Mini LED Support for Color-Corrected Real-World Displays

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED Technology Background and Objectives

Mini LED technology represents a significant advancement in display technology, bridging the gap between traditional LCD and OLED displays. Emerging in the mid-2010s, Mini LEDs are semiconductor light sources with dimensions typically ranging from 50 to 200 micrometers, substantially smaller than conventional LEDs but larger than microLEDs. This technology has evolved from traditional LED backlighting systems, offering enhanced control over local dimming zones and improved contrast ratios.

The evolution of Mini LED technology has been driven by the increasing demand for higher display quality in various applications, including televisions, monitors, tablets, and automotive displays. The technology's development trajectory shows a clear trend toward miniaturization of LED components, enabling more precise backlighting control and better image quality. Industry forecasts suggest that the Mini LED market is poised for substantial growth, with an expected CAGR of approximately 20% through 2026.

The primary objective of Mini LED technology in color-corrected real-world displays is to achieve superior color accuracy, contrast, and brightness while maintaining energy efficiency. By incorporating thousands of tiny LEDs as backlighting sources, Mini LED displays aim to deliver more precise local dimming capabilities, resulting in deeper blacks and more vibrant colors that closely mimic real-world visual experiences. This is particularly crucial for applications requiring high color fidelity, such as professional content creation, medical imaging, and high-end consumer electronics.

Another key objective is to address the limitations of current display technologies. While OLED displays offer excellent contrast and color reproduction, they suffer from issues like burn-in and limited brightness. Traditional LCD displays, conversely, struggle with contrast ratios and black levels. Mini LED technology seeks to combine the best attributes of both: the contrast capabilities approaching OLED quality with the brightness and longevity advantages of LCD technology.

The integration of Mini LED technology with color correction algorithms represents a frontier in display technology. The goal is to develop systems that can dynamically adjust backlighting based on ambient conditions and content requirements, ensuring consistent color reproduction across varying environments. This adaptive capability is essential for creating displays that maintain color accuracy regardless of viewing conditions, a critical feature for both professional and consumer applications.

Looking forward, the technical roadmap for Mini LED displays includes further reducing the LED size, increasing the number of dimming zones, and developing more sophisticated control algorithms. These advancements aim to enhance HDR performance, reduce power consumption, and minimize production costs, making the technology more accessible across various market segments while pushing the boundaries of visual fidelity in electronic displays.

The evolution of Mini LED technology has been driven by the increasing demand for higher display quality in various applications, including televisions, monitors, tablets, and automotive displays. The technology's development trajectory shows a clear trend toward miniaturization of LED components, enabling more precise backlighting control and better image quality. Industry forecasts suggest that the Mini LED market is poised for substantial growth, with an expected CAGR of approximately 20% through 2026.

The primary objective of Mini LED technology in color-corrected real-world displays is to achieve superior color accuracy, contrast, and brightness while maintaining energy efficiency. By incorporating thousands of tiny LEDs as backlighting sources, Mini LED displays aim to deliver more precise local dimming capabilities, resulting in deeper blacks and more vibrant colors that closely mimic real-world visual experiences. This is particularly crucial for applications requiring high color fidelity, such as professional content creation, medical imaging, and high-end consumer electronics.

Another key objective is to address the limitations of current display technologies. While OLED displays offer excellent contrast and color reproduction, they suffer from issues like burn-in and limited brightness. Traditional LCD displays, conversely, struggle with contrast ratios and black levels. Mini LED technology seeks to combine the best attributes of both: the contrast capabilities approaching OLED quality with the brightness and longevity advantages of LCD technology.

The integration of Mini LED technology with color correction algorithms represents a frontier in display technology. The goal is to develop systems that can dynamically adjust backlighting based on ambient conditions and content requirements, ensuring consistent color reproduction across varying environments. This adaptive capability is essential for creating displays that maintain color accuracy regardless of viewing conditions, a critical feature for both professional and consumer applications.

