Mini LED vs Nanorods: Reducing Energy Waste Efficacy

SEP 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED and Nanorod Technology Evolution

The evolution of display technologies has witnessed significant advancements over the past decade, with Mini LED and nanorod technologies emerging as promising solutions to address energy efficiency challenges in display systems. Mini LED technology, first conceptualized in the early 2010s, represents an intermediate step between conventional LED backlighting and microLED displays, featuring LED chips typically ranging from 50 to 200 micrometers.

The developmental trajectory of Mini LED technology gained substantial momentum around 2017-2018 when major display manufacturers began investing heavily in research and commercialization efforts. This period marked the transition from prototype demonstrations to actual product integration, with the first consumer electronics featuring Mini LED backlighting appearing in premium television models by 2019.

Concurrently, nanorod technology has followed a distinct evolutionary path. Originating from fundamental research in semiconductor nanomaterials during the early 2000s, nanorods—cylindrical nanostructures with diameters typically below 100 nanometers—initially faced significant manufacturing challenges that limited their practical application in display technologies.

A critical breakthrough occurred around 2015 when researchers developed more reliable methods for synthesizing uniform nanorods with precisely controlled dimensions and optical properties. This advancement catalyzed increased interest in their potential for display applications, particularly for their unique light-emitting characteristics and energy efficiency advantages.

The convergence of these two technologies began to materialize around 2018-2020, as researchers explored hybrid approaches combining Mini LED backlighting with nanorod-based color conversion layers. This integration aimed to leverage the brightness control capabilities of Mini LEDs with the superior color performance and energy efficiency of nanorods.

From an energy efficiency perspective, the evolution has been remarkable. Early Mini LED implementations demonstrated approximately 20-30% improvement in energy efficiency compared to conventional LED backlighting. However, the integration of nanorod technology has pushed these boundaries further, with recent prototypes showing potential energy savings of 40-50% while maintaining or even enhancing display performance metrics.

The most recent developmental phase, spanning 2021 to present, has focused on addressing manufacturing scalability challenges for both technologies. Innovations in mass transfer techniques for Mini LEDs and solution-processing methods for nanorods have significantly reduced production costs, bringing these technologies closer to mainstream adoption across various display applications, from smartphones and tablets to automotive displays and large-format televisions.

The developmental trajectory of Mini LED technology gained substantial momentum around 2017-2018 when major display manufacturers began investing heavily in research and commercialization efforts. This period marked the transition from prototype demonstrations to actual product integration, with the first consumer electronics featuring Mini LED backlighting appearing in premium television models by 2019.

Concurrently, nanorod technology has followed a distinct evolutionary path. Originating from fundamental research in semiconductor nanomaterials during the early 2000s, nanorods—cylindrical nanostructures with diameters typically below 100 nanometers—initially faced significant manufacturing challenges that limited their practical application in display technologies.

A critical breakthrough occurred around 2015 when researchers developed more reliable methods for synthesizing uniform nanorods with precisely controlled dimensions and optical properties. This advancement catalyzed increased interest in their potential for display applications, particularly for their unique light-emitting characteristics and energy efficiency advantages.

The convergence of these two technologies began to materialize around 2018-2020, as researchers explored hybrid approaches combining Mini LED backlighting with nanorod-based color conversion layers. This integration aimed to leverage the brightness control capabilities of Mini LEDs with the superior color performance and energy efficiency of nanorods.

From an energy efficiency perspective, the evolution has been remarkable. Early Mini LED implementations demonstrated approximately 20-30% improvement in energy efficiency compared to conventional LED backlighting. However, the integration of nanorod technology has pushed these boundaries further, with recent prototypes showing potential energy savings of 40-50% while maintaining or even enhancing display performance metrics.

The most recent developmental phase, spanning 2021 to present, has focused on addressing manufacturing scalability challenges for both technologies. Innovations in mass transfer techniques for Mini LEDs and solution-processing methods for nanorods have significantly reduced production costs, bringing these technologies closer to mainstream adoption across various display applications, from smartphones and tablets to automotive displays and large-format televisions.

Market Demand for Energy-Efficient Display Technologies

The display technology market is witnessing a significant shift toward energy-efficient solutions, driven primarily by increasing environmental concerns, regulatory pressures, and consumer demand for sustainable products. Energy consumption in display technologies has become a critical factor as displays continue to increase in size and brightness while being integrated into more devices across various sectors.

Consumer electronics manufacturers are facing mounting pressure to reduce the carbon footprint of their products, with displays accounting for a substantial portion of energy consumption in devices such as smartphones, tablets, televisions, and monitors. Market research indicates that energy efficiency has risen to become one of the top five purchasing considerations for consumers when selecting new display products, particularly in premium segments.

The commercial sector represents another substantial market driver, with businesses increasingly prioritizing energy-efficient displays to reduce operational costs and meet corporate sustainability goals. Large-format displays in retail, hospitality, and corporate environments operate continuously, making their energy consumption profile particularly significant for total cost of ownership calculations.

Regulatory frameworks worldwide are tightening energy consumption standards for electronic displays. The European Union's Ecodesign Directive, Energy Star certification in North America, and similar programs in Asia-Pacific markets have established increasingly stringent efficiency requirements that manufacturers must meet to maintain market access. These regulations are expected to become more demanding over the next five years, creating market pressure for technological advancement.

