Mini LED vs Tungsten Filament: Energy Efficiency Benchmark

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED and Tungsten Lighting Evolution

The evolution of lighting technology has witnessed significant transformations over the past century, with tungsten filament lighting representing a cornerstone innovation of the early 20th century and Mini LED emerging as a cutting-edge solution in recent years. This technological progression reflects humanity's continuous pursuit of more efficient, sustainable, and versatile lighting solutions.

Tungsten filament technology, introduced commercially around 1906, revolutionized artificial lighting by replacing carbon filaments with tungsten, which offered higher melting points and greater luminous efficacy. The technology matured through the 1920s and 1930s with improvements in manufacturing processes, gas-filling techniques, and filament designs that enhanced durability and efficiency. Despite these advancements, tungsten lighting fundamentally remained constrained by its operating principle—generating light through incandescence, where only about 5-10% of energy converts to visible light.

The mid-20th century saw the emergence of alternative lighting technologies including fluorescent, halogen, and eventually LED solutions, each offering incremental improvements in energy efficiency. Traditional LEDs began gaining commercial traction in the 1990s and 2000s, setting the foundation for more sophisticated implementations like Mini LED technology.

Mini LED represents a significant evolutionary step in LED technology, emerging in the late 2010s. Unlike conventional LEDs, Mini LEDs typically measure 0.1-0.2mm in size, allowing for much higher density placement and more precise local dimming zones. This technology bridges the gap between traditional LED backlighting and the more advanced Micro LED technology still under development.

The transition from tungsten to Mini LED illustrates a fundamental shift in lighting principles—moving from thermal radiation to electroluminescence. While tungsten filaments generate light by heating a metal wire to incandescence, Mini LEDs produce light through semiconductor processes when electrons recombine with electron holes, releasing energy as photons.

Energy efficiency metrics demonstrate this evolution dramatically. Modern tungsten filament bulbs typically achieve 10-17 lumens per watt, whereas Mini LED implementations can deliver 100-200 lumens per watt—representing a 10-20x improvement in efficiency. This translates to significantly reduced energy consumption, lower heat generation, and extended operational lifespans.

Beyond efficiency, this technological evolution has expanded lighting functionality. While tungsten lighting offered limited control beyond basic dimming, Mini LED enables precise brightness control, color temperature adjustment, and integration with smart systems—transforming lighting from a simple utility to an interactive element of modern environments.

Tungsten filament technology, introduced commercially around 1906, revolutionized artificial lighting by replacing carbon filaments with tungsten, which offered higher melting points and greater luminous efficacy. The technology matured through the 1920s and 1930s with improvements in manufacturing processes, gas-filling techniques, and filament designs that enhanced durability and efficiency. Despite these advancements, tungsten lighting fundamentally remained constrained by its operating principle—generating light through incandescence, where only about 5-10% of energy converts to visible light.

The mid-20th century saw the emergence of alternative lighting technologies including fluorescent, halogen, and eventually LED solutions, each offering incremental improvements in energy efficiency. Traditional LEDs began gaining commercial traction in the 1990s and 2000s, setting the foundation for more sophisticated implementations like Mini LED technology.

Mini LED represents a significant evolutionary step in LED technology, emerging in the late 2010s. Unlike conventional LEDs, Mini LEDs typically measure 0.1-0.2mm in size, allowing for much higher density placement and more precise local dimming zones. This technology bridges the gap between traditional LED backlighting and the more advanced Micro LED technology still under development.

The transition from tungsten to Mini LED illustrates a fundamental shift in lighting principles—moving from thermal radiation to electroluminescence. While tungsten filaments generate light by heating a metal wire to incandescence, Mini LEDs produce light through semiconductor processes when electrons recombine with electron holes, releasing energy as photons.

Energy efficiency metrics demonstrate this evolution dramatically. Modern tungsten filament bulbs typically achieve 10-17 lumens per watt, whereas Mini LED implementations can deliver 100-200 lumens per watt—representing a 10-20x improvement in efficiency. This translates to significantly reduced energy consumption, lower heat generation, and extended operational lifespans.

Beyond efficiency, this technological evolution has expanded lighting functionality. While tungsten lighting offered limited control beyond basic dimming, Mini LED enables precise brightness control, color temperature adjustment, and integration with smart systems—transforming lighting from a simple utility to an interactive element of modern environments.

Market Demand Analysis for Energy-Efficient Lighting

The global lighting market has witnessed a significant shift towards energy-efficient solutions over the past decade, driven by increasing energy costs, environmental concerns, and regulatory pressures. The comparison between Mini LED and traditional tungsten filament technologies represents a critical aspect of this evolving landscape. Current market analysis indicates that energy-efficient lighting solutions are projected to dominate over 80% of the global lighting market by 2025, with a compound annual growth rate exceeding 12%.

Consumer demand for energy-efficient lighting has been accelerated by multiple factors. Rising electricity costs worldwide have made operational efficiency a primary consideration for both residential and commercial consumers. Environmental awareness has also played a crucial role, with consumers increasingly seeking products that reduce carbon footprints. Government regulations and incentives in major markets including the European Union, United States, and China have further catalyzed this transition through phased bans on inefficient lighting technologies and financial incentives for energy-efficient alternatives.

The commercial sector represents the largest market segment for energy-efficient lighting solutions, accounting for approximately 60% of total demand. Office buildings, retail spaces, and industrial facilities are rapidly transitioning to advanced lighting technologies to reduce operational costs and meet corporate sustainability goals. The residential sector follows with growing adoption rates as consumers become more aware of long-term cost savings despite higher initial investments.

