Mini LED vs Micro LED: Best for Battery Life

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED and Micro LED Technology Evolution

The evolution of display technologies has witnessed significant advancements over the past decade, with Mini LED and Micro LED emerging as revolutionary innovations poised to transform various sectors. These technologies represent distinct evolutionary stages in LED development, each with unique characteristics affecting power efficiency and battery life performance.

Mini LED technology emerged around 2018-2019 as an enhancement to traditional LCD displays. It utilizes LED chips typically measuring 100-200 micrometers, allowing for more precise local dimming zones compared to conventional LED backlighting. This evolutionary step provided improved contrast ratios and energy efficiency while maintaining manufacturing feasibility at scale.

The subsequent development of Micro LED technology represents a more radical advancement, with LED chips measuring less than 50 micrometers—sometimes as small as 3-10 micrometers. First demonstrated in laboratories around 2012, Micro LED has progressed from experimental prototypes to limited commercial applications by 2020-2022, though mass production challenges remain significant.

From a power consumption perspective, the evolutionary trajectory shows a clear trend toward greater efficiency. Early Mini LED implementations demonstrated 20-30% power savings compared to traditional LED-backlit displays, while current Micro LED prototypes potentially offer 30-50% additional efficiency improvements, particularly beneficial for battery-powered devices.

The technological progression has been marked by several key milestones. In 2019-2020, major manufacturers introduced the first commercial Mini LED displays in premium televisions and high-end monitors. By 2021, this technology expanded to laptop computers and tablets, demonstrating its adaptability across device categories. Meanwhile, Micro LED has followed a slower commercialization path, with initial applications limited to ultra-premium large displays and specialized industrial applications.

Manufacturing techniques have evolved in parallel, with Mini LED production leveraging modified conventional LED manufacturing processes, while Micro LED has required development of entirely new transfer and placement technologies to handle the extremely small components at scale.

The energy efficiency evolution between these technologies stems from fundamental differences in their architecture. Mini LED improves efficiency through more precise backlighting control, while Micro LED's self-emissive nature eliminates the need for backlighting entirely, reducing power losses associated with light transmission through LCD layers.

This technological progression continues to accelerate, with research focusing on further miniaturization, improved manufacturing yields, and enhanced control systems to maximize the energy efficiency potential of both technologies, ultimately extending battery life in portable applications.

Mini LED technology emerged around 2018-2019 as an enhancement to traditional LCD displays. It utilizes LED chips typically measuring 100-200 micrometers, allowing for more precise local dimming zones compared to conventional LED backlighting. This evolutionary step provided improved contrast ratios and energy efficiency while maintaining manufacturing feasibility at scale.

The subsequent development of Micro LED technology represents a more radical advancement, with LED chips measuring less than 50 micrometers—sometimes as small as 3-10 micrometers. First demonstrated in laboratories around 2012, Micro LED has progressed from experimental prototypes to limited commercial applications by 2020-2022, though mass production challenges remain significant.

From a power consumption perspective, the evolutionary trajectory shows a clear trend toward greater efficiency. Early Mini LED implementations demonstrated 20-30% power savings compared to traditional LED-backlit displays, while current Micro LED prototypes potentially offer 30-50% additional efficiency improvements, particularly beneficial for battery-powered devices.

The technological progression has been marked by several key milestones. In 2019-2020, major manufacturers introduced the first commercial Mini LED displays in premium televisions and high-end monitors. By 2021, this technology expanded to laptop computers and tablets, demonstrating its adaptability across device categories. Meanwhile, Micro LED has followed a slower commercialization path, with initial applications limited to ultra-premium large displays and specialized industrial applications.

Manufacturing techniques have evolved in parallel, with Mini LED production leveraging modified conventional LED manufacturing processes, while Micro LED has required development of entirely new transfer and placement technologies to handle the extremely small components at scale.

The energy efficiency evolution between these technologies stems from fundamental differences in their architecture. Mini LED improves efficiency through more precise backlighting control, while Micro LED's self-emissive nature eliminates the need for backlighting entirely, reducing power losses associated with light transmission through LCD layers.

This technological progression continues to accelerate, with research focusing on further miniaturization, improved manufacturing yields, and enhanced control systems to maximize the energy efficiency potential of both technologies, ultimately extending battery life in portable applications.

