Open-Source Tools For PID Controller Design And Verification

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

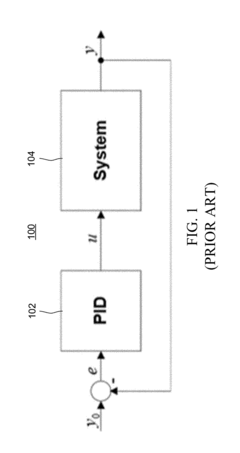

PID Control Evolution and Research Objectives

Proportional-Integral-Derivative (PID) control has evolved significantly since its inception in the early 20th century. Initially developed for ship steering systems by Nicholas Minorsky in 1922, PID controllers have become the most widely implemented control algorithm in industrial applications. Their popularity stems from their relatively simple structure, robust performance across a wide range of operating conditions, and the ability to provide satisfactory control without requiring a precise analytical model of the system.

The evolution of PID control technology has been marked by several key developments. In the 1940s and 1950s, the theoretical foundations were strengthened through frequency domain analysis techniques. The 1970s saw the transition from analog to digital implementations, enabling more sophisticated control strategies. By the 1990s, auto-tuning methods emerged, significantly reducing the expertise required for controller deployment. The 2000s brought advanced adaptive PID algorithms capable of handling nonlinear systems and varying process dynamics.

Despite these advancements, the fundamental challenge in PID control remains finding the optimal balance between response speed, stability, and robustness. This challenge has driven continuous innovation in tuning methodologies and controller structures. Recent trends show increasing integration of PID controllers with artificial intelligence techniques, creating hybrid systems that combine the reliability of traditional PID with the adaptability of machine learning approaches.

Open-source tools for PID controller design have emerged as a critical enabler for both academic research and industrial implementation. These tools democratize access to sophisticated control techniques that were previously available only through expensive proprietary software. The open-source movement in control engineering has accelerated knowledge sharing and collaborative development, leading to rapid improvements in controller design methodologies.

The primary research objectives in this field focus on several interconnected areas. First, evaluating the capabilities and limitations of existing open-source PID design tools compared to commercial alternatives. Second, identifying gaps in current open-source offerings that limit their adoption in industrial settings. Third, exploring how these tools can incorporate recent theoretical advances in control theory while maintaining user accessibility.

Additionally, there is significant interest in developing standardized benchmarking methodologies for PID controller performance verification. Such benchmarks would enable objective comparison between different design approaches and implementation platforms. The research also aims to investigate how open-source tools can better support the entire controller lifecycle, from initial design through deployment to maintenance and optimization.

The ultimate goal is to establish a comprehensive ecosystem of open-source tools that supports state-of-the-art PID controller design and verification across diverse application domains, from traditional industrial processes to emerging fields like robotics, renewable energy systems, and biomedical devices.

The evolution of PID control technology has been marked by several key developments. In the 1940s and 1950s, the theoretical foundations were strengthened through frequency domain analysis techniques. The 1970s saw the transition from analog to digital implementations, enabling more sophisticated control strategies. By the 1990s, auto-tuning methods emerged, significantly reducing the expertise required for controller deployment. The 2000s brought advanced adaptive PID algorithms capable of handling nonlinear systems and varying process dynamics.

Despite these advancements, the fundamental challenge in PID control remains finding the optimal balance between response speed, stability, and robustness. This challenge has driven continuous innovation in tuning methodologies and controller structures. Recent trends show increasing integration of PID controllers with artificial intelligence techniques, creating hybrid systems that combine the reliability of traditional PID with the adaptability of machine learning approaches.

Open-source tools for PID controller design have emerged as a critical enabler for both academic research and industrial implementation. These tools democratize access to sophisticated control techniques that were previously available only through expensive proprietary software. The open-source movement in control engineering has accelerated knowledge sharing and collaborative development, leading to rapid improvements in controller design methodologies.

The primary research objectives in this field focus on several interconnected areas. First, evaluating the capabilities and limitations of existing open-source PID design tools compared to commercial alternatives. Second, identifying gaps in current open-source offerings that limit their adoption in industrial settings. Third, exploring how these tools can incorporate recent theoretical advances in control theory while maintaining user accessibility.

Additionally, there is significant interest in developing standardized benchmarking methodologies for PID controller performance verification. Such benchmarks would enable objective comparison between different design approaches and implementation platforms. The research also aims to investigate how open-source tools can better support the entire controller lifecycle, from initial design through deployment to maintenance and optimization.

The ultimate goal is to establish a comprehensive ecosystem of open-source tools that supports state-of-the-art PID controller design and verification across diverse application domains, from traditional industrial processes to emerging fields like robotics, renewable energy systems, and biomedical devices.

