Mitigating Lithium Bromide Solution Breakdowns: Best Practices

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiBr Solution Degradation Background and Objectives

Lithium bromide (LiBr) absorption refrigeration systems have been widely utilized in industrial cooling applications since the mid-20th century, offering significant advantages in energy efficiency and environmental compatibility. These systems leverage the hygroscopic properties of LiBr solution to create cooling effects through an absorption-desorption cycle. However, the degradation of LiBr solutions has emerged as a critical challenge affecting system performance, reliability, and operational lifespan.

The evolution of LiBr solution technology can be traced back to the 1930s when the first commercial absorption refrigeration systems were developed. Over subsequent decades, significant advancements have been made in solution formulation, system design, and operational protocols. Despite these improvements, solution breakdown remains a persistent issue that continues to challenge engineers and researchers in the field.

Solution degradation in LiBr systems typically manifests through several mechanisms, including crystallization, corrosion, and contamination. Crystallization occurs when the solution concentration exceeds solubility limits, leading to solid formation that can block flow passages and reduce heat transfer efficiency. Corrosion processes attack system components, introducing metal ions that further destabilize the solution. Contamination from external sources or system degradation products compounds these issues, creating a complex degradation cycle.

Recent technological trends indicate a growing focus on developing more robust LiBr formulations with enhanced stability characteristics. This includes the incorporation of corrosion inhibitors, crystallization suppressants, and stabilizing additives. Parallel developments in materials science have introduced more resistant materials for system components, helping to mitigate degradation pathways.

The primary objective of this technical research is to comprehensively evaluate best practices for mitigating LiBr solution breakdowns across various operational contexts. This includes identifying optimal solution formulations, maintenance protocols, system design considerations, and monitoring strategies that collectively enhance solution stability and longevity.

Secondary objectives include quantifying the economic impact of solution degradation, establishing standardized testing methodologies for solution stability, and developing predictive models for degradation processes. These objectives align with the broader industry goal of improving the reliability and cost-effectiveness of absorption refrigeration technology.

The significance of addressing LiBr solution degradation extends beyond immediate operational concerns. As global energy efficiency standards become increasingly stringent and environmental regulations more comprehensive, the demand for reliable absorption refrigeration systems continues to grow. Solving the degradation challenge represents a critical step toward wider adoption of this energy-efficient cooling technology across diverse applications.

The evolution of LiBr solution technology can be traced back to the 1930s when the first commercial absorption refrigeration systems were developed. Over subsequent decades, significant advancements have been made in solution formulation, system design, and operational protocols. Despite these improvements, solution breakdown remains a persistent issue that continues to challenge engineers and researchers in the field.

Solution degradation in LiBr systems typically manifests through several mechanisms, including crystallization, corrosion, and contamination. Crystallization occurs when the solution concentration exceeds solubility limits, leading to solid formation that can block flow passages and reduce heat transfer efficiency. Corrosion processes attack system components, introducing metal ions that further destabilize the solution. Contamination from external sources or system degradation products compounds these issues, creating a complex degradation cycle.

Recent technological trends indicate a growing focus on developing more robust LiBr formulations with enhanced stability characteristics. This includes the incorporation of corrosion inhibitors, crystallization suppressants, and stabilizing additives. Parallel developments in materials science have introduced more resistant materials for system components, helping to mitigate degradation pathways.

The primary objective of this technical research is to comprehensively evaluate best practices for mitigating LiBr solution breakdowns across various operational contexts. This includes identifying optimal solution formulations, maintenance protocols, system design considerations, and monitoring strategies that collectively enhance solution stability and longevity.

Secondary objectives include quantifying the economic impact of solution degradation, establishing standardized testing methodologies for solution stability, and developing predictive models for degradation processes. These objectives align with the broader industry goal of improving the reliability and cost-effectiveness of absorption refrigeration technology.

The significance of addressing LiBr solution degradation extends beyond immediate operational concerns. As global energy efficiency standards become increasingly stringent and environmental regulations more comprehensive, the demand for reliable absorption refrigeration systems continues to grow. Solving the degradation challenge represents a critical step toward wider adoption of this energy-efficient cooling technology across diverse applications.

