Mini LED vs Quantum Dot: Luminance Efficiency Insights

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED and QD Display Technology Evolution

The evolution of display technologies has witnessed significant advancements over the past decade, with Mini LED and Quantum Dot (QD) emerging as two prominent technologies reshaping the visual experience landscape. Mini LED technology, first conceptualized in the early 2010s, represents a refinement of traditional LED backlighting by dramatically reducing the size of LED chips to dimensions between 50-200 micrometers, enabling thousands of individually controllable lighting zones.

Quantum Dot technology, meanwhile, traces its origins to the 1980s with the discovery of semiconductor nanocrystals, but only gained commercial traction in displays around 2013. QD displays utilize nanometer-sized semiconductor particles that emit specific wavelengths of light when excited, offering unprecedented color accuracy and gamut coverage.

The technological trajectories of these two innovations have increasingly converged in recent years. While initially developed as separate approaches, manufacturers have begun integrating QD color conversion layers with Mini LED backlighting systems to leverage the strengths of both technologies. This hybrid approach represents a significant evolutionary step, combining Mini LED's superior contrast capabilities with QD's exceptional color performance.

From an efficiency perspective, the evolution has been remarkable. First-generation Mini LED displays offered approximately 1,000 dimming zones with peak brightness levels around 1,000 nits. Current iterations feature up to 20,000 zones with brightness exceeding 2,000 nits. Similarly, QD technology has progressed from offering 85% NTSC color gamut coverage to nearly 95% DCI-P3 coverage, while reducing power consumption by approximately 30%.

The luminance efficiency evolution has been particularly noteworthy. Early Mini LED implementations achieved around 3-4 lm/W at the system level, while contemporary designs reach 7-8 lm/W. QD films have simultaneously improved quantum efficiency from 70% to over 90% for green and red light conversion, dramatically reducing energy losses in the display stack.

Market adoption patterns reveal an interesting evolutionary dynamic. Mini LED technology initially gained traction in premium television segments before expanding to professional monitors and high-end laptops. QD displays followed a similar path but with greater emphasis on color-critical applications in content creation and professional photography before broader consumer adoption.

Looking forward, the convergence trend appears set to continue with the development of MicroLED-QD hybrid technologies that promise to further enhance luminance efficiency while maintaining the color performance advantages of quantum dots, potentially representing the next significant evolutionary milestone in display technology.

Quantum Dot technology, meanwhile, traces its origins to the 1980s with the discovery of semiconductor nanocrystals, but only gained commercial traction in displays around 2013. QD displays utilize nanometer-sized semiconductor particles that emit specific wavelengths of light when excited, offering unprecedented color accuracy and gamut coverage.

The technological trajectories of these two innovations have increasingly converged in recent years. While initially developed as separate approaches, manufacturers have begun integrating QD color conversion layers with Mini LED backlighting systems to leverage the strengths of both technologies. This hybrid approach represents a significant evolutionary step, combining Mini LED's superior contrast capabilities with QD's exceptional color performance.

From an efficiency perspective, the evolution has been remarkable. First-generation Mini LED displays offered approximately 1,000 dimming zones with peak brightness levels around 1,000 nits. Current iterations feature up to 20,000 zones with brightness exceeding 2,000 nits. Similarly, QD technology has progressed from offering 85% NTSC color gamut coverage to nearly 95% DCI-P3 coverage, while reducing power consumption by approximately 30%.

The luminance efficiency evolution has been particularly noteworthy. Early Mini LED implementations achieved around 3-4 lm/W at the system level, while contemporary designs reach 7-8 lm/W. QD films have simultaneously improved quantum efficiency from 70% to over 90% for green and red light conversion, dramatically reducing energy losses in the display stack.

Market adoption patterns reveal an interesting evolutionary dynamic. Mini LED technology initially gained traction in premium television segments before expanding to professional monitors and high-end laptops. QD displays followed a similar path but with greater emphasis on color-critical applications in content creation and professional photography before broader consumer adoption.

