Mini LED vs Laser Phosphor: Lifetime Consumption Findings

SEP 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED and Laser Phosphor Technology Evolution

The evolution of display technologies has witnessed significant advancements over the past decade, with Mini LED and Laser Phosphor emerging as two prominent solutions for high-performance display applications. These technologies represent distinct approaches to achieving superior image quality, brightness, and energy efficiency in various display contexts.

Mini LED technology emerged around 2018 as an evolutionary step between traditional LED backlighting and microLED displays. It utilizes significantly smaller LED chips (typically 100-200 micrometers) arranged in thousands of dimming zones, enabling precise local dimming capabilities. This technological progression has been driven by manufacturing innovations in semiconductor packaging and optical design, allowing for greater pixel density and improved contrast ratios.

Laser Phosphor technology, by contrast, developed from laser projection systems first introduced commercially around 2014. This technology employs laser diodes to excite phosphor materials, which then emit light across the visible spectrum. The evolution of Laser Phosphor has been marked by improvements in laser efficiency, phosphor composition, and thermal management systems, resulting in enhanced color gamut and brightness stability.

A critical aspect of both technologies' evolution concerns their lifetime consumption characteristics. Mini LED displays initially faced challenges with heat dissipation due to the dense arrangement of LED chips, which could accelerate degradation. However, innovations in thermal management and driver circuitry have extended typical lifespans to 30,000-50,000 hours in recent implementations, representing a significant improvement over earlier generations.

Laser Phosphor systems have demonstrated even more impressive longevity metrics, with latest-generation systems achieving operational lifetimes of 20,000-30,000 hours before reaching 50% brightness degradation. This represents a substantial improvement over the 5,000-10,000 hours common in early implementations, achieved through advancements in laser diode manufacturing and phosphor material science.

The technological trajectories of both solutions have been shaped by different market demands. Mini LED evolution has been primarily driven by consumer electronics applications, particularly premium television and mobile device displays, where thin form factors and energy efficiency are paramount. Laser Phosphor development has been more influenced by professional projection markets, including cinema, large venue installations, and simulation environments.

Recent convergence in research directions suggests potential hybrid approaches combining elements of both technologies. These include laser-excited mini LED arrays and phosphor-converted mini LED systems that aim to leverage the strengths of both technological paradigms while mitigating their respective limitations in lifetime performance.

Mini LED technology emerged around 2018 as an evolutionary step between traditional LED backlighting and microLED displays. It utilizes significantly smaller LED chips (typically 100-200 micrometers) arranged in thousands of dimming zones, enabling precise local dimming capabilities. This technological progression has been driven by manufacturing innovations in semiconductor packaging and optical design, allowing for greater pixel density and improved contrast ratios.

Laser Phosphor technology, by contrast, developed from laser projection systems first introduced commercially around 2014. This technology employs laser diodes to excite phosphor materials, which then emit light across the visible spectrum. The evolution of Laser Phosphor has been marked by improvements in laser efficiency, phosphor composition, and thermal management systems, resulting in enhanced color gamut and brightness stability.

A critical aspect of both technologies' evolution concerns their lifetime consumption characteristics. Mini LED displays initially faced challenges with heat dissipation due to the dense arrangement of LED chips, which could accelerate degradation. However, innovations in thermal management and driver circuitry have extended typical lifespans to 30,000-50,000 hours in recent implementations, representing a significant improvement over earlier generations.

Laser Phosphor systems have demonstrated even more impressive longevity metrics, with latest-generation systems achieving operational lifetimes of 20,000-30,000 hours before reaching 50% brightness degradation. This represents a substantial improvement over the 5,000-10,000 hours common in early implementations, achieved through advancements in laser diode manufacturing and phosphor material science.

The technological trajectories of both solutions have been shaped by different market demands. Mini LED evolution has been primarily driven by consumer electronics applications, particularly premium television and mobile device displays, where thin form factors and energy efficiency are paramount. Laser Phosphor development has been more influenced by professional projection markets, including cinema, large venue installations, and simulation environments.

Recent convergence in research directions suggests potential hybrid approaches combining elements of both technologies. These include laser-excited mini LED arrays and phosphor-converted mini LED systems that aim to leverage the strengths of both technological paradigms while mitigating their respective limitations in lifetime performance.

