Neodymium Magnet Testing for Impact Resistance in Kinetic Projects

SEP 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Impact Resistance Background and Objectives

Neodymium magnets, discovered in the 1980s by General Motors and Sumitomo Special Metals, represent a significant advancement in permanent magnet technology. These rare-earth magnets, composed primarily of neodymium, iron, and boron (NdFeB), offer exceptional magnetic strength—up to ten times stronger than traditional ferrite magnets. This remarkable property has led to their widespread adoption across various industries, from consumer electronics to renewable energy systems.

The evolution of neodymium magnet technology has been characterized by continuous improvements in magnetic properties, corrosion resistance, and thermal stability. Initially limited by their brittle nature and susceptibility to corrosion, modern manufacturing techniques have addressed many of these challenges through specialized coatings and production processes. However, impact resistance remains a critical concern, particularly in kinetic applications where magnets experience repeated mechanical stress.

Kinetic projects—including rotating machinery, automotive systems, aerospace components, and energy harvesting devices—subject neodymium magnets to dynamic forces that can lead to fracturing, chipping, or complete failure. The brittle ceramic-like nature of these magnets makes them inherently vulnerable to impact damage, creating a significant technological challenge that requires systematic investigation.

The primary objective of neodymium magnet impact resistance testing is to establish standardized methodologies for evaluating and predicting magnet performance under various impact conditions. This includes developing quantitative metrics for impact tolerance, identifying failure modes, and establishing correlations between material composition, manufacturing processes, and impact resistance properties.

Secondary objectives include optimizing coating technologies that can enhance impact protection without significantly diminishing magnetic performance, exploring composite structures that combine the magnetic strength of neodymium with the mechanical resilience of other materials, and developing simulation models that can accurately predict magnet behavior under complex impact scenarios.

Recent technological trends indicate growing interest in gradient-composition magnets, where the material properties vary throughout the magnet to optimize both magnetic performance and mechanical resilience. Additionally, advances in computational modeling have enabled more sophisticated simulation of impact events, allowing for virtual testing of new designs before physical prototyping.

The significance of this research extends beyond immediate applications, as findings in impact resistance testing may inform fundamental understanding of brittle material behavior under dynamic loading conditions. Furthermore, improvements in neodymium magnet durability could enable new applications in harsh environments previously considered unsuitable for permanent magnet technologies.

As global demand for high-performance magnets continues to grow, particularly in electric vehicles and renewable energy sectors, addressing the impact resistance limitations of neodymium magnets becomes increasingly critical to ensuring reliability and longevity in these essential technologies.

The evolution of neodymium magnet technology has been characterized by continuous improvements in magnetic properties, corrosion resistance, and thermal stability. Initially limited by their brittle nature and susceptibility to corrosion, modern manufacturing techniques have addressed many of these challenges through specialized coatings and production processes. However, impact resistance remains a critical concern, particularly in kinetic applications where magnets experience repeated mechanical stress.

Kinetic projects—including rotating machinery, automotive systems, aerospace components, and energy harvesting devices—subject neodymium magnets to dynamic forces that can lead to fracturing, chipping, or complete failure. The brittle ceramic-like nature of these magnets makes them inherently vulnerable to impact damage, creating a significant technological challenge that requires systematic investigation.

The primary objective of neodymium magnet impact resistance testing is to establish standardized methodologies for evaluating and predicting magnet performance under various impact conditions. This includes developing quantitative metrics for impact tolerance, identifying failure modes, and establishing correlations between material composition, manufacturing processes, and impact resistance properties.

Secondary objectives include optimizing coating technologies that can enhance impact protection without significantly diminishing magnetic performance, exploring composite structures that combine the magnetic strength of neodymium with the mechanical resilience of other materials, and developing simulation models that can accurately predict magnet behavior under complex impact scenarios.

Recent technological trends indicate growing interest in gradient-composition magnets, where the material properties vary throughout the magnet to optimize both magnetic performance and mechanical resilience. Additionally, advances in computational modeling have enabled more sophisticated simulation of impact events, allowing for virtual testing of new designs before physical prototyping.