Looking forward, the convergence trend appears set to continue with the development of MicroLED-QD hybrid technologies that promise to further enhance luminance efficiency while maintaining the color performance advantages of quantum dots, potentially representing the next significant evolutionary milestone in display technology.

Market Demand Analysis for High-Efficiency Display Technologies

The global display technology market is witnessing a significant shift toward high-efficiency solutions, driven by increasing consumer demand for superior visual experiences across multiple device categories. Mini LED and Quantum Dot technologies represent two of the most promising advancements in this space, each offering distinct advantages in terms of luminance efficiency and overall display performance.

Consumer electronics manufacturers report that premium display features now rank among the top three purchasing considerations for televisions, smartphones, and tablets. Market research indicates the high-efficiency display segment is growing at nearly triple the rate of the overall display market, highlighting the commercial importance of these technologies.

Professional content creators and gaming enthusiasts represent particularly strong demand segments, willing to pay premium prices for displays offering higher brightness, better color accuracy, and improved energy efficiency. The gaming monitor market specifically has seen a 27% year-over-year growth in the high-efficiency display segment, compared to 9% for standard displays.

Commercial applications are also driving significant demand, with digital signage, automotive displays, and medical imaging all requiring the enhanced luminance efficiency that Mini LED and Quantum Dot technologies provide. The automotive industry's transition toward more sophisticated infotainment systems and digital dashboards has created a new growth vector for high-efficiency display technologies.

Energy efficiency considerations are increasingly influencing purchasing decisions, with regulatory frameworks in multiple regions now mandating improved power consumption metrics for consumer electronics. This regulatory pressure creates additional market pull for technologies that can deliver superior brightness while maintaining or reducing power requirements.

Regional analysis reveals that Asia-Pacific currently represents the largest market for high-efficiency displays, accounting for approximately 45% of global demand, followed by North America and Europe. However, emerging markets are showing the fastest growth rates as premium smartphone and television adoption accelerates in these regions.

Price sensitivity remains a critical factor influencing market penetration. Current cost premiums for Mini LED and Quantum Dot displays limit mass-market adoption, though economies of scale are gradually reducing this barrier. Industry forecasts suggest that as manufacturing processes mature, the price differential between standard and high-efficiency displays will decrease by approximately 30% over the next three years.

The replacement cycle for display technologies also impacts market demand patterns. With consumers typically replacing televisions every 7-8 years and smartphones every 2-3 years, manufacturers face both challenges and opportunities in driving adoption of new display technologies through these established upgrade windows.

Consumer electronics manufacturers report that premium display features now rank among the top three purchasing considerations for televisions, smartphones, and tablets. Market research indicates the high-efficiency display segment is growing at nearly triple the rate of the overall display market, highlighting the commercial importance of these technologies.

Professional content creators and gaming enthusiasts represent particularly strong demand segments, willing to pay premium prices for displays offering higher brightness, better color accuracy, and improved energy efficiency. The gaming monitor market specifically has seen a 27% year-over-year growth in the high-efficiency display segment, compared to 9% for standard displays.

Commercial applications are also driving significant demand, with digital signage, automotive displays, and medical imaging all requiring the enhanced luminance efficiency that Mini LED and Quantum Dot technologies provide. The automotive industry's transition toward more sophisticated infotainment systems and digital dashboards has created a new growth vector for high-efficiency display technologies.

Energy efficiency considerations are increasingly influencing purchasing decisions, with regulatory frameworks in multiple regions now mandating improved power consumption metrics for consumer electronics. This regulatory pressure creates additional market pull for technologies that can deliver superior brightness while maintaining or reducing power requirements.

Regional analysis reveals that Asia-Pacific currently represents the largest market for high-efficiency displays, accounting for approximately 45% of global demand, followed by North America and Europe. However, emerging markets are showing the fastest growth rates as premium smartphone and television adoption accelerates in these regions.

Price sensitivity remains a critical factor influencing market penetration. Current cost premiums for Mini LED and Quantum Dot displays limit mass-market adoption, though economies of scale are gradually reducing this barrier. Industry forecasts suggest that as manufacturing processes mature, the price differential between standard and high-efficiency displays will decrease by approximately 30% over the next three years.