Regional market analysis reveals varying adoption patterns. Developed markets in North America and Europe show mature adoption curves with emphasis on premium features beyond mere energy efficiency, including color accuracy, longevity, and smart connectivity. Meanwhile, emerging markets in Asia-Pacific and Latin America demonstrate accelerating growth rates driven by urbanization, infrastructure development, and decreasing technology costs.

Mini LED technology specifically addresses several unmet market needs compared to tungsten filaments. The demand for higher energy efficiency without compromising light quality represents the primary market driver. Additionally, consumers increasingly seek longer product lifespans to justify premium pricing, with expected operational lifetimes becoming a key purchasing consideration. The compact form factor of Mini LED solutions enables innovative design applications previously impossible with traditional lighting technologies.

Market forecasts indicate that the energy-efficient lighting segment will continue expanding at double-digit rates through 2030, with particular acceleration in smart lighting systems that incorporate Mini LED technology. Price sensitivity remains a significant factor influencing adoption rates, though the gap between premium and standard solutions continues to narrow as manufacturing scales and technologies mature.

Consumer demand for energy-efficient lighting has been accelerated by multiple factors. Rising electricity costs worldwide have made operational efficiency a primary consideration for both residential and commercial consumers. Environmental awareness has also played a crucial role, with consumers increasingly seeking products that reduce carbon footprints. Government regulations and incentives in major markets including the European Union, United States, and China have further catalyzed this transition through phased bans on inefficient lighting technologies and financial incentives for energy-efficient alternatives.

The commercial sector represents the largest market segment for energy-efficient lighting solutions, accounting for approximately 60% of total demand. Office buildings, retail spaces, and industrial facilities are rapidly transitioning to advanced lighting technologies to reduce operational costs and meet corporate sustainability goals. The residential sector follows with growing adoption rates as consumers become more aware of long-term cost savings despite higher initial investments.

Regional market analysis reveals varying adoption patterns. Developed markets in North America and Europe show mature adoption curves with emphasis on premium features beyond mere energy efficiency, including color accuracy, longevity, and smart connectivity. Meanwhile, emerging markets in Asia-Pacific and Latin America demonstrate accelerating growth rates driven by urbanization, infrastructure development, and decreasing technology costs.

Mini LED technology specifically addresses several unmet market needs compared to tungsten filaments. The demand for higher energy efficiency without compromising light quality represents the primary market driver. Additionally, consumers increasingly seek longer product lifespans to justify premium pricing, with expected operational lifetimes becoming a key purchasing consideration. The compact form factor of Mini LED solutions enables innovative design applications previously impossible with traditional lighting technologies.

Market forecasts indicate that the energy-efficient lighting segment will continue expanding at double-digit rates through 2030, with particular acceleration in smart lighting systems that incorporate Mini LED technology. Price sensitivity remains a significant factor influencing adoption rates, though the gap between premium and standard solutions continues to narrow as manufacturing scales and technologies mature.

Technical Comparison and Efficiency Challenges

Mini LED and tungsten filament technologies represent two distinct generations of lighting solutions with fundamentally different operating principles and efficiency characteristics. Mini LED, a relatively recent advancement in display and lighting technology, utilizes semiconductor materials to convert electrical energy directly into light through electroluminescence. In contrast, tungsten filament technology, which has dominated lighting for over a century, generates light through incandescence—heating a metal filament until it glows.

The energy efficiency disparity between these technologies is substantial. Tungsten filaments typically convert only 5-10% of input energy into visible light, with the remaining 90-95% dissipated as heat. This inherent inefficiency stems from the physical limitations of incandescent technology, where light production is a byproduct of heating rather than the primary mechanism. The tungsten filament must reach temperatures of approximately 2,500-3,000°C to produce adequate illumination, resulting in significant thermal energy loss.

Mini LEDs, conversely, demonstrate remarkable efficiency advantages, converting 40-60% of electrical energy into visible light. This efficiency derives from their direct energy conversion process, where electrons moving through the semiconductor material release photons without generating excessive heat. The technology's efficiency is further enhanced by precise wavelength control, allowing light to be produced at specific frequencies without wasting energy on non-visible spectrum emissions.

Power consumption metrics reveal the practical implications of these efficiency differences. A typical 60-watt tungsten bulb produces approximately 800 lumens of light output, yielding roughly 13.3 lumens per watt. By comparison, Mini LED solutions can deliver the same luminous output while consuming only 7-10 watts, achieving 80-115 lumens per watt—a 6-8 fold improvement in energy efficiency.

Despite Mini LED's clear advantages, several technical challenges persist. Color rendering capabilities remain a concern, as tungsten filaments naturally produce a full-spectrum light closely resembling sunlight (CRI 95+), while Mini LEDs typically achieve CRI ratings of 80-90 without specialized engineering. Heat management also presents challenges for Mini LED implementations, particularly in high-density arrays where thermal accumulation can affect performance and longevity.

Manufacturing complexity represents another significant challenge for Mini LED technology. The production process requires precise semiconductor fabrication techniques, clean room environments, and sophisticated quality control systems. These requirements contribute to higher initial costs compared to the relatively simple manufacturing process for tungsten filaments, which involves basic wire drawing and glass-blowing techniques.

Dimming performance presents contrasting challenges for both technologies. Tungsten filaments dim naturally and smoothly across their entire range, while Mini LEDs require complex pulse-width modulation systems to achieve similar dimming capabilities, sometimes resulting in visible stepping or flickering at low brightness levels.