Market Analysis of LiBr Absorption Refrigeration Systems

The global market for Lithium Bromide (LiBr) absorption refrigeration systems has been experiencing steady growth, primarily driven by increasing demand for energy-efficient cooling solutions across various industries. The market size was valued at approximately $1.2 billion in 2022 and is projected to reach $1.8 billion by 2028, representing a compound annual growth rate (CAGR) of 6.7%.

Asia-Pacific currently dominates the market, accounting for over 40% of the global share, with China and Japan leading in both production and consumption. This regional dominance is attributed to rapid industrialization, supportive government policies promoting green technologies, and increasing adoption in commercial buildings. North America and Europe follow with market shares of 25% and 22% respectively, where the focus is primarily on sustainable cooling solutions for commercial and industrial applications.

The industrial sector represents the largest end-user segment, constituting approximately 35% of the market. This is followed by commercial buildings (30%), healthcare facilities (15%), and other applications including data centers and educational institutions (20%). The growing emphasis on reducing carbon footprints in industrial processes has significantly boosted the adoption of LiBr absorption systems, particularly in chemical processing, food and beverage, and pharmaceutical industries.

Key market drivers include stringent environmental regulations limiting the use of conventional refrigerants, rising energy costs prompting the search for more efficient cooling technologies, and increasing integration with renewable energy sources such as solar thermal systems. The ability of LiBr systems to utilize waste heat from industrial processes offers substantial operational cost savings, further enhancing market appeal.

However, the market faces several challenges. The high initial capital investment compared to conventional cooling systems remains a significant barrier to widespread adoption. Additionally, concerns regarding solution breakdown and crystallization issues in LiBr systems have impacted market confidence, necessitating advanced mitigation strategies and best practices.

Market trends indicate a growing preference for modular and compact LiBr systems that offer easier installation and maintenance. There is also increasing demand for hybrid systems that combine absorption cooling with conventional technologies to optimize performance across varying load conditions. The integration of smart monitoring systems to predict and prevent solution breakdowns represents an emerging opportunity segment with substantial growth potential.

The competitive landscape features established players like Carrier Corporation, Trane Technologies, and Johnson Controls dominating with approximately 45% combined market share, alongside emerging regional manufacturers particularly from China and South Korea who are rapidly gaining ground through cost-competitive offerings and technological innovations.

Asia-Pacific currently dominates the market, accounting for over 40% of the global share, with China and Japan leading in both production and consumption. This regional dominance is attributed to rapid industrialization, supportive government policies promoting green technologies, and increasing adoption in commercial buildings. North America and Europe follow with market shares of 25% and 22% respectively, where the focus is primarily on sustainable cooling solutions for commercial and industrial applications.

The industrial sector represents the largest end-user segment, constituting approximately 35% of the market. This is followed by commercial buildings (30%), healthcare facilities (15%), and other applications including data centers and educational institutions (20%). The growing emphasis on reducing carbon footprints in industrial processes has significantly boosted the adoption of LiBr absorption systems, particularly in chemical processing, food and beverage, and pharmaceutical industries.

Key market drivers include stringent environmental regulations limiting the use of conventional refrigerants, rising energy costs prompting the search for more efficient cooling technologies, and increasing integration with renewable energy sources such as solar thermal systems. The ability of LiBr systems to utilize waste heat from industrial processes offers substantial operational cost savings, further enhancing market appeal.

However, the market faces several challenges. The high initial capital investment compared to conventional cooling systems remains a significant barrier to widespread adoption. Additionally, concerns regarding solution breakdown and crystallization issues in LiBr systems have impacted market confidence, necessitating advanced mitigation strategies and best practices.

Market trends indicate a growing preference for modular and compact LiBr systems that offer easier installation and maintenance. There is also increasing demand for hybrid systems that combine absorption cooling with conventional technologies to optimize performance across varying load conditions. The integration of smart monitoring systems to predict and prevent solution breakdowns represents an emerging opportunity segment with substantial growth potential.