The replacement cycle for display technologies also impacts market demand patterns. With consumers typically replacing televisions every 7-8 years and smartphones every 2-3 years, manufacturers face both challenges and opportunities in driving adoption of new display technologies through these established upgrade windows.

Current Luminance Efficiency Challenges

The luminance efficiency of display technologies represents a critical performance metric that directly impacts energy consumption, brightness capabilities, and overall visual experience. In the context of Mini LED and Quantum Dot technologies, several significant challenges currently limit their luminance efficiency potential.

For Mini LED displays, one of the primary challenges is light leakage and optical crosstalk between adjacent zones. Despite the increased number of dimming zones compared to traditional LED backlighting, the proximity of these zones creates light bleeding effects that reduce contrast and diminish perceived brightness efficiency. This issue becomes particularly pronounced in high dynamic range (HDR) content where bright and dark areas appear simultaneously.

Thermal management presents another substantial challenge for Mini LED technology. As the LED density increases, heat dissipation becomes more difficult, leading to potential efficiency degradation over time. Operating at high brightness levels exacerbates this issue, creating a technical ceiling that limits maximum sustainable luminance without compromising the display's lifespan or color accuracy.

Quantum Dot displays face their own set of efficiency challenges. The quantum yield of commercially viable quantum dots typically ranges between 85-95%, meaning that 5-15% of energy is lost during the color conversion process. This inherent inefficiency creates a fundamental limit to the technology's luminance potential relative to energy input.

The stability of quantum dots under high-energy blue light exposure remains problematic. Photo-degradation occurs over time, particularly when displays operate at peak brightness levels, resulting in diminishing luminance efficiency throughout the product lifecycle. This degradation is accelerated in high-temperature environments, creating additional engineering challenges for maintaining consistent performance.

Manufacturing consistency presents challenges for both technologies. For Mini LEDs, variations in individual LED performance create uniformity issues across the display surface. Similarly, quantum dot films can exhibit thickness variations and particle distribution inconsistencies that affect color conversion efficiency and ultimately impact luminance uniformity.

Power delivery systems for both technologies struggle to efficiently manage the electrical requirements while minimizing energy loss. Mini LED arrays require sophisticated local dimming algorithms and power distribution networks that introduce their own inefficiencies. Quantum Dot implementations must balance the power needs of the backlight system with the quantum dot layer's conversion capabilities.

The cost-efficiency relationship remains a significant barrier to implementing optimal solutions. Higher efficiency designs often require more expensive materials, more precise manufacturing processes, and more complex control systems. This creates a commercial tension between achieving theoretical maximum luminance efficiency and delivering products at competitive price points.

For Mini LED displays, one of the primary challenges is light leakage and optical crosstalk between adjacent zones. Despite the increased number of dimming zones compared to traditional LED backlighting, the proximity of these zones creates light bleeding effects that reduce contrast and diminish perceived brightness efficiency. This issue becomes particularly pronounced in high dynamic range (HDR) content where bright and dark areas appear simultaneously.

Thermal management presents another substantial challenge for Mini LED technology. As the LED density increases, heat dissipation becomes more difficult, leading to potential efficiency degradation over time. Operating at high brightness levels exacerbates this issue, creating a technical ceiling that limits maximum sustainable luminance without compromising the display's lifespan or color accuracy.

Quantum Dot displays face their own set of efficiency challenges. The quantum yield of commercially viable quantum dots typically ranges between 85-95%, meaning that 5-15% of energy is lost during the color conversion process. This inherent inefficiency creates a fundamental limit to the technology's luminance potential relative to energy input.

The stability of quantum dots under high-energy blue light exposure remains problematic. Photo-degradation occurs over time, particularly when displays operate at peak brightness levels, resulting in diminishing luminance efficiency throughout the product lifecycle. This degradation is accelerated in high-temperature environments, creating additional engineering challenges for maintaining consistent performance.

