Mini LED vs QLED: Clarifying Contrast Levels

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Display Technology Evolution and Objectives

Display technology has undergone remarkable evolution over the past several decades, transitioning from cathode ray tubes (CRTs) to liquid crystal displays (LCDs), plasma display panels (PDPs), and more recently to organic light-emitting diodes (OLEDs). Each technological leap has brought significant improvements in picture quality, energy efficiency, form factor, and user experience. The latest frontier in this evolutionary journey involves Mini LED and QLED technologies, both representing advanced approaches to enhance contrast levels and overall visual performance.

Mini LED technology emerged as a refinement of traditional LCD displays, utilizing significantly smaller LED backlights (typically 0.2mm or less in diameter) arranged in numerous dimming zones. This innovation allows for more precise local dimming capabilities, substantially improving contrast ratios by creating deeper blacks in specific screen areas while maintaining brightness in others. The technology represents an intermediate step between conventional LED-backlit LCDs and the pixel-level illumination control offered by OLED displays.

QLED (Quantum Dot LED) technology, meanwhile, incorporates quantum dots—semiconductor nanocrystals that emit light of specific wavelengths when excited by energy—to enhance color reproduction and brightness. While traditional QLEDs still rely on LED backlighting systems similar to conventional LCDs, they deliver superior color volume and peak brightness compared to standard displays. However, they historically faced limitations in achieving the deep black levels necessary for high contrast ratios.

The primary technical objective in comparing Mini LED and QLED technologies centers on clarifying their respective capabilities in delivering contrast—the difference between the brightest whites and darkest blacks a display can produce. Contrast ratio significantly impacts perceived image quality, depth perception, and overall viewing experience, particularly in high dynamic range (HDR) content consumption scenarios.

Recent technological convergence has seen the integration of Mini LED backlighting systems into QLED displays, creating hybrid solutions that leverage the strengths of both technologies. These advanced implementations aim to combine QLED's superior color performance with Mini LED's enhanced local dimming capabilities, potentially offering the best of both worlds in terms of contrast performance.

The technical evolution trajectory suggests continued refinement in both technologies, with increasing dimming zones in Mini LED implementations and improved quantum dot formulations in QLED displays. The ultimate objective remains achieving OLED-like contrast levels while maintaining the brightness advantages and eliminating burn-in concerns associated with traditional LED-based displays.

Mini LED technology emerged as a refinement of traditional LCD displays, utilizing significantly smaller LED backlights (typically 0.2mm or less in diameter) arranged in numerous dimming zones. This innovation allows for more precise local dimming capabilities, substantially improving contrast ratios by creating deeper blacks in specific screen areas while maintaining brightness in others. The technology represents an intermediate step between conventional LED-backlit LCDs and the pixel-level illumination control offered by OLED displays.

QLED (Quantum Dot LED) technology, meanwhile, incorporates quantum dots—semiconductor nanocrystals that emit light of specific wavelengths when excited by energy—to enhance color reproduction and brightness. While traditional QLEDs still rely on LED backlighting systems similar to conventional LCDs, they deliver superior color volume and peak brightness compared to standard displays. However, they historically faced limitations in achieving the deep black levels necessary for high contrast ratios.

The primary technical objective in comparing Mini LED and QLED technologies centers on clarifying their respective capabilities in delivering contrast—the difference between the brightest whites and darkest blacks a display can produce. Contrast ratio significantly impacts perceived image quality, depth perception, and overall viewing experience, particularly in high dynamic range (HDR) content consumption scenarios.

Recent technological convergence has seen the integration of Mini LED backlighting systems into QLED displays, creating hybrid solutions that leverage the strengths of both technologies. These advanced implementations aim to combine QLED's superior color performance with Mini LED's enhanced local dimming capabilities, potentially offering the best of both worlds in terms of contrast performance.

The technical evolution trajectory suggests continued refinement in both technologies, with increasing dimming zones in Mini LED implementations and improved quantum dot formulations in QLED displays. The ultimate objective remains achieving OLED-like contrast levels while maintaining the brightness advantages and eliminating burn-in concerns associated with traditional LED-based displays.

Market Analysis for Premium Display Technologies

The premium display technology market has witnessed significant growth in recent years, driven by increasing consumer demand for superior visual experiences across various applications. The global premium display market reached approximately $115 billion in 2022 and is projected to grow at a CAGR of 7.8% through 2028, with Mini LED and QLED technologies representing key growth segments.