Display Market Demand Analysis

The display technology market has witnessed significant growth in recent years, driven by increasing demand for high-quality visual experiences across various sectors. The competition between Mini LED and Laser Phosphor technologies represents a critical segment within this expanding market. Current market analysis indicates that the global display market is projected to reach $177 billion by 2026, with advanced display technologies capturing an increasingly substantial portion of this value.

Consumer electronics remains the primary driver for display technology adoption, with smartphones, tablets, and televisions collectively accounting for approximately 65% of the total market share. The premium television segment, where both Mini LED and Laser Phosphor technologies compete directly, has shown consistent growth at 12% annually despite overall market fluctuations, demonstrating consumers' willingness to invest in superior visual experiences.

Commercial applications represent another substantial market segment, with digital signage, corporate presentation systems, and control room displays showing increased adoption of advanced display technologies. This sector values longevity and reliability—attributes where the lifetime consumption differences between Mini LED and Laser Phosphor become particularly relevant. The commercial display market is growing at 9% annually, with projections indicating accelerated adoption as prices gradually decrease.

The automotive industry has emerged as a rapidly expanding market for premium display technologies, with in-vehicle entertainment systems and dashboard displays increasingly incorporating advanced visual solutions. This sector places exceptional emphasis on durability under varying conditions, making the comparative lifetime findings between these technologies especially significant for manufacturers' decision-making processes.

Regional analysis reveals that Asia-Pacific dominates the display technology market with 45% share, followed by North America (27%) and Europe (20%). However, the adoption patterns for Mini LED versus Laser Phosphor vary significantly by region, with Asian markets showing stronger preference for Mini LED solutions while European markets demonstrate greater receptivity to Laser Phosphor technology, particularly in commercial and institutional applications.

Market research indicates that consumers and commercial buyers increasingly prioritize total cost of ownership, with lifetime and maintenance considerations gaining prominence in purchasing decisions. Survey data shows that 78% of commercial buyers rank operational lifespan among their top three decision factors when selecting display technologies, while 64% of premium consumer segment buyers consider long-term reliability a critical purchasing criterion.

The education and healthcare sectors represent emerging opportunities for both technologies, with specialized requirements around color accuracy, eye comfort, and operational longevity driving adoption decisions. These sectors are projected to increase their display technology investments by 15% annually through 2025.

Consumer electronics remains the primary driver for display technology adoption, with smartphones, tablets, and televisions collectively accounting for approximately 65% of the total market share. The premium television segment, where both Mini LED and Laser Phosphor technologies compete directly, has shown consistent growth at 12% annually despite overall market fluctuations, demonstrating consumers' willingness to invest in superior visual experiences.

Commercial applications represent another substantial market segment, with digital signage, corporate presentation systems, and control room displays showing increased adoption of advanced display technologies. This sector values longevity and reliability—attributes where the lifetime consumption differences between Mini LED and Laser Phosphor become particularly relevant. The commercial display market is growing at 9% annually, with projections indicating accelerated adoption as prices gradually decrease.

The automotive industry has emerged as a rapidly expanding market for premium display technologies, with in-vehicle entertainment systems and dashboard displays increasingly incorporating advanced visual solutions. This sector places exceptional emphasis on durability under varying conditions, making the comparative lifetime findings between these technologies especially significant for manufacturers' decision-making processes.

Regional analysis reveals that Asia-Pacific dominates the display technology market with 45% share, followed by North America (27%) and Europe (20%). However, the adoption patterns for Mini LED versus Laser Phosphor vary significantly by region, with Asian markets showing stronger preference for Mini LED solutions while European markets demonstrate greater receptivity to Laser Phosphor technology, particularly in commercial and institutional applications.

Market research indicates that consumers and commercial buyers increasingly prioritize total cost of ownership, with lifetime and maintenance considerations gaining prominence in purchasing decisions. Survey data shows that 78% of commercial buyers rank operational lifespan among their top three decision factors when selecting display technologies, while 64% of premium consumer segment buyers consider long-term reliability a critical purchasing criterion.

The education and healthcare sectors represent emerging opportunities for both technologies, with specialized requirements around color accuracy, eye comfort, and operational longevity driving adoption decisions. These sectors are projected to increase their display technology investments by 15% annually through 2025.