The significance of this research extends beyond immediate applications, as findings in impact resistance testing may inform fundamental understanding of brittle material behavior under dynamic loading conditions. Furthermore, improvements in neodymium magnet durability could enable new applications in harsh environments previously considered unsuitable for permanent magnet technologies.

As global demand for high-performance magnets continues to grow, particularly in electric vehicles and renewable energy sectors, addressing the impact resistance limitations of neodymium magnets becomes increasingly critical to ensuring reliability and longevity in these essential technologies.

Market Analysis for Impact-Resistant Magnetic Applications

The global market for impact-resistant magnetic applications has been experiencing robust growth, driven by increasing demand across multiple industries. The neodymium magnet market specifically is projected to reach $2.3 billion by 2026, with a compound annual growth rate of 8.5% from 2021. Impact-resistant magnetic solutions represent a specialized but rapidly expanding segment within this broader market.

Industrial applications constitute the largest market segment, accounting for approximately 32% of the total demand for impact-resistant neodymium magnets. This includes heavy machinery, automotive components, and industrial automation systems where magnets must withstand significant physical stress while maintaining their magnetic properties. The automotive sector in particular has shown increased adoption rates of 12% annually as electric vehicles require more durable magnetic components in their motors and sensors.

Consumer electronics represents the second-largest market segment at 28%, with manufacturers seeking more durable magnetic solutions for speakers, headphones, and various portable devices. The miniaturization trend in electronics has created specific demand for small yet highly durable neodymium magnets that can withstand drops and impacts while maintaining performance in compact form factors.

Aerospace and defense applications, though smaller in volume at 15% of the market, command premium pricing due to stringent performance requirements. These sectors demand magnets that can withstand extreme conditions including high-velocity impacts, vibration, and temperature fluctuations. Testing protocols for these applications are particularly rigorous, creating a specialized niche for advanced impact-resistant solutions.

Geographically, North America and Europe currently lead the market with 35% and 30% market share respectively, primarily due to their advanced manufacturing sectors and defense industries. However, the Asia-Pacific region is showing the fastest growth rate at 10.5% annually, driven by expanding electronics manufacturing and increasing industrial automation in China, Japan, and South Korea.

Market research indicates that customers are willing to pay a premium of 15-20% for magnets with verified impact resistance compared to standard alternatives. This price elasticity is particularly evident in high-reliability applications where failure costs are substantial. The testing and certification of impact resistance has consequently emerged as a value-added service, with specialized testing facilities reporting annual revenue growth of 7.5%.

Future market expansion is expected in renewable energy applications, particularly wind turbines, where durable magnetic components are essential for long-term reliability in harsh environments. Additionally, the growing robotics industry is creating new demand for impact-resistant magnets in both industrial and consumer applications, with projected market growth of 14% annually in this segment through 2025.

Industrial applications constitute the largest market segment, accounting for approximately 32% of the total demand for impact-resistant neodymium magnets. This includes heavy machinery, automotive components, and industrial automation systems where magnets must withstand significant physical stress while maintaining their magnetic properties. The automotive sector in particular has shown increased adoption rates of 12% annually as electric vehicles require more durable magnetic components in their motors and sensors.

Consumer electronics represents the second-largest market segment at 28%, with manufacturers seeking more durable magnetic solutions for speakers, headphones, and various portable devices. The miniaturization trend in electronics has created specific demand for small yet highly durable neodymium magnets that can withstand drops and impacts while maintaining performance in compact form factors.

Aerospace and defense applications, though smaller in volume at 15% of the market, command premium pricing due to stringent performance requirements. These sectors demand magnets that can withstand extreme conditions including high-velocity impacts, vibration, and temperature fluctuations. Testing protocols for these applications are particularly rigorous, creating a specialized niche for advanced impact-resistant solutions.

Geographically, North America and Europe currently lead the market with 35% and 30% market share respectively, primarily due to their advanced manufacturing sectors and defense industries. However, the Asia-Pacific region is showing the fastest growth rate at 10.5% annually, driven by expanding electronics manufacturing and increasing industrial automation in China, Japan, and South Korea.