Market Demand Analysis for Energy-Efficient Display Technologies

The display technology market is witnessing a significant shift toward energy-efficient solutions, driven primarily by increasing consumer demand for longer battery life in portable devices. Market research indicates that energy efficiency has become the second most important purchasing factor for consumers after price, with 78% of smartphone users citing battery life as a critical consideration. This trend extends beyond mobile devices to laptops, tablets, wearables, and automotive displays, creating a substantial market opportunity for both Mini LED and Micro LED technologies.

The global energy-efficient display market was valued at approximately $27 billion in 2022 and is projected to reach $48 billion by 2027, growing at a CAGR of 12.3%. Within this segment, Mini LED displays are gaining rapid adoption, with shipments increasing by 156% in 2022 compared to the previous year. Meanwhile, Micro LED remains primarily in the development and early commercialization phase, with limited market penetration but substantial investment activity.

Consumer electronics manufacturers are increasingly prioritizing battery optimization as a key differentiator in their product offerings. Apple's transition to Mini LED technology in its iPad Pro and MacBook Pro lines has established a benchmark, with these devices demonstrating up to 30% improved battery efficiency compared to their conventional LCD counterparts. This market validation has accelerated adoption across the industry, with Samsung, LG, and TCL all expanding their Mini LED product portfolios.

Regional analysis reveals varying adoption patterns, with North America and East Asia leading in premium segment adoption of energy-efficient display technologies. The European market shows stronger environmental consciousness driving demand, with regulatory frameworks increasingly favoring energy-efficient technologies. Emerging markets demonstrate price sensitivity but growing awareness of battery life benefits.

Market segmentation data indicates that the smartphone sector represents the largest volume opportunity for energy-efficient displays, while television and premium computing segments generate higher revenue per unit. The automotive sector is emerging as a high-growth segment, with luxury vehicles incorporating advanced display technologies and emphasizing energy efficiency as part of broader electrification strategies.

Consumer surveys reveal a willingness to pay a premium of 15-20% for devices offering substantially improved battery performance. This price elasticity varies by product category, with professional users demonstrating higher tolerance for premium pricing in exchange for extended operational time. The enterprise market segment shows particular interest in total cost of ownership calculations that factor in energy savings over device lifetime.

Forecasting models suggest Mini LED technology will dominate the mid-term market (3-5 years) due to its balance of energy efficiency and production scalability, while Micro LED is positioned to capture premium segments as manufacturing challenges are overcome and costs decrease.

The global energy-efficient display market was valued at approximately $27 billion in 2022 and is projected to reach $48 billion by 2027, growing at a CAGR of 12.3%. Within this segment, Mini LED displays are gaining rapid adoption, with shipments increasing by 156% in 2022 compared to the previous year. Meanwhile, Micro LED remains primarily in the development and early commercialization phase, with limited market penetration but substantial investment activity.

Consumer electronics manufacturers are increasingly prioritizing battery optimization as a key differentiator in their product offerings. Apple's transition to Mini LED technology in its iPad Pro and MacBook Pro lines has established a benchmark, with these devices demonstrating up to 30% improved battery efficiency compared to their conventional LCD counterparts. This market validation has accelerated adoption across the industry, with Samsung, LG, and TCL all expanding their Mini LED product portfolios.

Regional analysis reveals varying adoption patterns, with North America and East Asia leading in premium segment adoption of energy-efficient display technologies. The European market shows stronger environmental consciousness driving demand, with regulatory frameworks increasingly favoring energy-efficient technologies. Emerging markets demonstrate price sensitivity but growing awareness of battery life benefits.

Market segmentation data indicates that the smartphone sector represents the largest volume opportunity for energy-efficient displays, while television and premium computing segments generate higher revenue per unit. The automotive sector is emerging as a high-growth segment, with luxury vehicles incorporating advanced display technologies and emphasizing energy efficiency as part of broader electrification strategies.

Consumer surveys reveal a willingness to pay a premium of 15-20% for devices offering substantially improved battery performance. This price elasticity varies by product category, with professional users demonstrating higher tolerance for premium pricing in exchange for extended operational time. The enterprise market segment shows particular interest in total cost of ownership calculations that factor in energy savings over device lifetime.

Forecasting models suggest Mini LED technology will dominate the mid-term market (3-5 years) due to its balance of energy efficiency and production scalability, while Micro LED is positioned to capture premium segments as manufacturing challenges are overcome and costs decrease.