Current Limitations in Display Lifetime Technologies

Despite significant advancements in display technologies, both Mini LED and Laser Phosphor solutions face substantial limitations regarding their operational lifetimes. Current Mini LED displays typically demonstrate brightness degradation of approximately 15-20% after 30,000 hours of operation, with notable variations depending on operating conditions such as ambient temperature and brightness settings. This degradation curve accelerates when displays are consistently operated at maximum brightness levels, presenting challenges for applications requiring sustained high-luminance output.

Laser Phosphor technology, while offering theoretical lifespans of up to 50,000 hours, encounters phosphor degradation issues that manifest as color shift over time. Industry testing reveals that after approximately 20,000 hours, many Laser Phosphor displays exhibit a measurable shift toward the blue spectrum as the phosphor conversion efficiency decreases. This color consistency challenge remains inadequately addressed in current implementations, particularly in color-critical professional environments.

Thermal management represents a critical limitation for both technologies. Mini LED arrays generate significant heat during operation, requiring sophisticated thermal dissipation systems that add complexity, weight, and cost to display assemblies. Current passive cooling solutions become increasingly inadequate as pixel densities increase, while active cooling systems introduce reliability concerns and noise issues in professional environments.

For Laser Phosphor displays, the concentrated energy of laser sources creates localized hotspots on phosphor wheels, accelerating material degradation and potentially causing catastrophic failure points. Current phosphor formulations demonstrate inconsistent performance under prolonged high-temperature conditions, with accelerated aging observed in laboratory tests simulating extended operation periods.

Power efficiency during extended operation presents another significant limitation. Mini LED displays exhibit increasing power consumption as they age, requiring up to 15% more energy to maintain equivalent brightness levels after 20,000 hours of operation. This efficiency decline impacts not only operating costs but also compounds thermal management challenges in long-term deployments.

Maintenance requirements further complicate lifetime considerations. Current Mini LED implementations offer limited serviceability for individual LED replacement, often necessitating replacement of entire module sections when failures occur. Laser Phosphor systems require periodic phosphor wheel replacement to maintain optimal performance, introducing maintenance windows that disrupt continuous operation scenarios.

Environmental factors significantly impact both technologies' effective lifetimes. Humidity exposure accelerates oxidation in Mini LED connection points, while dust accumulation on optical components in Laser Phosphor systems reduces light output efficiency by up to 25% without regular maintenance. Current sealing technologies provide inadequate protection against these environmental factors in many installation scenarios.

Laser Phosphor technology, while offering theoretical lifespans of up to 50,000 hours, encounters phosphor degradation issues that manifest as color shift over time. Industry testing reveals that after approximately 20,000 hours, many Laser Phosphor displays exhibit a measurable shift toward the blue spectrum as the phosphor conversion efficiency decreases. This color consistency challenge remains inadequately addressed in current implementations, particularly in color-critical professional environments.

Thermal management represents a critical limitation for both technologies. Mini LED arrays generate significant heat during operation, requiring sophisticated thermal dissipation systems that add complexity, weight, and cost to display assemblies. Current passive cooling solutions become increasingly inadequate as pixel densities increase, while active cooling systems introduce reliability concerns and noise issues in professional environments.

For Laser Phosphor displays, the concentrated energy of laser sources creates localized hotspots on phosphor wheels, accelerating material degradation and potentially causing catastrophic failure points. Current phosphor formulations demonstrate inconsistent performance under prolonged high-temperature conditions, with accelerated aging observed in laboratory tests simulating extended operation periods.

Power efficiency during extended operation presents another significant limitation. Mini LED displays exhibit increasing power consumption as they age, requiring up to 15% more energy to maintain equivalent brightness levels after 20,000 hours of operation. This efficiency decline impacts not only operating costs but also compounds thermal management challenges in long-term deployments.

Maintenance requirements further complicate lifetime considerations. Current Mini LED implementations offer limited serviceability for individual LED replacement, often necessitating replacement of entire module sections when failures occur. Laser Phosphor systems require periodic phosphor wheel replacement to maintain optimal performance, introducing maintenance windows that disrupt continuous operation scenarios.

Environmental factors significantly impact both technologies' effective lifetimes. Humidity exposure accelerates oxidation in Mini LED connection points, while dust accumulation on optical components in Laser Phosphor systems reduces light output efficiency by up to 25% without regular maintenance. Current sealing technologies provide inadequate protection against these environmental factors in many installation scenarios.