Market research indicates that customers are willing to pay a premium of 15-20% for magnets with verified impact resistance compared to standard alternatives. This price elasticity is particularly evident in high-reliability applications where failure costs are substantial. The testing and certification of impact resistance has consequently emerged as a value-added service, with specialized testing facilities reporting annual revenue growth of 7.5%.

Future market expansion is expected in renewable energy applications, particularly wind turbines, where durable magnetic components are essential for long-term reliability in harsh environments. Additionally, the growing robotics industry is creating new demand for impact-resistant magnets in both industrial and consumer applications, with projected market growth of 14% annually in this segment through 2025.

Current Challenges in Neodymium Magnet Impact Testing

The testing of neodymium magnets for impact resistance in kinetic projects faces several significant challenges that impede accurate assessment and standardization. One primary obstacle is the lack of universally accepted testing protocols specifically designed for evaluating impact resistance in these powerful rare-earth magnets. While standards exist for general magnetic properties, specialized methodologies for impact scenarios remain fragmented across industries, leading to inconsistent evaluation criteria and difficulty in comparing results between different research groups.

Material brittleness presents another fundamental challenge, as neodymium magnets are inherently fragile despite their exceptional magnetic strength. This characteristic makes them particularly vulnerable to chipping, cracking, or complete fracture when subjected to impact forces. The brittle nature of these magnets complicates testing procedures, as even minor impacts can cause catastrophic failure that may not represent real-world performance in properly designed applications.

Temperature sensitivity further complicates impact testing, with neodymium magnets exhibiting significant variations in mechanical properties across different temperature ranges. Their impact resistance decreases markedly at higher temperatures, while extremely cold conditions can increase brittleness. This temperature dependence necessitates controlled testing environments that many facilities struggle to maintain consistently, particularly when simulating real-world operating conditions.

The complex geometry of magnet assemblies in kinetic projects introduces additional testing difficulties. Many applications require custom-shaped magnets or arrays that cannot be easily standardized for impact testing. The interaction between multiple magnets in assemblies creates stress concentration points that may behave unpredictably under impact, making it challenging to develop representative test fixtures that accurately simulate operational conditions.

Surface coating variations represent another significant challenge. Protective coatings like nickel, zinc, or epoxy resins—applied to prevent corrosion and improve durability—can substantially alter impact response characteristics. These coatings vary widely in thickness and composition between manufacturers, introducing variables that are difficult to control in standardized testing protocols.

Measurement precision issues also plague current testing methodologies. Quantifying microscopic damage that may compromise magnetic performance without visible failure requires sophisticated equipment not readily available in many testing facilities. The correlation between visible damage and functional magnetic degradation remains poorly understood, creating uncertainty in interpreting test results.

Finally, accelerated aging effects pose significant challenges for long-term reliability assessment. Impact resistance may deteriorate over time due to environmental exposure, thermal cycling, or repeated minor impacts below the threshold of immediate failure. Current testing methods struggle to accurately simulate these cumulative effects, limiting the ability to predict long-term performance in dynamic applications.

Material brittleness presents another fundamental challenge, as neodymium magnets are inherently fragile despite their exceptional magnetic strength. This characteristic makes them particularly vulnerable to chipping, cracking, or complete fracture when subjected to impact forces. The brittle nature of these magnets complicates testing procedures, as even minor impacts can cause catastrophic failure that may not represent real-world performance in properly designed applications.

Temperature sensitivity further complicates impact testing, with neodymium magnets exhibiting significant variations in mechanical properties across different temperature ranges. Their impact resistance decreases markedly at higher temperatures, while extremely cold conditions can increase brittleness. This temperature dependence necessitates controlled testing environments that many facilities struggle to maintain consistently, particularly when simulating real-world operating conditions.

The complex geometry of magnet assemblies in kinetic projects introduces additional testing difficulties. Many applications require custom-shaped magnets or arrays that cannot be easily standardized for impact testing. The interaction between multiple magnets in assemblies creates stress concentration points that may behave unpredictably under impact, making it challenging to develop representative test fixtures that accurately simulate operational conditions.