Consumer electronics, particularly high-end televisions and monitors, constitute the largest application segment for premium display technologies. Mini LED and QLED displays have gained substantial traction in this sector, with television sales accounting for nearly 65% of the premium display market. The professional display segment, including digital signage and commercial displays, represents the second-largest application area, growing at 9.2% annually.

Regionally, Asia-Pacific dominates the premium display market, accounting for 48% of global revenue, followed by North America (27%) and Europe (19%). China and South Korea lead manufacturing capacity, while North America and Western Europe represent the largest consumer markets for premium display products based on revenue per unit.

Price sensitivity analysis reveals interesting patterns in consumer behavior. While premium display technologies command higher prices, the price differential between Mini LED and QLED has narrowed significantly over the past two years. The average price premium for Mini LED displays over conventional LED displays has decreased from 85% to approximately 40%, accelerating market adoption.

Consumer preference studies indicate that contrast ratio ranks as the third most important purchasing factor after price and screen size. Approximately 72% of consumers in the premium segment specifically evaluate contrast performance when making purchasing decisions, highlighting the strategic importance of contrast level improvements in both Mini LED and QLED technologies.

Market forecasts suggest that Mini LED displays will experience faster growth (11.3% CAGR) compared to QLED (8.7% CAGR) through 2027, primarily due to superior contrast performance in challenging viewing environments. However, QLED maintains stronger brand recognition among consumers, with 68% of surveyed consumers familiar with QLED compared to 41% for Mini LED technology.

Distribution channel analysis shows that specialized electronics retailers account for 42% of premium display sales, followed by online channels (31%) and mass-market retailers (18%). Direct manufacturer sales represent a growing channel at 9%, particularly for high-end models where technical demonstrations of contrast performance can influence purchasing decisions.

The competitive landscape features strategic positioning around contrast performance, with manufacturers increasingly highlighting contrast ratios and HDR capabilities in marketing materials. Premium display technologies with superior contrast levels command an average price premium of 22% over comparable models with standard contrast performance.

Consumer electronics, particularly high-end televisions and monitors, constitute the largest application segment for premium display technologies. Mini LED and QLED displays have gained substantial traction in this sector, with television sales accounting for nearly 65% of the premium display market. The professional display segment, including digital signage and commercial displays, represents the second-largest application area, growing at 9.2% annually.

Regionally, Asia-Pacific dominates the premium display market, accounting for 48% of global revenue, followed by North America (27%) and Europe (19%). China and South Korea lead manufacturing capacity, while North America and Western Europe represent the largest consumer markets for premium display products based on revenue per unit.

Price sensitivity analysis reveals interesting patterns in consumer behavior. While premium display technologies command higher prices, the price differential between Mini LED and QLED has narrowed significantly over the past two years. The average price premium for Mini LED displays over conventional LED displays has decreased from 85% to approximately 40%, accelerating market adoption.

Consumer preference studies indicate that contrast ratio ranks as the third most important purchasing factor after price and screen size. Approximately 72% of consumers in the premium segment specifically evaluate contrast performance when making purchasing decisions, highlighting the strategic importance of contrast level improvements in both Mini LED and QLED technologies.

Market forecasts suggest that Mini LED displays will experience faster growth (11.3% CAGR) compared to QLED (8.7% CAGR) through 2027, primarily due to superior contrast performance in challenging viewing environments. However, QLED maintains stronger brand recognition among consumers, with 68% of surveyed consumers familiar with QLED compared to 41% for Mini LED technology.

Distribution channel analysis shows that specialized electronics retailers account for 42% of premium display sales, followed by online channels (31%) and mass-market retailers (18%). Direct manufacturer sales represent a growing channel at 9%, particularly for high-end models where technical demonstrations of contrast performance can influence purchasing decisions.

The competitive landscape features strategic positioning around contrast performance, with manufacturers increasingly highlighting contrast ratios and HDR capabilities in marketing materials. Premium display technologies with superior contrast levels command an average price premium of 22% over comparable models with standard contrast performance.

Mini LED and QLED Technical Challenges

Both Mini LED and QLED technologies face significant technical challenges that impact their performance, particularly in achieving optimal contrast levels. These challenges stem from fundamental differences in their underlying technologies and implementation approaches.

