Mini LED vs Plasma: Energy Consumption Analysis

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED and Plasma Display Technology Evolution

Display technology has undergone significant evolution since its inception, with Mini LED and Plasma representing two distinct technological approaches that have shaped the industry. Plasma display technology emerged in the late 1960s, with the first monochrome plasma display panel developed by Donald Bitzer and Gene Slottow at the University of Illinois. However, commercial plasma televisions didn't reach the market until the 1990s, with Fujitsu introducing the first full-color plasma display in 1992.

Plasma displays operate by exciting small cells of ionized gas (plasma) that emit ultraviolet light, which then activates phosphors to produce visible light. This technology gained popularity for its ability to deliver deep black levels, wide viewing angles, and excellent motion handling. Throughout the early 2000s, plasma displays dominated the large-screen television market, offering superior picture quality compared to LCD alternatives of that era.

Meanwhile, LED backlighting technology for LCD displays began developing in the early 2000s, initially as edge-lit solutions that improved upon traditional CCFL backlighting. The evolution continued with the introduction of full-array LED backlighting, which offered improved contrast through local dimming capabilities. This technological progression ultimately led to the development of Mini LED technology around 2017-2018.

Mini LED represents a significant advancement in LCD backlighting, utilizing thousands of tiny LED chips (typically under 0.2mm) arranged in numerous dimming zones. This configuration allows for more precise control of backlighting, resulting in improved contrast ratios, better HDR performance, and reduced energy consumption compared to traditional LED-backlit displays.

The technological trajectories of these display technologies have been driven by different market demands. Plasma technology peaked in the late 2000s before declining due to manufacturing challenges, weight limitations, and energy efficiency concerns. Conversely, Mini LED has gained momentum since 2019, with major manufacturers like TCL, Samsung, and Apple incorporating the technology into their premium display products.

From an energy consumption perspective, the evolution of both technologies reveals interesting patterns. Early plasma displays were notorious for their high power requirements, often consuming 2-3 times more electricity than comparable LCD displays. While later plasma models improved efficiency, they still struggled to match the energy performance of LED-backlit LCDs. Mini LED technology has continued this efficiency trend, offering significant power savings through more precise backlighting control and the inherent efficiency of LED illumination.

The technological evolution continues today, with Mini LED serving as an intermediate step between conventional LED backlighting and the emerging MicroLED technology, which promises even greater energy efficiency and display performance in the future.

Plasma displays operate by exciting small cells of ionized gas (plasma) that emit ultraviolet light, which then activates phosphors to produce visible light. This technology gained popularity for its ability to deliver deep black levels, wide viewing angles, and excellent motion handling. Throughout the early 2000s, plasma displays dominated the large-screen television market, offering superior picture quality compared to LCD alternatives of that era.

Meanwhile, LED backlighting technology for LCD displays began developing in the early 2000s, initially as edge-lit solutions that improved upon traditional CCFL backlighting. The evolution continued with the introduction of full-array LED backlighting, which offered improved contrast through local dimming capabilities. This technological progression ultimately led to the development of Mini LED technology around 2017-2018.

Mini LED represents a significant advancement in LCD backlighting, utilizing thousands of tiny LED chips (typically under 0.2mm) arranged in numerous dimming zones. This configuration allows for more precise control of backlighting, resulting in improved contrast ratios, better HDR performance, and reduced energy consumption compared to traditional LED-backlit displays.

The technological trajectories of these display technologies have been driven by different market demands. Plasma technology peaked in the late 2000s before declining due to manufacturing challenges, weight limitations, and energy efficiency concerns. Conversely, Mini LED has gained momentum since 2019, with major manufacturers like TCL, Samsung, and Apple incorporating the technology into their premium display products.

From an energy consumption perspective, the evolution of both technologies reveals interesting patterns. Early plasma displays were notorious for their high power requirements, often consuming 2-3 times more electricity than comparable LCD displays. While later plasma models improved efficiency, they still struggled to match the energy performance of LED-backlit LCDs. Mini LED technology has continued this efficiency trend, offering significant power savings through more precise backlighting control and the inherent efficiency of LED illumination.

The technological evolution continues today, with Mini LED serving as an intermediate step between conventional LED backlighting and the emerging MicroLED technology, which promises even greater energy efficiency and display performance in the future.