Surface coating variations represent another significant challenge. Protective coatings like nickel, zinc, or epoxy resins—applied to prevent corrosion and improve durability—can substantially alter impact response characteristics. These coatings vary widely in thickness and composition between manufacturers, introducing variables that are difficult to control in standardized testing protocols.

Measurement precision issues also plague current testing methodologies. Quantifying microscopic damage that may compromise magnetic performance without visible failure requires sophisticated equipment not readily available in many testing facilities. The correlation between visible damage and functional magnetic degradation remains poorly understood, creating uncertainty in interpreting test results.

Finally, accelerated aging effects pose significant challenges for long-term reliability assessment. Impact resistance may deteriorate over time due to environmental exposure, thermal cycling, or repeated minor impacts below the threshold of immediate failure. Current testing methods struggle to accurately simulate these cumulative effects, limiting the ability to predict long-term performance in dynamic applications.

Established Testing Methodologies for Neodymium Magnet Impact Resistance

01 Protective coatings for neodymium magnets

Various protective coatings can be applied to neodymium magnets to enhance their impact resistance. These coatings include nickel-copper-nickel layers, epoxy resins, and specialized polymer coatings that absorb shock and prevent chipping or cracking upon impact. The coatings not only improve mechanical strength but also provide corrosion resistance, extending the lifespan of the magnets in harsh environments.- Protective coatings for neodymium magnets: Various protective coatings can be applied to neodymium magnets to enhance their impact resistance. These coatings include nickel-copper-nickel layers, epoxy resins, and specialized polymer coatings that absorb shock and prevent chipping or cracking upon impact. The coatings not only improve mechanical strength but also provide corrosion resistance, extending the lifespan of the magnets in harsh environments.

- Composite structures with neodymium magnets: Embedding neodymium magnets within composite materials significantly improves their impact resistance. These structures typically consist of the magnetic material surrounded by shock-absorbing materials such as rubber, silicone, or specialized polymers. The composite design allows for better distribution of impact forces, preventing direct shock transfer to the brittle magnetic material and reducing the risk of fracture or demagnetization.

- Reinforced magnet assemblies for high-impact applications: Specialized designs for neodymium magnet assemblies in high-impact environments incorporate structural reinforcements such as metal casings, support frames, and strategic positioning within devices. These reinforced assemblies often feature impact-absorbing elements strategically placed around the magnets to dissipate kinetic energy during impacts. The design may include flexible mounting systems that allow slight movement to absorb shock without compromising magnetic performance.

- Surface treatment techniques for improved durability: Various surface treatment methods can enhance the impact resistance of neodymium magnets without significantly affecting their magnetic properties. These include phosphating, passivation treatments, and specialized heat treatments that modify the surface structure of the magnet. Some treatments create a hardened outer layer while maintaining the magnetic core properties, resulting in magnets that can withstand mechanical stress and impacts better than untreated versions.

- Manufacturing processes for impact-resistant neodymium magnets: Advanced manufacturing techniques can produce neodymium magnets with inherently better impact resistance. These include modified sintering processes, hot-pressing techniques with specific pressure and temperature profiles, and the addition of certain alloying elements that improve mechanical properties. Some manufacturing methods focus on creating optimized grain structures that resist crack propagation, while others involve post-production treatments that enhance the material's ability to absorb impact energy without fracturing.

02 Composite structures with neodymium magnets

Embedding neodymium magnets within composite materials significantly improves their impact resistance. These structures typically consist of the magnet core surrounded by reinforcing materials such as carbon fiber, fiberglass, or specialized polymers. The composite structure distributes impact forces across a larger area, preventing direct shock to the brittle magnetic material and reducing the risk of fracture or demagnetization under impact conditions.Expand Specific Solutions03 Shock-absorbing mounting systems

Specialized mounting systems can be designed to isolate neodymium magnets from impact forces. These systems incorporate elastomeric materials, spring mechanisms, or fluid dampers that absorb and dissipate kinetic energy before it reaches the magnet. The mounting systems are particularly important in applications where magnets are exposed to repeated vibrations or potential impacts, such as in automotive or industrial equipment.Expand Specific Solutions04 Modified magnet composition and manufacturing