Mini LED backlighting systems encounter several critical hurdles. The primary challenge lies in the precise control of thousands of dimming zones. While Mini LEDs offer substantially more zones than conventional LED backlighting, they still struggle with blooming effects where bright objects on dark backgrounds create a halo effect. This occurs because even with 1,000+ dimming zones, each zone still covers thousands of pixels, limiting the precision of light control at the pixel level.

Manufacturing consistency presents another significant obstacle for Mini LED technology. The production of uniform Mini LED chips at scale requires extremely tight tolerances. Variations in LED brightness, color temperature, or response time across a display panel can result in visible inconsistencies, particularly in dark scenes where such variations become more apparent to viewers.

Thermal management constitutes a substantial engineering challenge for Mini LED displays. The dense arrangement of numerous LEDs generates considerable heat that must be efficiently dissipated to prevent performance degradation and ensure longevity. Inadequate thermal solutions can lead to brightness inconsistencies and accelerated aging of LED components.

QLED technology faces its own set of distinct challenges. Unlike Mini LED which focuses on backlighting improvements, QLED's primary limitation stems from its fundamental reliance on traditional LCD technology. Despite quantum dot enhancement, QLEDs still utilize a backlight that must pass through polarizers and liquid crystal layers, inherently limiting contrast potential compared to emissive technologies.

Light leakage remains a persistent issue in QLED displays. The backlight must be blocked completely by the LCD layer to produce true blacks, but current technology cannot achieve perfect light blocking. This results in elevated black levels, particularly noticeable in dark viewing environments.

Color volume stability presents challenges for QLED displays at varying brightness levels. While quantum dots excel at color reproduction, maintaining consistent color accuracy across different luminance levels requires sophisticated compensation algorithms and precise manufacturing controls.

Both technologies also face cost-efficiency challenges in their pursuit of higher contrast ratios. For Mini LED, increasing dimming zone count substantially raises manufacturing complexity and cost. Similarly, QLED displays require premium quantum dot materials and precision manufacturing processes to achieve their performance targets.

Mini LED backlighting systems encounter several critical hurdles. The primary challenge lies in the precise control of thousands of dimming zones. While Mini LEDs offer substantially more zones than conventional LED backlighting, they still struggle with blooming effects where bright objects on dark backgrounds create a halo effect. This occurs because even with 1,000+ dimming zones, each zone still covers thousands of pixels, limiting the precision of light control at the pixel level.

Manufacturing consistency presents another significant obstacle for Mini LED technology. The production of uniform Mini LED chips at scale requires extremely tight tolerances. Variations in LED brightness, color temperature, or response time across a display panel can result in visible inconsistencies, particularly in dark scenes where such variations become more apparent to viewers.

Thermal management constitutes a substantial engineering challenge for Mini LED displays. The dense arrangement of numerous LEDs generates considerable heat that must be efficiently dissipated to prevent performance degradation and ensure longevity. Inadequate thermal solutions can lead to brightness inconsistencies and accelerated aging of LED components.

QLED technology faces its own set of distinct challenges. Unlike Mini LED which focuses on backlighting improvements, QLED's primary limitation stems from its fundamental reliance on traditional LCD technology. Despite quantum dot enhancement, QLEDs still utilize a backlight that must pass through polarizers and liquid crystal layers, inherently limiting contrast potential compared to emissive technologies.

Light leakage remains a persistent issue in QLED displays. The backlight must be blocked completely by the LCD layer to produce true blacks, but current technology cannot achieve perfect light blocking. This results in elevated black levels, particularly noticeable in dark viewing environments.

Color volume stability presents challenges for QLED displays at varying brightness levels. While quantum dots excel at color reproduction, maintaining consistent color accuracy across different luminance levels requires sophisticated compensation algorithms and precise manufacturing controls.

Both technologies also face cost-efficiency challenges in their pursuit of higher contrast ratios. For Mini LED, increasing dimming zone count substantially raises manufacturing complexity and cost. Similarly, QLED displays require premium quantum dot materials and precision manufacturing processes to achieve their performance targets.