The competitive landscape features established players like Carrier Corporation, Trane Technologies, and Johnson Controls dominating with approximately 45% combined market share, alongside emerging regional manufacturers particularly from China and South Korea who are rapidly gaining ground through cost-competitive offerings and technological innovations.

Current Challenges in LiBr Solution Stability

Lithium bromide (LiBr) absorption refrigeration systems face significant operational challenges related to solution stability. The primary concern is crystallization, which occurs when LiBr concentration exceeds solubility limits, typically during low evaporator temperatures or high condenser temperatures. This phenomenon can block flow passages, damage components, and cause system failure, requiring costly maintenance interventions and operational downtime.

Corrosion presents another major challenge, as LiBr solutions are inherently corrosive to many common system materials, particularly at elevated temperatures and concentrations. This corrosivity is exacerbated by the presence of oxygen, which accelerates degradation of metal components through electrochemical reactions. The resulting corrosion products not only compromise structural integrity but also contaminate the solution, further destabilizing its performance characteristics.

Solution degradation through thermal decomposition occurs when LiBr solutions are exposed to high temperatures for extended periods. This leads to the formation of hydrogen bromide (HBr) and other byproducts that alter solution properties and increase corrosivity. The degradation process is often self-accelerating, as decomposition products further catalyze additional breakdown reactions.

Air infiltration into the vacuum environment of absorption systems introduces non-condensable gases that impede heat and mass transfer processes. These gases accumulate at heat exchange surfaces, creating additional thermal resistance and reducing system efficiency. Moreover, oxygen introduced through air leaks accelerates corrosion processes and solution degradation.

Contamination from external sources or internal corrosion products represents another significant stability challenge. Particulate matter, oils, and other impurities can alter solution properties, promote crystallization, and foul heat transfer surfaces. These contaminants often concentrate at specific system locations, creating localized instability zones that can trigger broader system failures.

The industry also faces challenges with solution concentration control. Maintaining optimal LiBr concentration is difficult during variable load conditions or during system startup and shutdown sequences. Concentration fluctuations can lead to crystallization events or reduced absorption efficiency, compromising overall system performance.

Temperature stratification within solution reservoirs creates zones of varying concentration, potentially leading to localized crystallization even when average solution parameters appear within safe operating ranges. This phenomenon is particularly problematic in large-scale industrial systems where solution volumes are substantial and mixing may be inadequate.

These challenges collectively impact system reliability, efficiency, and operational lifespan, making solution stability management a critical aspect of LiBr absorption system design and operation. The interdependent nature of these issues often requires comprehensive mitigation strategies rather than isolated interventions.

Corrosion presents another major challenge, as LiBr solutions are inherently corrosive to many common system materials, particularly at elevated temperatures and concentrations. This corrosivity is exacerbated by the presence of oxygen, which accelerates degradation of metal components through electrochemical reactions. The resulting corrosion products not only compromise structural integrity but also contaminate the solution, further destabilizing its performance characteristics.

Solution degradation through thermal decomposition occurs when LiBr solutions are exposed to high temperatures for extended periods. This leads to the formation of hydrogen bromide (HBr) and other byproducts that alter solution properties and increase corrosivity. The degradation process is often self-accelerating, as decomposition products further catalyze additional breakdown reactions.

Air infiltration into the vacuum environment of absorption systems introduces non-condensable gases that impede heat and mass transfer processes. These gases accumulate at heat exchange surfaces, creating additional thermal resistance and reducing system efficiency. Moreover, oxygen introduced through air leaks accelerates corrosion processes and solution degradation.

Contamination from external sources or internal corrosion products represents another significant stability challenge. Particulate matter, oils, and other impurities can alter solution properties, promote crystallization, and foul heat transfer surfaces. These contaminants often concentrate at specific system locations, creating localized instability zones that can trigger broader system failures.

The industry also faces challenges with solution concentration control. Maintaining optimal LiBr concentration is difficult during variable load conditions or during system startup and shutdown sequences. Concentration fluctuations can lead to crystallization events or reduced absorption efficiency, compromising overall system performance.