The automotive industry presents a rapidly expanding market for energy-efficient display technologies, with the average vehicle now containing multiple displays that must operate under varying lighting conditions while minimizing battery drain. As electric vehicles gain market share, the energy efficiency of all onboard systems, including displays, becomes increasingly critical to overall vehicle range and performance.

Market analysis reveals that technologies offering 30-50% energy savings compared to conventional LCD displays can command premium pricing, with consumers demonstrating willingness to pay 15-20% more for products with verified efficiency improvements. This price tolerance creates significant revenue opportunities for manufacturers who can deliver meaningful advances in display efficiency.

The healthcare and industrial sectors also represent growing markets for energy-efficient displays, with requirements for specialized performance characteristics alongside reduced power consumption. These professional markets value long-term reliability and consistent performance, creating opportunities for advanced technologies that can deliver both efficiency and stability.

Forecasts indicate the global market for energy-efficient display technologies will expand at a compound annual growth rate exceeding the overall display market by 4-6 percentage points through 2030, representing a substantial opportunity for technologies that can effectively address energy waste while maintaining or improving visual performance.

Consumer electronics manufacturers are facing mounting pressure to reduce the carbon footprint of their products, with displays accounting for a substantial portion of energy consumption in devices such as smartphones, tablets, televisions, and monitors. Market research indicates that energy efficiency has risen to become one of the top five purchasing considerations for consumers when selecting new display products, particularly in premium segments.

The commercial sector represents another substantial market driver, with businesses increasingly prioritizing energy-efficient displays to reduce operational costs and meet corporate sustainability goals. Large-format displays in retail, hospitality, and corporate environments operate continuously, making their energy consumption profile particularly significant for total cost of ownership calculations.

Regulatory frameworks worldwide are tightening energy consumption standards for electronic displays. The European Union's Ecodesign Directive, Energy Star certification in North America, and similar programs in Asia-Pacific markets have established increasingly stringent efficiency requirements that manufacturers must meet to maintain market access. These regulations are expected to become more demanding over the next five years, creating market pressure for technological advancement.

The automotive industry presents a rapidly expanding market for energy-efficient display technologies, with the average vehicle now containing multiple displays that must operate under varying lighting conditions while minimizing battery drain. As electric vehicles gain market share, the energy efficiency of all onboard systems, including displays, becomes increasingly critical to overall vehicle range and performance.

Market analysis reveals that technologies offering 30-50% energy savings compared to conventional LCD displays can command premium pricing, with consumers demonstrating willingness to pay 15-20% more for products with verified efficiency improvements. This price tolerance creates significant revenue opportunities for manufacturers who can deliver meaningful advances in display efficiency.

The healthcare and industrial sectors also represent growing markets for energy-efficient displays, with requirements for specialized performance characteristics alongside reduced power consumption. These professional markets value long-term reliability and consistent performance, creating opportunities for advanced technologies that can deliver both efficiency and stability.

Forecasts indicate the global market for energy-efficient display technologies will expand at a compound annual growth rate exceeding the overall display market by 4-6 percentage points through 2030, representing a substantial opportunity for technologies that can effectively address energy waste while maintaining or improving visual performance.

Technical Challenges in Energy Efficiency for Display Technologies

The display technology landscape faces significant challenges in energy efficiency, with conventional LCD and OLED displays consuming substantial power. These technologies suffer from inherent limitations: LCDs require constant backlighting regardless of displayed content, while OLEDs struggle with blue pixel efficiency and lifespan issues. Both technologies convert considerable energy into waste heat rather than usable light, reducing battery life in portable devices and increasing cooling requirements in larger displays.

Mini LED technology has emerged as an intermediate solution, offering improved local dimming capabilities through thousands of tiny LED backlights arranged in multiple dimming zones. While this approach significantly reduces energy waste compared to traditional edge-lit LCDs, it still faces challenges in precise light control, with issues like blooming (light bleeding around bright objects) and limited dimming zones compared to per-pixel control technologies.

Thermal management presents another critical challenge, as both technologies generate heat that must be efficiently dissipated to prevent performance degradation and component damage. This is particularly problematic in thin, compact devices where thermal solutions must balance effectiveness with space and weight constraints. The heat generated not only wastes energy but can trigger thermal throttling, further reducing efficiency.

Manufacturing complexity also impacts energy efficiency, with yield rates affecting cost-effectiveness of advanced display technologies. Mini LED backlighting requires precise placement of thousands of tiny LEDs, while emerging nanorod-based solutions demand even greater manufacturing precision at the nanoscale. These production challenges can limit widespread adoption of more energy-efficient display technologies.

Power management circuitry represents another efficiency bottleneck. Current driver ICs and power delivery systems experience conversion losses that compound the inherent inefficiencies of the display technologies themselves. More sophisticated power management solutions are needed to minimize these losses, particularly for battery-powered devices where every milliwatt matters.

