent evaluation methods across manufacturers and testing facilities.

The zone-based local dimming architecture of Mini LED displays introduces additional complexity to uniformity measurement. The interaction between zones, particularly at zone boundaries, creates unique artifacts such as blooming and halos that require specialized measurement techniques. Current tools often fail to accurately quantify these zone-transition effects that significantly impact perceived image quality.

Temperature variations during operation present another measurement challenge. Mini LEDs exhibit performance shifts under different thermal conditions, yet most current testing occurs under controlled laboratory environments that may not reflect real-world usage scenarios. This disconnect between testing conditions and actual usage environments creates a blind spot in uniformity assessment.

Manufacturing variability compounds these challenges, as slight differences in LED chip quality, placement precision, and driver circuit performance all contribute to uniformity issues. Current in-line testing methods often lack the sensitivity to detect these subtle manufacturing variations before final assembly, making remediation costly and inefficient.

The industry also faces challenges in correlating objective measurements with subjective human perception. What measurement instruments detect as uniformity issues may not always align with what the human visual system perceives as problematic, creating a disconnect between technical specifications and actual viewing experience quality.

Current measurement methodologies struggle with the scale and precision required for comprehensive Mini LED uniformity assessment. Traditional imaging colorimeters and spectroradiometers, while effective for conventional displays, often lack the resolution and dynamic range necessary to capture the subtle variations across thousands of Mini LEDs simultaneously. This creates a fundamental measurement gap that impacts quality control processes.

Another significant challenge is the multi-dimensional nature of uniformity issues in Mini LED displays. Uniformity must be assessed across brightness levels, viewing angles, and over time as the display ages. The industry lacks standardized testing protocols that address all these dimensions comprehensively, leading to inconsistent evaluation methods across manufacturers and testing facilities.

The zone-based local dimming architecture of Mini LED displays introduces additional complexity to uniformity measurement. The interaction between zones, particularly at zone boundaries, creates unique artifacts such as blooming and halos that require specialized measurement techniques. Current tools often fail to accurately quantify these zone-transition effects that significantly impact perceived image quality.

Temperature variations during operation present another measurement challenge. Mini LEDs exhibit performance shifts under different thermal conditions, yet most current testing occurs under controlled laboratory environments that may not reflect real-world usage scenarios. This disconnect between testing conditions and actual usage environments creates a blind spot in uniformity assessment.

Manufacturing variability compounds these challenges, as slight differences in LED chip quality, placement precision, and driver circuit performance all contribute to uniformity issues. Current in-line testing methods often lack the sensitivity to detect these subtle manufacturing variations before final assembly, making remediation costly and inefficient.

The industry also faces challenges in correlating objective measurements with subjective human perception. What measurement instruments detect as uniformity issues may not always align with what the human visual system perceives as problematic, creating a disconnect between technical specifications and actual viewing experience quality.

Current Measurement Methods for Mini LED Uniformity

01 Optical diffusion techniques for Mini LED uniformity

Various optical diffusion techniques are employed to improve the uniformity of Mini LED displays. These include using diffusion films, light guide plates, and micro-lens arrays that help to spread the light evenly across the display surface. These components work by scattering the light from individual Mini LEDs to reduce hotspots and create a more uniform luminance distribution, which is essential for high-quality display performance.- Optical diffusion techniques for Mini LED uniformity: Various optical diffusion techniques are employed to enhance the uniformity of Mini LED displays. These include using diffusion films, optical sheets, and specialized lenses that help distribute light evenly across the display surface. These components work by scattering light from individual Mini LEDs to eliminate hotspots and dark areas, resulting in more consistent brightness and color across the entire display.

- Backlight structure optimization for Mini LED displays: The design and arrangement of the backlight structure significantly impacts Mini LED display uniformity. This includes optimizing the placement and spacing of Mini LEDs, incorporating reflective materials, and designing specialized light guide plates. Advanced backlight structures can reduce light leakage and improve light distribution, leading to enhanced brightness uniformity across the display panel.