Temperature stratification within solution reservoirs creates zones of varying concentration, potentially leading to localized crystallization even when average solution parameters appear within safe operating ranges. This phenomenon is particularly problematic in large-scale industrial systems where solution volumes are substantial and mixing may be inadequate.

These challenges collectively impact system reliability, efficiency, and operational lifespan, making solution stability management a critical aspect of LiBr absorption system design and operation. The interdependent nature of these issues often requires comprehensive mitigation strategies rather than isolated interventions.

Established Mitigation Strategies for LiBr Solution Breakdown

01 Addition of corrosion inhibitors

Corrosion inhibitors can be added to lithium bromide solutions to prevent breakdown. These compounds form protective films on metal surfaces, reducing the corrosive effects of the solution. Common inhibitors include molybdates, nitrates, and organic compounds that can effectively protect absorption refrigeration systems using lithium bromide as the working fluid.- Addition of corrosion inhibitors to lithium bromide solutions: Corrosion inhibitors can be added to lithium bromide solutions to prevent breakdown and extend the lifespan of absorption refrigeration systems. These inhibitors form protective films on metal surfaces, reducing corrosion rates and preventing the degradation of the lithium bromide solution. Common corrosion inhibitors include molybdate compounds, nitrates, and organic inhibitors that can effectively protect various metal components in the system.

- Purification and filtration systems for lithium bromide solutions: Implementing purification and filtration systems helps remove impurities and contaminants that can accelerate the breakdown of lithium bromide solutions. These systems typically include mechanical filters, ion exchange resins, and chemical treatment processes to remove suspended solids, metal ions, and other harmful substances. Regular purification maintains the solution quality and prevents crystallization and corrosion issues in absorption refrigeration equipment.

- pH control and stabilization methods: Maintaining optimal pH levels in lithium bromide solutions is crucial for preventing breakdown. pH control methods include adding alkaline compounds like lithium hydroxide or buffering agents to neutralize acidic components that form during operation. Stabilizing the pH within the recommended range (typically 7.5-9.5) helps prevent corrosion of system components and extends the service life of the absorption refrigeration system.

- Degassing and oxygen removal techniques: Removing dissolved gases, particularly oxygen, from lithium bromide solutions is essential for preventing oxidation and breakdown. Degassing techniques include vacuum treatment, thermal deaeration, and chemical oxygen scavengers. These methods reduce the oxygen content in the solution, minimizing oxidation reactions that can lead to corrosion and degradation of the lithium bromide solution in absorption refrigeration systems.

- Advanced system design and monitoring for solution stability: Innovative system designs and continuous monitoring help maintain lithium bromide solution stability. These include heat exchangers with corrosion-resistant materials, solution distribution systems that prevent concentration gradients, and real-time monitoring of solution parameters such as concentration, temperature, and pH. Advanced control systems can automatically adjust operating conditions to prevent crystallization and maintain optimal solution properties throughout the system lifecycle.

02 pH control and buffering agents

Maintaining optimal pH levels in lithium bromide solutions is crucial for preventing breakdown. Buffering agents can be added to stabilize the pH within a desired range, typically slightly alkaline, which minimizes corrosion and solution degradation. These agents help neutralize acids formed during operation and maintain the solution's stability over extended periods.Expand Specific Solutions03 Oxygen removal systems

Dissolved oxygen in lithium bromide solutions accelerates corrosion and solution breakdown. Implementing oxygen removal systems, such as vacuum deaerators or chemical oxygen scavengers, can significantly extend the solution's lifespan. These systems reduce oxidation reactions that lead to the formation of corrosive compounds and precipitates in the solution.Expand Specific Solutions04 Heat exchanger design improvements

Specialized heat exchanger designs can minimize lithium bromide solution breakdown. Features such as enhanced surface treatments, optimized flow patterns, and materials selection reduce localized heating and concentration gradients that contribute to solution degradation. These design improvements help maintain uniform temperature distribution and prevent crystallization issues.Expand Specific Solutions05 Filtration and purification systems

Continuous filtration and purification systems can remove contaminants and breakdown products from lithium bromide solutions. These systems typically include mechanical filters, ion exchange resins, or activated carbon beds that trap impurities that would otherwise accelerate solution degradation. Regular purification extends solution life and maintains optimal system performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions in LiBr Technology

