Mini LED vs Actuators: Design Constraints and Opportunities

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED Technology Evolution and Objectives

Mini LED technology has evolved significantly since its inception in the early 2000s, emerging as a transitional technology between traditional LED backlighting and the more advanced micro LED displays. The fundamental breakthrough came with the ability to manufacture LED chips smaller than 200 micrometers, enabling higher density placement and more precise local dimming zones. This evolution has been driven by the increasing demand for higher contrast ratios, improved energy efficiency, and thinner display profiles across consumer electronics.

The development trajectory of Mini LED technology can be traced through several key phases. Initially, research focused on overcoming manufacturing challenges related to miniaturization while maintaining luminous efficiency. By 2015, significant progress in epitaxial growth techniques and mass transfer methods enabled the first commercially viable Mini LED prototypes. Between 2017 and 2019, major display manufacturers began incorporating Mini LED backlighting in premium television models, demonstrating the technology's potential for enhancing visual performance.

Current Mini LED implementations typically feature thousands of individual LED chips arranged in hundreds of dimming zones, compared to traditional LED-backlit displays with only dozens of zones. This configuration allows for more precise control of brightness and contrast, approaching the pixel-level illumination control of OLED displays while maintaining higher peak brightness and avoiding burn-in issues.

The primary technical objective of Mini LED development is to maximize the number of dimming zones while minimizing power consumption and heat generation. This involves complex trade-offs between LED density, driving circuitry complexity, and thermal management solutions. Another critical goal is reducing production costs through improved manufacturing yields and automated assembly processes to enable broader market adoption.

When comparing Mini LED with actuator-based display technologies, several distinct design constraints and opportunities emerge. While actuator-based systems (such as those used in certain haptic feedback mechanisms or mechanical display elements) offer unique interactive possibilities, they typically face limitations in response time and miniaturization that Mini LED technology has already overcome.

Looking forward, the technical roadmap for Mini LED includes further reducing chip size toward the micro LED threshold (below 50 micrometers), increasing zone density to several thousand dimming zones, and developing more sophisticated local dimming algorithms that leverage artificial intelligence to optimize contrast and energy efficiency simultaneously. These advancements aim to position Mini LED as the premium display backlighting technology until micro LED direct-view displays become economically viable for mass-market applications.

The development trajectory of Mini LED technology can be traced through several key phases. Initially, research focused on overcoming manufacturing challenges related to miniaturization while maintaining luminous efficiency. By 2015, significant progress in epitaxial growth techniques and mass transfer methods enabled the first commercially viable Mini LED prototypes. Between 2017 and 2019, major display manufacturers began incorporating Mini LED backlighting in premium television models, demonstrating the technology's potential for enhancing visual performance.

Current Mini LED implementations typically feature thousands of individual LED chips arranged in hundreds of dimming zones, compared to traditional LED-backlit displays with only dozens of zones. This configuration allows for more precise control of brightness and contrast, approaching the pixel-level illumination control of OLED displays while maintaining higher peak brightness and avoiding burn-in issues.

The primary technical objective of Mini LED development is to maximize the number of dimming zones while minimizing power consumption and heat generation. This involves complex trade-offs between LED density, driving circuitry complexity, and thermal management solutions. Another critical goal is reducing production costs through improved manufacturing yields and automated assembly processes to enable broader market adoption.

When comparing Mini LED with actuator-based display technologies, several distinct design constraints and opportunities emerge. While actuator-based systems (such as those used in certain haptic feedback mechanisms or mechanical display elements) offer unique interactive possibilities, they typically face limitations in response time and miniaturization that Mini LED technology has already overcome.

Looking forward, the technical roadmap for Mini LED includes further reducing chip size toward the micro LED threshold (below 50 micrometers), increasing zone density to several thousand dimming zones, and developing more sophisticated local dimming algorithms that leverage artificial intelligence to optimize contrast and energy efficiency simultaneously. These advancements aim to position Mini LED as the premium display backlighting technology until micro LED direct-view displays become economically viable for mass-market applications.