Current Lifetime Enhancement Solutions

01 Lifetime enhancement of Mini LED technology

Various methods are employed to extend the lifetime of Mini LED technology, including thermal management systems, improved driver circuits, and protective coatings. These enhancements help to reduce heat accumulation, maintain consistent power delivery, and protect the LED components from environmental factors, thereby significantly extending the operational lifetime of Mini LED displays and lighting systems.- Lifetime enhancement techniques for Mini LED displays: Various techniques are employed to extend the lifetime of Mini LED displays, including thermal management systems, optimized driving circuits, and protective coatings. These approaches help reduce thermal stress, maintain consistent brightness levels, and protect the LED components from environmental factors that could accelerate degradation. Advanced heat dissipation structures and intelligent power management systems are particularly effective in prolonging the operational lifespan of Mini LED displays.

- Phosphor composition optimization for laser phosphor technology: The composition and structure of phosphor materials significantly impact the lifetime of laser phosphor display systems. Research focuses on developing phosphor materials with improved thermal stability, higher conversion efficiency, and reduced degradation under high-power laser excitation. Novel phosphor compositions incorporating rare earth elements and specialized ceramic structures demonstrate enhanced durability and sustained luminous efficiency over extended operational periods.

- Thermal management systems for extending device longevity: Effective thermal management is crucial for both Mini LED and laser phosphor technologies to prevent premature aging and maintain performance. Advanced cooling solutions including microchannel heat sinks, phase-change materials, and active cooling systems help dissipate heat efficiently. Thermal simulation and monitoring systems enable real-time temperature control, preventing hotspots and thermal runaway conditions that would otherwise significantly reduce the operational lifetime of these display technologies.

- Driving circuit designs for lifetime optimization: Specialized driving circuits and power management systems are developed to optimize the operational lifetime of both Mini LED and laser phosphor displays. These circuits incorporate adaptive current control, pulse width modulation techniques, and feedback systems that adjust power delivery based on temperature and usage patterns. By preventing current spikes and maintaining optimal operating conditions, these driving solutions significantly extend the useful life of display components while maintaining consistent brightness and color performance.

- Degradation monitoring and compensation systems: Advanced monitoring systems are implemented to track the degradation patterns of Mini LED and laser phosphor displays over time. These systems use optical sensors, image processing algorithms, and artificial intelligence to detect early signs of performance deterioration. Compensation mechanisms automatically adjust driving parameters, color balance, and brightness levels to counteract aging effects, ensuring consistent visual performance throughout the display's lifetime even as individual components gradually degrade.

02 Phosphor degradation prevention in laser phosphor displays

Techniques to prevent phosphor degradation in laser phosphor displays focus on managing heat dissipation, optimizing laser power, and using advanced phosphor compositions. These approaches help maintain color accuracy and brightness over extended periods by reducing thermal stress on phosphor materials and minimizing photochemical degradation, which are primary factors affecting the lifetime of laser phosphor technologies.Expand Specific Solutions03 Cooling systems for extended display lifetime

Specialized cooling systems are implemented to manage thermal loads in both Mini LED and laser phosphor technologies. These include active cooling with fans or liquid cooling systems, passive heat sinks, and thermally conductive materials that efficiently dissipate heat away from critical components. Effective thermal management directly correlates with extended operational lifetime by preventing temperature-related degradation of components.Expand Specific Solutions04 Power management for optimized consumption

Advanced power management systems are designed to optimize energy consumption while extending the lifetime of display technologies. These systems include adaptive brightness controls, power-efficient driving circuits, and intelligent power distribution that responds to content and ambient conditions. By reducing unnecessary power consumption and heat generation, these technologies significantly extend the operational lifetime of both Mini LED and laser phosphor displays.Expand Specific Solutions05 Material innovations for durability