Looking forward, the technical roadmap for Mini LED displays includes further reducing the LED size, increasing the number of dimming zones, and developing more sophisticated control algorithms. These advancements aim to enhance HDR performance, reduce power consumption, and minimize production costs, making the technology more accessible across various market segments while pushing the boundaries of visual fidelity in electronic displays.

Market Analysis for Color-Corrected Display Solutions

The color-corrected display market is experiencing significant growth driven by increasing demand for high-fidelity visual experiences across multiple sectors. Current market valuations place the global color-accurate display market at approximately 9.8 billion USD in 2023, with projections indicating a compound annual growth rate of 11.3% through 2028. This growth trajectory is supported by expanding applications in professional content creation, medical imaging, automotive displays, and premium consumer electronics.

Professional sectors represent the largest market segment, with content creators, graphic designers, and video production studios requiring displays that can accurately reproduce color spaces such as Adobe RGB, DCI-P3, and Rec. 2020. This segment accounts for roughly 38% of the current market share, with particularly strong demand in North America and East Asia.

The consumer electronics segment is showing the fastest growth rate, as smartphone and television manufacturers increasingly implement color correction technologies to differentiate their premium product lines. Mini LED backlighting solutions are gaining particular traction in this space, with market penetration increasing from 7% in 2021 to an estimated 18% in 2023 for high-end displays.

Regional analysis reveals that Asia-Pacific dominates manufacturing capacity, accounting for approximately 65% of global production of color-corrected displays, with particular concentration in Taiwan, South Korea, and increasingly China. North America and Europe represent the largest consumer markets by revenue, collectively accounting for 58% of global sales value.

Market research indicates that consumers are increasingly willing to pay premium prices for displays with superior color accuracy, with surveys showing 72% of professional users and 41% of premium consumers identifying color fidelity as a "very important" purchase consideration. This represents a significant shift from five years ago when these figures were 54% and 23% respectively.

Key market drivers include the proliferation of HDR content, growing adoption of wide color gamut standards, increasing consumer awareness of display quality, and the expanding creator economy. The integration of Mini LED technology with advanced color correction algorithms represents a particularly promising market opportunity, with early adopters reporting 30-40% improvements in color volume and accuracy compared to conventional LED-backlit displays.

Market challenges include high production costs, technical complexity in calibration processes, and consumer education regarding the benefits of color-accurate displays. Additionally, the market faces supply chain constraints for certain specialized components, particularly high-quality color filters and advanced local dimming controllers essential for Mini LED implementations.

Professional sectors represent the largest market segment, with content creators, graphic designers, and video production studios requiring displays that can accurately reproduce color spaces such as Adobe RGB, DCI-P3, and Rec. 2020. This segment accounts for roughly 38% of the current market share, with particularly strong demand in North America and East Asia.

The consumer electronics segment is showing the fastest growth rate, as smartphone and television manufacturers increasingly implement color correction technologies to differentiate their premium product lines. Mini LED backlighting solutions are gaining particular traction in this space, with market penetration increasing from 7% in 2021 to an estimated 18% in 2023 for high-end displays.

Regional analysis reveals that Asia-Pacific dominates manufacturing capacity, accounting for approximately 65% of global production of color-corrected displays, with particular concentration in Taiwan, South Korea, and increasingly China. North America and Europe represent the largest consumer markets by revenue, collectively accounting for 58% of global sales value.

Market research indicates that consumers are increasingly willing to pay premium prices for displays with superior color accuracy, with surveys showing 72% of professional users and 41% of premium consumers identifying color fidelity as a "very important" purchase consideration. This represents a significant shift from five years ago when these figures were 54% and 23% respectively.

Key market drivers include the proliferation of HDR content, growing adoption of wide color gamut standards, increasing consumer awareness of display quality, and the expanding creator economy. The integration of Mini LED technology with advanced color correction algorithms represents a particularly promising market opportunity, with early adopters reporting 30-40% improvements in color volume and accuracy compared to conventional LED-backlit displays.

Market challenges include high production costs, technical complexity in calibration processes, and consumer education regarding the benefits of color-accurate displays. Additionally, the market faces supply chain constraints for certain specialized components, particularly high-quality color filters and advanced local dimming controllers essential for Mini LED implementations.