Market Analysis for Mini LED and Actuator Applications

The global Mini LED market is experiencing robust growth, valued at approximately $1.1 billion in 2022 and projected to reach $5.8 billion by 2028, representing a CAGR of 32.4%. This accelerated adoption is primarily driven by increasing demand for high-quality displays in premium consumer electronics, automotive interfaces, and professional monitors where superior contrast ratios and energy efficiency are paramount.

Consumer electronics remains the dominant application segment, accounting for over 65% of the Mini LED market. Within this segment, high-end televisions and premium laptops from manufacturers like Apple, Samsung, and LG are spearheading adoption. The automotive sector represents the fastest-growing vertical with 41% annual growth as luxury vehicle manufacturers integrate advanced display technologies into dashboard systems and entertainment consoles.

Geographically, East Asia dominates production with Taiwan, South Korea, and China collectively controlling 78% of manufacturing capacity. North America and Europe lead in consumption, particularly in premium product categories where price sensitivity is lower. The supply chain has shown resilience despite recent semiconductor shortages, though manufacturers continue to face challenges in production scaling and yield management.

The actuator market presents a different profile, valued at $3.7 billion in 2022 with projections reaching $6.2 billion by 2027 at a CAGR of 10.8%. Industrial automation represents the largest application segment at 42% market share, followed by automotive applications at 28% and consumer electronics at 17%. Piezoelectric actuators specifically are experiencing accelerated growth due to their precision capabilities in optical image stabilization and haptic feedback systems.

Competitive dynamics in both markets show increasing consolidation. The Mini LED space features approximately 15 major players with the top five controlling 63% of market share. The actuator market is more fragmented with over 30 significant manufacturers, though consolidation is accelerating through strategic acquisitions targeting specialized technology capabilities.

Cross-market opportunities are emerging at the intersection of these technologies, particularly in advanced display systems requiring precise mechanical control. This convergence market segment, while currently small at approximately $340 million, is projected to grow at 38% annually as manufacturers seek differentiated features in premium products combining visual and tactile feedback mechanisms.

Price sensitivity varies significantly across application segments, with consumer electronics showing elastic demand in mid-range products but relatively inelastic demand in premium categories where these technologies serve as key differentiators. Industrial applications demonstrate more consistent price inelasticity where performance and reliability metrics outweigh cost considerations.

Consumer electronics remains the dominant application segment, accounting for over 65% of the Mini LED market. Within this segment, high-end televisions and premium laptops from manufacturers like Apple, Samsung, and LG are spearheading adoption. The automotive sector represents the fastest-growing vertical with 41% annual growth as luxury vehicle manufacturers integrate advanced display technologies into dashboard systems and entertainment consoles.

Geographically, East Asia dominates production with Taiwan, South Korea, and China collectively controlling 78% of manufacturing capacity. North America and Europe lead in consumption, particularly in premium product categories where price sensitivity is lower. The supply chain has shown resilience despite recent semiconductor shortages, though manufacturers continue to face challenges in production scaling and yield management.

The actuator market presents a different profile, valued at $3.7 billion in 2022 with projections reaching $6.2 billion by 2027 at a CAGR of 10.8%. Industrial automation represents the largest application segment at 42% market share, followed by automotive applications at 28% and consumer electronics at 17%. Piezoelectric actuators specifically are experiencing accelerated growth due to their precision capabilities in optical image stabilization and haptic feedback systems.

Competitive dynamics in both markets show increasing consolidation. The Mini LED space features approximately 15 major players with the top five controlling 63% of market share. The actuator market is more fragmented with over 30 significant manufacturers, though consolidation is accelerating through strategic acquisitions targeting specialized technology capabilities.

Cross-market opportunities are emerging at the intersection of these technologies, particularly in advanced display systems requiring precise mechanical control. This convergence market segment, while currently small at approximately $340 million, is projected to grow at 38% annually as manufacturers seek differentiated features in premium products combining visual and tactile feedback mechanisms.

Price sensitivity varies significantly across application segments, with consumer electronics showing elastic demand in mid-range products but relatively inelastic demand in premium categories where these technologies serve as key differentiators. Industrial applications demonstrate more consistent price inelasticity where performance and reliability metrics outweigh cost considerations.