- Driving circuit and control algorithms for uniform illumination: Sophisticated driving circuits and control algorithms are implemented to ensure uniform illumination across Mini LED displays. These include local dimming technologies, current compensation circuits, and feedback systems that adjust the power supplied to individual LEDs based on real-time measurements. These electronic solutions help compensate for manufacturing variations between LEDs and maintain consistent brightness levels.

- Manufacturing process improvements for Mini LED uniformity: Advancements in manufacturing processes contribute to improved Mini LED uniformity. These include precision placement techniques, enhanced quality control during LED production, and specialized bonding methods. By reducing variations in LED characteristics during production and ensuring accurate positioning during assembly, these manufacturing improvements help achieve more consistent performance across all Mini LEDs in a display.

- Thermal management solutions for consistent Mini LED performance: Effective thermal management is crucial for maintaining uniform Mini LED performance. Various solutions include heat dissipation structures, thermal interface materials, and active cooling systems. These components help distribute and remove heat evenly from the Mini LED array, preventing temperature-induced variations in brightness and color that could compromise display uniformity.

02 Backlight structure optimization for Mini LED displays

The design and arrangement of the backlight structure significantly impacts the uniformity of Mini LED displays. This includes optimizing the placement of Mini LEDs, using reflective materials, and implementing multi-layer structures. By carefully designing the backlight module with appropriate spacing between LEDs and incorporating reflective surfaces, light distribution can be made more uniform, reducing brightness variations across the display.Expand Specific Solutions03 Driving circuit and control methods for uniform brightness

Advanced driving circuits and control methods are implemented to ensure uniform brightness across Mini LED displays. These include local dimming technologies, current compensation algorithms, and feedback control systems that adjust the power supplied to individual LEDs or LED zones. By precisely controlling the current and voltage to each Mini LED based on real-time measurements, brightness variations can be minimized even as components age or operate under different temperature conditions.Expand Specific Solutions04 Manufacturing processes for consistent Mini LED performance

Specialized manufacturing processes are developed to ensure consistent performance among Mini LEDs. These include precise epitaxial growth techniques, improved chip binning methods, and advanced packaging technologies. By controlling the manufacturing variables and implementing strict quality control measures, the inherent variations between individual Mini LEDs can be minimized, leading to better uniformity in the final display product.Expand Specific Solutions05 Thermal management solutions for uniform Mini LED operation

Effective thermal management solutions are crucial for maintaining uniform Mini LED operation. These include heat dissipation structures, thermal interface materials, and active cooling systems that help to distribute and remove heat evenly. Since LED performance is temperature-dependent, controlling the thermal environment ensures that all Mini LEDs operate under similar conditions, preventing temperature-induced brightness variations and extending the lifespan of the display.Expand Specific Solutions

Key Industry Players in Mini LED Manufacturing

The Mini LED uniformity measurement technology landscape is evolving rapidly as the display industry transitions from early adoption to growth phase. The market is projected to expand significantly with Mini LED displays gaining traction in premium consumer electronics. From a technological maturity perspective, established players like BOE Technology, Samsung Electronics, and TCL China Star Optoelectronics are leading with advanced uniformity measurement solutions, while specialized companies such as Xian NovaStar Tech and Shenzhen Refond Optoelectronics are developing complementary technologies. LG Innotek and Seoul Viosys contribute significant innovations in LED packaging and testing methodologies. The competitive landscape is characterized by increasing collaboration between display manufacturers and metrology solution providers to address the critical challenge of ensuring consistent brightness and color across Mini LED arrays for optimal viewing experiences.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive Mini LED uniformity measurement system that combines high-precision optical sensors with AI-driven analysis algorithms. Their approach utilizes a multi-point scanning technique that captures luminance variations across the entire display surface at various viewing angles. The system employs spectroradiometers with ±2% accuracy to measure brightness, color temperature, and gamma consistency. BOE's proprietary "Active Matrix Compensation" technology dynamically adjusts individual Mini LED zones based on real-time uniformity measurements, ensuring consistent brightness across the panel. Their measurement protocol includes evaluation under different ambient light conditions (0-500 lux) to simulate real-world viewing environments. The company has implemented automated production line testing that can detect uniformity issues with 98.5% accuracy, significantly reducing defect rates in their high-end display products.