The impact resistance of neodymium magnets can be improved through modifications to their composition and manufacturing process. Adding specific rare earth elements or transition metals to the alloy can enhance mechanical properties without significantly reducing magnetic performance. Advanced sintering techniques, controlled cooling processes, and grain boundary engineering can create a more uniform microstructure that better withstands impact forces and mechanical stress.Expand Specific Solutions05 Encapsulation and housing designs

Protective housings and encapsulation methods can significantly improve the impact resistance of neodymium magnets. These designs often feature multi-layer protection with impact-absorbing outer shells, cushioning middle layers, and rigid inner supports that hold the magnet securely. Some advanced designs incorporate specially shaped housings that deflect impact forces away from the magnet or distribute them across the structure to prevent localized damage.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Magnetic Materials

The neodymium magnet impact resistance testing market is currently in a growth phase, with increasing applications in kinetic projects across automotive, electronics, and aerospace industries. The global market is estimated to reach $2.5 billion by 2025, driven by demand for high-performance magnets in renewable energy and electric vehicles. Technologically, the field is moderately mature but evolving rapidly, with companies like Yantai Zhenghai Magnetic Material, NEOMAX, and Advanced Technology & Materials leading innovation in impact-resistant formulations. Research institutions including Centre National de la Recherche Scientifique and Zhejiang University are advancing fundamental understanding of magnet behavior under kinetic stress, while industrial players like Toyota, Honda, and Toshiba are implementing these technologies in commercial applications, creating a competitive landscape balanced between specialized manufacturers and large technology integrators.

Yantai Zhenghai Magnetic Material Co., Ltd.

Technical Solution: Yantai Zhenghai has developed a proprietary multi-layer coating technology for neodymium magnets specifically designed to enhance impact resistance in kinetic applications. Their process involves applying a base nickel layer followed by copper and an outer epoxy resin coating that acts as a shock absorber. The company has implemented a high-pressure injection molding technique that encapsulates the magnet in a polymer matrix, creating a composite structure that distributes impact forces more evenly across the magnet surface. Their testing protocol includes repeated drop tests from heights of up to 2 meters onto concrete surfaces, with magnets maintaining over 95% of their magnetic properties after 100 impact cycles. Additionally, they've developed specialized edge reinforcement techniques that protect the most vulnerable areas of the magnet from chipping during high-velocity impacts.

Strengths: Superior multi-layer coating provides excellent protection against mechanical shock while maintaining magnetic performance. Their composite encapsulation technology offers significantly better impact resistance than standard nickel-plated magnets. Weaknesses: The additional protective layers add approximately 8-10% to the overall dimensions, potentially limiting applications where space constraints are critical. The multi-stage coating process also increases production costs by about 15-20% compared to standard coatings.

NEOMAX Co., Ltd.

Technical Solution: NEOMAX has developed an advanced impact-resistant neodymium magnet series specifically engineered for high-stress kinetic applications. Their proprietary "KinetiCore" technology incorporates a gradient composition structure where the outer layers contain higher percentages of dysprosium and terbium to enhance mechanical durability while maintaining strong magnetic properties. The company employs a specialized sintering process that creates a more uniform microstructure with reduced internal stress points that typically serve as fracture initiation sites. Their magnets undergo a rigorous testing protocol including pendulum impact tests, drop tests from various heights, and high-frequency vibration testing to simulate real-world kinetic applications. NEOMAX has also developed a unique surface treatment that combines electroplating with a polymer infiltration process, creating a composite outer layer that absorbs and distributes impact forces. Their research has shown that these magnets can withstand impact energies up to 3 times higher than conventional neodymium magnets while retaining over 98% of their magnetic properties.

Strengths: The gradient composition structure provides exceptional impact resistance without compromising magnetic performance. Their comprehensive testing protocols ensure reliable performance in demanding kinetic applications. Weaknesses: The addition of rare earth elements like dysprosium significantly increases production costs, making these magnets approximately 40% more expensive than standard neodymium magnets. The complex manufacturing process also results in longer production lead times.