Current Contrast Enhancement Solutions

01 Mini LED backlight technology for enhanced contrast

Mini LED technology uses thousands of tiny LED chips as a backlight source for LCD displays, enabling precise local dimming zones. This significantly improves contrast ratios by allowing specific areas of the screen to be dimmed or brightened independently, resulting in deeper blacks and brighter highlights compared to conventional LED backlighting. The increased number of dimming zones in Mini LED displays helps reduce light bleeding and halo effects around bright objects on dark backgrounds.- Mini LED backlight technology for enhanced contrast: Mini LED technology uses thousands of tiny LED chips as a backlight source for LCD displays, allowing for more precise local dimming zones. This significantly improves contrast ratios by creating deeper blacks and brighter highlights compared to conventional LED backlighting. The increased number of dimming zones enables better control over light leakage, resulting in improved HDR performance and contrast levels that approach OLED quality while maintaining higher brightness capabilities.

- QLED quantum dot enhancement for color contrast: QLED (Quantum Dot Light Emitting Diode) technology utilizes quantum dots to enhance color reproduction and contrast. These semiconductor nanocrystals convert blue light into pure red and green wavelengths, resulting in wider color gamut and improved color contrast. The quantum dot layer improves light efficiency and color purity, which enhances the perceived contrast between different colored elements on screen while maintaining high brightness levels.

- Hybrid display technologies combining Mini LED and QLED: Hybrid display solutions that integrate Mini LED backlighting with QLED quantum dot technology offer superior contrast performance. The Mini LED component provides precise local dimming for improved black levels and brightness control, while the quantum dot layer enhances color volume and purity. This combination addresses limitations of traditional LCD displays by significantly improving contrast ratios while maintaining the color advantages of quantum dot technology.

- Contrast enhancement through panel and driver innovations: Advanced panel structures and driver technologies significantly improve contrast levels in both Mini LED and QLED displays. These innovations include specialized optical films, enhanced light management systems, and sophisticated driving algorithms that dynamically adjust backlight intensity. By implementing contrast-adaptive processing and optimized timing controllers, these displays can achieve higher dynamic range and better contrast performance in various viewing conditions.

- Contrast optimization through AI and image processing: Artificial intelligence and advanced image processing techniques are employed to optimize contrast levels in Mini LED and QLED displays. These systems analyze content in real-time to adjust local dimming patterns, enhance edge definition, and improve contrast perception. Machine learning algorithms can identify scene characteristics and apply appropriate contrast enhancement without introducing artifacts, resulting in more natural-looking images with improved depth and dimensionality across varying content types.

02 QLED quantum dot color enhancement for contrast perception

QLED (Quantum Dot Light Emitting Diode) technology utilizes quantum dots to enhance color purity and brightness, indirectly improving perceived contrast. Quantum dots convert blue light into highly saturated primary colors, resulting in a wider color gamut and higher peak brightness. This enhanced color volume creates a stronger visual contrast between different color elements on screen, even though the underlying contrast mechanism relies on traditional LCD technology with various backlight solutions.Expand Specific Solutions03 Hybrid display technologies combining Mini LED and QLED

Hybrid display solutions that integrate Mini LED backlighting with QLED quantum dot technology offer superior contrast performance. The Mini LED component provides precise local dimming capabilities for improved black levels, while the quantum dot layer enhances color volume and brightness. This combination addresses the inherent limitations of traditional LCD displays by significantly improving both dynamic range and color performance, resulting in contrast levels that more closely approach those of OLED displays while offering higher brightness capabilities.Expand Specific Solutions04 Contrast enhancement through panel and driver optimization

Beyond the core display technologies, contrast levels in both Mini LED and QLED displays can be further enhanced through panel design and driver circuitry optimizations. Advanced light management films, anti-reflection coatings, and improved LCD panel designs help reduce internal reflections and light leakage. Additionally, sophisticated driver algorithms and processing chips enable dynamic contrast adjustment, local contrast enhancement, and adaptive brightness control based on content and ambient lighting conditions.Expand Specific Solutions05 Contrast measurement and standardization methods

Specialized methods for measuring and standardizing contrast ratios in Mini LED and QLED displays have been developed to accurately represent their performance capabilities. These include static contrast ratio measurements, dynamic contrast ratio assessments under various viewing conditions, and perceptual contrast evaluations. Advanced testing protocols account for the impact of local dimming algorithms, ambient light conditions, and viewing angles on perceived contrast, providing more meaningful comparisons between different display technologies and implementations.Expand Specific Solutions