The energy efficiency disparity between these technologies is substantial. Tungsten filaments typically convert only 5-10% of input energy into visible light, with the remaining 90-95% dissipated as heat. This inherent inefficiency stems from the physical limitations of incandescent technology, where light production is a byproduct of heating rather than the primary mechanism. The tungsten filament must reach temperatures of approximately 2,500-3,000°C to produce adequate illumination, resulting in significant thermal energy loss.

Mini LEDs, conversely, demonstrate remarkable efficiency advantages, converting 40-60% of electrical energy into visible light. This efficiency derives from their direct energy conversion process, where electrons moving through the semiconductor material release photons without generating excessive heat. The technology's efficiency is further enhanced by precise wavelength control, allowing light to be produced at specific frequencies without wasting energy on non-visible spectrum emissions.

Power consumption metrics reveal the practical implications of these efficiency differences. A typical 60-watt tungsten bulb produces approximately 800 lumens of light output, yielding roughly 13.3 lumens per watt. By comparison, Mini LED solutions can deliver the same luminous output while consuming only 7-10 watts, achieving 80-115 lumens per watt—a 6-8 fold improvement in energy efficiency.

Despite Mini LED's clear advantages, several technical challenges persist. Color rendering capabilities remain a concern, as tungsten filaments naturally produce a full-spectrum light closely resembling sunlight (CRI 95+), while Mini LEDs typically achieve CRI ratings of 80-90 without specialized engineering. Heat management also presents challenges for Mini LED implementations, particularly in high-density arrays where thermal accumulation can affect performance and longevity.

Manufacturing complexity represents another significant challenge for Mini LED technology. The production process requires precise semiconductor fabrication techniques, clean room environments, and sophisticated quality control systems. These requirements contribute to higher initial costs compared to the relatively simple manufacturing process for tungsten filaments, which involves basic wire drawing and glass-blowing techniques.

Dimming performance presents contrasting challenges for both technologies. Tungsten filaments dim naturally and smoothly across their entire range, while Mini LEDs require complex pulse-width modulation systems to achieve similar dimming capabilities, sometimes resulting in visible stepping or flickering at low brightness levels.

Current Energy Efficiency Solutions

01 Energy efficiency comparison between Mini LED and tungsten filament

Mini LEDs offer significantly higher energy efficiency compared to traditional tungsten filament lighting. While tungsten filaments convert only about 5-10% of energy into light (with the rest lost as heat), Mini LEDs can achieve efficiency rates of 80-90%. This substantial difference in energy conversion makes Mini LED technology a more sustainable and cost-effective lighting solution for various applications, resulting in lower power consumption and reduced environmental impact.- Energy efficiency comparison between Mini LED and tungsten filament: Mini LEDs offer significantly higher energy efficiency compared to traditional tungsten filament lighting. While tungsten filaments convert only about 5-10% of energy into light (with the rest lost as heat), Mini LEDs can achieve efficiency rates of 80-90%. This dramatic difference in energy conversion makes Mini LED technology a more sustainable and cost-effective lighting solution for various applications, resulting in lower power consumption and reduced environmental impact.

- Thermal management in Mini LED vs tungsten filament systems: Thermal management represents a key difference between Mini LED and tungsten filament technologies. Tungsten filaments operate at extremely high temperatures (2000-3000°C) to produce light, requiring special housing and safety considerations. In contrast, Mini LEDs generate significantly less heat while producing equivalent or greater illumination, allowing for more compact designs and reduced cooling requirements. Advanced thermal management systems in Mini LED applications further enhance efficiency and extend operational lifespan.

- Hybrid lighting systems combining LED and filament technologies: Innovative hybrid lighting systems combine Mini LED and tungsten filament technologies to leverage the advantages of both. These systems use efficient LEDs for primary illumination while incorporating tungsten elements for specific applications requiring particular light qualities or color temperatures. The hybrid approach allows for optimized energy consumption while maintaining desired lighting characteristics, with intelligent control systems managing the balance between the two technologies based on usage requirements.

- Lifespan and durability comparison: Mini LEDs significantly outperform tungsten filaments in terms of operational lifespan and durability. While traditional tungsten bulbs typically last 1,000-2,000 hours before failure, Mini LEDs can function for 50,000-100,000 hours under proper operating conditions. This dramatic difference in longevity translates to reduced replacement frequency, lower maintenance costs, and decreased waste generation. Additionally, Mini LEDs are more resistant to physical shock, vibration, and power fluctuations compared to fragile tungsten filaments.

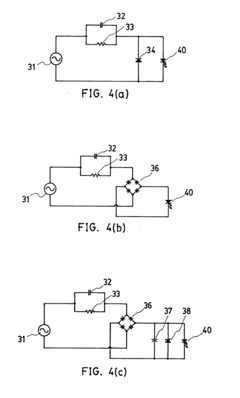

- Application-specific energy efficiency optimizations: Both Mini LED and tungsten filament technologies can be optimized for specific applications to maximize energy efficiency. For Mini LEDs, this includes advanced driver circuits, optical designs, and phosphor formulations tailored to particular use cases. For tungsten filaments, specialized gas fillings, filament designs, and reflective coatings can improve efficiency within the limitations of the technology. The selection between these technologies depends on specific requirements such as color rendering, dimming capabilities, startup time, and environmental conditions.