Current Challenges in Mini LED Color Correction

Despite significant advancements in Mini LED technology for displays, several critical challenges persist in achieving accurate color correction. The primary obstacle lies in the inherent limitations of local dimming zones, which, while numerous compared to traditional backlighting systems, still create blooming effects around bright objects displayed against dark backgrounds. This phenomenon results in color inconsistencies and reduced contrast in these transition areas, compromising the display's color accuracy.

Temperature management presents another significant challenge, as Mini LEDs generate considerable heat during operation. This thermal variation across the display panel causes inconsistent color performance, with some regions exhibiting color drift as components reach different operating temperatures. The industry has yet to develop comprehensive thermal management solutions that maintain uniform color reproduction across the entire display surface.

Manufacturing precision remains problematic for color correction. The production process for Mini LED arrays inevitably introduces variations in LED brightness and color characteristics. Even minor inconsistencies between individual LEDs can create visible non-uniformity across the display, requiring sophisticated calibration systems that add complexity and cost to the manufacturing process.

Power consumption optimization while maintaining color accuracy presents a delicate balancing act. Implementing advanced color correction algorithms requires substantial computational resources, increasing power demands. This challenge becomes particularly acute in portable devices where battery life is a critical consideration, forcing engineers to make compromises between color accuracy and energy efficiency.

The complexity of real-time color correction algorithms represents perhaps the most significant technical hurdle. As Mini LED displays must adapt to changing content and viewing conditions, they require sophisticated algorithms that can analyze and adjust thousands of dimming zones simultaneously. Current computational approaches struggle to perform these calculations with sufficient speed while maintaining color accuracy, especially for HDR content with extreme brightness variations.

Calibration drift over the display's lifetime further complicates color correction efforts. Mini LEDs exhibit aging characteristics that affect their color output over time, with different LEDs aging at different rates. This progressive degradation necessitates periodic recalibration or intelligent compensation algorithms that can adapt to these changes, adding another layer of complexity to maintaining consistent color performance throughout the product lifecycle.

Temperature management presents another significant challenge, as Mini LEDs generate considerable heat during operation. This thermal variation across the display panel causes inconsistent color performance, with some regions exhibiting color drift as components reach different operating temperatures. The industry has yet to develop comprehensive thermal management solutions that maintain uniform color reproduction across the entire display surface.

Manufacturing precision remains problematic for color correction. The production process for Mini LED arrays inevitably introduces variations in LED brightness and color characteristics. Even minor inconsistencies between individual LEDs can create visible non-uniformity across the display, requiring sophisticated calibration systems that add complexity and cost to the manufacturing process.

Power consumption optimization while maintaining color accuracy presents a delicate balancing act. Implementing advanced color correction algorithms requires substantial computational resources, increasing power demands. This challenge becomes particularly acute in portable devices where battery life is a critical consideration, forcing engineers to make compromises between color accuracy and energy efficiency.

The complexity of real-time color correction algorithms represents perhaps the most significant technical hurdle. As Mini LED displays must adapt to changing content and viewing conditions, they require sophisticated algorithms that can analyze and adjust thousands of dimming zones simultaneously. Current computational approaches struggle to perform these calculations with sufficient speed while maintaining color accuracy, especially for HDR content with extreme brightness variations.

Calibration drift over the display's lifetime further complicates color correction efforts. Mini LEDs exhibit aging characteristics that affect their color output over time, with different LEDs aging at different rates. This progressive degradation necessitates periodic recalibration or intelligent compensation algorithms that can adapt to these changes, adding another layer of complexity to maintaining consistent color performance throughout the product lifecycle.

Current Color Correction Solutions for Mini LED

01 Color correction techniques for Mini LED displays

Various techniques are employed to correct color inconsistencies in Mini LED displays. These methods include algorithmic adjustments to compensate for color variations, calibration processes that measure and correct color output, and hardware solutions that ensure uniform color reproduction across the display. These techniques help achieve accurate color representation and improve overall display quality.- Color correction techniques for Mini LED displays: Various techniques are employed to correct color inconsistencies in Mini LED displays. These methods include algorithmic approaches that adjust color parameters based on measured deviations, hardware-based solutions that modify the electrical signals to LEDs, and optical filters that can be applied to achieve more accurate color reproduction. These techniques help ensure uniform color appearance across the display panel and improve overall visual quality.