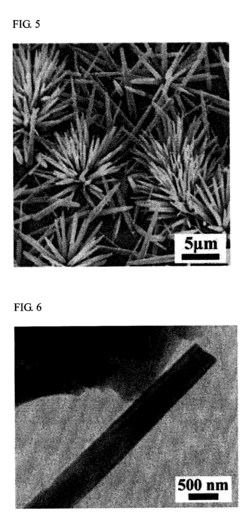

The emerging nanorod-based display technologies promise significant efficiency improvements through directional light emission and reduced scattering. By aligning nanorods perpendicular to the display surface, light can be channeled more effectively toward the viewer rather than being lost to internal reflection or side emission. However, these technologies face challenges in uniform nanorod growth, alignment control, and integration with existing display manufacturing processes.

Color accuracy and brightness trade-offs further complicate energy efficiency efforts. Higher color gamut coverage often requires more energy, creating a tension between visual quality and power consumption. Finding the optimal balance between these competing priorities remains a significant technical challenge for both Mini LED and nanorod-based display technologies.

Mini LED technology has emerged as an intermediate solution, offering improved local dimming capabilities through thousands of tiny LED backlights arranged in multiple dimming zones. While this approach significantly reduces energy waste compared to traditional edge-lit LCDs, it still faces challenges in precise light control, with issues like blooming (light bleeding around bright objects) and limited dimming zones compared to per-pixel control technologies.

Thermal management presents another critical challenge, as both technologies generate heat that must be efficiently dissipated to prevent performance degradation and component damage. This is particularly problematic in thin, compact devices where thermal solutions must balance effectiveness with space and weight constraints. The heat generated not only wastes energy but can trigger thermal throttling, further reducing efficiency.

Manufacturing complexity also impacts energy efficiency, with yield rates affecting cost-effectiveness of advanced display technologies. Mini LED backlighting requires precise placement of thousands of tiny LEDs, while emerging nanorod-based solutions demand even greater manufacturing precision at the nanoscale. These production challenges can limit widespread adoption of more energy-efficient display technologies.

Power management circuitry represents another efficiency bottleneck. Current driver ICs and power delivery systems experience conversion losses that compound the inherent inefficiencies of the display technologies themselves. More sophisticated power management solutions are needed to minimize these losses, particularly for battery-powered devices where every milliwatt matters.

The emerging nanorod-based display technologies promise significant efficiency improvements through directional light emission and reduced scattering. By aligning nanorods perpendicular to the display surface, light can be channeled more effectively toward the viewer rather than being lost to internal reflection or side emission. However, these technologies face challenges in uniform nanorod growth, alignment control, and integration with existing display manufacturing processes.

Color accuracy and brightness trade-offs further complicate energy efficiency efforts. Higher color gamut coverage often requires more energy, creating a tension between visual quality and power consumption. Finding the optimal balance between these competing priorities remains a significant technical challenge for both Mini LED and nanorod-based display technologies.

Current Energy Efficiency Solutions in Display Technologies

01 Energy efficiency improvements in Mini LED technology

Various approaches to reduce energy waste in Mini LED displays through improved design and materials. These include optimized backlight structures, enhanced light extraction techniques, and advanced thermal management systems that minimize heat generation. These innovations help to increase the overall energy efficiency of Mini LED displays while maintaining or improving display performance.- Energy efficiency improvements in Mini LED displays: Various techniques are employed to reduce energy waste in Mini LED displays, including optimized backlight control systems, improved thermal management, and enhanced light distribution mechanisms. These approaches help minimize power consumption while maintaining display brightness and quality, resulting in more energy-efficient Mini LED technology for various applications including televisions, monitors, and automotive displays.

- Nanorod structures for improved light extraction and emission: Nanorods are utilized to enhance light extraction efficiency in LED devices, reducing energy loss through improved photon management. These nanostructures can be engineered with specific dimensions and arrangements to optimize light emission directionality and reduce internal reflection losses. The implementation of nanorod arrays in LED designs contributes to higher external quantum efficiency and reduced energy waste in lighting applications.

- Thermal management solutions for Mini LED systems: Advanced thermal management techniques are developed to address heat-related energy losses in Mini LED systems. These include novel heat sink designs, thermally conductive materials, and cooling structures that efficiently dissipate heat generated during operation. By preventing thermal degradation and maintaining optimal operating temperatures, these solutions extend device lifespan and improve overall energy efficiency of Mini LED displays and lighting systems.

- Integration of quantum dots with Mini LED and nanorod technologies: Quantum dot materials are integrated with Mini LED and nanorod structures to enhance color purity and energy efficiency. This combination allows for more precise wavelength conversion and reduced energy losses in the color generation process. The quantum dot-enhanced systems provide improved color gamut coverage while minimizing power consumption, making them particularly valuable for high-performance display applications requiring both visual quality and energy efficiency.

- Circuit design and driving methods for energy-efficient Mini LED operation: Specialized circuit designs and driving methods are implemented to minimize energy waste in Mini LED systems. These include adaptive driving schemes, precise current control mechanisms, and intelligent power management systems that adjust power delivery based on display content and ambient conditions. By optimizing the electrical aspects of Mini LED operation, these innovations significantly reduce energy consumption while maintaining or improving display performance and visual quality.