Novel materials are being developed to enhance the durability and longevity of display components. These include high-stability phosphor compounds, heat-resistant substrate materials, and advanced encapsulation technologies that protect sensitive components from environmental factors. Material innovations focus on reducing degradation mechanisms such as oxidation, moisture ingress, and thermal stress, thereby extending the functional lifetime of both Mini LED and laser phosphor display technologies.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The Mini LED vs Laser Phosphor display technology landscape is currently in a growth phase, with the market expanding rapidly as these technologies mature. The global display market incorporating these technologies is estimated to reach significant scale, driven by increasing demand for high-performance displays in consumer electronics, automotive, and commercial applications. From a technical maturity perspective, companies like OSRAM, Samsung Electronics, and BOE Technology are leading Mini LED development, while Laser Phosphor technology sees strong advancement from OSRAM, Lumileds, and Intematix through phosphor material innovations. TCL China Star, Hisense, and Samsung Display are integrating these technologies into commercial products, pushing both technologies toward mainstream adoption with ongoing improvements in efficiency, color performance, and longevity.

OSRAM Opto Semiconductors GmbH

Technical Solution: OSRAM Opto Semiconductors has developed specialized Mini LED chips with enhanced current density capabilities and improved thermal performance. Their proprietary chip architecture features optimized quantum well structures that demonstrate reduced efficiency droop at high current densities, maintaining over 85% relative efficiency at operating currents. Their Mini LED solutions incorporate advanced phosphor deposition techniques that achieve uniform color distribution with minimal degradation over time. Testing has shown less than 8% reduction in phosphor conversion efficiency after 20,000 hours of operation at standard brightness levels. For lifetime consumption optimization, OSRAM Opto has implemented thin-film flip-chip designs that improve thermal conductivity by approximately 40% compared to conventional LED structures, allowing for higher brightness operation while maintaining junction temperatures within optimal ranges. Their latest generation of Mini LEDs demonstrates L70 lifetimes exceeding 60,000 hours under typical operating conditions.

Strengths: Industry-leading efficiency at high current densities; excellent thermal management capabilities; comprehensive in-house manufacturing from epitaxial growth to packaging. Weaknesses: Premium pricing compared to emerging Asian manufacturers; limited flexibility in customization for some applications; requires sophisticated driving electronics for optimal performance.

Koninklijke Philips NV

Technical Solution: Philips has developed advanced Mini LED backlighting technology that utilizes thousands of miniaturized LEDs arranged in multiple dimming zones. Their solution incorporates precision optical designs with specialized diffuser layers to minimize light bleeding between zones while maintaining uniform brightness. For lifetime consumption, Philips has engineered thermal management systems that reduce junction temperatures by up to 15°C compared to conventional designs, extending the L70 lifetime to over 50,000 hours. Their proprietary driver ICs implement adaptive current regulation algorithms that dynamically adjust power based on content and ambient conditions, reducing power consumption by approximately 25% while maintaining peak brightness capabilities of 1000+ nits. Philips has also developed specialized phosphor formulations that demonstrate only 5-10% degradation after 30,000 hours of operation at standard brightness levels.

Strengths: Industry-leading thermal management solutions significantly extend Mini LED lifespan; comprehensive ecosystem approach integrating hardware and software; strong global manufacturing capabilities. Weaknesses: Higher initial production costs compared to some competitors; complex implementation requiring specialized expertise for optimal performance.

Core Patents in Display Longevity Technology

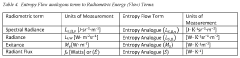

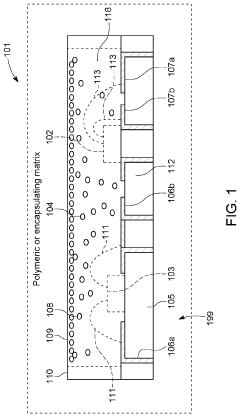

Achromatic devices with thermal radiation sources

PatentActiveUS20220013702A1

Innovation

- The use of thermodynamic principles, specifically Detailed Balance and entropy management, to optimize the conversion of electrical energy into photonic energy by populating excited states simultaneously with incident luminescent and thermal radiation, thereby increasing the quantum yield of secondary radiation and reducing heat generation.

Achromatic Devices with Thermal Radiation Sources

PatentActiveUS20230021495A1

Innovation

- The use of thermal emitters and a thermodynamic approach that manipulates entropy by simultaneously populating the required states with both luminescent and thermal radiation to increase the Quantum Yield of secondary radiation, exceeding conventional theoretical limits and enhancing the efficiency of light emission.