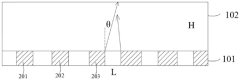

- Mini LED backlight uniformity correction: Backlight uniformity is critical for Mini LED displays. Correction methods include zone-specific brightness adjustment, optical diffusion techniques to blend light from adjacent LEDs, and compensation algorithms that account for manufacturing variations. These approaches help eliminate hotspots, dark regions, and ensure consistent illumination across the display surface, resulting in improved image quality and color accuracy.

- Temperature-based color compensation for Mini LEDs: Mini LEDs experience color shifts due to temperature variations during operation. Temperature-based compensation systems monitor thermal conditions and dynamically adjust color parameters to maintain consistent output. These systems may include thermal sensors, feedback control mechanisms, and calibration data to correct for temperature-induced color shifts, ensuring stable color performance across different operating conditions.

- Manufacturing and calibration processes for color-accurate Mini LEDs: Specialized manufacturing and calibration processes are employed to ensure color accuracy in Mini LED displays. These include binning techniques to group LEDs with similar color characteristics, factory calibration procedures that measure and store correction data, and automated testing systems that verify color performance. Post-production adjustments may also be applied to fine-tune color reproduction before the display reaches end users.

- Multi-channel color management systems for Mini LED displays: Advanced color management systems for Mini LED displays utilize multi-channel approaches to achieve precise color correction. These systems process color data through separate channels for different color components, apply device-specific correction profiles, and may incorporate machine learning algorithms to optimize color accuracy. The multi-channel approach allows for more granular control over color reproduction and can adapt to different content types and viewing environments.

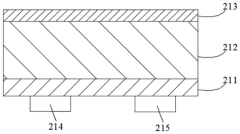

02 Mini LED backlight structure for improved color performance

Specialized backlight structures for Mini LED displays can enhance color performance. These designs include optimized light guide plates, reflective materials, and diffusion layers that work together to provide uniform illumination. The arrangement and spacing of Mini LEDs within the backlight unit also affects color consistency and can be engineered to minimize color variation across the display surface.Expand Specific Solutions03 Thermal management for color stability in Mini LEDs

Thermal management solutions are critical for maintaining color stability in Mini LED displays. As temperature affects LED performance and color output, various cooling mechanisms and heat dissipation structures are implemented to maintain consistent operating temperatures. These include heat sinks, thermal interface materials, and active cooling systems that help preserve color accuracy during extended operation.Expand Specific Solutions04 Driver circuits for precise Mini LED color control

Specialized driver circuits enable precise control of Mini LED color output. These circuits provide accurate current regulation to each LED or LED zone, allowing for fine adjustment of brightness and color. Advanced driver designs incorporate feedback mechanisms that monitor and adjust output in real-time to maintain color consistency despite variations in component characteristics or operating conditions.Expand Specific Solutions05 Manufacturing processes for color-consistent Mini LEDs

Manufacturing processes specifically designed for Mini LEDs focus on achieving color consistency across production batches. These include sorting and binning techniques that group LEDs with similar color characteristics, precision deposition methods for phosphor materials, and quality control procedures that verify color performance. Advanced fabrication technologies help minimize variations in LED structure that could affect color output.Expand Specific Solutions

Key Industry Players in Mini LED Display Market

Mini LED technology for color-corrected real-world displays is currently in a growth phase, with the market expanding rapidly as manufacturers seek to bridge the gap between traditional LCD and OLED technologies. The global market size is projected to reach significant scale by 2025, driven by increasing demand for high-quality displays with improved contrast ratios and color accuracy. In terms of technical maturity, companies like BOE Technology Group, TCL China Star Optoelectronics, and APT Electronics are leading development with advanced manufacturing capabilities, while Xian NovaStar Tech and Magicray are focusing on specialized control systems and visual inspection equipment. Google's involvement signals mainstream adoption potential, while traditional display manufacturers such as Hisense, Skyworth, and Changhong are integrating Mini LED into their product ecosystems to enhance consumer display performance.