Manufacturing consistency presents challenges for both technologies. For Mini LEDs, variations in individual LED performance create uniformity issues across the display surface. Similarly, quantum dot films can exhibit thickness variations and particle distribution inconsistencies that affect color conversion efficiency and ultimately impact luminance uniformity.

Power delivery systems for both technologies struggle to efficiently manage the electrical requirements while minimizing energy loss. Mini LED arrays require sophisticated local dimming algorithms and power distribution networks that introduce their own inefficiencies. Quantum Dot implementations must balance the power needs of the backlight system with the quantum dot layer's conversion capabilities.

The cost-efficiency relationship remains a significant barrier to implementing optimal solutions. Higher efficiency designs often require more expensive materials, more precise manufacturing processes, and more complex control systems. This creates a commercial tension between achieving theoretical maximum luminance efficiency and delivering products at competitive price points.

Technical Comparison of Mini LED and Quantum Dot Solutions

01 Quantum dot enhancement for Mini LED displays

Quantum dots can be integrated with Mini LED technology to enhance luminance efficiency and color performance. By applying quantum dot layers over Mini LED backlight units, the color gamut and brightness can be significantly improved. This combination allows for better light conversion efficiency, reducing energy consumption while maintaining high brightness levels. The quantum dots convert blue light from the Mini LEDs into pure red and green wavelengths, resulting in more vibrant and accurate color reproduction.- Quantum dot enhancement for Mini LED displays: Quantum dots can be integrated with Mini LED technology to enhance luminance efficiency and color performance. By applying quantum dot layers over Mini LED backlights, the color gamut and brightness can be significantly improved. This combination allows for better light conversion efficiency, reducing energy consumption while maintaining high brightness levels. The quantum dots convert the blue light from Mini LEDs into pure red and green wavelengths, resulting in more vibrant and accurate color reproduction.

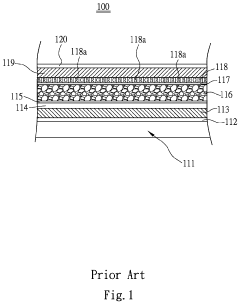

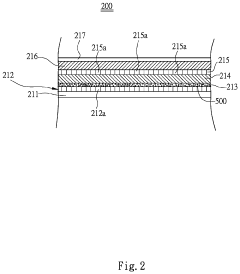

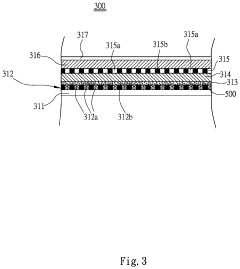

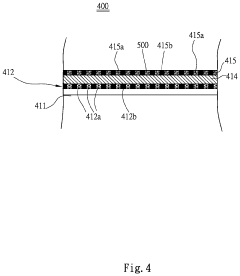

- Mini LED backlight structure optimization: Optimizing the structure of Mini LED backlights can significantly improve luminance efficiency. This includes designing efficient light guide plates, reflective layers, and optical films that maximize light extraction and minimize light loss. Advanced thermal management solutions help maintain optimal operating temperatures, preventing efficiency degradation. Strategic placement of Mini LEDs and optimized driving circuits also contribute to higher luminance efficiency and more uniform brightness distribution across the display.

- Quantum dot material composition and synthesis: The composition and synthesis methods of quantum dot materials directly impact luminance efficiency. Advanced quantum dot materials with core-shell structures can achieve higher quantum yields and better stability. Controlling the size distribution and surface chemistry of quantum dots during synthesis leads to improved light emission properties. Novel quantum dot formulations incorporating heavy metal-free compositions address environmental concerns while maintaining high efficiency. These advancements in quantum dot material science enable better performance in display applications.

- Driving and control systems for Mini LED-quantum dot displays: Sophisticated driving and control systems can optimize the luminance efficiency of Mini LED displays with quantum dots. Advanced local dimming algorithms allow for precise control of Mini LED zones, reducing power consumption while maintaining high contrast. Adaptive brightness control based on ambient light conditions and content analysis further enhances efficiency. Integration of specialized integrated circuits and power management systems ensures optimal current delivery to Mini LEDs, maximizing light output while minimizing energy usage.