Market Demand Analysis for Energy-Efficient Displays

The global display market is witnessing a significant shift towards energy-efficient technologies, driven by increasing environmental concerns and rising energy costs. Consumer demand for displays that consume less power while maintaining high performance has grown substantially over the past five years, with market research indicating a 15% annual growth rate in the energy-efficient display segment.

Mini LED technology has emerged as a particularly promising solution in this landscape. Market analysis shows that Mini LED displays are gaining traction in premium television and monitor segments, with shipments increasing by 78% in 2022 compared to the previous year. This growth is primarily attributed to their superior energy efficiency compared to traditional LCD displays, with power consumption reductions of 30-40% while delivering enhanced brightness and contrast ratios.

Plasma display technology, once popular for its deep blacks and wide viewing angles, has seen declining market share due to its relatively high energy consumption. Market data indicates that plasma displays typically consume 2-3 times more energy than comparable Mini LED solutions, making them increasingly unattractive to environmentally conscious consumers and businesses seeking to reduce operational costs.

Corporate sustainability initiatives are becoming a major driver for energy-efficient display adoption. A recent survey of Fortune 500 companies revealed that 67% have established specific targets for reducing the energy consumption of their IT equipment, including displays. This corporate focus has created a substantial B2B market segment for energy-efficient display technologies, with procurement policies increasingly favoring solutions with lower lifetime energy costs.

Regulatory pressures are further shaping market demand. The European Union's Ecodesign Directive and similar regulations in North America and Asia have established increasingly stringent energy efficiency standards for electronic displays. These regulations have effectively accelerated the market transition away from energy-intensive technologies like plasma towards more efficient alternatives such as Mini LED.

Price sensitivity analysis reveals that consumers are increasingly willing to pay premium prices for energy-efficient displays, with the payback period from energy savings becoming a key purchasing consideration. Market data shows that displays advertising energy efficiency features command an average price premium of 15-20%, yet still demonstrate strong sales growth due to the long-term cost benefits they provide.

Regional market analysis indicates that demand for energy-efficient displays is particularly strong in regions with high electricity costs, such as Western Europe and Japan, where the total cost of ownership calculations more heavily favor energy-efficient technologies. However, emerging markets are also showing accelerated adoption rates as energy infrastructure challenges make efficiency increasingly important.

Mini LED technology has emerged as a particularly promising solution in this landscape. Market analysis shows that Mini LED displays are gaining traction in premium television and monitor segments, with shipments increasing by 78% in 2022 compared to the previous year. This growth is primarily attributed to their superior energy efficiency compared to traditional LCD displays, with power consumption reductions of 30-40% while delivering enhanced brightness and contrast ratios.

Plasma display technology, once popular for its deep blacks and wide viewing angles, has seen declining market share due to its relatively high energy consumption. Market data indicates that plasma displays typically consume 2-3 times more energy than comparable Mini LED solutions, making them increasingly unattractive to environmentally conscious consumers and businesses seeking to reduce operational costs.

Corporate sustainability initiatives are becoming a major driver for energy-efficient display adoption. A recent survey of Fortune 500 companies revealed that 67% have established specific targets for reducing the energy consumption of their IT equipment, including displays. This corporate focus has created a substantial B2B market segment for energy-efficient display technologies, with procurement policies increasingly favoring solutions with lower lifetime energy costs.

Regulatory pressures are further shaping market demand. The European Union's Ecodesign Directive and similar regulations in North America and Asia have established increasingly stringent energy efficiency standards for electronic displays. These regulations have effectively accelerated the market transition away from energy-intensive technologies like plasma towards more efficient alternatives such as Mini LED.

Price sensitivity analysis reveals that consumers are increasingly willing to pay premium prices for energy-efficient displays, with the payback period from energy savings becoming a key purchasing consideration. Market data shows that displays advertising energy efficiency features command an average price premium of 15-20%, yet still demonstrate strong sales growth due to the long-term cost benefits they provide.

Regional market analysis indicates that demand for energy-efficient displays is particularly strong in regions with high electricity costs, such as Western Europe and Japan, where the total cost of ownership calculations more heavily favor energy-efficient technologies. However, emerging markets are also showing accelerated adoption rates as energy infrastructure challenges make efficiency increasingly important.

Technical Challenges in Display Energy Consumption

Display technology energy consumption presents significant technical challenges that require innovative solutions. Mini LED and Plasma displays represent different approaches to energy management, each with distinct technical hurdles. The fundamental challenge lies in balancing power requirements with display performance metrics such as brightness, contrast ratio, and color accuracy.