BOE Technology Group Co., Ltd.

Technical Solution: BOE's Mini LED technology employs advanced local dimming control with up to 2,048 dimming zones for precise color correction in real-world displays. Their solution integrates proprietary algorithms that dynamically adjust brightness and color temperature based on ambient light conditions. BOE has developed a dual-layer backlight structure that combines Mini LED arrays with quantum dot enhancement film (QDEF) to achieve over 95% DCI-P3 color gamut coverage while maintaining high energy efficiency. Their displays incorporate real-time color calibration systems that use embedded sensors to detect environmental lighting changes and automatically adjust display parameters. BOE's latest Mini LED panels feature pixel-level luminance compensation technology that addresses color shift issues in off-axis viewing angles, particularly important for large-format commercial displays in varying lighting environments.

Strengths: Superior local dimming capabilities with high zone count enabling precise HDR rendering; advanced color management system that adapts to ambient conditions; energy-efficient design despite high brightness capabilities. Weaknesses: Higher manufacturing costs compared to traditional LCD technologies; thermal management challenges in ultra-thin display designs; requires sophisticated driving circuits that increase overall system complexity.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has developed a comprehensive Mini LED solution called "Vidrian" that integrates thousands of miniaturized LEDs directly into a glass substrate for superior color accuracy and brightness control. Their technology implements an advanced 16-bit grayscale control system that enables over 65,000 brightness levels per zone, allowing for precise color correction across varying ambient lighting conditions. The company's displays feature a proprietary "Real Color Pro" algorithm that continuously analyzes content and environmental factors to optimize color reproduction. TCL CSOT's Mini LED panels incorporate quantum dot enhancement layers that expand the color gamut to cover 100% of DCI-P3 and up to 85% of Rec.2020 standards. Their latest generation displays utilize machine learning algorithms to predict and compensate for color shifts caused by viewing angle and ambient light variations, ensuring consistent color performance in real-world environments.

Strengths: Direct integration of Mini LEDs into glass substrate reduces optical layers and improves efficiency; advanced quantum dot implementation provides exceptional color volume; sophisticated AI-driven color management system. Weaknesses: Premium pricing positions products primarily in high-end market segments; higher power consumption compared to OLED alternatives; complex manufacturing process affects production yields.

Core Patents and Innovations in Mini LED Technology

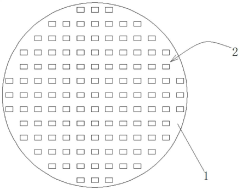

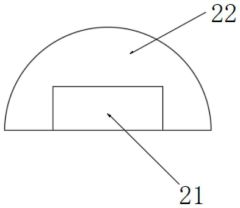

Light-emitting module and display device

PatentPendingCN117525241A

Innovation

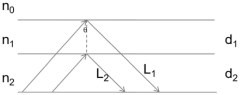

- Design a light-emitting module, including a substrate and a light-emitting device. The light-emitting device is set in the opening of the substrate. The coating layer has different thicknesses of different colors, and the propagation angle and transmission of light are adjusted through the distribution of the sealant layer and black particles. efficiency, ensuring that light of different colors has the same color cast effect under a large viewing angle.

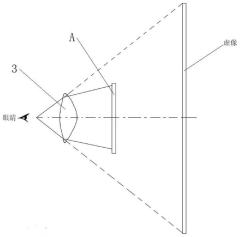

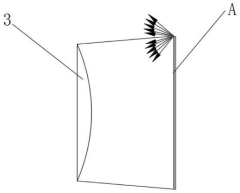

Mini LED-based VR display screen and VR device

PatentActiveCN115171549A

Innovation

- Design a VR display screen based on Mini LED by arranging light-emitting elements in an array on the substrate. Each light-emitting element includes a Mini LED chip and packaged colloid. The shape of the colloid near the center of the substrate is different from that of the colloid near the edge of the substrate. Different lighting angles to maximize the concentration of light to the human eye.