The lithium bromide solution breakdown mitigation market is currently in a growth phase, with increasing demand driven by the expanding HVAC and refrigeration sectors. The market size is estimated to be around $2-3 billion globally, with projected annual growth of 5-7%. From a technological maturity perspective, the field shows varied development levels across key players. Industry leaders like Samsung Electronics and Albemarle Corp. have established advanced prevention technologies, while specialized companies such as Bromine Compounds Ltd. and Global Graphene Group are developing innovative stabilization methods. Academic institutions including Oregon State University and Central South University are contributing fundamental research on corrosion inhibition mechanisms. The competitive landscape features both chemical manufacturing giants and specialized solution providers, with increasing focus on environmentally sustainable approaches to lithium bromide stabilization.

Albemarle Corp.

Technical Solution: Albemarle has developed advanced stabilization techniques for lithium bromide (LiBr) solutions used in absorption refrigeration systems. Their approach combines chemical inhibitors with proprietary corrosion-resistant materials to prevent solution breakdown. The company's multi-layered protection system includes: (1) Specialized metal passivation agents that form protective films on heat exchanger surfaces, (2) Oxygen scavengers that remove dissolved oxygen to prevent oxidative degradation, (3) pH buffering compounds that maintain optimal alkalinity levels between 10.5-11.5, and (4) Advanced filtration systems that continuously remove particulates and contaminants. Albemarle's technology also incorporates real-time monitoring with proprietary sensors that detect early signs of solution degradation, allowing for preventive maintenance before system failure occurs. Their solutions have demonstrated up to 40% longer service life in industrial absorption chillers compared to untreated systems.

Strengths: Comprehensive approach addressing multiple breakdown mechanisms simultaneously; proprietary inhibitor formulations with proven field performance; integrated monitoring capabilities for predictive maintenance. Weaknesses: Higher initial implementation cost compared to basic treatments; requires periodic replenishment of inhibitor chemicals; may necessitate specialized training for maintenance personnel.

Bromine Compounds Ltd.

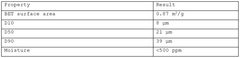

Technical Solution: Bromine Compounds Ltd. has pioneered a stabilization technology specifically designed for high-concentration lithium bromide solutions used in absorption refrigeration systems. Their approach centers on a proprietary "BromShield" additive package that addresses the primary causes of LiBr solution breakdown. The technology incorporates lithium chromate and lithium molybdate as primary corrosion inhibitors, working synergistically with organic stabilizers to form protective films on metal surfaces. Their solution maintains critical parameters within narrow ranges: pH between 10.8-11.2, oxygen content below 10 ppb, and iron concentration under 5 ppm. The company has developed specialized degassing procedures that remove non-condensable gases that can impair heat transfer efficiency. Additionally, their patented regeneration process can restore degraded LiBr solutions in-situ, extending solution life by up to 300% compared to untreated systems while maintaining absorption efficiency above 95%.

Strengths: Specialized expertise in bromine chemistry; comprehensive solution addressing multiple breakdown mechanisms; proven track record in industrial refrigeration applications; in-situ regeneration capability reduces downtime. Weaknesses: Reliance on chromate compounds raises environmental concerns in some regions; requires specialized handling procedures; higher initial cost compared to basic treatment options.

Critical Patents and Innovations in LiBr Solution Stabilization

Operating medium for an absorption refrigeration device

PatentWO2011069822A1

Innovation

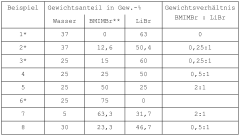

- A working medium comprising 5 to 30% water and 65 to 95% lithium bromide with an ionic liquid, where the lithium bromide to ionic liquid weight ratio ranges from 0.5:1 to 5:1, reducing friction and preventing crystallization, and optionally including corrosion inhibitors and wetting promoters.