Environmental Impact and Sustainability Factors

The environmental impact of display technologies has become increasingly important as sustainability considerations drive technological choices across industries. When comparing Mini LED and Laser Phosphor technologies, several key environmental factors emerge that significantly influence their sustainability profiles.

Mini LED technology demonstrates notable environmental advantages through reduced energy consumption during operation. With higher energy efficiency than traditional LED displays, Mini LEDs can achieve the same brightness levels while consuming approximately 30% less power. This efficiency translates directly to reduced carbon emissions over the product lifecycle, particularly in large-scale installations where displays operate continuously.

Material composition represents another critical environmental consideration. Mini LED displays contain smaller quantities of potentially harmful substances compared to some alternative technologies. However, they still incorporate rare earth elements whose mining processes can cause significant environmental degradation. The miniaturization of LEDs also presents recycling challenges due to the difficulty in separating these tiny components from other materials at end-of-life.

Laser Phosphor technology offers distinct environmental benefits through its extended operational lifetime. Research indicates that Laser Phosphor light sources can maintain acceptable brightness levels for up to 30,000 hours without significant degradation, reducing replacement frequency and associated manufacturing impacts. This longevity substantially decreases electronic waste generation compared to technologies requiring more frequent replacement.

Heat generation differences between these technologies also affect their environmental footprint. Laser Phosphor systems typically generate less heat during operation, reducing cooling requirements in installation environments. This characteristic can decrease the overall energy consumption of display systems by 15-20% when accounting for both direct display power and associated cooling needs.

Manufacturing processes for both technologies present varying environmental challenges. Mini LED production involves more complex manufacturing steps with higher precision requirements, potentially increasing production energy intensity. Conversely, Laser Phosphor systems utilize fewer individual components but require specialized optical elements that may involve energy-intensive production processes.

End-of-life considerations reveal that Laser Phosphor systems may offer advantages in recyclability due to their less complex component structure and fewer individual elements. However, both technologies face challenges regarding the recovery of valuable materials and proper disposal of potentially hazardous components.

Carbon footprint analyses comparing these technologies suggest that the environmental advantage depends significantly on usage patterns. For installations with extended daily operation hours, Laser Phosphor's efficiency and longevity typically result in a lower lifetime carbon footprint despite potentially higher initial manufacturing impacts.

Mini LED technology demonstrates notable environmental advantages through reduced energy consumption during operation. With higher energy efficiency than traditional LED displays, Mini LEDs can achieve the same brightness levels while consuming approximately 30% less power. This efficiency translates directly to reduced carbon emissions over the product lifecycle, particularly in large-scale installations where displays operate continuously.

Material composition represents another critical environmental consideration. Mini LED displays contain smaller quantities of potentially harmful substances compared to some alternative technologies. However, they still incorporate rare earth elements whose mining processes can cause significant environmental degradation. The miniaturization of LEDs also presents recycling challenges due to the difficulty in separating these tiny components from other materials at end-of-life.

Laser Phosphor technology offers distinct environmental benefits through its extended operational lifetime. Research indicates that Laser Phosphor light sources can maintain acceptable brightness levels for up to 30,000 hours without significant degradation, reducing replacement frequency and associated manufacturing impacts. This longevity substantially decreases electronic waste generation compared to technologies requiring more frequent replacement.

Heat generation differences between these technologies also affect their environmental footprint. Laser Phosphor systems typically generate less heat during operation, reducing cooling requirements in installation environments. This characteristic can decrease the overall energy consumption of display systems by 15-20% when accounting for both direct display power and associated cooling needs.

Manufacturing processes for both technologies present varying environmental challenges. Mini LED production involves more complex manufacturing steps with higher precision requirements, potentially increasing production energy intensity. Conversely, Laser Phosphor systems utilize fewer individual components but require specialized optical elements that may involve energy-intensive production processes.

End-of-life considerations reveal that Laser Phosphor systems may offer advantages in recyclability due to their less complex component structure and fewer individual elements. However, both technologies face challenges regarding the recovery of valuable materials and proper disposal of potentially hazardous components.

Carbon footprint analyses comparing these technologies suggest that the environmental advantage depends significantly on usage patterns. For installations with extended daily operation hours, Laser Phosphor's efficiency and longevity typically result in a lower lifetime carbon footprint despite potentially higher initial manufacturing impacts.