Power Efficiency and Thermal Management Considerations

Mini LED technology in color-corrected real-world displays presents significant challenges in power efficiency and thermal management that require careful consideration. The implementation of Mini LED backlighting systems typically involves thousands of individually controllable LED zones, each consuming power and generating heat during operation. Current Mini LED displays demonstrate 30-40% improved energy efficiency compared to traditional LCD displays, primarily due to their ability to selectively dim or turn off zones where dark content is displayed, while maintaining brightness in highlighted areas.

The power consumption profile of Mini LED displays varies significantly based on content being displayed. High Dynamic Range (HDR) content with extreme contrast ratios can cause certain zones to operate at maximum brightness while others remain dimmed, creating uneven power distribution across the display panel. This variable power consumption pattern necessitates sophisticated power management systems that can dynamically adjust current delivery to different zones while maintaining color accuracy and brightness consistency.

Thermal management represents a critical challenge in Mini LED implementation, particularly in thin form factor devices such as tablets and laptops. The concentrated heat generation from densely packed Mini LED arrays can lead to thermal hotspots that potentially affect display performance, color accuracy, and component longevity. Advanced thermal dissipation solutions including graphite sheets, vapor chambers, and micro-channel cooling systems are being integrated to address these concerns. Research indicates that operating temperatures above 85°C can significantly reduce Mini LED efficiency and accelerate color shift, emphasizing the importance of effective thermal management.

Power delivery systems for Mini LED displays require precise current regulation to maintain color consistency across thousands of zones. Multi-channel LED drivers with adaptive current control have been developed to optimize power delivery while minimizing heat generation. These sophisticated driver ICs can adjust current levels with microsecond precision, enabling both power savings and enhanced display performance. Industry data suggests that advanced driver solutions can reduce overall system power consumption by 15-20% compared to first-generation Mini LED implementations.

The relationship between power efficiency and color accuracy presents another significant challenge. As Mini LEDs operate at different power levels to achieve varying brightness levels, maintaining consistent color temperature and spectral output becomes increasingly difficult. Compensation algorithms that account for LED behavior across different power states are essential for preserving color accuracy in real-world applications. These algorithms continuously monitor thermal conditions and adjust power delivery parameters to maintain consistent visual output, though this adaptive approach itself introduces additional computational overhead and power requirements.

The power consumption profile of Mini LED displays varies significantly based on content being displayed. High Dynamic Range (HDR) content with extreme contrast ratios can cause certain zones to operate at maximum brightness while others remain dimmed, creating uneven power distribution across the display panel. This variable power consumption pattern necessitates sophisticated power management systems that can dynamically adjust current delivery to different zones while maintaining color accuracy and brightness consistency.

Thermal management represents a critical challenge in Mini LED implementation, particularly in thin form factor devices such as tablets and laptops. The concentrated heat generation from densely packed Mini LED arrays can lead to thermal hotspots that potentially affect display performance, color accuracy, and component longevity. Advanced thermal dissipation solutions including graphite sheets, vapor chambers, and micro-channel cooling systems are being integrated to address these concerns. Research indicates that operating temperatures above 85°C can significantly reduce Mini LED efficiency and accelerate color shift, emphasizing the importance of effective thermal management.

Power delivery systems for Mini LED displays require precise current regulation to maintain color consistency across thousands of zones. Multi-channel LED drivers with adaptive current control have been developed to optimize power delivery while minimizing heat generation. These sophisticated driver ICs can adjust current levels with microsecond precision, enabling both power savings and enhanced display performance. Industry data suggests that advanced driver solutions can reduce overall system power consumption by 15-20% compared to first-generation Mini LED implementations.