Strengths: Industry-leading measurement precision with comprehensive multi-angle testing capabilities. Integration with production systems allows for immediate correction of uniformity issues. Weaknesses: The system requires frequent calibration and is more complex/expensive than traditional measurement approaches, potentially limiting implementation in lower-cost product lines.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has developed the "Uniform Vision" measurement system specifically designed for Mini LED backlight uniformity assessment. Their approach utilizes a combination of high-precision imaging colorimeters and spectroradiometers to capture both luminance and chromaticity variations across display panels. The system employs a multi-angle measurement protocol that evaluates uniformity from 9 different viewing positions to ensure consistent performance regardless of viewing angle. TCL's proprietary algorithm quantifies uniformity using a "Deviation Index" that considers both local and global variations, with measurements taken at over 1,000 points across the display surface. Their measurement system is integrated with their Mini LED production line, allowing for real-time adjustments to LED current drivers based on uniformity data. The company has implemented an AI-based prediction model that can anticipate uniformity degradation over time, enabling proactive compensation in their high-end display products. TCL's system achieves measurement accuracy within ±3% for luminance and ±0.002 for chromaticity coordinates.

Strengths: Comprehensive multi-angle measurement approach provides excellent correlation with human visual perception of uniformity. Integration with production systems enables immediate correction. Weaknesses: The system requires significant calibration time and specialized equipment, making it less suitable for rapid quality control in high-volume manufacturing environments.

Critical Technologies for Precise Uniformity Assessment

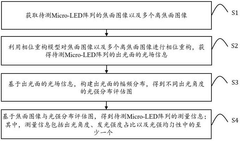

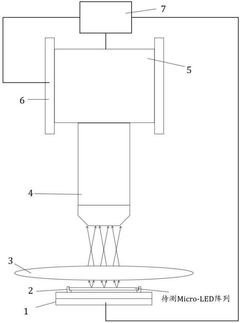

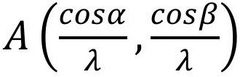

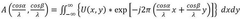

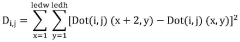

Micro-LED array measurement method and system based on phase reconstruction

PatentActiveCN120194914A

Innovation

- The Micro-LED array measurement method based on phase reconstruction is adopted. By acquiring the focal surface image and multiple defocal surface images, phase reconstruction is performed using the phase reconstruction model to construct light field information and evaluate the light intensity distribution, and obtaining the light angle, luminous intensity ratio and light intensity uniformity.

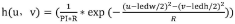

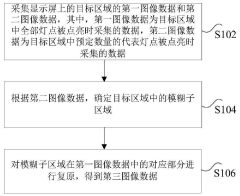

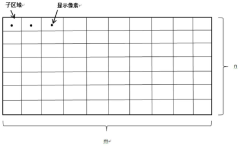

Data processing method, device, storage medium and computer equipment

PatentActiveCN112529816B

Innovation

- By collecting all the light points in the target area of the display screen and a predetermined number of image data representing the light points, the fuzzy sub-area is determined and restored in the first image data to obtain clear third image data, realizing the fuzzy area of recovery.

Visual Perception Factors in Display Quality Evaluation

Visual perception represents the cornerstone of display quality evaluation, particularly when assessing Mini LED uniformity. Human visual systems process display information through complex mechanisms that significantly impact the perceived quality of Mini LED displays. Understanding these perceptual factors is essential for developing effective uniformity measurement methodologies.

Color perception plays a critical role in uniformity assessment. The human eye exhibits varying sensitivity across different wavelengths, with greatest sensitivity to green light, followed by red and blue. This non-uniform spectral sensitivity means that uniformity issues in certain color channels may be more perceptible than others. Mini LED displays must account for these perceptual differences when calibrating for optimal uniformity.