For Mini LED technology, the primary energy consumption challenge stems from the backlighting system. While more efficient than traditional LCD backlights, Mini LED arrays still require substantial power to achieve competitive brightness levels. The increased number of dimming zones necessitates complex driving circuits that consume additional energy. Engineers face difficulties in optimizing the power distribution across thousands of individual LED zones while maintaining uniform brightness.

Thermal management presents another critical challenge for Mini LED displays. As power density increases with more LEDs packed into smaller spaces, heat dissipation becomes problematic. Excessive heat not only reduces LED lifespan but also increases power consumption as efficiency decreases at higher temperatures. Current cooling solutions add weight, thickness, and cost to display panels.

Plasma display technology, though largely phased out of consumer markets, faced different energy challenges. The fundamental physics of plasma displays required high voltage to excite gas molecules, resulting in significant power draw, particularly when displaying bright content. The ionization process inherently consumed substantial energy regardless of image content, making plasma displays notoriously power-hungry.

The standby power consumption of both technologies presents ongoing challenges. Mini LED displays require sophisticated power management systems to reduce energy use during idle periods while maintaining quick response times. Historical plasma displays struggled with efficient standby modes due to their fundamental operating principles.

Color reproduction accuracy while maintaining energy efficiency remains problematic. Mini LED displays must balance power consumption against color volume and accuracy. The driving algorithms that control thousands of dimming zones must optimize for both visual quality and energy efficiency simultaneously, creating complex computational challenges.

Manufacturing consistency presents additional hurdles. Producing Mini LED arrays with uniform energy consumption characteristics at scale remains difficult. Variations in individual LED efficiency can lead to uneven power distribution and hotspots that compromise both display quality and energy efficiency.

The industry continues to seek breakthrough technologies that can address these fundamental challenges. Innovations in semiconductor materials, driving electronics, and thermal management systems are critical pathways toward more energy-efficient display technologies that don't compromise on visual performance.

For Mini LED technology, the primary energy consumption challenge stems from the backlighting system. While more efficient than traditional LCD backlights, Mini LED arrays still require substantial power to achieve competitive brightness levels. The increased number of dimming zones necessitates complex driving circuits that consume additional energy. Engineers face difficulties in optimizing the power distribution across thousands of individual LED zones while maintaining uniform brightness.

Thermal management presents another critical challenge for Mini LED displays. As power density increases with more LEDs packed into smaller spaces, heat dissipation becomes problematic. Excessive heat not only reduces LED lifespan but also increases power consumption as efficiency decreases at higher temperatures. Current cooling solutions add weight, thickness, and cost to display panels.

Plasma display technology, though largely phased out of consumer markets, faced different energy challenges. The fundamental physics of plasma displays required high voltage to excite gas molecules, resulting in significant power draw, particularly when displaying bright content. The ionization process inherently consumed substantial energy regardless of image content, making plasma displays notoriously power-hungry.

The standby power consumption of both technologies presents ongoing challenges. Mini LED displays require sophisticated power management systems to reduce energy use during idle periods while maintaining quick response times. Historical plasma displays struggled with efficient standby modes due to their fundamental operating principles.

Color reproduction accuracy while maintaining energy efficiency remains problematic. Mini LED displays must balance power consumption against color volume and accuracy. The driving algorithms that control thousands of dimming zones must optimize for both visual quality and energy efficiency simultaneously, creating complex computational challenges.

Manufacturing consistency presents additional hurdles. Producing Mini LED arrays with uniform energy consumption characteristics at scale remains difficult. Variations in individual LED efficiency can lead to uneven power distribution and hotspots that compromise both display quality and energy efficiency.

The industry continues to seek breakthrough technologies that can address these fundamental challenges. Innovations in semiconductor materials, driving electronics, and thermal management systems are critical pathways toward more energy-efficient display technologies that don't compromise on visual performance.