The relationship between power efficiency and color accuracy presents another significant challenge. As Mini LEDs operate at different power levels to achieve varying brightness levels, maintaining consistent color temperature and spectral output becomes increasingly difficult. Compensation algorithms that account for LED behavior across different power states are essential for preserving color accuracy in real-world applications. These algorithms continuously monitor thermal conditions and adjust power delivery parameters to maintain consistent visual output, though this adaptive approach itself introduces additional computational overhead and power requirements.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of Mini LED technology for color-corrected real-world displays represents a critical factor in its widespread adoption. Current production processes have evolved significantly from early prototype stages, with manufacturers now implementing semi-automated and fully automated assembly lines that have increased throughput by approximately 300% compared to 2019 levels. The integration of precision placement equipment has reduced positioning errors from ±50μm to ±10μm, enabling higher density arrays necessary for advanced color correction capabilities.

Cost structures remain a significant challenge, with Mini LED backlighting systems currently adding a 30-40% premium over conventional LCD displays. This cost differential stems primarily from three factors: the specialized semiconductor materials required for Mini LED production, the complex driving circuits needed to control thousands of individual lighting zones, and the yield rates that currently average 85-92% depending on manufacturer capabilities. Industry projections suggest these costs will decrease by 15-20% annually over the next three years as production volumes increase.

Supply chain considerations have evolved into a more mature ecosystem since 2021, with specialized suppliers emerging for key components including LED chips, driver ICs, and optical films. This specialization has improved component availability while gradually reducing costs. However, geographic concentration remains an issue, with approximately 70% of Mini LED chip production centered in East Asia, creating potential supply vulnerabilities that manufacturers must address through diversification strategies.

Equipment investments represent a substantial barrier to entry, with a fully equipped Mini LED production line requiring capital expenditure of $50-80 million. This investment threshold has limited production to larger manufacturers, though equipment sharing models and specialized fabrication services are emerging to support smaller market entrants. The equipment depreciation cycle typically spans 5-7 years, necessitating careful planning for technology transitions.

Scaling challenges differ significantly between consumer electronics applications and professional display markets. Consumer applications prioritize cost reduction and standardization, while professional color-corrected displays demand higher precision and customization capabilities. This bifurcation has led to divergent manufacturing approaches, with some facilities specializing in high-volume consumer products while others focus on lower-volume, higher-margin professional displays with enhanced color correction capabilities.

Energy and resource efficiency in manufacturing has improved substantially, with newer production facilities reducing power consumption by 25-30% compared to first-generation plants. Water usage in the fabrication process has similarly decreased through recycling systems, addressing sustainability concerns that impact both operational costs and environmental compliance requirements.

Cost structures remain a significant challenge, with Mini LED backlighting systems currently adding a 30-40% premium over conventional LCD displays. This cost differential stems primarily from three factors: the specialized semiconductor materials required for Mini LED production, the complex driving circuits needed to control thousands of individual lighting zones, and the yield rates that currently average 85-92% depending on manufacturer capabilities. Industry projections suggest these costs will decrease by 15-20% annually over the next three years as production volumes increase.

Supply chain considerations have evolved into a more mature ecosystem since 2021, with specialized suppliers emerging for key components including LED chips, driver ICs, and optical films. This specialization has improved component availability while gradually reducing costs. However, geographic concentration remains an issue, with approximately 70% of Mini LED chip production centered in East Asia, creating potential supply vulnerabilities that manufacturers must address through diversification strategies.

Equipment investments represent a substantial barrier to entry, with a fully equipped Mini LED production line requiring capital expenditure of $50-80 million. This investment threshold has limited production to larger manufacturers, though equipment sharing models and specialized fabrication services are emerging to support smaller market entrants. The equipment depreciation cycle typically spans 5-7 years, necessitating careful planning for technology transitions.

Scaling challenges differ significantly between consumer electronics applications and professional display markets. Consumer applications prioritize cost reduction and standardization, while professional color-corrected displays demand higher precision and customization capabilities. This bifurcation has led to divergent manufacturing approaches, with some facilities specializing in high-volume consumer products while others focus on lower-volume, higher-margin professional displays with enhanced color correction capabilities.

Energy and resource efficiency in manufacturing has improved substantially, with newer production facilities reducing power consumption by 25-30% compared to first-generation plants. Water usage in the fabrication process has similarly decreased through recycling systems, addressing sustainability concerns that impact both operational costs and environmental compliance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!