Contrast sensitivity fundamentally influences how viewers perceive brightness variations across a display. The Weber-Fechner law indicates that humans detect relative rather than absolute differences in luminance, with sensitivity following a logarithmic rather than linear relationship. This explains why even minor uniformity issues in darker scenes can be highly noticeable, while similar deviations in brighter areas may remain imperceptible.

Spatial frequency sensitivity affects how viewers perceive patterns of non-uniformity. The human visual system demonstrates varying sensitivity to different spatial frequencies, with peak sensitivity typically occurring at around 4-6 cycles per degree of visual angle. Consequently, certain patterns of Mini LED non-uniformity may be more visually disturbing than others, even when measured values are identical.

Viewing angle considerations significantly impact perceived uniformity. Visual acuity and color perception change with viewing angle, making off-axis uniformity particularly challenging for Mini LED displays. The visual system's adaptation mechanisms also influence uniformity perception, as the eye continuously adjusts to changing brightness and color conditions.

Temporal factors further complicate uniformity evaluation. The persistence of vision and temporal integration properties of the human visual system mean that rapidly changing content may mask certain uniformity issues, while static content makes them more apparent. Additionally, viewer fatigue and adaptation over extended viewing periods can alter uniformity perception.

Understanding these visual perception factors enables the development of perceptually-weighted uniformity measurement methodologies that correlate more closely with actual viewing experiences. By incorporating these human factors into Mini LED uniformity assessment, manufacturers can optimize displays for real-world viewing conditions rather than merely achieving technical specifications that may not translate to superior perceived quality.

Color perception plays a critical role in uniformity assessment. The human eye exhibits varying sensitivity across different wavelengths, with greatest sensitivity to green light, followed by red and blue. This non-uniform spectral sensitivity means that uniformity issues in certain color channels may be more perceptible than others. Mini LED displays must account for these perceptual differences when calibrating for optimal uniformity.

Contrast sensitivity fundamentally influences how viewers perceive brightness variations across a display. The Weber-Fechner law indicates that humans detect relative rather than absolute differences in luminance, with sensitivity following a logarithmic rather than linear relationship. This explains why even minor uniformity issues in darker scenes can be highly noticeable, while similar deviations in brighter areas may remain imperceptible.

Spatial frequency sensitivity affects how viewers perceive patterns of non-uniformity. The human visual system demonstrates varying sensitivity to different spatial frequencies, with peak sensitivity typically occurring at around 4-6 cycles per degree of visual angle. Consequently, certain patterns of Mini LED non-uniformity may be more visually disturbing than others, even when measured values are identical.

Viewing angle considerations significantly impact perceived uniformity. Visual acuity and color perception change with viewing angle, making off-axis uniformity particularly challenging for Mini LED displays. The visual system's adaptation mechanisms also influence uniformity perception, as the eye continuously adjusts to changing brightness and color conditions.

Temporal factors further complicate uniformity evaluation. The persistence of vision and temporal integration properties of the human visual system mean that rapidly changing content may mask certain uniformity issues, while static content makes them more apparent. Additionally, viewer fatigue and adaptation over extended viewing periods can alter uniformity perception.

Understanding these visual perception factors enables the development of perceptually-weighted uniformity measurement methodologies that correlate more closely with actual viewing experiences. By incorporating these human factors into Mini LED uniformity assessment, manufacturers can optimize displays for real-world viewing conditions rather than merely achieving technical specifications that may not translate to superior perceived quality.

Manufacturing Process Optimization for Uniformity

Achieving optimal uniformity in Mini LED displays requires systematic optimization of manufacturing processes across multiple stages. The production line must be calibrated to ensure consistent LED chip quality, with precise control over epitaxial growth parameters including temperature, pressure, and gas flow rates. Statistical process control methods should be implemented to monitor variations in wafer quality, enabling real-time adjustments that minimize batch-to-batch inconsistencies.