Market Analysis for Open-Source PID Control Solutions

The open-source PID controller tools market has experienced significant growth over the past decade, driven by increasing industrial automation, the rise of IoT applications, and the maker movement. The global industrial automation market, where PID controllers are extensively used, was valued at approximately $191.89 billion in 2021 and is projected to reach $355.44 billion by 2028, with a compound annual growth rate of 9.2%. Within this broader market, open-source control solutions represent a small but rapidly expanding segment.

The demand for open-source PID control tools comes primarily from four key sectors. First, educational institutions seek affordable, transparent solutions for teaching control theory and practical implementation. Second, small and medium-sized manufacturers looking to automate processes without investing in expensive proprietary systems. Third, research institutions requiring customizable control solutions for experimental setups. Fourth, the maker and DIY community developing innovative applications ranging from 3D printers to home automation systems.

Market research indicates that approximately 68% of engineering students and professionals have used or considered using open-source tools for control system design, representing a significant potential user base. The accessibility of these tools has democratized advanced control techniques, previously limited to specialized industrial applications.

Regional analysis shows North America leading the adoption of open-source PID control solutions, accounting for roughly 42% of global usage, followed by Europe at 31% and Asia-Pacific at 22%. The remaining 5% is distributed across other regions. This distribution correlates strongly with regions having robust maker communities and advanced manufacturing sectors.

Customer segmentation reveals distinct needs across different user groups. Academic users prioritize educational value and theoretical foundations, while industrial users focus on reliability, performance, and integration capabilities. The maker community values simplicity, community support, and hardware compatibility.

The economic value proposition of open-source PID tools is compelling. Traditional proprietary control system development environments can cost between $5,000 to $50,000 per license, while open-source alternatives provide comparable functionality at minimal or no direct cost. This represents a potential market disruption value of hundreds of millions of dollars annually.

Growth projections for open-source PID control solutions indicate a 15-20% annual increase in adoption over the next five years, outpacing the broader industrial automation market. This accelerated growth is fueled by increasing awareness, improved documentation, expanding community support, and the continuous enhancement of features and usability in open-source offerings.

The demand for open-source PID control tools comes primarily from four key sectors. First, educational institutions seek affordable, transparent solutions for teaching control theory and practical implementation. Second, small and medium-sized manufacturers looking to automate processes without investing in expensive proprietary systems. Third, research institutions requiring customizable control solutions for experimental setups. Fourth, the maker and DIY community developing innovative applications ranging from 3D printers to home automation systems.

Market research indicates that approximately 68% of engineering students and professionals have used or considered using open-source tools for control system design, representing a significant potential user base. The accessibility of these tools has democratized advanced control techniques, previously limited to specialized industrial applications.

Regional analysis shows North America leading the adoption of open-source PID control solutions, accounting for roughly 42% of global usage, followed by Europe at 31% and Asia-Pacific at 22%. The remaining 5% is distributed across other regions. This distribution correlates strongly with regions having robust maker communities and advanced manufacturing sectors.

Customer segmentation reveals distinct needs across different user groups. Academic users prioritize educational value and theoretical foundations, while industrial users focus on reliability, performance, and integration capabilities. The maker community values simplicity, community support, and hardware compatibility.

The economic value proposition of open-source PID tools is compelling. Traditional proprietary control system development environments can cost between $5,000 to $50,000 per license, while open-source alternatives provide comparable functionality at minimal or no direct cost. This represents a potential market disruption value of hundreds of millions of dollars annually.

Growth projections for open-source PID control solutions indicate a 15-20% annual increase in adoption over the next five years, outpacing the broader industrial automation market. This accelerated growth is fueled by increasing awareness, improved documentation, expanding community support, and the continuous enhancement of features and usability in open-source offerings.

Current Landscape and Challenges in PID Controller Tools

The landscape of open-source tools for PID controller design and verification is characterized by a diverse ecosystem of software solutions, each with varying capabilities and limitations. Currently, MATLAB/Simulink dominates the commercial space, but numerous open-source alternatives have emerged to address specific needs in control system engineering.

Python-based libraries such as Control, SciPy, and PyControl have gained significant traction due to their accessibility and integration with the broader Python ecosystem. These tools offer fundamental PID tuning capabilities but often lack comprehensive verification frameworks and industrial-grade robustness testing features. The Control library provides basic frequency and time domain analysis, while SciPy offers optimization routines that can be adapted for controller tuning.