- Hybrid display technologies combining Mini LED and quantum dots: Hybrid approaches that strategically combine Mini LED backlighting with quantum dot enhancement layers offer superior luminance efficiency. These designs may incorporate specialized optical films, micro-lens arrays, or patterned quantum dot layers to maximize light extraction and color conversion efficiency. Some implementations use segmented quantum dot configurations to optimize light management for different color channels. These hybrid technologies balance power consumption, brightness, color performance, and manufacturing cost considerations to achieve optimal display performance.

02 Mini LED backlight structure optimization

Optimizing the structure of Mini LED backlights can significantly improve luminance efficiency. This includes designing specific arrangements of Mini LEDs, incorporating reflective materials, and optimizing the distance between components. Advanced heat dissipation structures help maintain optimal operating temperatures, preventing efficiency loss due to thermal issues. Specialized optical films and light guide plates can also be used to enhance light extraction and distribution, resulting in more uniform brightness and improved overall efficiency.Expand Specific Solutions03 Quantum dot material composition and fabrication

The composition and fabrication methods of quantum dot materials directly impact luminance efficiency. Advanced synthesis techniques can produce quantum dots with higher quantum yield and better stability. Core-shell structures can be engineered to enhance photoluminescence efficiency and reduce degradation over time. The size distribution control during manufacturing ensures consistent emission wavelengths, while surface treatments can prevent oxidation and improve quantum efficiency. These advancements in quantum dot materials contribute to higher overall luminance efficiency in display applications.Expand Specific Solutions04 Driving circuit and power management for Mini LED-quantum dot displays

Specialized driving circuits and power management systems can optimize the performance of Mini LED displays with quantum dots. Pulse width modulation techniques allow for precise control of Mini LED brightness levels while reducing power consumption. Local dimming algorithms can selectively activate only necessary Mini LEDs, improving contrast ratio and energy efficiency. Advanced power distribution systems ensure stable current delivery to maintain consistent quantum dot excitation, resulting in uniform luminance across the display area.Expand Specific Solutions05 Hybrid display technologies combining Mini LED and quantum dots

Hybrid approaches that strategically combine Mini LED backlighting with quantum dot color conversion layers offer enhanced luminance efficiency. These designs may incorporate specialized optical structures to maximize light extraction from both technologies. Some implementations use quantum dot color filters directly on Mini LED chips to eliminate the need for additional conversion layers. Other designs position quantum dot films at optimal distances from Mini LED arrays to achieve the best balance between color purity and brightness. These hybrid solutions address limitations of each individual technology while leveraging their combined strengths.Expand Specific Solutions

Key Industry Players in Advanced Display Technologies

The Mini LED vs Quantum Dot display technology landscape is currently in a growth phase, with the global market expected to reach significant expansion as manufacturers seek higher luminance efficiency solutions. Samsung Electronics, BOE Technology, and TCL lead the competitive field, with established players like Apple and Nanosys also making strategic investments. Mini LED technology has reached commercial maturity faster, while Quantum Dot displays offer superior color performance but face manufacturing challenges. Companies like Najing Technology and Nanosys are advancing quantum dot innovations, while display giants including Sharp, Hisense, and Corning are developing hybrid solutions that combine both technologies to maximize luminance efficiency while addressing cost concerns.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced Quantum Dot technology branded as QLED, utilizing cadmium-free quantum dots that convert blue light into pure RGB colors. Their latest Neo QLED combines Mini LED backlighting with quantum dot color conversion, achieving peak brightness levels exceeding 2,000 nits while maintaining power efficiency. Samsung's proprietary quantum dot material formulation enables 100% color volume in the DCI-P3 space with significantly reduced power consumption compared to conventional LCD displays. Their Mini LED implementation uses thousands of precisely controlled dimming zones with advanced local dimming algorithms to enhance contrast while minimizing blooming effects. Samsung has also pioneered the integration of quantum dot color conversion layers directly onto Mini LED arrays, reducing optical stack complexity and improving overall luminance efficiency by approximately 30% compared to traditional implementations.