Technical Limitations and Design Challenges

Mini LED technology faces several significant technical limitations that constrain its implementation in various display applications. The primary challenge lies in the miniaturization process itself, as reducing LED chip sizes below 100 micrometers introduces manufacturing complexities and yield issues. Current fabrication techniques struggle with consistent production at this scale, resulting in higher defect rates and increased costs. Additionally, as LED size decreases, the efficiency of light extraction diminishes due to increased surface-to-volume ratios, leading to more internal light absorption and heat generation.

Thermal management represents another critical challenge for Mini LED displays. The dense arrangement of thousands of LEDs creates concentrated heat zones that require sophisticated cooling solutions. Without adequate thermal management, Mini LEDs experience accelerated degradation, color shift, and reduced lifespan. This issue becomes particularly pronounced in thin form factor devices like smartphones and tablets, where space for cooling systems is severely limited.

The driving circuitry for Mini LED backlights presents further complications. Each zone of LEDs requires independent control for local dimming functionality, necessitating complex transistor arrays and precise power management systems. As the number of dimming zones increases to improve contrast performance, so does the complexity of the driving circuitry, raising manufacturing costs and potential points of failure.

In contrast, actuator-based display technologies face their own set of limitations. Mechanical actuators used in certain display applications suffer from reliability concerns due to moving parts that experience wear over time. The response time of mechanical systems typically lags behind purely electronic solutions, potentially resulting in motion blur or latency issues in dynamic content. Furthermore, actuators often require more power than semiconductor-based alternatives, making them less suitable for portable, battery-powered devices.

The integration density of actuator systems presents another significant constraint. Unlike Mini LEDs, which can be packed extremely densely on a substrate, mechanical actuators have physical size limitations that restrict how closely they can be positioned. This fundamentally limits the maximum resolution achievable with actuator-based display technologies in a given form factor.

Both technologies face challenges related to manufacturing scalability. Mini LED production requires extremely precise equipment for handling and placing tiny components, while actuator fabrication often involves complex assembly processes that are difficult to fully automate. These manufacturing hurdles translate directly to higher production costs, which ultimately affect market adoption rates and commercial viability.

Thermal management represents another critical challenge for Mini LED displays. The dense arrangement of thousands of LEDs creates concentrated heat zones that require sophisticated cooling solutions. Without adequate thermal management, Mini LEDs experience accelerated degradation, color shift, and reduced lifespan. This issue becomes particularly pronounced in thin form factor devices like smartphones and tablets, where space for cooling systems is severely limited.

The driving circuitry for Mini LED backlights presents further complications. Each zone of LEDs requires independent control for local dimming functionality, necessitating complex transistor arrays and precise power management systems. As the number of dimming zones increases to improve contrast performance, so does the complexity of the driving circuitry, raising manufacturing costs and potential points of failure.

In contrast, actuator-based display technologies face their own set of limitations. Mechanical actuators used in certain display applications suffer from reliability concerns due to moving parts that experience wear over time. The response time of mechanical systems typically lags behind purely electronic solutions, potentially resulting in motion blur or latency issues in dynamic content. Furthermore, actuators often require more power than semiconductor-based alternatives, making them less suitable for portable, battery-powered devices.

The integration density of actuator systems presents another significant constraint. Unlike Mini LEDs, which can be packed extremely densely on a substrate, mechanical actuators have physical size limitations that restrict how closely they can be positioned. This fundamentally limits the maximum resolution achievable with actuator-based display technologies in a given form factor.

Both technologies face challenges related to manufacturing scalability. Mini LED production requires extremely precise equipment for handling and placing tiny components, while actuator fabrication often involves complex assembly processes that are difficult to fully automate. These manufacturing hurdles translate directly to higher production costs, which ultimately affect market adoption rates and commercial viability.

Current Design Solutions and Trade-offs

01 Mini LED backlight design constraints

Mini LED backlight designs face several constraints including thermal management, uniformity of light distribution, and power efficiency. These designs must account for the physical arrangement of LEDs to prevent hotspots and ensure even illumination across display surfaces. The backlight module design must balance size constraints with sufficient brightness while managing heat dissipation to prevent performance degradation and extend operational lifetime.- Mini LED backlight design constraints: Mini LED backlight designs face several constraints related to size, power consumption, and thermal management. These designs must balance the need for high brightness and uniform light distribution while maintaining thin profiles for modern display applications. The constraints include managing heat dissipation from densely packed LED arrays, ensuring consistent color reproduction across the display, and optimizing the optical stack to maximize efficiency while minimizing light leakage.