Preparation of lithium bromide and li-argyrodite

PatentWO2025079070A1

Innovation

- A modified synthesis process for anhydrous lithium bromide involves converting an aqueous suspension of lithium carbonate with hydrobromic acid, followed by gas-stripping to remove residual carbon dioxide, neutralizing the acidic solution with lithium hydroxide, and recovering the anhydrous lithium bromide from the resulting brine.

Environmental Impact and Sustainability Considerations

The environmental implications of lithium bromide (LiBr) solution management extend far beyond operational efficiency concerns. When LiBr solutions break down or require replacement, they pose significant environmental hazards if improperly handled. The high salt content and potential corrosive properties can damage aquatic ecosystems and contaminate soil when discharged without adequate treatment. Regulatory frameworks worldwide increasingly mandate proper disposal protocols for such industrial chemicals, with penalties for non-compliance becoming more stringent.

Sustainable management practices for LiBr solutions represent a growing priority in absorption refrigeration systems. Implementing closed-loop recycling systems can significantly reduce the environmental footprint by recovering and purifying spent solutions rather than disposing of them. Advanced filtration technologies now enable the removal of contaminants while preserving the valuable lithium bromide, extending solution life cycles by up to 300% compared to traditional replacement schedules.

Energy consumption considerations also factor prominently in environmental assessments. Properly maintained LiBr solutions operate at optimal efficiency, reducing the overall energy demands of absorption refrigeration systems. This efficiency translates directly to reduced carbon emissions, particularly important as many facilities transition toward renewable energy sources. Calculations indicate that preventing premature LiBr breakdowns can reduce associated carbon emissions by 15-20% over system lifetimes.

Water conservation represents another critical sustainability dimension. Modern LiBr solution management systems incorporate water recovery mechanisms that minimize consumption during purification and reconditioning processes. These systems can reclaim up to 85% of water used in maintenance procedures, addressing growing concerns about industrial water usage in water-stressed regions.

The manufacturing footprint of LiBr solutions must also be considered in comprehensive sustainability assessments. Lithium extraction has significant environmental impacts, including water depletion and habitat disruption in source regions. Extending solution lifespans through proper maintenance directly reduces demand for new production, creating a multiplier effect in environmental benefit throughout the supply chain.

Life cycle assessment (LCA) methodologies increasingly incorporate LiBr solution management as a key factor in evaluating absorption refrigeration systems. These assessments reveal that proper maintenance protocols can reduce the overall environmental impact by 25-30% compared to systems with frequent solution replacements. This holistic approach considers impacts from raw material extraction through operational life to ultimate disposal.

Sustainable management practices for LiBr solutions represent a growing priority in absorption refrigeration systems. Implementing closed-loop recycling systems can significantly reduce the environmental footprint by recovering and purifying spent solutions rather than disposing of them. Advanced filtration technologies now enable the removal of contaminants while preserving the valuable lithium bromide, extending solution life cycles by up to 300% compared to traditional replacement schedules.

Energy consumption considerations also factor prominently in environmental assessments. Properly maintained LiBr solutions operate at optimal efficiency, reducing the overall energy demands of absorption refrigeration systems. This efficiency translates directly to reduced carbon emissions, particularly important as many facilities transition toward renewable energy sources. Calculations indicate that preventing premature LiBr breakdowns can reduce associated carbon emissions by 15-20% over system lifetimes.

Water conservation represents another critical sustainability dimension. Modern LiBr solution management systems incorporate water recovery mechanisms that minimize consumption during purification and reconditioning processes. These systems can reclaim up to 85% of water used in maintenance procedures, addressing growing concerns about industrial water usage in water-stressed regions.

The manufacturing footprint of LiBr solutions must also be considered in comprehensive sustainability assessments. Lithium extraction has significant environmental impacts, including water depletion and habitat disruption in source regions. Extending solution lifespans through proper maintenance directly reduces demand for new production, creating a multiplier effect in environmental benefit throughout the supply chain.

Life cycle assessment (LCA) methodologies increasingly incorporate LiBr solution management as a key factor in evaluating absorption refrigeration systems. These assessments reveal that proper maintenance protocols can reduce the overall environmental impact by 25-30% compared to systems with frequent solution replacements. This holistic approach considers impacts from raw material extraction through operational life to ultimate disposal.