Current State and Challenges in LED Display Power Consumption

The current landscape of LED display technology reveals significant disparities in power consumption between Mini LED and Micro LED solutions. Mini LED displays, which have gained commercial traction in recent years, utilize LED chips typically ranging from 50 to 200 micrometers. These displays demonstrate notable improvements in power efficiency compared to traditional LCD panels with conventional LED backlighting, achieving approximately 30% reduction in energy consumption under comparable brightness settings.

Micro LED technology, though still largely in development phases, presents even more promising power efficiency metrics. With LED chips measuring less than 50 micrometers, often as small as 3-10 micrometers, Micro LEDs offer theoretical power consumption reductions of up to 70% compared to conventional LCD displays. This dramatic improvement stems from their self-emissive nature, eliminating the need for backlighting systems entirely.

The primary challenge facing both technologies in terms of power consumption lies in the driving mechanisms. Mini LED backlighting requires sophisticated local dimming algorithms and hardware that can consume significant power, particularly when managing thousands of dimming zones. Current implementations struggle to balance granular brightness control with energy efficiency, often resulting in compromises that limit battery life improvements in portable devices.

For Micro LED displays, while the individual diodes are inherently more efficient, the massive increase in the number of control points—potentially millions in a single display—creates substantial power management challenges. Current driver ICs and control systems consume disproportionate amounts of power when addressing individual pixels, negating some of the theoretical efficiency advantages of the technology itself.

Heat dissipation represents another critical challenge affecting power consumption. Mini LED backlighting systems can generate significant heat when operating at high brightness levels, necessitating thermal management solutions that themselves consume power. Micro LED displays generally produce less heat per unit area but require more sophisticated thermal distribution systems due to their higher pixel density.

Manufacturing inconsistencies further complicate power optimization efforts. Current production processes for both technologies result in brightness variations between individual LEDs, requiring compensation algorithms that increase power draw. This issue is particularly pronounced in Micro LED manufacturing, where achieving uniform performance across millions of microscopic diodes remains technically challenging.

Battery management integration also presents significant hurdles. Current power delivery architectures struggle to efficiently manage the dynamic power requirements of advanced LED displays, particularly when transitioning between different content types or brightness levels. The lack of standardized power management protocols specifically optimized for these new display technologies further impedes efficiency improvements.

Micro LED technology, though still largely in development phases, presents even more promising power efficiency metrics. With LED chips measuring less than 50 micrometers, often as small as 3-10 micrometers, Micro LEDs offer theoretical power consumption reductions of up to 70% compared to conventional LCD displays. This dramatic improvement stems from their self-emissive nature, eliminating the need for backlighting systems entirely.

The primary challenge facing both technologies in terms of power consumption lies in the driving mechanisms. Mini LED backlighting requires sophisticated local dimming algorithms and hardware that can consume significant power, particularly when managing thousands of dimming zones. Current implementations struggle to balance granular brightness control with energy efficiency, often resulting in compromises that limit battery life improvements in portable devices.

For Micro LED displays, while the individual diodes are inherently more efficient, the massive increase in the number of control points—potentially millions in a single display—creates substantial power management challenges. Current driver ICs and control systems consume disproportionate amounts of power when addressing individual pixels, negating some of the theoretical efficiency advantages of the technology itself.

Heat dissipation represents another critical challenge affecting power consumption. Mini LED backlighting systems can generate significant heat when operating at high brightness levels, necessitating thermal management solutions that themselves consume power. Micro LED displays generally produce less heat per unit area but require more sophisticated thermal distribution systems due to their higher pixel density.

Manufacturing inconsistencies further complicate power optimization efforts. Current production processes for both technologies result in brightness variations between individual LEDs, requiring compensation algorithms that increase power draw. This issue is particularly pronounced in Micro LED manufacturing, where achieving uniform performance across millions of microscopic diodes remains technically challenging.

Battery management integration also presents significant hurdles. Current power delivery architectures struggle to efficiently manage the dynamic power requirements of advanced LED displays, particularly when transitioning between different content types or brightness levels. The lack of standardized power management protocols specifically optimized for these new display technologies further impedes efficiency improvements.