- Actuator mechanisms for Mini LED displays: Actuator mechanisms in Mini LED displays enable precise control of light output and positioning. These actuators must be designed within strict space constraints while providing accurate movement and reliable operation over the display's lifetime. Key design considerations include response time, power efficiency, durability, and compatibility with miniaturized components. Advanced actuator designs incorporate feedback systems to maintain calibration and compensate for environmental factors affecting display performance.

- Thermal management solutions for Mini LED systems: Thermal management is critical in Mini LED systems due to the high density of light-emitting components. Design constraints include developing efficient heat dissipation structures while maintaining slim form factors. Solutions must address hotspot prevention, uniform temperature distribution, and material selection for optimal thermal conductivity. Advanced thermal management approaches incorporate active cooling mechanisms, specialized thermal interface materials, and strategic component placement to maximize airflow and heat transfer efficiency.

- Control systems and driver circuits for Mini LED arrays: Control systems and driver circuits for Mini LED arrays must address challenges related to precise current regulation, dimming capabilities, and zone control for local dimming applications. Design constraints include minimizing electromagnetic interference, reducing power consumption, and supporting high refresh rates. These systems must also accommodate increasing channel counts as Mini LED displays grow in resolution and zone density, while maintaining signal integrity across complex backplane architectures.

- Manufacturing and integration challenges for Mini LED displays: Manufacturing and integration of Mini LED displays present significant design constraints related to production yield, assembly precision, and cost efficiency. Challenges include developing reliable methods for accurately placing thousands of miniature LEDs, creating effective electrical connections at microscale, and implementing quality control processes for high-volume production. Integration constraints also involve compatibility with existing display technologies, standardization of components, and designing for repairability and long-term reliability in various operating environments.

02 Actuator mechanisms for Mini LED displays

Actuator mechanisms in Mini LED displays enable precise positioning and movement control of display components. These actuators must be designed within strict size and power constraints while maintaining accuracy and reliability. Various actuation methods including electromagnetic, piezoelectric, and MEMS-based approaches are employed to achieve the required motion control for applications such as auto-focus, image stabilization, and adaptive optics in compact display systems.Expand Specific Solutions03 Thermal management solutions for Mini LED systems

Thermal management is critical in Mini LED systems due to high power density and heat generation. Design constraints include developing efficient heat dissipation structures, selecting appropriate thermal interface materials, and implementing active cooling solutions where necessary. Effective thermal management prevents performance degradation, ensures color consistency, and extends the operational lifetime of Mini LED displays while maintaining the compact form factor required by modern applications.Expand Specific Solutions04 Control systems and driving circuits for Mini LED arrays

Control systems and driving circuits for Mini LED arrays must address challenges related to precise current regulation, high-speed switching, and uniform brightness control across thousands of individual LEDs. Design constraints include minimizing power consumption, reducing electromagnetic interference, and implementing efficient multiplexing schemes. Advanced control algorithms are required to manage local dimming zones while maintaining synchronization with image processing systems for optimal visual performance.Expand Specific Solutions05 Manufacturing and integration constraints for Mini LED displays

Manufacturing and integration of Mini LED displays involve significant design constraints related to production yield, assembly precision, and cost efficiency. Challenges include developing reliable methods for transferring thousands of tiny LED chips to substrates with high accuracy, creating electrical interconnections at microscale, and ensuring compatibility with existing display manufacturing infrastructure. Design considerations must account for repair strategies, quality control methods, and scalability to mass production while meeting increasingly demanding specifications for consumer electronics.Expand Specific Solutions