Safety Protocols and Risk Management for LiBr Systems

Safety protocols for Lithium Bromide (LiBr) systems are critical due to the corrosive and potentially hazardous nature of LiBr solutions. Comprehensive risk management begins with proper handling procedures, including mandatory use of personal protective equipment such as chemical-resistant gloves, safety goggles, and appropriate clothing to prevent skin contact and inhalation of vapors. Regular training sessions should be conducted to ensure all personnel understand the risks associated with LiBr and can respond appropriately to emergencies.

System design considerations play a vital role in risk mitigation. Installations should incorporate secondary containment systems to capture potential leaks, preventing environmental contamination and reducing workplace hazards. Proper ventilation systems are essential to disperse any hydrogen gas that may form during system operation, particularly when LiBr solutions come into contact with metals under certain conditions.

Monitoring protocols represent another crucial aspect of LiBr system safety. Regular inspection schedules should be established to check for signs of corrosion, leakage, or solution degradation. Automated monitoring systems with appropriate sensors can provide real-time data on solution concentration, pH levels, and system pressure, enabling early detection of potential breakdown conditions before they escalate into safety incidents.

Emergency response planning must be comprehensive and well-documented. This includes clear procedures for handling spills, exposure incidents, and system failures. Neutralization agents such as sodium bicarbonate should be readily available for LiBr spill containment. Emergency eyewash stations and safety showers must be installed in proximity to LiBr handling areas, with clear signage and unobstructed access.

Maintenance protocols should incorporate safety considerations, including system depressurization procedures, solution handling guidelines, and proper disposal methods for spent LiBr solutions. Scheduled preventive maintenance helps identify potential failure points before they lead to catastrophic breakdowns or safety incidents.

Documentation and compliance requirements form the foundation of effective risk management. Material Safety Data Sheets (MSDS) must be readily accessible to all personnel. Regular safety audits should verify compliance with local regulations and industry standards. Incident reporting systems should be established to document any safety events, enabling continuous improvement of safety protocols through lessons learned analysis.

Cross-functional collaboration between engineering, operations, and safety teams ensures that safety considerations are integrated into all aspects of LiBr system management, from design through decommissioning. This holistic approach to risk management significantly reduces the likelihood of solution breakdowns while minimizing potential impacts when incidents do occur.

System design considerations play a vital role in risk mitigation. Installations should incorporate secondary containment systems to capture potential leaks, preventing environmental contamination and reducing workplace hazards. Proper ventilation systems are essential to disperse any hydrogen gas that may form during system operation, particularly when LiBr solutions come into contact with metals under certain conditions.

Monitoring protocols represent another crucial aspect of LiBr system safety. Regular inspection schedules should be established to check for signs of corrosion, leakage, or solution degradation. Automated monitoring systems with appropriate sensors can provide real-time data on solution concentration, pH levels, and system pressure, enabling early detection of potential breakdown conditions before they escalate into safety incidents.

Emergency response planning must be comprehensive and well-documented. This includes clear procedures for handling spills, exposure incidents, and system failures. Neutralization agents such as sodium bicarbonate should be readily available for LiBr spill containment. Emergency eyewash stations and safety showers must be installed in proximity to LiBr handling areas, with clear signage and unobstructed access.

Maintenance protocols should incorporate safety considerations, including system depressurization procedures, solution handling guidelines, and proper disposal methods for spent LiBr solutions. Scheduled preventive maintenance helps identify potential failure points before they lead to catastrophic breakdowns or safety incidents.

Documentation and compliance requirements form the foundation of effective risk management. Material Safety Data Sheets (MSDS) must be readily accessible to all personnel. Regular safety audits should verify compliance with local regulations and industry standards. Incident reporting systems should be established to document any safety events, enabling continuous improvement of safety protocols through lessons learned analysis.

Cross-functional collaboration between engineering, operations, and safety teams ensures that safety considerations are integrated into all aspects of LiBr system management, from design through decommissioning. This holistic approach to risk management significantly reduces the likelihood of solution breakdowns while minimizing potential impacts when incidents do occur.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!