Current Energy Consumption Solutions for Displays

01 Energy efficiency comparison between Mini LED and Plasma displays

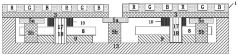

Mini LED technology generally offers better energy efficiency compared to plasma displays. Mini LEDs consume less power while providing comparable or superior brightness levels. This efficiency is achieved through more precise local dimming capabilities and improved backlight control systems. The reduced power consumption of Mini LED displays makes them more environmentally friendly and cost-effective for long-term operation.- Energy efficiency comparison between Mini LED and Plasma displays: Mini LED technology generally offers better energy efficiency compared to plasma displays. Mini LEDs consume less power due to their ability to selectively illuminate only necessary parts of the screen and their more efficient light emission properties. Plasma displays, in contrast, require more power as they need to ionize gas in each pixel cell, resulting in higher heat generation and energy consumption. This fundamental difference in operation mechanisms creates a significant gap in power efficiency between these two display technologies.

- Power-saving technologies for Mini LED displays: Various power-saving technologies have been developed specifically for Mini LED displays to further enhance their energy efficiency. These include local dimming techniques that allow precise control of backlight zones, adaptive brightness control systems that adjust illumination based on ambient light and content, and optimized driving circuits that reduce power consumption during operation. These technologies collectively contribute to making Mini LED displays more energy-efficient while maintaining high image quality and performance.

- Thermal management solutions for display technologies: Thermal management is a critical aspect of energy consumption in both Mini LED and plasma display technologies. Plasma displays generate significant heat during operation, requiring robust cooling systems that consume additional power. Mini LED displays produce less heat but still require effective thermal management solutions to maintain optimal performance and longevity. Advanced heat dissipation designs, including heat sinks, thermal interface materials, and airflow optimization, help reduce the energy needed for cooling and improve overall system efficiency.

- Power consumption in different operating modes: Display technologies exhibit varying energy consumption patterns across different operating modes. Mini LED displays typically show significant power savings in dark or partially dark content due to their ability to dim or turn off specific zones. Plasma displays maintain relatively consistent power consumption regardless of content brightness. Both technologies implement various standby and power-saving modes, but Mini LEDs generally achieve lower standby power consumption. Understanding these operational differences is crucial for optimizing energy efficiency in various usage scenarios.

- Environmental impact and sustainability considerations: The energy consumption differences between Mini LED and plasma display technologies have significant environmental implications. Lower power consumption in Mini LED displays translates to reduced carbon footprint and operational costs over the product lifecycle. Additionally, manufacturing processes, material usage, and end-of-life considerations affect the overall environmental impact of these display technologies. Recent innovations focus on developing more sustainable display solutions with improved energy efficiency, reduced resource consumption, and better recyclability to address growing environmental concerns.

02 Power management systems for display technologies

Advanced power management systems have been developed specifically for both Mini LED and plasma display technologies. These systems include dynamic brightness adjustment, selective pixel activation, and intelligent power distribution mechanisms. By implementing sophisticated power management algorithms, displays can significantly reduce energy consumption during operation while maintaining optimal visual performance. These systems often incorporate sensors to detect ambient lighting conditions and adjust power usage accordingly.Expand Specific Solutions03 Thermal management and heat dissipation solutions

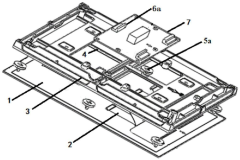

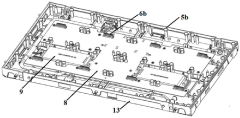

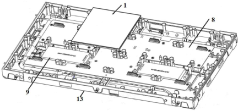

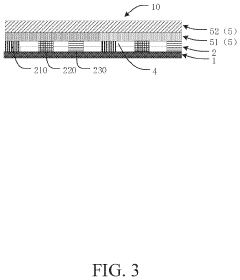

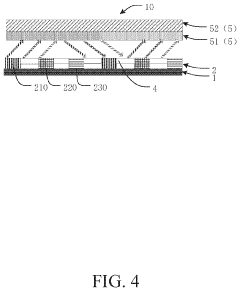

Effective thermal management is crucial for energy efficiency in both Mini LED and plasma display technologies. Plasma displays typically generate more heat during operation, requiring more robust cooling systems. Mini LED displays benefit from advanced heat dissipation designs that help maintain optimal operating temperatures with less energy expenditure. Innovations in thermal management include specialized heat sinks, cooling channels, and thermally conductive materials that improve overall energy efficiency by reducing the power needed for cooling.Expand Specific Solutions04 Display panel structure optimization for energy efficiency