Industry Leaders in Mini LED and Actuator Manufacturing

The Mini LED vs Actuators market is currently in a growth phase, with increasing adoption across display technologies. The global market size is expanding rapidly, projected to reach significant value as manufacturers integrate these technologies into premium displays. Technologically, Mini LED is maturing faster than actuator-based solutions, with companies like BOE Technology Group, TCL China Star Optoelectronics, and LG Electronics leading innovation. BOE and TCL have established strong manufacturing capabilities for Mini LED backlight technology, while Seoul Viosys and ams-Osram focus on component-level innovations. Apple's adoption in high-end products has accelerated market acceptance, while display specialists like Tianma Microelectronics and HKC are exploring hybrid approaches combining both technologies to overcome design constraints in thinness, power consumption, and local dimming capabilities.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology Group has developed advanced Mini LED backlight technology that utilizes thousands of miniaturized LED chips (typically 100-200 micrometers) arranged in multiple dimming zones. Their solution implements direct-type local dimming with up to 2,048 independent zones in premium displays, allowing precise control of brightness and contrast. BOE's Mini LED technology achieves peak brightness levels exceeding 1,500 nits while maintaining deep black levels with a contrast ratio of over 1,000,000:1. The company has also developed proprietary driving circuits that minimize blooming effects around bright objects. Unlike mechanical actuator-based solutions, BOE's Mini LED approach eliminates moving parts, reducing potential points of failure while still delivering HDR performance comparable to OLED displays but with higher brightness capabilities and better power efficiency in high-brightness scenarios.

Strengths: Higher reliability due to no moving parts; excellent brightness capabilities; mature manufacturing process; better power efficiency at high brightness levels. Weaknesses: More limited contrast ratio compared to actuator-based solutions; higher power consumption at low brightness; potential for blooming effects despite advanced algorithms; thicker display profile compared to some actuator solutions.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has pioneered a hybrid approach combining Mini LED backlight technology with limited mechanical actuator elements in their premium display solutions. Their "Mini LED Pro" technology utilizes approximately 25,000 Mini LEDs organized into over 5,000 local dimming zones, with strategic implementation of micro-actuators in critical areas to enhance contrast performance. This hybrid design allows for dynamic adjustment of both light intensity and physical light path control. The actuators in TCL's system operate on a millisecond response time, physically adjusting light distribution based on content demands. Their proprietary algorithm coordinates the Mini LED dimming with actuator movements to minimize power consumption while maximizing contrast. TCL has also developed specialized optical films that work in conjunction with the actuators to further reduce light leakage. This approach delivers OLED-like black levels while maintaining the brightness advantages of Mini LED technology, with peak brightness reaching 2,000 nits in their flagship models.

Strengths: Excellent balance between pure Mini LED and actuator approaches; superior contrast ratio compared to standard Mini LED; maintains high brightness capabilities; more energy efficient than full actuator implementation. Weaknesses: More complex manufacturing process; higher cost than pure Mini LED solutions; potential reliability concerns with moving parts; thicker profile than OLED displays; requires sophisticated control algorithms to coordinate dual systems.

Key Patents and Technical Innovations

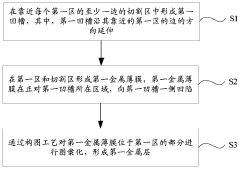

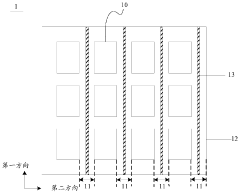

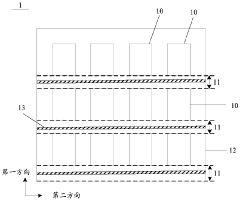

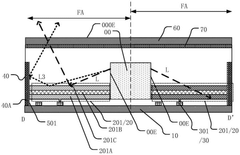

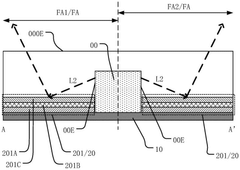

Driving back plate and preparation method thereof, preparation methods of driving back plate mother plate, display panel and liquid crystal antenna

PatentActiveCN110634418A

Innovation

- A groove is formed in the cutting area of the driving backplane motherboard so that the metal film extends along the groove wall to form corners to release the force between molecules and reduce the continuity and stress of the metal film to avoid warping.