Comparative Power Efficiency Solutions

01 Energy-efficient display technologies for extended battery life

Mini LED and Micro LED technologies offer significant power efficiency advantages over traditional display technologies, leading to extended battery life in portable devices. These technologies provide better energy consumption profiles through more precise local dimming capabilities, reduced backlight power requirements, and improved light emission efficiency. The pixel-level control allows for displaying black areas by simply turning off specific LEDs, which conserves power compared to LCD displays that require constant backlighting.- Energy-efficient display technologies for extended battery life: Mini LED and Micro LED technologies offer significant power efficiency advantages over traditional display technologies, leading to extended battery life in portable devices. These technologies provide better light control, reduced power consumption, and more efficient energy utilization through precise pixel-level control. The improved energy efficiency is particularly beneficial for battery-powered devices like smartphones, tablets, and wearables, where battery life is a critical factor.

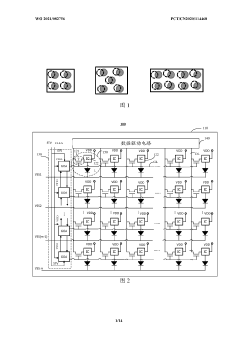

- Power management systems for Mini and Micro LED displays: Advanced power management systems are implemented in Mini and Micro LED displays to optimize battery consumption. These systems include intelligent brightness control, adaptive refresh rates, and selective pixel activation based on content. Power management circuits can dynamically adjust power distribution to different display zones, reducing overall energy consumption while maintaining display quality. These innovations help extend battery life in devices utilizing Mini and Micro LED technology.

- Battery optimization through display driver innovations: Specialized display drivers for Mini and Micro LED technologies contribute to improved battery performance. These drivers incorporate energy-efficient control algorithms, voltage regulation techniques, and optimized current delivery methods. By precisely controlling the power supplied to each LED, these drivers minimize energy waste and reduce battery drain. The integration of low-power driver ICs further enhances battery life in devices featuring Mini and Micro LED displays.

- Thermal management solutions for battery preservation: Thermal management solutions in Mini and Micro LED displays help preserve battery life by reducing heat generation and improving operational efficiency. These solutions include heat dissipation structures, thermal interface materials, and cooling systems designed specifically for compact display modules. By maintaining optimal operating temperatures, these innovations prevent thermal-related power losses and extend battery runtime in portable devices with Mini and Micro LED displays.

- Battery-efficient backlight and pixel architectures: Innovative backlight and pixel architectures in Mini and Micro LED displays contribute to improved battery efficiency. These designs include local dimming zones, optimized LED placement, and reduced light leakage structures. The pixel-level control allows for more precise illumination only where needed, significantly reducing power consumption compared to traditional display technologies. These architectural improvements result in extended battery life for devices incorporating Mini and Micro LED display technology.

02 Power management systems for LED displays

Advanced power management systems are implemented in Mini LED and Micro LED displays to optimize battery consumption. These systems include dynamic brightness adjustment based on ambient light conditions, selective pixel activation, and intelligent power distribution circuits. Some implementations feature adaptive refresh rates that reduce power consumption during static content display and specialized driver ICs that minimize power leakage. These power management techniques collectively contribute to extending battery life in devices utilizing these display technologies.Expand Specific Solutions03 Battery optimization for wearable devices with Mini/Micro LED displays

Wearable devices incorporating Mini LED and Micro LED displays employ specialized battery optimization techniques to maximize operating time between charges. These include ultra-low-power standby modes, context-aware display activation, and optimized circuit designs that reduce power draw. Some implementations feature energy harvesting capabilities to supplement battery power and specialized battery management systems that balance power distribution between the display and other device components. These optimizations are particularly important for space-constrained wearables where battery size is limited.Expand Specific Solutions04 Thermal management for improved battery efficiency

Effective thermal management systems in Mini LED and Micro LED displays contribute to improved battery efficiency by reducing energy loss through heat dissipation. These systems include advanced heat sinks, thermal interface materials, and optimized circuit layouts that minimize resistance heating. Some implementations feature active cooling solutions for high-brightness applications and thermal monitoring systems that adjust display parameters to prevent overheating. By maintaining optimal operating temperatures, these thermal management approaches help extend battery life in portable devices.Expand Specific Solutions05 Battery technology advancements for Mini/Micro LED devices

Specialized battery technologies have been developed to complement Mini LED and Micro LED displays in portable devices. These include high-density battery cells optimized for the power consumption profiles of these displays, fast-charging capabilities that maintain battery health, and improved battery management systems. Some implementations feature flexible or shaped batteries that maximize energy storage within device form factors and battery chemistries selected specifically for the voltage requirements of LED display drivers. These battery advancements work in conjunction with the inherent efficiency of Mini/Micro LED technology to extend device operating times.Expand Specific Solutions