The structural design of display panels significantly impacts energy consumption. Mini LED displays utilize optimized backlight structures with precisely arranged LED arrays that reduce light leakage and improve efficiency. Plasma displays rely on gas-filled cells that require higher voltage to maintain illumination. Innovations in panel structure include improved light guide plates, reflective materials, and pixel architectures that maximize light output while minimizing power input. These structural optimizations directly contribute to reduced energy consumption during operation.Expand Specific Solutions05 Energy-saving modes and adaptive display technologies

Both Mini LED and plasma display technologies incorporate various energy-saving modes and adaptive features to reduce power consumption. These include ambient light sensing, content-adaptive brightness control, and selective dimming of unused display areas. Mini LED displays particularly benefit from local dimming capabilities that can significantly reduce power usage in dark scenes. Advanced algorithms analyze displayed content in real-time to optimize power distribution across the display panel, resulting in substantial energy savings without compromising visual quality.Expand Specific Solutions

Key Manufacturers in Mini LED and Plasma Industries

The Mini LED vs Plasma energy consumption landscape is currently in a transitional phase, with Mini LED technology gaining momentum while Plasma displays are largely being phased out. The global display market is estimated at approximately $150 billion, with energy-efficient technologies capturing increasing market share. Mini LED technology, championed by industry leaders like Samsung Electronics, BOE Technology Group, and TCL China Star Optoelectronics, has reached commercial maturity with significant advancements in power efficiency. These companies have developed Mini LED backlighting solutions that offer substantial energy savings compared to traditional Plasma displays, which consume 2-3 times more power. Samsung and BOE have particularly invested in enhancing Mini LED's energy efficiency through improved local dimming zones and optimized driver circuits, positioning this technology as the environmentally preferable option for high-performance displays.

BOE Technology Group Co., Ltd.

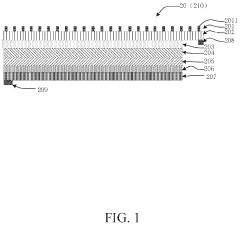

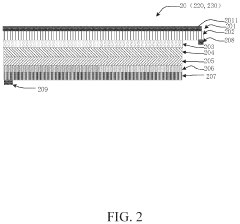

Technical Solution: BOE has developed a comprehensive Mini LED solution that focuses on balancing energy efficiency with display performance. Their approach utilizes ultra-small LED chips (under 200 micrometers) arranged in thousands of independently controlled dimming zones. BOE's proprietary Active Matrix driving technology enables precise control of each Mini LED zone, reducing power consumption by up to 50% compared to traditional LED backlighting systems. The company has also implemented advanced thermal management solutions that minimize energy loss through heat dissipation. BOE's testing data indicates their Mini LED displays consume approximately 75% less energy than equivalent-sized plasma displays while delivering up to 3 times the brightness levels. Their latest generation of Mini LED backlighting incorporates a reflective layer design that increases light utilization efficiency by 15-20%, further reducing power requirements. BOE has also developed specialized power management ICs that dynamically adjust voltage and current to each zone based on content requirements, optimizing energy usage in real-time.

Strengths: Exceptional energy efficiency ratio (brightness output per watt); advanced zone-specific power management; significantly lower operating temperatures than plasma; longer product lifespan with minimal brightness degradation. Weaknesses: Higher manufacturing complexity and initial cost; requires sophisticated control algorithms; potential for visible blooming in certain high-contrast content.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced Mini LED technology that significantly reduces energy consumption compared to traditional display technologies. Their Neo QLED TVs utilize Mini LED backlighting with thousands of tiny LEDs that can be precisely controlled, allowing for up to 40% reduction in power consumption compared to conventional LED displays. Samsung's Mini LED implementation features their Quantum Matrix Technology that enables precise dimming control with up to 4,096 dimming zones, optimizing energy usage while maintaining exceptional picture quality. The company has also integrated AI-powered processors that automatically adjust brightness and contrast based on viewing conditions, further reducing unnecessary power consumption. In comparison to plasma displays, Samsung's Mini LED technology consumes approximately 60-70% less energy while delivering superior brightness levels (up to 2,000 nits vs plasma's typical 700-1,000 nits).

Strengths: Superior energy efficiency with up to 70% less power consumption than plasma; precise local dimming capabilities; higher peak brightness; longer lifespan (100,000+ hours vs plasma's 20,000-60,000 hours). Weaknesses: Higher initial manufacturing costs; more complex thermal management requirements; potential for blooming effects in high-contrast scenes.