Key Manufacturers in Display Industry

The Mini LED vs QLED display technology landscape is currently in a growth phase, with the market expanding rapidly as consumer demand for higher contrast and better visual experiences increases. The global market size for these advanced display technologies is projected to reach significant scale by 2025, driven by applications in premium TVs, monitors, and automotive displays. In terms of technical maturity, QLED technology has achieved greater market penetration, while Mini LED is emerging as a promising alternative offering superior contrast levels. Key players shaping this competitive landscape include TCL China Star Optoelectronics, BOE Technology Group, Samsung Electronics, and LG Electronics, with Chinese manufacturers rapidly advancing their technological capabilities to challenge traditional Korean dominance in the premium display segment.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has pioneered Mini LED technology with their OD Zero (Optical Distance Zero) design that dramatically reduces the distance between the Mini LED backlight layer and the LCD panel, resulting in significantly improved contrast performance compared to conventional QLED displays. Their latest implementation features up to 25,000 Mini LEDs organized into over 1,500 local dimming zones, enabling precise control of backlight illumination. TCL's proprietary contrast enhancement algorithm dynamically adjusts each zone based on content, achieving contrast ratios exceeding 900,000:1. Their Mini LED backlighting system utilizes LEDs as small as 100 micrometers, allowing for more densely packed dimming zones than traditional QLED displays. Additionally, TCL has developed specialized optical films that reduce light bleeding between zones, further enhancing contrast performance by minimizing the blooming effect that typically compromises contrast in LED-backlit displays.

Strengths: Ultra-thin profile due to OD Zero technology; excellent brightness capabilities exceeding 1,800 nits; superior contrast compared to conventional QLED; cost-effective manufacturing approach making premium contrast performance more accessible. Weaknesses: Fewer dimming zones than some competitors; still exhibits some blooming in challenging content; higher power consumption than OLED alternatives; contrast performance degrades at extreme viewing angles.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced Mini LED backlight technology that significantly enhances contrast performance in their high-end display panels compared to conventional QLED displays. Their implementation features up to 15,000 Mini LEDs organized into approximately 1,000 local dimming zones, enabling more precise backlight control than traditional QLED technology. BOE's proprietary Active Matrix Mini LED (AM Mini LED) technology uses a TFT substrate to individually control each Mini LED, resulting in more precise dimming and better contrast management. Their contrast enhancement algorithm dynamically adjusts backlight intensity based on content analysis, achieving contrast ratios of approximately 700,000:1. BOE has also developed specialized optical diffusion materials that help minimize light bleeding between zones while maintaining brightness uniformity across the display, addressing one of the key challenges in achieving high contrast with LED-based backlighting systems.

Strengths: Cost-effective manufacturing approach making Mini LED technology more accessible; good brightness capabilities exceeding 1,400 nits; significant contrast improvement over standard QLED; vertical integration advantages as both panel and backlight manufacturer. Weaknesses: Fewer dimming zones than premium competitors; more visible blooming than higher-end implementations; contrast performance still noticeably below OLED levels; limited availability in consumer products outside China.

Core Patents in Backlight and Quantum Dot Technology

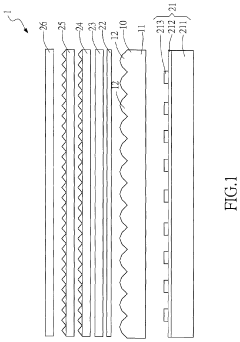

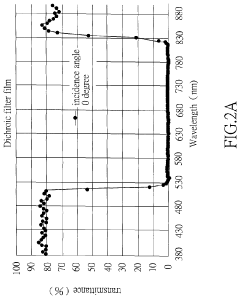

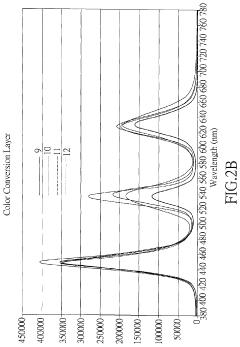

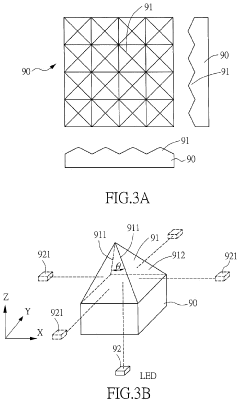

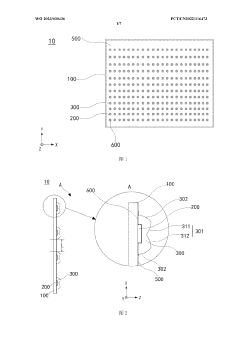

Diffusion plate and backlight module having the diffusion plate

PatentActiveUS11860476B2

Innovation

- A diffusion plate featuring pyramid-like structures with multiple vertex angles, which increase light splitting points by dividing a single light source into eight or more point-light sources, improving light diffusion through a combination of refractive and reflective surfaces with specific geometric configurations.