02 Thermal management in Mini LED vs. tungsten filament systems

Thermal management represents a key difference between Mini LED and tungsten filament technologies. Tungsten filaments operate at extremely high temperatures (2000-3000°C) to produce light, requiring significant heat dissipation mechanisms. In contrast, Mini LEDs generate much less heat during operation, allowing for more compact designs and reduced cooling requirements. Advanced thermal management systems in Mini LED applications include heat sinks, thermal interface materials, and optimized circuit designs that further enhance energy efficiency and extend operational lifespan.Expand Specific Solutions03 Lifespan and durability comparison

Mini LEDs significantly outperform tungsten filaments in terms of operational lifespan and durability. While traditional tungsten filament bulbs typically last 1,000-2,000 hours before failure, Mini LEDs can operate for 50,000-100,000 hours under proper conditions. This extended lifespan is due to the solid-state nature of LED technology, which lacks the fragile filament that eventually burns out in traditional bulbs. The superior durability of Mini LEDs also makes them more resistant to vibration and physical shock, contributing to their overall energy efficiency by reducing replacement frequency and associated manufacturing energy costs.Expand Specific Solutions04 Lighting quality and control capabilities

Mini LED technology offers superior lighting quality and control capabilities compared to tungsten filaments. While tungsten filaments provide a warm, continuous spectrum light with limited control options, Mini LEDs deliver precise color temperature control, dimming capabilities, and dynamic lighting effects. Advanced Mini LED systems incorporate sophisticated drivers and control circuits that optimize energy usage based on ambient conditions and user preferences. This precision control contributes significantly to energy efficiency by allowing light output to be tailored to specific needs rather than operating at full power continuously.Expand Specific Solutions05 Application-specific energy efficiency considerations

The energy efficiency advantages of Mini LEDs over tungsten filaments vary across different applications. In display technologies, Mini LEDs enable local dimming zones that significantly reduce power consumption compared to traditional backlight systems. For architectural and automotive lighting, Mini LEDs provide directional light output that reduces wasted illumination. Industrial applications benefit from the instant-on capability of Mini LEDs, eliminating the warm-up period required by tungsten filaments. These application-specific advantages contribute to overall energy savings beyond the basic efficiency differences between the two technologies.Expand Specific Solutions

Key Manufacturers and Industry Leaders

The Mini LED vs Tungsten Filament energy efficiency landscape is currently in a growth phase, with the market expanding rapidly as energy efficiency becomes a priority globally. The Mini LED technology is reaching maturity, with major players like BOE Technology Group, Samsung Electronics, and TCL China Star Optoelectronics leading innovation in this space. These companies have established strong R&D capabilities and manufacturing infrastructure for Mini LED displays and lighting solutions. Meanwhile, traditional tungsten filament technology, represented by companies like Xiamen Honglu Tungsten Molybdenum Industry and Foshan Electrical & Lighting, is being gradually displaced in many applications due to significantly lower energy efficiency compared to LED alternatives. The market is witnessing a clear transition toward Mini LED technology, driven by its superior energy efficiency, longer lifespan, and decreasing production costs.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has pioneered Mini LED backlighting technology that demonstrates substantial energy efficiency advantages over tungsten filament lighting. Their approach integrates ultra-small LED chips (typically 100-200 micrometers) arranged in dense arrays with sophisticated local dimming algorithms. BOE's Mini LED displays achieve energy efficiency ratings of approximately 90-110 lm/W, representing a 6-7x improvement over tungsten filament's 15-17 lm/W. The company has developed proprietary driver ICs that minimize power leakage and optimize current delivery to each Mini LED zone. BOE's technology also incorporates adaptive brightness control that adjusts power consumption based on ambient lighting conditions and displayed content, further enhancing real-world energy efficiency by an additional 15-20% compared to fixed-brightness systems.

Strengths: Dramatically higher energy efficiency than tungsten lighting; adaptive brightness technology optimizes power usage; minimal heat generation reducing cooling requirements; precise local dimming capabilities. Weaknesses: Higher production complexity and initial cost; requires sophisticated control systems; potential for more complex repair/replacement procedures compared to simpler tungsten systems.

Wuhan China Star Optoelectronics Technology Co., Ltd.

Technical Solution: Wuhan CSOT has developed advanced Mini LED backlighting technology that demonstrates significant energy efficiency advantages over traditional tungsten filament lighting. Their approach utilizes ultra-compact LED chips (approximately 100-200 micrometers) arranged in precise arrays with sophisticated local dimming capabilities. Wuhan CSOT's Mini LED displays achieve energy efficiency ratings of 75-90 lumens per watt, substantially outperforming tungsten filament's typical 10-15 lm/W. The company has implemented proprietary driver circuitry that reduces power consumption during partial brightness operation, a common usage scenario that further widens the efficiency gap compared to tungsten solutions. Their technology incorporates advanced optical films that enhance light extraction and directional control, improving system-level efficiency by reducing light loss within the display structure. Wuhan CSOT has also developed specialized thermal management solutions that maintain optimal LED junction temperatures, preventing efficiency degradation under extended operation.

Strengths: Dramatically higher luminous efficacy than tungsten lighting; excellent dimming capabilities without efficiency loss; minimal heat generation reducing cooling requirements; substantially longer operational lifespan reducing replacement frequency and associated energy costs. Weaknesses: More complex manufacturing process increasing production costs; requires sophisticated control systems; potential for uniformity challenges across large display areas if not properly implemented.