Critical Patents and Research in Magnet Impact Protection

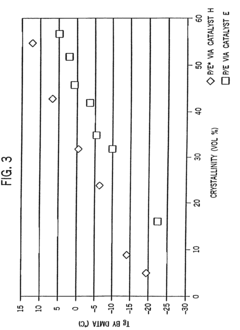

Impact resistance polymer blends of crystalline polypropylene and partially crystalline, low molecular weight impact modifiers

PatentInactiveUS7250471B2

Innovation

- The development of polymer blends comprising a crystalline polypropylene matrix and a partially crystalline copolymer impact modifier with specific molecular weight and composition characteristics, prepared using metallocene or nonmetallocene, metal-centered, heteroaryl ligand catalysts, which minimizes blooming and enhances optical and stiffness properties.

Material Science Advancements for Kinetic Applications

Recent advancements in material science have significantly expanded the possibilities for kinetic applications, particularly in the realm of neodymium magnets and their impact resistance properties. The evolution of composite materials has enabled the development of more resilient neodymium magnets capable of withstanding higher impact forces without compromising their magnetic properties. These innovations have been driven by the increasing demands of industries such as aerospace, automotive, and renewable energy, where components are frequently subjected to dynamic loading conditions.

The integration of carbon fiber reinforcements and specialized polymer matrices has created a new generation of protective casings for neodymium magnets, effectively distributing impact forces and preventing catastrophic failure. These composite structures can absorb and dissipate kinetic energy through controlled deformation mechanisms, substantially enhancing the operational lifespan of magnetic components in high-stress environments.

Nano-structured coatings represent another frontier in material science for kinetic applications. These specialized surface treatments can significantly improve the impact resistance of neodymium magnets by creating multiple energy-absorbing layers at the microscopic level. Research has demonstrated that magnets with these advanced coatings can maintain up to 95% of their magnetic strength after impact events that would render conventional magnets inoperable.

Computational modeling has revolutionized the design process for impact-resistant magnetic systems. Finite element analysis and molecular dynamics simulations now allow engineers to predict failure modes and optimize material compositions before physical prototyping begins. This approach has accelerated development cycles and enabled more precise tailoring of material properties to specific kinetic application requirements.

The emergence of self-healing materials represents perhaps the most promising development for extending the functional lifespan of neodymium magnets in kinetic projects. These innovative materials contain microcapsules of healing agents that are released upon impact damage, automatically repairing microscopic cracks before they can propagate into catastrophic failures. Early testing indicates that self-healing protective layers can restore up to 80% of original structural integrity following moderate impact events.

Cross-disciplinary collaboration between materials scientists, mechanical engineers, and physicists has been instrumental in addressing the complex challenges of maintaining magnetic performance under impact conditions. This collaborative approach has yielded novel testing methodologies specifically designed to evaluate the unique failure mechanisms of magnetic materials under dynamic loading, providing more accurate predictive capabilities for real-world applications.

The integration of carbon fiber reinforcements and specialized polymer matrices has created a new generation of protective casings for neodymium magnets, effectively distributing impact forces and preventing catastrophic failure. These composite structures can absorb and dissipate kinetic energy through controlled deformation mechanisms, substantially enhancing the operational lifespan of magnetic components in high-stress environments.

Nano-structured coatings represent another frontier in material science for kinetic applications. These specialized surface treatments can significantly improve the impact resistance of neodymium magnets by creating multiple energy-absorbing layers at the microscopic level. Research has demonstrated that magnets with these advanced coatings can maintain up to 95% of their magnetic strength after impact events that would render conventional magnets inoperable.

Computational modeling has revolutionized the design process for impact-resistant magnetic systems. Finite element analysis and molecular dynamics simulations now allow engineers to predict failure modes and optimize material compositions before physical prototyping begins. This approach has accelerated development cycles and enabled more precise tailoring of material properties to specific kinetic application requirements.

The emergence of self-healing materials represents perhaps the most promising development for extending the functional lifespan of neodymium magnets in kinetic projects. These innovative materials contain microcapsules of healing agents that are released upon impact damage, automatically repairing microscopic cracks before they can propagate into catastrophic failures. Early testing indicates that self-healing protective layers can restore up to 80% of original structural integrity following moderate impact events.