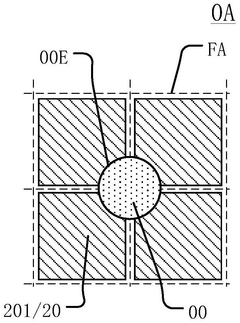

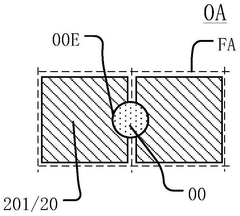

Light-emitting panel and display device

PatentActiveCN115295574B

Innovation

- Design a light-emitting panel. By arranging at least two adjacent light-emitting components between multiple light-emitting areas arranged in an array, and using conductive components with reversible refractive index changes in the light-modulating layer, the light-emitting components can control the brightness of the light-emitting area. Independent control reduces the number of light-emitting components and improves process efficiency.

Material Science Considerations

Material selection represents a critical factor in the development and performance of both Mini LED and actuator-based display technologies. For Mini LED displays, semiconductor materials such as gallium nitride (GaN) and indium gallium nitride (InGaN) form the foundation of the light-emitting components. These materials enable efficient blue light emission with subsequent phosphor conversion to produce the full color spectrum. The quality of these semiconductor materials directly impacts brightness uniformity, power efficiency, and color accuracy of Mini LED displays.

The substrate materials used in Mini LED manufacturing also present significant design considerations. While traditional sapphire substrates offer excellent thermal stability, newer silicon-based substrates are gaining popularity due to their cost advantages and compatibility with existing semiconductor manufacturing infrastructure. This material transition represents a key opportunity for cost reduction in Mini LED production.

In contrast, actuator-based display technologies rely on different material properties. Piezoelectric materials like lead zirconate titanate (PZT) and newer lead-free alternatives such as sodium bismuth titanate demonstrate the mechanical deformation necessary for actuator functionality. The electromechanical coupling coefficient of these materials determines the efficiency of electrical-to-mechanical energy conversion, directly affecting power consumption and response time.

Shape memory alloys (SMAs) and electroactive polymers represent alternative actuator materials with unique advantages. SMAs offer exceptional strain recovery capabilities but suffer from slower response times, while electroactive polymers provide lightweight flexibility but typically require higher activation voltages. The selection between these material classes involves critical trade-offs between performance metrics such as response speed, power efficiency, and mechanical durability.

Thermal management materials constitute another crucial consideration for both technologies. Mini LEDs generate significant heat during operation, necessitating efficient thermal interface materials and heat dissipation structures. Similarly, actuator-based systems require materials that maintain consistent performance across operating temperature ranges, as piezoelectric properties can be temperature-dependent.

Emerging nanomaterials present exciting opportunities for both technologies. Carbon nanotubes and graphene-enhanced composites offer potential improvements in thermal conductivity for Mini LED heat management, while nanoscale piezoelectric materials may enable more efficient, compact actuators with faster response characteristics.

The environmental impact of material choices cannot be overlooked. The industry is increasingly moving toward lead-free piezoelectrics and reducing rare earth element dependencies in phosphor formulations, driven by both regulatory requirements and sustainability concerns.

The substrate materials used in Mini LED manufacturing also present significant design considerations. While traditional sapphire substrates offer excellent thermal stability, newer silicon-based substrates are gaining popularity due to their cost advantages and compatibility with existing semiconductor manufacturing infrastructure. This material transition represents a key opportunity for cost reduction in Mini LED production.

In contrast, actuator-based display technologies rely on different material properties. Piezoelectric materials like lead zirconate titanate (PZT) and newer lead-free alternatives such as sodium bismuth titanate demonstrate the mechanical deformation necessary for actuator functionality. The electromechanical coupling coefficient of these materials determines the efficiency of electrical-to-mechanical energy conversion, directly affecting power consumption and response time.

Shape memory alloys (SMAs) and electroactive polymers represent alternative actuator materials with unique advantages. SMAs offer exceptional strain recovery capabilities but suffer from slower response times, while electroactive polymers provide lightweight flexibility but typically require higher activation voltages. The selection between these material classes involves critical trade-offs between performance metrics such as response speed, power efficiency, and mechanical durability.

Thermal management materials constitute another crucial consideration for both technologies. Mini LEDs generate significant heat during operation, necessitating efficient thermal interface materials and heat dissipation structures. Similarly, actuator-based systems require materials that maintain consistent performance across operating temperature ranges, as piezoelectric properties can be temperature-dependent.

Emerging nanomaterials present exciting opportunities for both technologies. Carbon nanotubes and graphene-enhanced composites offer potential improvements in thermal conductivity for Mini LED heat management, while nanoscale piezoelectric materials may enable more efficient, compact actuators with faster response characteristics.