Core Patents and Innovations in LED Technology

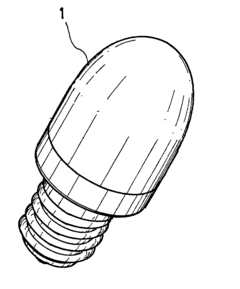

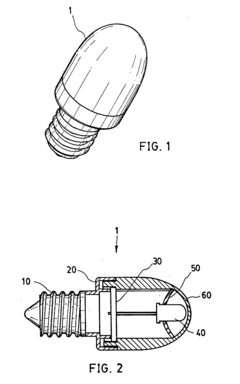

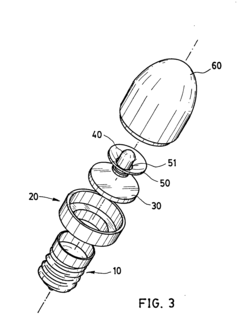

LED bulb for night-light

PatentInactiveUS20030185020A1

Innovation

- An LED bulb design featuring a screw base, substrate, circuit board, LED, and transparent cover, along with a plug-embedded LED variant, which incorporates components like capacitors, resistors, and diodes to provide power-efficient and long-lasting night-light solutions.

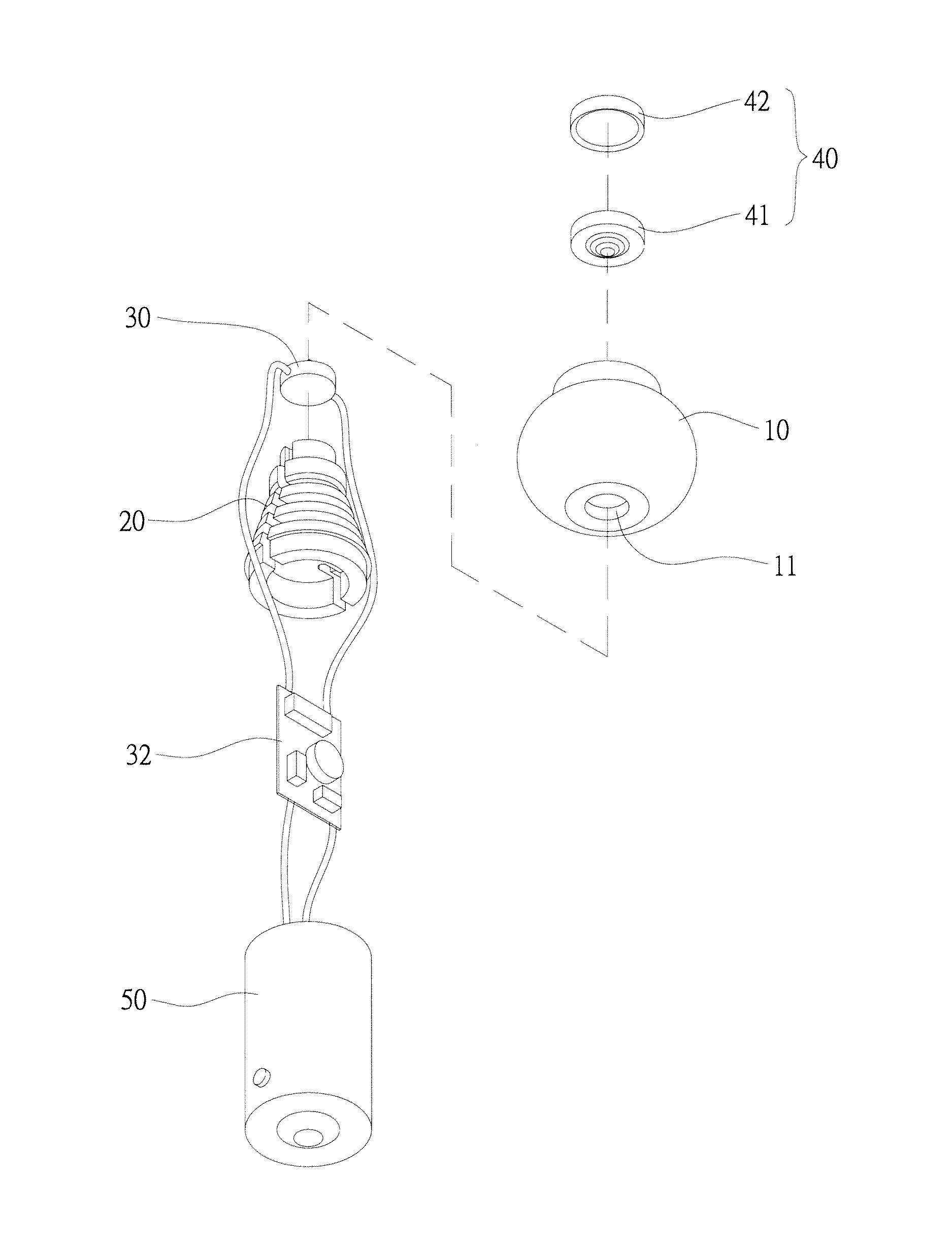

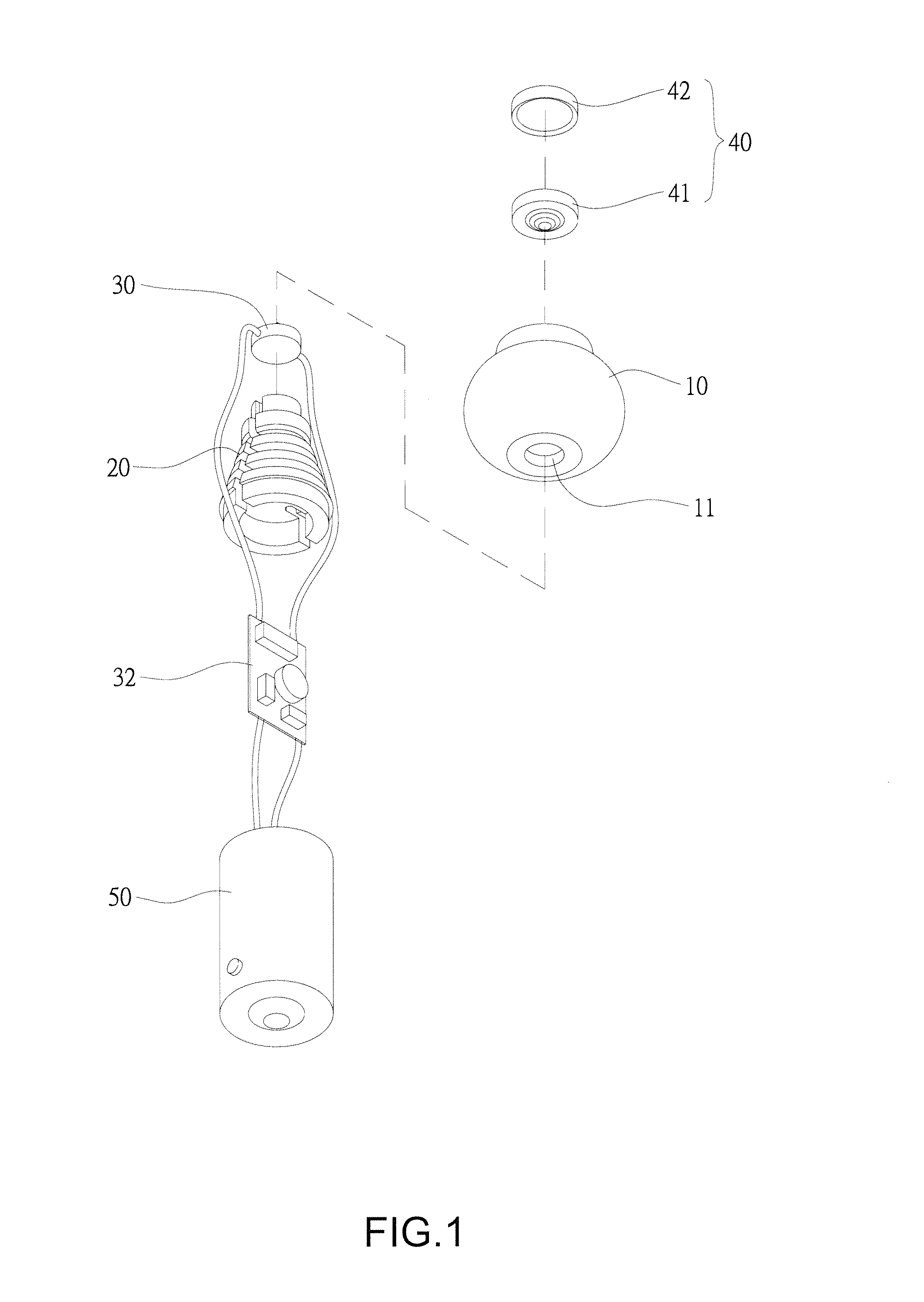

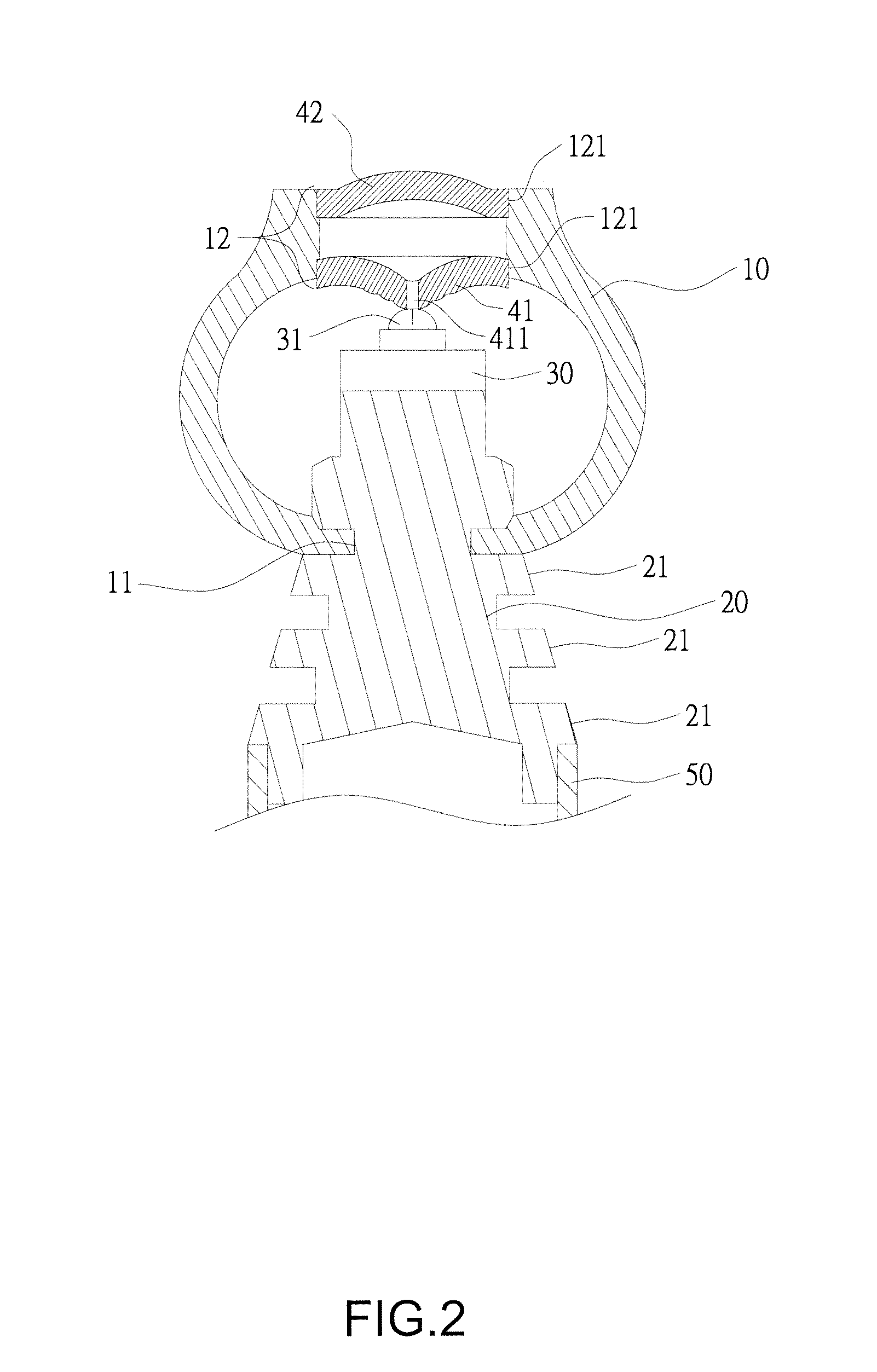

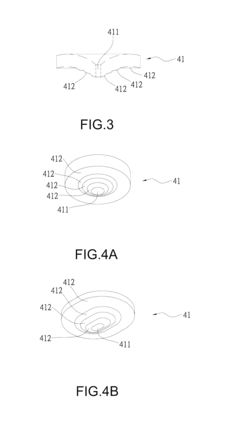

Tungsten-Filament-Like Light-Emitting Diode Lamp Structure

PatentInactiveUS20150184833A1

Innovation

- A tungsten-filament-like LED lamp structure incorporating a single LED, a heat dissipating frame, a lamp shade, a lamp holder, and a light spreader assembly with a reflective device and diverging element to expand the light emission angle and mimic the optical field of tungsten filament lamps, allowing direct replacement in conventional lamp fixtures.

Environmental Impact Assessment

The environmental impact of lighting technologies extends far beyond their immediate energy consumption, encompassing their entire lifecycle from manufacturing to disposal. When comparing Mini LED and traditional tungsten filament lighting systems, several critical environmental factors emerge that significantly differentiate these technologies.