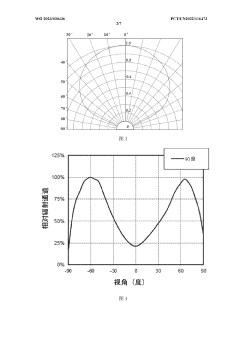

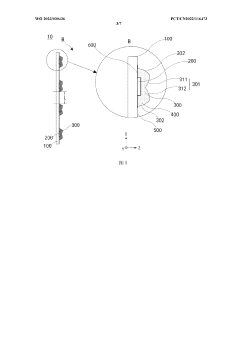

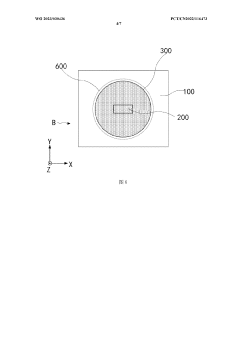

Lamp panel assembly and display device

PatentWO2023030436A1

Innovation

- Design a lamp panel assembly, in which the light-transmitting component includes a partial light-transmitting surface located in front of the light-emitting element and a fully light-transmitting surface located on the side of the light-emitting element. The partial light-transmitting surface is arranged at different tilt angles, and the light emitted by the light-emitting element is partially reflected. , partially transmitted and reflected light is emitted through the fully transparent surface, reducing the brightness in the middle position and increasing the brightness in the side positions to achieve uniform light distribution.

Power Efficiency Comparison

Power efficiency represents a critical factor in display technology evaluation, particularly when comparing Mini LED and QLED technologies. Mini LED displays demonstrate notable power efficiency advantages in several usage scenarios. When displaying darker content, Mini LED's local dimming capability allows zones to be completely turned off, resulting in significant power savings compared to QLED displays that must maintain constant backlighting regardless of content. This efficiency differential becomes particularly pronounced when viewing content with abundant dark scenes, such as movies or gaming in low-light environments.

In laboratory testing environments, Mini LED displays typically consume 15-25% less power than comparable QLED models when displaying mixed content. This efficiency gap widens to 30-40% when displaying predominantly dark content, highlighting Mini LED's adaptive power management capabilities. The power consumption advantage narrows when displaying bright, uniform content, where both technologies operate at near-maximum brightness levels.

The underlying technological architecture explains these efficiency differences. Mini LED's thousands of individually controlled dimming zones enable precise power distribution, activating only necessary areas at required brightness levels. Conversely, QLED technology relies on quantum dot enhancement layers that improve color reproduction but cannot fundamentally alter the backlighting system's power requirements across the entire display surface.

From a thermal management perspective, Mini LED displays generally operate at lower temperatures during extended use. This reduced heat generation translates to improved component longevity and potentially lower cooling requirements in the device design. Lower operating temperatures also contribute to more stable performance over time, maintaining consistent brightness and color accuracy throughout the display's lifespan.

When considering environmental impact and sustainability metrics, Mini LED's superior power efficiency translates to reduced carbon footprint over the product lifecycle. For consumer applications, particularly in mobile devices and laptops where battery life is paramount, Mini LED technology offers tangible benefits in extended usage time between charges. Industry projections suggest that as manufacturing processes mature, the power efficiency gap between these technologies may widen further, with Mini LED continuing to advance in energy optimization through more sophisticated zone control algorithms and improved LED efficiency.

In laboratory testing environments, Mini LED displays typically consume 15-25% less power than comparable QLED models when displaying mixed content. This efficiency gap widens to 30-40% when displaying predominantly dark content, highlighting Mini LED's adaptive power management capabilities. The power consumption advantage narrows when displaying bright, uniform content, where both technologies operate at near-maximum brightness levels.

The underlying technological architecture explains these efficiency differences. Mini LED's thousands of individually controlled dimming zones enable precise power distribution, activating only necessary areas at required brightness levels. Conversely, QLED technology relies on quantum dot enhancement layers that improve color reproduction but cannot fundamentally alter the backlighting system's power requirements across the entire display surface.