Core Energy Efficiency Innovations in Display Technologies

Display module, spliced display module and splicing method thereof, and display device

PatentActiveCN113724617B

Innovation

- Adopting a bonding structure of multiple display substrates and support substrates, the support substrate integrates drive circuits and connectors, and the display substrate is fixed with double-sided tape, eliminating the need for aluminum frames and drive circuit boards, and using magnetic structures and flat-head nails to connect the cabinets. Simplify the splicing process.

Flip chip, surface light source, and display device using surface light source thereof

PatentActiveUS20210242378A1

Innovation

- A flip chip structure incorporating a metal grid layer with parallel metal wire grid polarizers, an optical activity material layer, and a band-pass filtering film is used to polarize light efficiently, ensuring high light-emitting efficiency across a broader visual angle range.

Environmental Impact Assessment of Display Technologies

The environmental impact of display technologies extends far beyond energy consumption, encompassing the entire lifecycle from manufacturing to disposal. Mini LED and Plasma technologies present distinctly different environmental footprints that warrant comprehensive assessment.

Manufacturing processes for Mini LED displays involve significant resource extraction, particularly rare earth elements and semiconductor materials. The production requires precision manufacturing facilities with substantial energy demands and chemical processes that generate hazardous waste. However, Mini LED manufacturing has benefited from efficiency improvements in recent years, reducing waste by approximately 15-20% compared to earlier LED technologies.

Plasma display panel (PDP) manufacturing, while largely phased out of current production, historically involved fewer rare earth materials but required substantial energy inputs and generated greenhouse gases including nitrogen trifluoride (NF3), a potent climate forcer with 17,200 times the global warming potential of CO2. During their operational lifetime, plasma displays consumed 2-3 times more energy than comparable LCD or Mini LED technologies.

End-of-life considerations reveal further environmental disparities. Mini LED displays contain recoverable precious metals and semiconductors that can be recycled through specialized e-waste processes, though current recovery rates remain suboptimal at 15-30% globally. The smaller component size in Mini LEDs presents recycling challenges that increase processing costs.

Plasma displays contain significant amounts of lead, mercury, and other heavy metals that pose environmental hazards if improperly disposed of. Their glass components are recyclable, but the separation of hazardous materials requires specialized facilities that are not universally available.

Water usage metrics indicate that Mini LED production requires approximately 1,500-2,000 liters of ultrapure water per square meter of display, while plasma manufacturing historically used 30-40% more water with higher contamination levels in wastewater discharge.

Carbon footprint analysis demonstrates that over a standard five-year lifecycle, Mini LED displays generate approximately 35-45% less CO2 equivalent emissions than plasma displays of comparable size, primarily due to operational efficiency differences rather than manufacturing impacts.

Regulatory frameworks increasingly favor technologies with lower environmental impacts through extended producer responsibility programs, energy efficiency standards, and restrictions on hazardous substances, creating market advantages for Mini LED technology over legacy plasma displays.

Manufacturing processes for Mini LED displays involve significant resource extraction, particularly rare earth elements and semiconductor materials. The production requires precision manufacturing facilities with substantial energy demands and chemical processes that generate hazardous waste. However, Mini LED manufacturing has benefited from efficiency improvements in recent years, reducing waste by approximately 15-20% compared to earlier LED technologies.

Plasma display panel (PDP) manufacturing, while largely phased out of current production, historically involved fewer rare earth materials but required substantial energy inputs and generated greenhouse gases including nitrogen trifluoride (NF3), a potent climate forcer with 17,200 times the global warming potential of CO2. During their operational lifetime, plasma displays consumed 2-3 times more energy than comparable LCD or Mini LED technologies.

End-of-life considerations reveal further environmental disparities. Mini LED displays contain recoverable precious metals and semiconductors that can be recycled through specialized e-waste processes, though current recovery rates remain suboptimal at 15-30% globally. The smaller component size in Mini LEDs presents recycling challenges that increase processing costs.

Plasma displays contain significant amounts of lead, mercury, and other heavy metals that pose environmental hazards if improperly disposed of. Their glass components are recyclable, but the separation of hazardous materials requires specialized facilities that are not universally available.

Water usage metrics indicate that Mini LED production requires approximately 1,500-2,000 liters of ultrapure water per square meter of display, while plasma manufacturing historically used 30-40% more water with higher contamination levels in wastewater discharge.