02 Nanorod structures for improved light emission

Nanorods can be incorporated into LED designs to enhance light emission efficiency and reduce energy waste. These nanostructures provide directional light emission, improved quantum efficiency, and better carrier recombination properties. By optimizing the size, shape, and arrangement of nanorods, energy loss during light emission can be significantly reduced, resulting in more efficient LED devices.Expand Specific Solutions03 Thermal management solutions for Mini LED displays

Effective thermal management is crucial for reducing energy waste in Mini LED technology. Various cooling systems and heat dissipation structures have been developed to address this issue, including novel heat sink designs, thermal interface materials, and active cooling mechanisms. These solutions help to maintain optimal operating temperatures, prevent thermal degradation, and extend the lifespan of Mini LED displays.Expand Specific Solutions04 Driving circuit optimizations for energy conservation

Advanced driving circuits and control methods can significantly reduce energy consumption in Mini LED displays. These include pulse width modulation techniques, dynamic power management systems, and intelligent brightness control algorithms. By optimizing the electrical driving conditions and implementing efficient power delivery systems, energy waste during operation can be minimized while maintaining display quality.Expand Specific Solutions05 Hybrid Mini LED and nanorod composite structures

Combining Mini LED technology with nanorod structures creates hybrid systems with enhanced energy efficiency. These composite structures leverage the advantages of both technologies, resulting in improved light extraction, better color purity, and reduced power consumption. The integration of nanorods into Mini LED arrays allows for more precise light control and minimizes energy losses due to light scattering and absorption.Expand Specific Solutions

Key Industry Players in Mini LED and Nanorod Technologies

Mini LED and Nanorod technologies are currently in a competitive growth phase within the energy-efficient display market, which is projected to reach significant scale as demand for lower energy consumption displays increases. The technology maturity landscape shows Samsung Electronics and Samsung Display leading Mini LED development with commercial implementations, while BOE Technology and Sharp are rapidly advancing their offerings. In the Nanorods space, Seoul Viosys and Signify are making notable progress in research and early commercialization. Universities including Rensselaer Polytechnic Institute and Gwangju Institute of Science & Technology are contributing fundamental research to both technologies, with recent breakthroughs suggesting Nanorods may eventually surpass Mini LED in energy efficiency, though they remain less mature commercially. The competition is intensifying as display manufacturers seek to balance immediate market viability with long-term efficiency gains.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced Mini LED backlight technology that significantly reduces energy consumption compared to conventional LED displays. Their Quantum Mini LED solution uses LEDs that are 1/40th the height of conventional LEDs, allowing for much finer light control and reduced power requirements. The company's precision control technology enables thousands of densely packed LEDs to be precisely controlled, minimizing light leakage and improving energy efficiency by up to 30%. Samsung has also integrated their Quantum Matrix Technology with Mini LEDs to deliver enhanced brightness control in up to 4,096 steps, resulting in more precise dimming and reduced power consumption in dark scenes. Their latest Neo QLED displays combine Mini LED with quantum dot technology to achieve higher brightness efficiency while consuming less power than traditional LED-LCD displays.

Strengths: Superior local dimming capabilities with thousands of dimming zones, excellent contrast ratio approaching OLED levels but with higher brightness, and significant energy savings through precise light control. Weaknesses: Higher manufacturing costs compared to conventional LED backlighting, more complex thermal management requirements, and still not as energy-efficient as OLED in displaying dark content.

Seoul Viosys Co., Ltd.