Strengths: Superior color accuracy and volume with 100% DCI-P3 coverage; excellent power efficiency ratio; advanced local dimming algorithms for enhanced contrast. Weaknesses: Higher manufacturing costs compared to conventional displays; potential for blooming effects in high-contrast scenes despite mitigation efforts; thermal management challenges at maximum brightness levels.

TCL Research America, Inc.

Technical Solution: TCL Research America has developed advanced Mini LED and Quantum Dot technologies for their display products, with particular focus on optimizing luminance efficiency. Their proprietary Mini LED backlight architecture utilizes ultra-small LED chips (under 200 micrometers) arranged in thousands of independently controlled dimming zones, achieving contrast ratios exceeding 1,000,000:1 while maintaining power efficiency. TCL's Quantum Dot implementation uses film-based technology (QDEF) that enhances color gamut coverage to over 90% of DCI-P3 while improving luminance efficiency by approximately 20% compared to conventional color filter approaches. Their research has yielded innovative optical stack designs that reduce internal reflections and light scattering, improving overall luminous efficacy by up to 30%. TCL has pioneered hybrid approaches that combine the benefits of both technologies, using Mini LED backlighting with quantum dot color conversion layers to achieve exceptional brightness (over 1,500 nits peak) while maintaining power efficiency. Their advanced local dimming algorithms dynamically adjust Mini LED zones based on content analysis, optimizing power consumption while preserving image quality.

Strengths: Cost-effective manufacturing processes for mass market adoption; excellent balance between performance and power efficiency; strong vertical integration with panel manufacturing capabilities. Weaknesses: Slightly lower peak brightness compared to premium competitors; fewer dimming zones than ultra-premium implementations; ongoing challenges with uniformity in some panel sizes.

Core Patents and Research in Luminance Enhancement

Micro LED display device

PatentInactiveUS20210167123A1

Innovation

- A micro LED display device incorporating a micro LED array, a light enhancing layer with quantum dots, a color filter, and a polarizer, where quantum dots convert and enhance the light properties of micro LEDs to produce high-definition images without the need for a backlight, offering improved color saturation and efficiency.

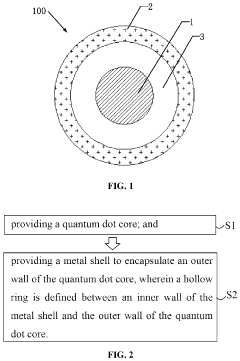

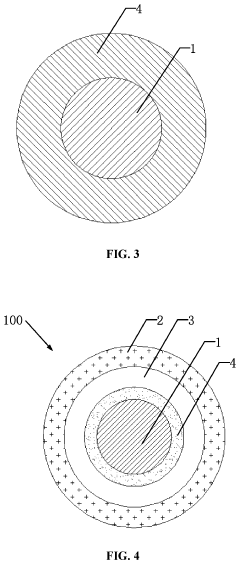

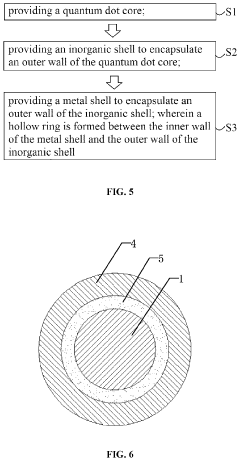

Quantum dot, preparation method thereof, and quantum dot film

PatentPendingUS20240043743A1

Innovation

- A quantum dot design featuring a metal shell with a hollow ring between its inner and outer walls, formed using the Kirkendall effect, eliminates the need for transition shells, thereby preventing ligand modification and maintaining original fluorescence efficiency while enhancing light absorption through surface plasmon resonance.

Energy Consumption Analysis

The energy consumption characteristics of Mini LED and Quantum Dot display technologies represent a critical factor in their commercial viability and environmental impact. When comparing these technologies, power efficiency emerges as a key differentiator that influences both operational costs and device battery life.