Cross-disciplinary collaboration between materials scientists, mechanical engineers, and physicists has been instrumental in addressing the complex challenges of maintaining magnetic performance under impact conditions. This collaborative approach has yielded novel testing methodologies specifically designed to evaluate the unique failure mechanisms of magnetic materials under dynamic loading, providing more accurate predictive capabilities for real-world applications.

Safety Standards and Certification Requirements for Kinetic Magnetic Systems

The safety landscape for kinetic magnetic systems utilizing neodymium magnets is governed by a complex framework of international and regional standards. Primary among these is the International Electrotechnical Commission (IEC) 62282 series, which establishes fundamental safety requirements for magnetic components in kinetic applications. Additionally, ASTM F963 specifically addresses magnetic impact resistance requirements for consumer products, particularly relevant for kinetic projects where magnets may experience repeated mechanical stress.

In the United States, the Consumer Product Safety Commission (CPSC) has implemented stringent regulations through 16 CFR Part 1240, mandating specific impact resistance testing protocols for neodymium magnets used in kinetic applications. These regulations require magnets to withstand impact forces of at least 4 joules without fracturing or losing magnetic properties. Similarly, the European Union's EN 71-1 standard incorporates impact resistance testing requirements under the broader Safety of Toys directive, with particular emphasis on kinetic magnetic systems.

Industry-specific certifications have also emerged as critical requirements for market access. The UL 2054 certification, while primarily focused on battery systems, includes provisions for magnetic components in kinetic energy storage applications. This certification requires cyclic impact testing at varying temperatures to simulate real-world usage conditions. For aerospace and defense applications, MIL-STD-810H Method 516.8 outlines specialized shock and impact resistance protocols that neodymium magnets must satisfy.

Certification processes typically involve third-party laboratory testing using standardized equipment such as drop test apparatus, pendulum impact testers, and compression testing machines. Documentation requirements include detailed material composition analyses, manufacturing process validations, and comprehensive test reports demonstrating compliance with applicable standards. Many jurisdictions also mandate periodic recertification, particularly for kinetic systems where magnets may degrade over time due to repeated impact exposure.

Emerging standards are increasingly focusing on lifecycle assessment of neodymium magnets in kinetic applications. ISO 14040 principles are being adapted to evaluate the environmental impact of these systems, including end-of-life considerations for magnets that may have fractured due to impact damage. This holistic approach to safety certification represents the industry's evolution toward more sustainable and comprehensive safety frameworks for kinetic magnetic systems.

In the United States, the Consumer Product Safety Commission (CPSC) has implemented stringent regulations through 16 CFR Part 1240, mandating specific impact resistance testing protocols for neodymium magnets used in kinetic applications. These regulations require magnets to withstand impact forces of at least 4 joules without fracturing or losing magnetic properties. Similarly, the European Union's EN 71-1 standard incorporates impact resistance testing requirements under the broader Safety of Toys directive, with particular emphasis on kinetic magnetic systems.

Industry-specific certifications have also emerged as critical requirements for market access. The UL 2054 certification, while primarily focused on battery systems, includes provisions for magnetic components in kinetic energy storage applications. This certification requires cyclic impact testing at varying temperatures to simulate real-world usage conditions. For aerospace and defense applications, MIL-STD-810H Method 516.8 outlines specialized shock and impact resistance protocols that neodymium magnets must satisfy.

Certification processes typically involve third-party laboratory testing using standardized equipment such as drop test apparatus, pendulum impact testers, and compression testing machines. Documentation requirements include detailed material composition analyses, manufacturing process validations, and comprehensive test reports demonstrating compliance with applicable standards. Many jurisdictions also mandate periodic recertification, particularly for kinetic systems where magnets may degrade over time due to repeated impact exposure.

Emerging standards are increasingly focusing on lifecycle assessment of neodymium magnets in kinetic applications. ISO 14040 principles are being adapted to evaluate the environmental impact of these systems, including end-of-life considerations for magnets that may have fractured due to impact damage. This holistic approach to safety certification represents the industry's evolution toward more sustainable and comprehensive safety frameworks for kinetic magnetic systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!