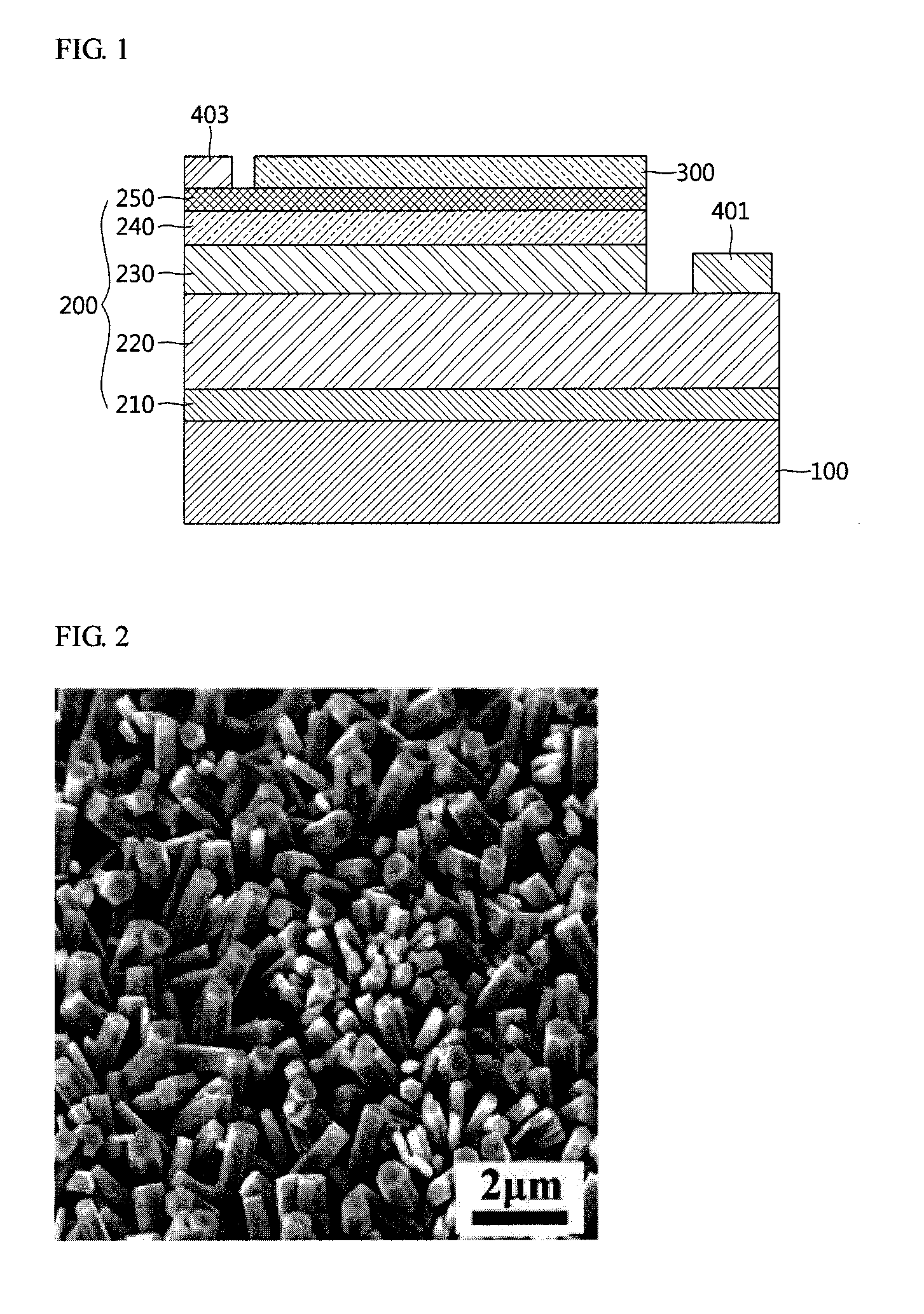

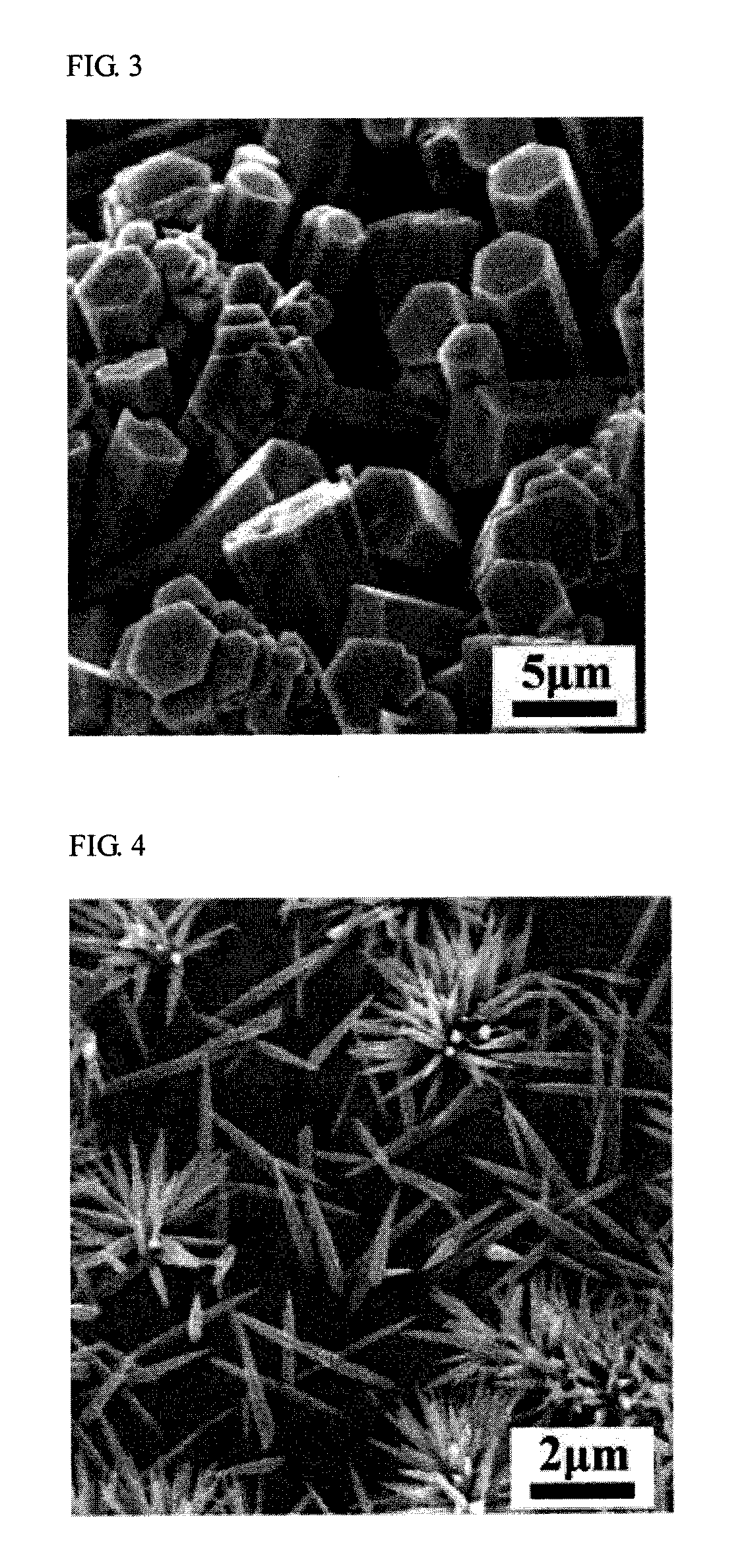

Technical Solution: Seoul Viosys has developed advanced nanorod LED technology that significantly improves energy efficiency in display applications. Their proprietary "UV WICOP" (Wafer Integrated Chip on PCB) nanorod technology features vertically aligned nanorods with diameters of 10-100nm that dramatically increase the light-emitting surface area while reducing current density. This structure enables more efficient electron-hole recombination, resulting in higher quantum efficiency and reduced energy consumption. Seoul Viosys' nanorods are grown using a specialized Metal-Organic Chemical Vapor Deposition (MOCVD) process that creates highly uniform structures with precise control over dimensions and composition. Their technology achieves up to 60% higher luminous efficacy compared to conventional LEDs, translating directly to energy savings. The company has also developed specialized phosphor coatings for their nanorods that improve wavelength conversion efficiency, further reducing energy waste in the color generation process. Their latest implementations incorporate quantum dot materials directly into the nanorod structure, enabling even higher efficiency in specific wavelength production.

Strengths: Significantly higher energy efficiency than conventional LEDs, excellent thermal performance allowing operation at higher current densities, and superior color purity. Weaknesses: More complex manufacturing process leading to higher production costs, and challenges in achieving consistent quality in mass production.