Tungsten filament lighting represents an older technology with substantial environmental drawbacks. These incandescent bulbs convert only 5-10% of energy into visible light, with the remainder dissipated as heat. This inefficiency translates directly into higher carbon emissions from power generation. Additionally, tungsten filaments typically contain small amounts of mercury and other potentially harmful materials that present disposal challenges and contamination risks when improperly handled.

Mini LED technology demonstrates markedly superior environmental credentials across multiple metrics. The manufacturing process for Mini LEDs requires significantly fewer raw materials per unit of light output compared to tungsten alternatives. Research indicates that the resource intensity of Mini LED production has decreased by approximately 60% over the past decade as manufacturing techniques have evolved and scaled.

Lifecycle assessment studies reveal that Mini LEDs generate approximately 75-80% less carbon dioxide equivalent emissions over their operational lifespan when compared to tungsten filament lighting of equivalent brightness. This reduction stems primarily from their dramatically improved energy efficiency but is complemented by their extended operational lifespan, which reduces replacement frequency and associated manufacturing impacts.

Waste stream considerations further highlight the environmental advantages of Mini LED technology. The average Mini LED fixture contains fewer hazardous substances and offers greater recyclability potential than tungsten alternatives. Current recycling programs can recover approximately 95% of materials from LED lighting systems, compared to only 30-40% for traditional incandescent bulbs.

Heat generation represents another significant environmental factor. Tungsten filament lighting's substantial heat output contributes to increased cooling requirements in buildings, creating a secondary energy demand that compounds their environmental impact. Mini LEDs operate at much lower temperatures, reducing this auxiliary energy burden by an estimated 15-20% in typical commercial applications.

Water usage throughout the production cycle also favors Mini LED technology. Manufacturing processes for Mini LEDs consume approximately 45% less water per unit than tungsten filament production, representing a substantial conservation benefit in regions where water scarcity presents environmental challenges.

Tungsten filament lighting represents an older technology with substantial environmental drawbacks. These incandescent bulbs convert only 5-10% of energy into visible light, with the remainder dissipated as heat. This inefficiency translates directly into higher carbon emissions from power generation. Additionally, tungsten filaments typically contain small amounts of mercury and other potentially harmful materials that present disposal challenges and contamination risks when improperly handled.

Mini LED technology demonstrates markedly superior environmental credentials across multiple metrics. The manufacturing process for Mini LEDs requires significantly fewer raw materials per unit of light output compared to tungsten alternatives. Research indicates that the resource intensity of Mini LED production has decreased by approximately 60% over the past decade as manufacturing techniques have evolved and scaled.