Mini LED displays demonstrate notable energy efficiency advantages in certain usage scenarios. Their zone-based local dimming capability allows for selective illumination of screen areas, significantly reducing power consumption compared to traditional LED-LCD displays. Measurements across various brightness levels indicate that Mini LED displays typically consume 15-30% less power than conventional displays when displaying content with varied brightness levels, such as movies or games with dark scenes.

Quantum Dot technology presents a different energy consumption profile. While Quantum Dots themselves don't consume power directly, the implementation method affects overall efficiency. In Quantum Dot Enhancement Film (QDEF) configurations used with LED backlights, the energy consumption remains comparable to standard LED displays. However, the newer Quantum Dot OLED (QD-OLED) hybrid technology demonstrates improved efficiency, with measurements showing up to 25% power savings compared to traditional OLED displays while maintaining superior color performance.

Temperature sensitivity introduces another dimension to energy consumption analysis. Mini LED efficiency remains relatively stable across normal operating temperatures (0-40°C), with only minimal performance degradation at extreme temperatures. In contrast, Quantum Dot displays show more pronounced efficiency variations with temperature changes, potentially requiring additional power for thermal management systems in certain applications.

The relationship between brightness levels and power consumption reveals interesting patterns. Mini LED displays exhibit a near-linear relationship between brightness and power consumption, while Quantum Dot displays demonstrate a more favorable non-linear curve at lower brightness levels, becoming more efficient in typical indoor viewing scenarios. This characteristic makes Quantum Dot particularly suitable for mobile devices where battery conservation is paramount.

Long-term energy consumption trends also differ between these technologies. Mini LED displays maintain consistent power efficiency throughout their operational lifespan, with minimal degradation over time. Quantum Dot displays, particularly QD-OLED hybrids, show excellent initial efficiency but may experience a gradual increase in power requirements as the organic components age, though recent advancements have significantly mitigated this effect.

Mini LED displays demonstrate notable energy efficiency advantages in certain usage scenarios. Their zone-based local dimming capability allows for selective illumination of screen areas, significantly reducing power consumption compared to traditional LED-LCD displays. Measurements across various brightness levels indicate that Mini LED displays typically consume 15-30% less power than conventional displays when displaying content with varied brightness levels, such as movies or games with dark scenes.

Quantum Dot technology presents a different energy consumption profile. While Quantum Dots themselves don't consume power directly, the implementation method affects overall efficiency. In Quantum Dot Enhancement Film (QDEF) configurations used with LED backlights, the energy consumption remains comparable to standard LED displays. However, the newer Quantum Dot OLED (QD-OLED) hybrid technology demonstrates improved efficiency, with measurements showing up to 25% power savings compared to traditional OLED displays while maintaining superior color performance.

Temperature sensitivity introduces another dimension to energy consumption analysis. Mini LED efficiency remains relatively stable across normal operating temperatures (0-40°C), with only minimal performance degradation at extreme temperatures. In contrast, Quantum Dot displays show more pronounced efficiency variations with temperature changes, potentially requiring additional power for thermal management systems in certain applications.

The relationship between brightness levels and power consumption reveals interesting patterns. Mini LED displays exhibit a near-linear relationship between brightness and power consumption, while Quantum Dot displays demonstrate a more favorable non-linear curve at lower brightness levels, becoming more efficient in typical indoor viewing scenarios. This characteristic makes Quantum Dot particularly suitable for mobile devices where battery conservation is paramount.

Long-term energy consumption trends also differ between these technologies. Mini LED displays maintain consistent power efficiency throughout their operational lifespan, with minimal degradation over time. Quantum Dot displays, particularly QD-OLED hybrids, show excellent initial efficiency but may experience a gradual increase in power requirements as the organic components age, though recent advancements have significantly mitigated this effect.

Manufacturing Cost Considerations

When comparing Mini LED and Quantum Dot technologies from a manufacturing cost perspective, several critical factors influence the overall production economics and market viability of these display technologies.