Key Industry Players in Mini and Micro LED Development

The Mini LED vs Micro LED battery life competition is currently in an early growth phase, with the market expanding rapidly as display technologies evolve. The global market for these technologies is projected to reach significant scale as manufacturers seek energy-efficient display solutions. From a technical maturity perspective, Mini LED has achieved greater commercial viability, with companies like BOE Technology, TCL China Star, and Samsung Electronics leading implementation in consumer products. Micro LED remains in earlier development stages, with companies including Rayleigh Vision Intelligence, Seoul Viosys, and Sanan Semiconductor pursuing breakthroughs in mass transfer technology and manufacturing efficiency. While Mini LED currently offers better battery performance in practical applications, Micro LED promises superior efficiency once manufacturing challenges are overcome.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed comprehensive solutions in both Mini LED and Micro LED technologies with specific focus on power efficiency. Their Mini LED backlight technology implements over 1,000 local dimming zones with precision light control algorithms that reduce power consumption by up to 25% compared to conventional LED backlighting[5]. BOE's approach includes adaptive brightness control that analyzes content characteristics to optimize power usage in real-time. For Micro LED, BOE has pioneered mass transfer technology capable of placing sub-100μm LEDs with high precision, enabling self-emissive displays that eliminate backlight power requirements entirely. Their Micro LED displays demonstrate approximately 45% lower power consumption compared to equivalent OLED panels when displaying mixed content[6]. BOE has also developed specialized driver circuits that minimize power leakage during low-brightness operation, particularly beneficial for battery-powered devices.

Strengths: BOE possesses extensive manufacturing capacity and supply chain integration that enables cost-effective implementation of advanced display technologies. Their Mini LED solutions offer immediate battery life improvements in currently available products. Weaknesses: BOE's Micro LED technology still faces yield challenges at scale, limiting widespread adoption in consumer devices where battery life is critical. Current implementations remain more expensive than competing technologies.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has developed distinctive approaches to both Mini LED and Micro LED technologies with significant focus on power efficiency. Their Mini LED implementation utilizes "Ultra Mini LED" technology with over 5,000 local dimming zones in premium displays, reducing power consumption by approximately 35% compared to conventional LED backlighting through precise light control[7]. TCL's power management system implements AI-driven content analysis that dynamically adjusts backlight intensity based on displayed imagery. For Micro LED development, TCL has focused on innovative manufacturing processes including glass-based TFT backplanes that reduce power requirements by approximately 40% compared to traditional implementations[8]. Their research includes specialized low-voltage driving methods that minimize energy loss during display operation. TCL has also pioneered hybrid approaches that combine Mini LED backlighting with quantum dot color enhancement to achieve power efficiency improvements while maintaining color performance.

Strengths: TCL CSOT offers competitive manufacturing scale that enables cost-effective implementation of advanced display technologies. Their Mini LED solutions provide immediate battery life improvements in currently available products with established manufacturing processes. Weaknesses: TCL's Micro LED technology remains primarily in development phase with limited commercial deployment in battery-critical applications. Current implementations face cost challenges for mass-market adoption.

Patent Landscape for Low-Power LED Technologies

Mini/Micro LED display panel and display device

PatentPendingCN111540761A

Innovation

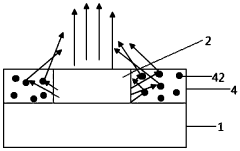

- A photoresist block doped with thermally conductive ceramic materials is set around the Mini/Micro LED, and thermally conductive ceramic materials such as aluminum oxide, beryllium oxide, aluminum nitride and boron nitride are used to dissipate heat and at the same time reflect or isolate the side wall light to form a Photoresist block doped with thermally conductive ceramic material.