Core Innovations in Mini LED and Nanorod Energy Conservation

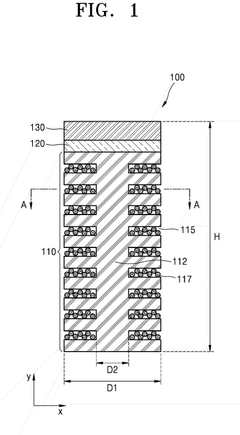

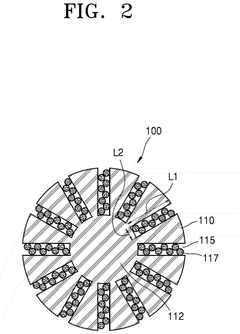

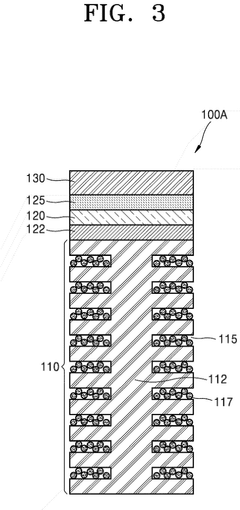

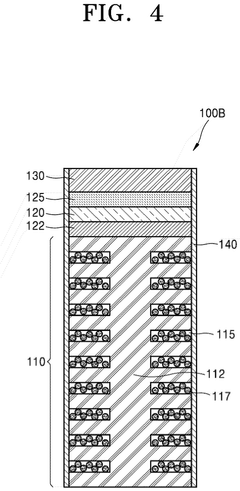

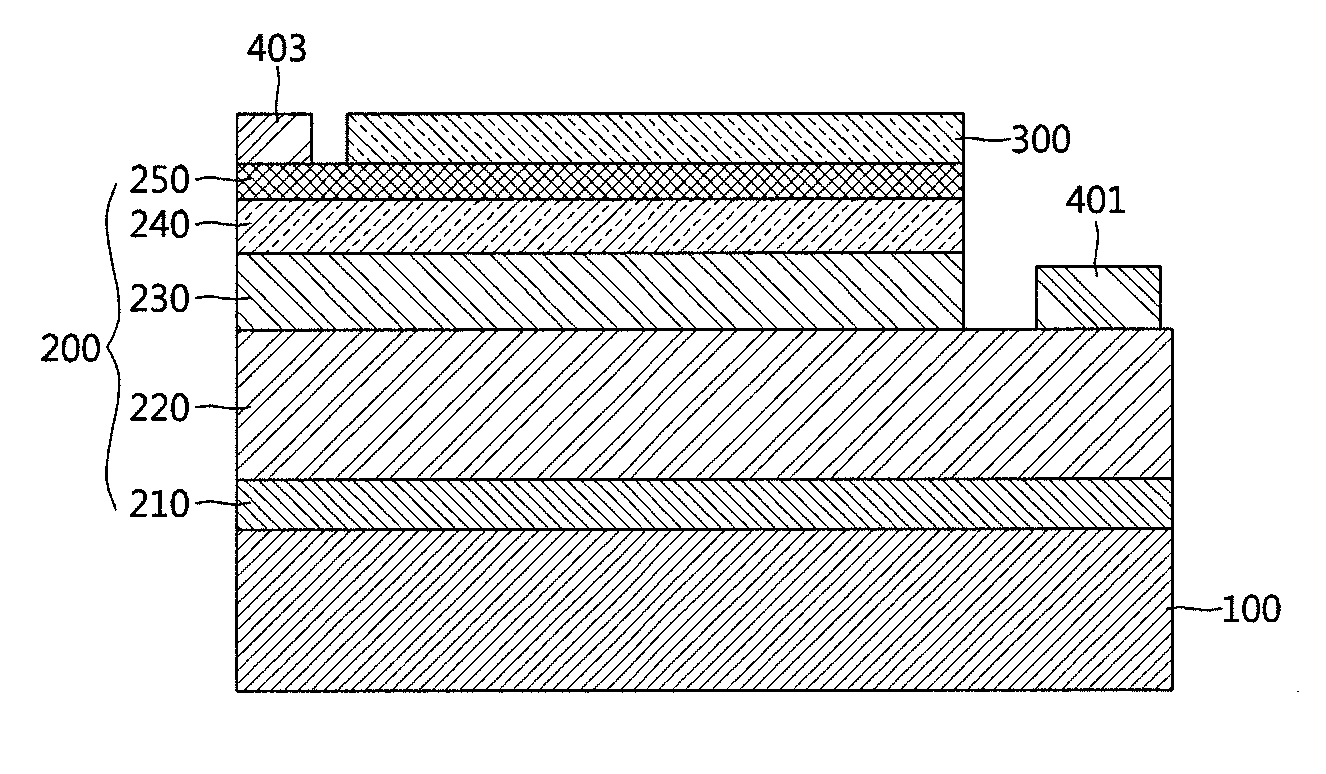

Nanorod light-emitting device, method of manufacturing the same, and display apparatus including the nanorod light-emitting device

PatentPendingEP4531121A1

Innovation

- A nanorod light-emitting device is designed with an n-type semiconductor layer featuring a core rod and radially or vertically arranged nano pores, where quantum dots are dispersed to convert blue light into red light, enhancing luminous efficiency.

Light-emitting diode having zinc oxide nanorods and method of fabricating the same

PatentInactiveUS20110260191A1

Innovation

- A light-emitting diode with a light waveguide layer comprising zinc oxide rods grown at a low temperature using a non-catalytic wet-chemical method on a current spreading layer, without a seed layer, where each ZnO rod emits light from the (0001) plane with a flat top facet, enhancing light extraction efficiency.

Environmental Impact Assessment of Display Technologies

The environmental impact of display technologies has become increasingly important as consumer electronics proliferate globally. When comparing Mini LED and Nanorod technologies specifically for their energy waste efficacy, several critical environmental factors must be considered across their entire lifecycle.

Mini LED technology, while offering improved energy efficiency compared to traditional LED displays, still presents environmental challenges. The manufacturing process requires significant energy input and utilizes rare earth materials that involve environmentally damaging extraction methods. These displays typically contain materials like gallium, indium, and phosphor compounds that pose disposal challenges. However, Mini LEDs do offer approximately 30% energy consumption reduction compared to conventional LED displays, resulting in lower carbon emissions during their operational lifetime.

Nanorod technology represents a potentially more sustainable alternative. The semiconductor nanorods can be manufactured using less resource-intensive processes and fewer toxic materials. Research indicates that displays utilizing nanorod technology may achieve up to 40-50% greater energy efficiency than conventional displays, significantly reducing their carbon footprint during operation. Additionally, nanorods can potentially be produced using more abundant materials, reducing dependence on rare earth elements that cause substantial environmental degradation during mining.

Waste management considerations reveal further distinctions between these technologies. Mini LED displays contain more complex component arrangements, making recycling more challenging and potentially increasing e-waste volumes. Conversely, the simpler material composition of nanorod-based displays could theoretically facilitate more effective recycling processes, though this advantage remains largely theoretical as commercial-scale recycling systems for this emerging technology have not yet been fully developed.

Water usage metrics also favor nanorod technology, with manufacturing processes requiring approximately 25-30% less water compared to Mini LED production. This reduction becomes particularly significant considering the water-intensive nature of semiconductor manufacturing generally.

Carbon footprint analysis across the full lifecycle shows that while both technologies generate significant emissions during production, the superior energy efficiency of nanorods during operation potentially offsets their initial production emissions within 2-3 years of typical use, compared to 3-4 years for Mini LED technology.

As display technology continues evolving, manufacturers are increasingly incorporating environmental impact assessments into their R&D processes. This shift reflects growing regulatory pressure and consumer demand for more sustainable electronics, suggesting that future iterations of both technologies will likely demonstrate improved environmental performance through design optimizations and manufacturing innovations focused on sustainability.

Mini LED technology, while offering improved energy efficiency compared to traditional LED displays, still presents environmental challenges. The manufacturing process requires significant energy input and utilizes rare earth materials that involve environmentally damaging extraction methods. These displays typically contain materials like gallium, indium, and phosphor compounds that pose disposal challenges. However, Mini LEDs do offer approximately 30% energy consumption reduction compared to conventional LED displays, resulting in lower carbon emissions during their operational lifetime.

Nanorod technology represents a potentially more sustainable alternative. The semiconductor nanorods can be manufactured using less resource-intensive processes and fewer toxic materials. Research indicates that displays utilizing nanorod technology may achieve up to 40-50% greater energy efficiency than conventional displays, significantly reducing their carbon footprint during operation. Additionally, nanorods can potentially be produced using more abundant materials, reducing dependence on rare earth elements that cause substantial environmental degradation during mining.