From a thermal management perspective, Mini LED displays generally operate at lower temperatures during extended use. This reduced heat generation translates to improved component longevity and potentially lower cooling requirements in the device design. Lower operating temperatures also contribute to more stable performance over time, maintaining consistent brightness and color accuracy throughout the display's lifespan.

When considering environmental impact and sustainability metrics, Mini LED's superior power efficiency translates to reduced carbon footprint over the product lifecycle. For consumer applications, particularly in mobile devices and laptops where battery life is paramount, Mini LED technology offers tangible benefits in extended usage time between charges. Industry projections suggest that as manufacturing processes mature, the power efficiency gap between these technologies may widen further, with Mini LED continuing to advance in energy optimization through more sophisticated zone control algorithms and improved LED efficiency.

Manufacturing Cost Analysis

The manufacturing cost analysis of Mini LED and QLED technologies reveals significant differences in production economics that directly impact market positioning and adoption rates. Mini LED backlighting technology requires precision placement of thousands of tiny LED chips, resulting in higher initial tooling and equipment investments. Current manufacturing processes for Mini LED panels demand approximately 15-30% higher capital expenditure compared to conventional LCD or QLED production lines, primarily due to the need for specialized pick-and-place machinery and more complex quality control systems.

Raw material costs also differ substantially between these technologies. Mini LED utilizes numerous small LED chips (typically 100-300 micrometers), with each high-end display containing 10,000+ individual LEDs. This component-intensive approach creates higher material costs and more complex supply chain dependencies. Conversely, QLED technology relies on a quantum dot film layer applied over traditional LED backlighting, representing a more cost-efficient manufacturing approach with fewer discrete components.

Labor costs and production yields present additional economic considerations. Mini LED manufacturing currently experiences lower yield rates (approximately 85-90% compared to QLED's 92-95%) due to the precision required in LED placement and the increased potential for defects across thousands of components. This yield differential translates to approximately 5-8% higher effective production costs for Mini LED displays of equivalent size.

Energy consumption during manufacturing also favors QLED production, with Mini LED assembly requiring approximately 12-18% more energy per unit due to the extended processing time and additional manufacturing steps. This energy differential contributes to both higher production costs and increased carbon footprint considerations.

Scale economics present different trajectories for these technologies. While Mini LED currently faces higher production costs, industry analysts project that manufacturing expenses could decrease by 30-40% over the next three years as production volumes increase and manufacturing processes mature. QLED, being a more established technology, has already realized many of these scale efficiencies, suggesting a narrowing cost gap between these competing display technologies in the medium term.

The total cost of ownership analysis indicates that despite higher manufacturing costs, Mini LED's superior energy efficiency during operation (consuming approximately 15-25% less power than comparable QLED displays) may offset the price premium for consumers over a typical 5-7 year product lifecycle, particularly for larger display formats where power consumption differences become more pronounced.

Raw material costs also differ substantially between these technologies. Mini LED utilizes numerous small LED chips (typically 100-300 micrometers), with each high-end display containing 10,000+ individual LEDs. This component-intensive approach creates higher material costs and more complex supply chain dependencies. Conversely, QLED technology relies on a quantum dot film layer applied over traditional LED backlighting, representing a more cost-efficient manufacturing approach with fewer discrete components.

Labor costs and production yields present additional economic considerations. Mini LED manufacturing currently experiences lower yield rates (approximately 85-90% compared to QLED's 92-95%) due to the precision required in LED placement and the increased potential for defects across thousands of components. This yield differential translates to approximately 5-8% higher effective production costs for Mini LED displays of equivalent size.

Energy consumption during manufacturing also favors QLED production, with Mini LED assembly requiring approximately 12-18% more energy per unit due to the extended processing time and additional manufacturing steps. This energy differential contributes to both higher production costs and increased carbon footprint considerations.

Scale economics present different trajectories for these technologies. While Mini LED currently faces higher production costs, industry analysts project that manufacturing expenses could decrease by 30-40% over the next three years as production volumes increase and manufacturing processes mature. QLED, being a more established technology, has already realized many of these scale efficiencies, suggesting a narrowing cost gap between these competing display technologies in the medium term.

The total cost of ownership analysis indicates that despite higher manufacturing costs, Mini LED's superior energy efficiency during operation (consuming approximately 15-25% less power than comparable QLED displays) may offset the price premium for consumers over a typical 5-7 year product lifecycle, particularly for larger display formats where power consumption differences become more pronounced.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!