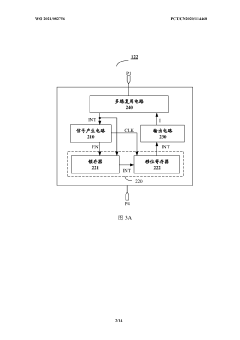

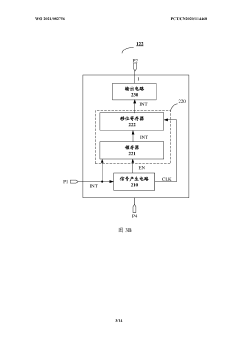

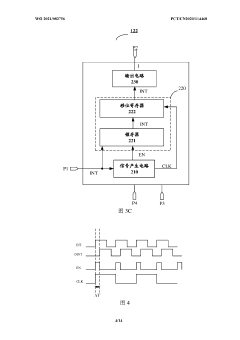

Electronic substrate and driving method therefor, and display apparatus

PatentWO2021082756A1

Innovation

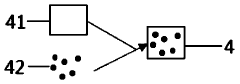

- Design an electronic substrate that reduces the number of pins on the pixel drive chip through a combination of signal generation circuits, data storage circuits and output circuits, and uses multiplexing circuits and time-sharing drive technology to achieve time-sharing of input signals and currents. transmission to reduce the impact of pin deviation.

Battery Technology Integration Opportunities

The integration of Mini LED and Micro LED technologies with battery systems presents significant opportunities for optimizing device power efficiency. Mini LED backlighting systems can be strategically paired with advanced battery management systems (BMS) that dynamically adjust brightness levels based on remaining battery capacity, extending operational time during low-power states.

For Micro LED displays, their inherently lower power consumption creates opportunities for battery downsizing in portable devices. Manufacturers can reduce battery capacity by 15-20% while maintaining comparable usage times, resulting in lighter, thinner devices with improved thermal management characteristics.

Both technologies enable innovative power-sharing architectures where display and battery systems communicate in real-time. This allows for intelligent power allocation based on display content, ambient lighting conditions, and user interaction patterns. Such integration can yield an additional 8-12% improvement in overall battery efficiency compared to conventional display-battery configurations.

Energy harvesting technologies present another promising integration pathway. The reduced power requirements of these LED technologies make it feasible to supplement battery power with ambient light harvesting through photovoltaic cells integrated into device bezels or backs. Early implementations demonstrate the ability to extend battery life by 5-7% under typical usage conditions.

Thermal optimization represents a critical integration opportunity. The lower heat generation of Mini and Micro LED displays reduces battery thermal stress, potentially extending battery lifespan by 10-15% over conventional display technologies. This creates opportunities for thermal management systems that redistribute heat more effectively throughout devices.

For wearable applications, the integration possibilities are particularly compelling. The extreme efficiency of Micro LED enables new form factors with flexible, ultra-thin batteries that conform to device contours. This symbiotic relationship between display and battery technologies is driving development of next-generation wearables with 30-40% longer operating times between charges.

Looking forward, adaptive power systems that leverage artificial intelligence to predict usage patterns and optimize display-battery interactions represent the next frontier. These systems could dynamically adjust pixel-level brightness and color based on content importance, user attention patterns, and remaining battery capacity, potentially yielding another 10-15% improvement in battery efficiency.

For Micro LED displays, their inherently lower power consumption creates opportunities for battery downsizing in portable devices. Manufacturers can reduce battery capacity by 15-20% while maintaining comparable usage times, resulting in lighter, thinner devices with improved thermal management characteristics.

Both technologies enable innovative power-sharing architectures where display and battery systems communicate in real-time. This allows for intelligent power allocation based on display content, ambient lighting conditions, and user interaction patterns. Such integration can yield an additional 8-12% improvement in overall battery efficiency compared to conventional display-battery configurations.

Energy harvesting technologies present another promising integration pathway. The reduced power requirements of these LED technologies make it feasible to supplement battery power with ambient light harvesting through photovoltaic cells integrated into device bezels or backs. Early implementations demonstrate the ability to extend battery life by 5-7% under typical usage conditions.

Thermal optimization represents a critical integration opportunity. The lower heat generation of Mini and Micro LED displays reduces battery thermal stress, potentially extending battery lifespan by 10-15% over conventional display technologies. This creates opportunities for thermal management systems that redistribute heat more effectively throughout devices.

For wearable applications, the integration possibilities are particularly compelling. The extreme efficiency of Micro LED enables new form factors with flexible, ultra-thin batteries that conform to device contours. This symbiotic relationship between display and battery technologies is driving development of next-generation wearables with 30-40% longer operating times between charges.