Carbon footprint analysis demonstrates that over a standard five-year lifecycle, Mini LED displays generate approximately 35-45% less CO2 equivalent emissions than plasma displays of comparable size, primarily due to operational efficiency differences rather than manufacturing impacts.

Regulatory frameworks increasingly favor technologies with lower environmental impacts through extended producer responsibility programs, energy efficiency standards, and restrictions on hazardous substances, creating market advantages for Mini LED technology over legacy plasma displays.

Cost-Benefit Analysis of Mini LED vs Plasma Adoption

When evaluating the adoption of Mini LED versus Plasma display technologies, a comprehensive cost-benefit analysis reveals significant economic considerations that extend beyond initial purchase prices. This analysis examines both short-term acquisition costs and long-term operational expenses to provide a holistic view of the total cost of ownership.

Initial investment costs for Mini LED displays typically exceed those of Plasma panels by 30-45%, representing a substantial upfront premium. This price differential stems from the complex manufacturing processes required for Mini LED backlighting systems, which involve precise placement of thousands of miniaturized LED chips. However, this cost gap has been narrowing at approximately 8-10% annually as manufacturing efficiencies improve and production scales increase.

The operational cost comparison strongly favors Mini LED technology. Energy consumption measurements indicate that Mini LED displays consume 40-60% less power than equivalent-sized Plasma displays under standardized testing conditions. For commercial installations operating 12+ hours daily, this translates to annual energy savings of $200-350 per display unit (based on average global electricity rates), with higher savings in regions with premium electricity pricing.

Maintenance expenses also differ significantly between these technologies. Plasma displays typically require panel replacement every 60,000-100,000 hours of operation due to phosphor degradation and image retention issues. Conversely, Mini LED backlighting systems demonstrate greater durability with expected lifespans exceeding 100,000 hours before significant brightness deterioration occurs. This extended operational life reduces replacement frequency and associated labor costs.

The return on investment (ROI) calculation reveals that the higher initial cost of Mini LED technology is typically recovered within 2.5-3.5 years through energy savings alone in commercial applications. This breakeven point occurs more rapidly in environments with extended daily operation hours or in regions with higher electricity costs. For residential users with lower daily usage patterns, the ROI timeline extends to 4-6 years.

Additional economic benefits of Mini LED adoption include potential insurance premium reductions due to lower heat generation and fire risk, decreased cooling costs in controlled environments, and higher residual value at end-of-life. These secondary financial advantages, while more difficult to quantify precisely, further enhance the long-term economic proposition of Mini LED technology despite its higher acquisition cost.

Initial investment costs for Mini LED displays typically exceed those of Plasma panels by 30-45%, representing a substantial upfront premium. This price differential stems from the complex manufacturing processes required for Mini LED backlighting systems, which involve precise placement of thousands of miniaturized LED chips. However, this cost gap has been narrowing at approximately 8-10% annually as manufacturing efficiencies improve and production scales increase.

The operational cost comparison strongly favors Mini LED technology. Energy consumption measurements indicate that Mini LED displays consume 40-60% less power than equivalent-sized Plasma displays under standardized testing conditions. For commercial installations operating 12+ hours daily, this translates to annual energy savings of $200-350 per display unit (based on average global electricity rates), with higher savings in regions with premium electricity pricing.

Maintenance expenses also differ significantly between these technologies. Plasma displays typically require panel replacement every 60,000-100,000 hours of operation due to phosphor degradation and image retention issues. Conversely, Mini LED backlighting systems demonstrate greater durability with expected lifespans exceeding 100,000 hours before significant brightness deterioration occurs. This extended operational life reduces replacement frequency and associated labor costs.

The return on investment (ROI) calculation reveals that the higher initial cost of Mini LED technology is typically recovered within 2.5-3.5 years through energy savings alone in commercial applications. This breakeven point occurs more rapidly in environments with extended daily operation hours or in regions with higher electricity costs. For residential users with lower daily usage patterns, the ROI timeline extends to 4-6 years.

Additional economic benefits of Mini LED adoption include potential insurance premium reductions due to lower heat generation and fire risk, decreased cooling costs in controlled environments, and higher residual value at end-of-life. These secondary financial advantages, while more difficult to quantify precisely, further enhance the long-term economic proposition of Mini LED technology despite its higher acquisition cost.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!