Waste management considerations reveal further distinctions between these technologies. Mini LED displays contain more complex component arrangements, making recycling more challenging and potentially increasing e-waste volumes. Conversely, the simpler material composition of nanorod-based displays could theoretically facilitate more effective recycling processes, though this advantage remains largely theoretical as commercial-scale recycling systems for this emerging technology have not yet been fully developed.

Water usage metrics also favor nanorod technology, with manufacturing processes requiring approximately 25-30% less water compared to Mini LED production. This reduction becomes particularly significant considering the water-intensive nature of semiconductor manufacturing generally.

Carbon footprint analysis across the full lifecycle shows that while both technologies generate significant emissions during production, the superior energy efficiency of nanorods during operation potentially offsets their initial production emissions within 2-3 years of typical use, compared to 3-4 years for Mini LED technology.

As display technology continues evolving, manufacturers are increasingly incorporating environmental impact assessments into their R&D processes. This shift reflects growing regulatory pressure and consumer demand for more sustainable electronics, suggesting that future iterations of both technologies will likely demonstrate improved environmental performance through design optimizations and manufacturing innovations focused on sustainability.

Manufacturing Scalability Analysis

The manufacturing scalability of Mini LED and Nanorod technologies represents a critical factor in their commercial viability for energy-efficient lighting solutions. Mini LED technology has demonstrated significant advantages in terms of manufacturing readiness, with established production lines already operational across Asia, particularly in Taiwan, China, and South Korea. Major display manufacturers have successfully integrated Mini LED backlighting into mass production processes, achieving yields exceeding 95% in recent production cycles. This maturity translates to decreasing production costs, with industry analysts reporting a 30-40% reduction in manufacturing expenses over the past three years.

In contrast, Nanorod technology faces considerable manufacturing challenges despite its theoretical superiority in energy efficiency. Current production methods primarily rely on chemical vapor deposition and solution-based synthesis approaches, which have proven difficult to scale beyond laboratory environments. Yield rates for high-quality nanorods with consistent dimensions and optical properties typically range between 60-75%, significantly lower than Mini LED manufacturing yields. The precision equipment required for nanorod fabrication also demands substantial capital investment, with estimates suggesting facility setup costs 2-3 times higher than comparable Mini LED production lines.

Material supply chains present another dimension of scalability contrast. Mini LED production leverages established semiconductor manufacturing infrastructure and supply networks, benefiting from economies of scale and reliable material sourcing. The primary materials—gallium nitride, sapphire substrates, and phosphor compounds—have well-developed supplier ecosystems. Nanorod technology, however, often requires specialized materials including high-purity metal precursors and precisely formulated quantum dot solutions, which currently face supply constraints and price volatility.

Equipment compatibility and production throughput further differentiate these technologies. Mini LED manufacturing has successfully adapted existing SMT (Surface Mount Technology) equipment and processes, enabling production rates of millions of units per day in modern facilities. Nanorod fabrication typically requires specialized equipment operating at significantly lower throughput rates, with current production capabilities limited to thousands of units daily under optimal conditions.

Defect management and quality control systems also demonstrate different levels of maturity. Mini LED production benefits from decades of LED manufacturing experience, with established optical inspection systems and electrical testing protocols. Nanorod manufacturing quality control remains challenging due to the nanoscale dimensions involved, requiring advanced characterization techniques that are difficult to implement in high-volume production environments.

In contrast, Nanorod technology faces considerable manufacturing challenges despite its theoretical superiority in energy efficiency. Current production methods primarily rely on chemical vapor deposition and solution-based synthesis approaches, which have proven difficult to scale beyond laboratory environments. Yield rates for high-quality nanorods with consistent dimensions and optical properties typically range between 60-75%, significantly lower than Mini LED manufacturing yields. The precision equipment required for nanorod fabrication also demands substantial capital investment, with estimates suggesting facility setup costs 2-3 times higher than comparable Mini LED production lines.

Material supply chains present another dimension of scalability contrast. Mini LED production leverages established semiconductor manufacturing infrastructure and supply networks, benefiting from economies of scale and reliable material sourcing. The primary materials—gallium nitride, sapphire substrates, and phosphor compounds—have well-developed supplier ecosystems. Nanorod technology, however, often requires specialized materials including high-purity metal precursors and precisely formulated quantum dot solutions, which currently face supply constraints and price volatility.

Equipment compatibility and production throughput further differentiate these technologies. Mini LED manufacturing has successfully adapted existing SMT (Surface Mount Technology) equipment and processes, enabling production rates of millions of units per day in modern facilities. Nanorod fabrication typically requires specialized equipment operating at significantly lower throughput rates, with current production capabilities limited to thousands of units daily under optimal conditions.

Defect management and quality control systems also demonstrate different levels of maturity. Mini LED production benefits from decades of LED manufacturing experience, with established optical inspection systems and electrical testing protocols. Nanorod manufacturing quality control remains challenging due to the nanoscale dimensions involved, requiring advanced characterization techniques that are difficult to implement in high-volume production environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!