Manufacturing Mini LED displays involves significant complexity due to the precise placement requirements of thousands of miniaturized LED chips. The production process requires specialized equipment for handling and positioning these tiny components, with dimensions typically ranging from 50 to 200 micrometers. This precision manufacturing necessitates substantial capital investment in advanced placement machinery capable of achieving high throughput while maintaining positioning accuracy within microns.

The yield rate presents another crucial cost factor for Mini LED production. Current manufacturing processes face challenges with defect rates during the transfer and bonding stages, where even minor misalignments can result in dead pixels or brightness inconsistencies. Industry data suggests that yield rates for Mini LED panels currently range between 70-85%, significantly impacting final unit costs.

Quantum Dot displays, by contrast, employ a fundamentally different manufacturing approach. The production process involves applying a quantum dot film or layer to conventional LCD panels, which represents a less capital-intensive modification to existing LCD manufacturing lines. This integration advantage allows manufacturers to leverage established production infrastructure, reducing the initial investment barrier compared to Mini LED technology.

Material costs constitute a significant portion of the overall expense for both technologies. Mini LED requires numerous individual LED chips, with current market prices averaging $0.005-0.01 per chip. For a premium display with 10,000+ local dimming zones, the LED components alone represent a substantial material cost. Quantum Dot technology relies on specialized nanoparticle materials, which have seen declining costs in recent years but remain premium components at approximately $25-40 per square meter of display area.

Energy consumption during manufacturing also differs notably between these technologies. Mini LED assembly requires precise thermal management during the bonding process, consuming approximately 1.2-1.5 times more energy per unit area than conventional LCD production. Quantum Dot manufacturing energy requirements are more comparable to standard LCD production, with only a 10-15% increase in energy consumption.

Scale economies play a decisive role in the cost trajectory of both technologies. Industry analysts project that Mini LED manufacturing costs could decrease by 25-30% over the next three years as production volumes increase and process optimizations are implemented. Quantum Dot technology, being more mature in its manufacturing process, is expected to see more modest cost reductions of 10-15% during the same period.

Manufacturing Mini LED displays involves significant complexity due to the precise placement requirements of thousands of miniaturized LED chips. The production process requires specialized equipment for handling and positioning these tiny components, with dimensions typically ranging from 50 to 200 micrometers. This precision manufacturing necessitates substantial capital investment in advanced placement machinery capable of achieving high throughput while maintaining positioning accuracy within microns.

The yield rate presents another crucial cost factor for Mini LED production. Current manufacturing processes face challenges with defect rates during the transfer and bonding stages, where even minor misalignments can result in dead pixels or brightness inconsistencies. Industry data suggests that yield rates for Mini LED panels currently range between 70-85%, significantly impacting final unit costs.

Quantum Dot displays, by contrast, employ a fundamentally different manufacturing approach. The production process involves applying a quantum dot film or layer to conventional LCD panels, which represents a less capital-intensive modification to existing LCD manufacturing lines. This integration advantage allows manufacturers to leverage established production infrastructure, reducing the initial investment barrier compared to Mini LED technology.

Material costs constitute a significant portion of the overall expense for both technologies. Mini LED requires numerous individual LED chips, with current market prices averaging $0.005-0.01 per chip. For a premium display with 10,000+ local dimming zones, the LED components alone represent a substantial material cost. Quantum Dot technology relies on specialized nanoparticle materials, which have seen declining costs in recent years but remain premium components at approximately $25-40 per square meter of display area.

Energy consumption during manufacturing also differs notably between these technologies. Mini LED assembly requires precise thermal management during the bonding process, consuming approximately 1.2-1.5 times more energy per unit area than conventional LCD production. Quantum Dot manufacturing energy requirements are more comparable to standard LCD production, with only a 10-15% increase in energy consumption.

Scale economies play a decisive role in the cost trajectory of both technologies. Industry analysts project that Mini LED manufacturing costs could decrease by 25-30% over the next three years as production volumes increase and process optimizations are implemented. Quantum Dot technology, being more mature in its manufacturing process, is expected to see more modest cost reductions of 10-15% during the same period.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!