Binning and sorting processes represent critical control points for uniformity management. Advanced optical measurement systems can categorize Mini LEDs based on brightness, color, and electrical characteristics with tolerances as tight as ±2%. Implementing automated sorting systems with machine vision capabilities ensures that only LEDs within specified uniformity parameters proceed to panel integration, significantly reducing final display variation.

Transfer and placement precision directly impacts uniformity outcomes. State-of-the-art pick-and-place equipment capable of micron-level accuracy must be employed, with regular calibration schedules to maintain placement precision. Environmental controls during this stage are essential, as temperature and humidity fluctuations can affect adhesive properties and placement accuracy. Manufacturers achieving the highest uniformity standards typically maintain cleanroom conditions with temperature variations under ±0.5°C.

Post-placement inspection represents another critical optimization opportunity. Automated optical inspection (AOI) systems can detect misalignments, defects, or brightness variations before final assembly. The integration of real-time feedback loops between inspection systems and placement equipment enables continuous process refinement, with leading manufacturers implementing closed-loop systems that reduce uniformity defects by up to 40%.

Thermal management during manufacturing significantly impacts uniformity performance. Controlled thermal cycling and stress relief processes help minimize thermal-induced variations in LED performance. Advanced manufacturers implement thermal profiling across production stages to ensure consistent thermal history for all components, reducing stress-induced brightness variations.

Final calibration processes can compensate for remaining non-uniformities through pixel-by-pixel adjustment algorithms. These calibration systems must be integrated into production lines with high-resolution imaging equipment capable of detecting subtle brightness variations. Machine learning algorithms can then generate compensation matrices that are programmed into display drivers, effectively normalizing brightness across the entire panel.

Quality assurance protocols should include uniformity-specific measurements at multiple production stages rather than relying solely on end-of-line testing. This distributed quality control approach enables earlier detection of uniformity issues, reducing waste and improving overall yield rates. Manufacturers implementing these comprehensive process optimizations typically achieve uniformity improvements of 30-50% compared to standard production methods.

Binning and sorting processes represent critical control points for uniformity management. Advanced optical measurement systems can categorize Mini LEDs based on brightness, color, and electrical characteristics with tolerances as tight as ±2%. Implementing automated sorting systems with machine vision capabilities ensures that only LEDs within specified uniformity parameters proceed to panel integration, significantly reducing final display variation.

Transfer and placement precision directly impacts uniformity outcomes. State-of-the-art pick-and-place equipment capable of micron-level accuracy must be employed, with regular calibration schedules to maintain placement precision. Environmental controls during this stage are essential, as temperature and humidity fluctuations can affect adhesive properties and placement accuracy. Manufacturers achieving the highest uniformity standards typically maintain cleanroom conditions with temperature variations under ±0.5°C.

Post-placement inspection represents another critical optimization opportunity. Automated optical inspection (AOI) systems can detect misalignments, defects, or brightness variations before final assembly. The integration of real-time feedback loops between inspection systems and placement equipment enables continuous process refinement, with leading manufacturers implementing closed-loop systems that reduce uniformity defects by up to 40%.

Thermal management during manufacturing significantly impacts uniformity performance. Controlled thermal cycling and stress relief processes help minimize thermal-induced variations in LED performance. Advanced manufacturers implement thermal profiling across production stages to ensure consistent thermal history for all components, reducing stress-induced brightness variations.

Final calibration processes can compensate for remaining non-uniformities through pixel-by-pixel adjustment algorithms. These calibration systems must be integrated into production lines with high-resolution imaging equipment capable of detecting subtle brightness variations. Machine learning algorithms can then generate compensation matrices that are programmed into display drivers, effectively normalizing brightness across the entire panel.

Quality assurance protocols should include uniformity-specific measurements at multiple production stages rather than relying solely on end-of-line testing. This distributed quality control approach enables earlier detection of uniformity issues, reducing waste and improving overall yield rates. Manufacturers implementing these comprehensive process optimizations typically achieve uniformity improvements of 30-50% compared to standard production methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!