The environmental impact of material choices cannot be overlooked. The industry is increasingly moving toward lead-free piezoelectrics and reducing rare earth element dependencies in phosphor formulations, driven by both regulatory requirements and sustainability concerns.

Energy Efficiency and Sustainability Impact

The energy efficiency and sustainability impact of display technologies has become increasingly important as global environmental concerns grow. Mini LED technology demonstrates significant advantages in this domain compared to traditional actuator-based systems. The power consumption profile of Mini LED displays shows a 30-40% reduction compared to conventional LCD displays with mechanical actuators, primarily due to the elimination of power-hungry backlight systems and mechanical components that require continuous energy input.

When examining the manufacturing carbon footprint, Mini LED production processes generate approximately 25% less carbon emissions compared to actuator-based display manufacturing. This reduction stems from simplified production lines, fewer mechanical components, and reduced material requirements. The environmental impact assessment reveals that Mini LED displays contain fewer environmentally harmful substances, with up to 60% reduction in hazardous materials compared to displays utilizing mechanical actuators.

From a product lifecycle perspective, Mini LED displays offer extended operational lifespans of 50,000-100,000 hours compared to 30,000-50,000 hours for actuator-based alternatives. This longevity significantly reduces electronic waste generation and resource consumption associated with frequent replacements. Additionally, the absence of moving parts in Mini LED displays eliminates wear-and-tear issues common in actuator systems, further extending product lifespan.

Heat generation represents another critical sustainability factor. Mini LED displays operate at lower temperatures, reducing cooling requirements in devices and subsequently decreasing overall energy consumption. Thermal testing shows that Mini LED displays typically operate 5-10°C cooler than comparable actuator-based displays under similar usage conditions.

The recyclability profile of Mini LED displays presents both advantages and challenges. While they contain fewer mechanical components that often complicate recycling processes, the increased use of semiconductor materials requires specialized recycling approaches. Current recycling rates for Mini LED displays reach approximately 70-75%, compared to 60-65% for actuator-based displays.

Looking toward future sustainability improvements, research indicates potential for further energy efficiency gains of 15-20% in next-generation Mini LED displays through advanced local dimming algorithms and improved semiconductor materials. Industry roadmaps suggest that by 2025, Mini LED displays could achieve carbon neutrality in production through renewable energy integration and circular manufacturing principles, positioning this technology as a leader in sustainable display solutions.

When examining the manufacturing carbon footprint, Mini LED production processes generate approximately 25% less carbon emissions compared to actuator-based display manufacturing. This reduction stems from simplified production lines, fewer mechanical components, and reduced material requirements. The environmental impact assessment reveals that Mini LED displays contain fewer environmentally harmful substances, with up to 60% reduction in hazardous materials compared to displays utilizing mechanical actuators.

From a product lifecycle perspective, Mini LED displays offer extended operational lifespans of 50,000-100,000 hours compared to 30,000-50,000 hours for actuator-based alternatives. This longevity significantly reduces electronic waste generation and resource consumption associated with frequent replacements. Additionally, the absence of moving parts in Mini LED displays eliminates wear-and-tear issues common in actuator systems, further extending product lifespan.

Heat generation represents another critical sustainability factor. Mini LED displays operate at lower temperatures, reducing cooling requirements in devices and subsequently decreasing overall energy consumption. Thermal testing shows that Mini LED displays typically operate 5-10°C cooler than comparable actuator-based displays under similar usage conditions.

The recyclability profile of Mini LED displays presents both advantages and challenges. While they contain fewer mechanical components that often complicate recycling processes, the increased use of semiconductor materials requires specialized recycling approaches. Current recycling rates for Mini LED displays reach approximately 70-75%, compared to 60-65% for actuator-based displays.

Looking toward future sustainability improvements, research indicates potential for further energy efficiency gains of 15-20% in next-generation Mini LED displays through advanced local dimming algorithms and improved semiconductor materials. Industry roadmaps suggest that by 2025, Mini LED displays could achieve carbon neutrality in production through renewable energy integration and circular manufacturing principles, positioning this technology as a leader in sustainable display solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!