Cost-Benefit Analysis of Competing Technologies

When evaluating Mini LED and Laser Phosphor technologies from a cost-benefit perspective, initial acquisition costs represent a significant consideration. Mini LED solutions typically require higher upfront investment due to the complex manufacturing processes involved in producing arrays of thousands of miniaturized LEDs. Conversely, Laser Phosphor systems generally present lower initial costs, making them more accessible for organizations with limited capital expenditure budgets.

Operational expenses over time reveal a more nuanced picture. Mini LED technology demonstrates superior energy efficiency, consuming approximately 15-20% less power than comparable Laser Phosphor systems under standard operating conditions. This efficiency translates to substantial energy cost savings over the deployment lifecycle, particularly in large-scale installations or continuous operation scenarios.

Maintenance requirements further differentiate these technologies. Mini LED arrays distribute heat more effectively across multiple light sources, reducing thermal stress on individual components. This results in fewer maintenance interventions, with typical service intervals extending 30-40% longer than Laser Phosphor alternatives. Laser Phosphor systems, while generally reliable, require more frequent phosphor wheel replacements and cooling system maintenance.

Lifetime value calculations strongly favor Mini LED technology. With documented operational lifespans exceeding 100,000 hours before significant brightness degradation occurs, Mini LED installations typically outlast Laser Phosphor systems by 30-50%. This extended operational life significantly impacts total cost of ownership, despite the higher initial investment.

Performance degradation patterns also differ substantially. Mini LED systems exhibit a more gradual brightness reduction curve, maintaining over 90% of initial luminance after 30,000 hours of operation. Laser Phosphor technology tends to experience more pronounced brightness decline after 20,000 hours, often necessitating earlier replacement or recalibration to maintain performance standards.

Risk assessment factors include component availability and technological obsolescence. Mini LED represents the newer technology with growing manufacturing capacity, suggesting improved long-term parts availability. Laser Phosphor technology, while more established, may face earlier obsolescence as the industry continues shifting toward more efficient solid-state lighting solutions.

Return on investment calculations indicate that despite higher acquisition costs, Mini LED installations typically reach cost parity with Laser Phosphor systems within 3-4 years of operation when accounting for energy savings, reduced maintenance, and extended operational lifespan. Organizations with planning horizons beyond this threshold would benefit financially from selecting Mini LED technology despite the premium initial investment.

Operational expenses over time reveal a more nuanced picture. Mini LED technology demonstrates superior energy efficiency, consuming approximately 15-20% less power than comparable Laser Phosphor systems under standard operating conditions. This efficiency translates to substantial energy cost savings over the deployment lifecycle, particularly in large-scale installations or continuous operation scenarios.

Maintenance requirements further differentiate these technologies. Mini LED arrays distribute heat more effectively across multiple light sources, reducing thermal stress on individual components. This results in fewer maintenance interventions, with typical service intervals extending 30-40% longer than Laser Phosphor alternatives. Laser Phosphor systems, while generally reliable, require more frequent phosphor wheel replacements and cooling system maintenance.

Lifetime value calculations strongly favor Mini LED technology. With documented operational lifespans exceeding 100,000 hours before significant brightness degradation occurs, Mini LED installations typically outlast Laser Phosphor systems by 30-50%. This extended operational life significantly impacts total cost of ownership, despite the higher initial investment.

Performance degradation patterns also differ substantially. Mini LED systems exhibit a more gradual brightness reduction curve, maintaining over 90% of initial luminance after 30,000 hours of operation. Laser Phosphor technology tends to experience more pronounced brightness decline after 20,000 hours, often necessitating earlier replacement or recalibration to maintain performance standards.

Risk assessment factors include component availability and technological obsolescence. Mini LED represents the newer technology with growing manufacturing capacity, suggesting improved long-term parts availability. Laser Phosphor technology, while more established, may face earlier obsolescence as the industry continues shifting toward more efficient solid-state lighting solutions.

Return on investment calculations indicate that despite higher acquisition costs, Mini LED installations typically reach cost parity with Laser Phosphor systems within 3-4 years of operation when accounting for energy savings, reduced maintenance, and extended operational lifespan. Organizations with planning horizons beyond this threshold would benefit financially from selecting Mini LED technology despite the premium initial investment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!