Lifecycle assessment studies reveal that Mini LEDs generate approximately 75-80% less carbon dioxide equivalent emissions over their operational lifespan when compared to tungsten filament lighting of equivalent brightness. This reduction stems primarily from their dramatically improved energy efficiency but is complemented by their extended operational lifespan, which reduces replacement frequency and associated manufacturing impacts.

Waste stream considerations further highlight the environmental advantages of Mini LED technology. The average Mini LED fixture contains fewer hazardous substances and offers greater recyclability potential than tungsten alternatives. Current recycling programs can recover approximately 95% of materials from LED lighting systems, compared to only 30-40% for traditional incandescent bulbs.

Heat generation represents another significant environmental factor. Tungsten filament lighting's substantial heat output contributes to increased cooling requirements in buildings, creating a secondary energy demand that compounds their environmental impact. Mini LEDs operate at much lower temperatures, reducing this auxiliary energy burden by an estimated 15-20% in typical commercial applications.

Water usage throughout the production cycle also favors Mini LED technology. Manufacturing processes for Mini LEDs consume approximately 45% less water per unit than tungsten filament production, representing a substantial conservation benefit in regions where water scarcity presents environmental challenges.

Cost-Benefit Analysis of Lighting Technologies

When evaluating the economic viability of lighting technologies, particularly comparing Mini LED and tungsten filament options, a comprehensive cost-benefit analysis reveals significant differences in both initial investment and long-term operational expenses.

The initial acquisition cost presents the first notable distinction. Tungsten filament bulbs typically range from $1-5 per unit, making them highly accessible for immediate implementation with minimal upfront investment. In contrast, Mini LED lighting solutions command premium pricing between $15-50 per comparable unit, representing a substantially higher initial capital requirement. This price differential creates an immediate barrier to adoption for budget-conscious consumers and organizations.

However, the operational cost trajectory reverses this relationship dramatically over time. Tungsten filament bulbs consume approximately 60 watts of electricity to produce 800 lumens of light output, whereas Mini LED technology requires only 7-10 watts to generate equivalent illumination. This translates to an 85-90% reduction in electricity consumption, yielding proportional savings on utility expenses throughout the operational lifespan.

Lifespan considerations further amplify this economic divergence. Traditional tungsten bulbs typically function for 1,000-2,000 hours before failure, necessitating frequent replacements. Mini LED solutions demonstrate remarkable longevity, with operational lifespans ranging from 25,000-50,000 hours. This extended service period significantly reduces replacement frequency and associated labor costs, particularly in commercial or industrial settings where maintenance accessibility presents logistical challenges.

The maintenance cost differential extends beyond simple replacement frequency. Tungsten filaments generate substantial heat during operation, potentially increasing cooling requirements in confined spaces or temperature-sensitive environments. This indirect energy consumption represents a hidden operational cost often overlooked in basic comparisons. Mini LED technology operates at significantly lower temperatures, eliminating this ancillary expense.

Return on investment calculations indicate that despite higher initial costs, Mini LED lighting typically achieves break-even within 1-3 years depending on usage patterns and local electricity rates. In environments with continuous operation (24/7 usage), this payback period can compress to under 12 months, after which the technology delivers net positive financial returns compared to tungsten alternatives.

Environmental externalities, while difficult to quantify precisely, represent additional economic considerations. Tungsten bulbs' higher energy consumption correlates directly with increased carbon emissions from power generation. As carbon pricing mechanisms expand globally, this factor may introduce additional cost implications for energy-intensive lighting solutions in the near future.

The initial acquisition cost presents the first notable distinction. Tungsten filament bulbs typically range from $1-5 per unit, making them highly accessible for immediate implementation with minimal upfront investment. In contrast, Mini LED lighting solutions command premium pricing between $15-50 per comparable unit, representing a substantially higher initial capital requirement. This price differential creates an immediate barrier to adoption for budget-conscious consumers and organizations.

However, the operational cost trajectory reverses this relationship dramatically over time. Tungsten filament bulbs consume approximately 60 watts of electricity to produce 800 lumens of light output, whereas Mini LED technology requires only 7-10 watts to generate equivalent illumination. This translates to an 85-90% reduction in electricity consumption, yielding proportional savings on utility expenses throughout the operational lifespan.

Lifespan considerations further amplify this economic divergence. Traditional tungsten bulbs typically function for 1,000-2,000 hours before failure, necessitating frequent replacements. Mini LED solutions demonstrate remarkable longevity, with operational lifespans ranging from 25,000-50,000 hours. This extended service period significantly reduces replacement frequency and associated labor costs, particularly in commercial or industrial settings where maintenance accessibility presents logistical challenges.

The maintenance cost differential extends beyond simple replacement frequency. Tungsten filaments generate substantial heat during operation, potentially increasing cooling requirements in confined spaces or temperature-sensitive environments. This indirect energy consumption represents a hidden operational cost often overlooked in basic comparisons. Mini LED technology operates at significantly lower temperatures, eliminating this ancillary expense.

Return on investment calculations indicate that despite higher initial costs, Mini LED lighting typically achieves break-even within 1-3 years depending on usage patterns and local electricity rates. In environments with continuous operation (24/7 usage), this payback period can compress to under 12 months, after which the technology delivers net positive financial returns compared to tungsten alternatives.

Environmental externalities, while difficult to quantify precisely, represent additional economic considerations. Tungsten bulbs' higher energy consumption correlates directly with increased carbon emissions from power generation. As carbon pricing mechanisms expand globally, this factor may introduce additional cost implications for energy-intensive lighting solutions in the near future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!