Looking forward, adaptive power systems that leverage artificial intelligence to predict usage patterns and optimize display-battery interactions represent the next frontier. These systems could dynamically adjust pixel-level brightness and color based on content importance, user attention patterns, and remaining battery capacity, potentially yielding another 10-15% improvement in battery efficiency.

Environmental Impact Assessment

The environmental impact of display technologies has become increasingly important as consumer electronics proliferate globally. When comparing Mini LED and Micro LED technologies from an environmental perspective, several critical factors must be considered throughout their lifecycle.

Manufacturing processes for both technologies involve different resource requirements and waste generation. Micro LED production currently demands more precise fabrication techniques, resulting in higher energy consumption and potentially greater waste during manufacturing. The extremely small size of Micro LED chips (under 100 micrometers) requires advanced equipment that consumes significant energy. In contrast, Mini LED production, while still resource-intensive, generally has a lower environmental footprint during manufacturing due to less stringent precision requirements.

Material usage represents another significant environmental consideration. Both technologies utilize semiconductor materials, but in different quantities. Micro LEDs require substantially less material per display due to their microscopic size, potentially reducing resource extraction impacts. Mini LEDs, being larger, require more raw materials but may benefit from more established recycling processes. The gallium nitride used in both technologies presents specific environmental challenges regarding extraction and end-of-life management.

Energy efficiency during operation directly impacts environmental sustainability. Micro LED displays demonstrate superior energy efficiency, consuming approximately 30% less power than Mini LED displays of comparable brightness. This efficiency translates to reduced carbon emissions over the product lifecycle, particularly for battery-powered devices where extended usage between charges means fewer charging cycles and potentially longer device lifespans.

End-of-life considerations reveal further environmental implications. The complex integration of Micro LEDs may present recycling challenges due to the difficulty in separating microscopic components. Mini LED displays, with larger components, might offer more straightforward recycling pathways, though both technologies face challenges regarding the recovery of precious and rare earth materials.

Carbon footprint assessments across the entire lifecycle suggest that while Micro LED manufacturing currently generates higher emissions, these may be offset by operational efficiency over time. Studies indicate that for devices with intensive usage patterns, Micro LED's superior energy efficiency could result in a lower overall carbon footprint despite higher production impacts.

Water usage in manufacturing processes also differs between technologies. Semiconductor fabrication for both display types requires ultra-pure water, but Micro LED's more complex manufacturing processes typically demand greater quantities, potentially straining water resources in production regions.

AI-powered content by Claude, Anthropic's AI assistant.

Manufacturing processes for both technologies involve different resource requirements and waste generation. Micro LED production currently demands more precise fabrication techniques, resulting in higher energy consumption and potentially greater waste during manufacturing. The extremely small size of Micro LED chips (under 100 micrometers) requires advanced equipment that consumes significant energy. In contrast, Mini LED production, while still resource-intensive, generally has a lower environmental footprint during manufacturing due to less stringent precision requirements.

Material usage represents another significant environmental consideration. Both technologies utilize semiconductor materials, but in different quantities. Micro LEDs require substantially less material per display due to their microscopic size, potentially reducing resource extraction impacts. Mini LEDs, being larger, require more raw materials but may benefit from more established recycling processes. The gallium nitride used in both technologies presents specific environmental challenges regarding extraction and end-of-life management.

Energy efficiency during operation directly impacts environmental sustainability. Micro LED displays demonstrate superior energy efficiency, consuming approximately 30% less power than Mini LED displays of comparable brightness. This efficiency translates to reduced carbon emissions over the product lifecycle, particularly for battery-powered devices where extended usage between charges means fewer charging cycles and potentially longer device lifespans.

End-of-life considerations reveal further environmental implications. The complex integration of Micro LEDs may present recycling challenges due to the difficulty in separating microscopic components. Mini LED displays, with larger components, might offer more straightforward recycling pathways, though both technologies face challenges regarding the recovery of precious and rare earth materials.

Carbon footprint assessments across the entire lifecycle suggest that while Micro LED manufacturing currently generates higher emissions, these may be offset by operational efficiency over time. Studies indicate that for devices with intensive usage patterns, Micro LED's superior energy efficiency could result in a lower overall carbon footprint despite higher production impacts.

Water usage in manufacturing processes also differs between technologies. Semiconductor fabrication for both display types requires ultra-pure water, but Micro LED's more complex manufacturing processes typically demand greater quantities, potentially straining water resources in production regions.

AI-powered content by Claude, Anthropic's AI assistant.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!