In the dedicated control system domain, tools like OpenModelica and Scilab/Xcos present more specialized environments. OpenModelica implements the Modelica language standard, enabling component-based modeling of complex systems, while Scilab/Xcos offers a free alternative to MATLAB/Simulink with similar block diagram interfaces. However, these platforms frequently struggle with documentation quality and community support compared to their commercial counterparts.

A significant challenge in the current landscape is the fragmentation of functionality across multiple tools. Engineers often need to combine several applications to complete the full PID design and verification workflow, leading to integration issues and workflow inefficiencies. Data exchange between different platforms remains problematic, with limited standardization of model formats and analysis results.

Real-time simulation capabilities represent another critical limitation. While tools like GNU Octave provide mathematical modeling capabilities, they typically lack robust real-time interfaces for hardware-in-the-loop testing, which is essential for industrial implementation validation. This gap forces many organizations to maintain hybrid toolchains combining open-source design tools with proprietary verification systems.

The user experience of many open-source PID tools presents additional barriers to adoption. Complex installation procedures, dependency management issues, and steep learning curves discourage many potential users, particularly those transitioning from commercial solutions. Interface inconsistencies between tools further complicate the situation, requiring engineers to adapt to multiple paradigms.

Verification and validation capabilities remain underdeveloped in most open-source offerings. While basic simulation is widely available, advanced features like uncertainty analysis, robustness evaluation, and automated test case generation are often missing or rudimentary. This limitation is particularly problematic for safety-critical applications where comprehensive verification is mandatory.

Python-based libraries such as Control, SciPy, and PyControl have gained significant traction due to their accessibility and integration with the broader Python ecosystem. These tools offer fundamental PID tuning capabilities but often lack comprehensive verification frameworks and industrial-grade robustness testing features. The Control library provides basic frequency and time domain analysis, while SciPy offers optimization routines that can be adapted for controller tuning.

In the dedicated control system domain, tools like OpenModelica and Scilab/Xcos present more specialized environments. OpenModelica implements the Modelica language standard, enabling component-based modeling of complex systems, while Scilab/Xcos offers a free alternative to MATLAB/Simulink with similar block diagram interfaces. However, these platforms frequently struggle with documentation quality and community support compared to their commercial counterparts.

A significant challenge in the current landscape is the fragmentation of functionality across multiple tools. Engineers often need to combine several applications to complete the full PID design and verification workflow, leading to integration issues and workflow inefficiencies. Data exchange between different platforms remains problematic, with limited standardization of model formats and analysis results.

Real-time simulation capabilities represent another critical limitation. While tools like GNU Octave provide mathematical modeling capabilities, they typically lack robust real-time interfaces for hardware-in-the-loop testing, which is essential for industrial implementation validation. This gap forces many organizations to maintain hybrid toolchains combining open-source design tools with proprietary verification systems.

The user experience of many open-source PID tools presents additional barriers to adoption. Complex installation procedures, dependency management issues, and steep learning curves discourage many potential users, particularly those transitioning from commercial solutions. Interface inconsistencies between tools further complicate the situation, requiring engineers to adapt to multiple paradigms.

Verification and validation capabilities remain underdeveloped in most open-source offerings. While basic simulation is widely available, advanced features like uncertainty analysis, robustness evaluation, and automated test case generation are often missing or rudimentary. This limitation is particularly problematic for safety-critical applications where comprehensive verification is mandatory.

Existing Open-Source PID Design and Verification Frameworks

01 Open-source simulation and modeling tools for PID controllers

Various open-source software platforms provide simulation and modeling capabilities for PID controller design. These tools allow engineers to create virtual models of control systems, simulate their behavior under different conditions, and optimize controller parameters before implementation. They typically include graphical interfaces for designing control loops, mathematical modeling functions, and visualization tools for analyzing system responses.- Open-source simulation environments for PID controller design: Various open-source simulation environments are available for designing and testing PID controllers. These tools provide platforms for modeling dynamic systems, implementing control algorithms, and visualizing results. They often include libraries of pre-built components, mathematical solvers, and graphical interfaces that allow engineers to design, tune, and verify PID controllers before implementation in physical systems.

- PID controller auto-tuning and optimization tools: Open-source tools for automatic tuning and optimization of PID controllers help engineers determine optimal control parameters. These tools implement various tuning methods such as Ziegler-Nichols, Cohen-Coon, and relay feedback techniques. They can analyze system responses, calculate appropriate PID gains, and optimize controller performance based on specified criteria like settling time, overshoot, and steady-state error.

- Hardware-in-the-loop testing frameworks for PID verification: Open-source hardware-in-the-loop (HIL) testing frameworks enable verification of PID controllers with physical components. These tools allow engineers to connect controller software to actual hardware components or simulated physical systems, providing realistic testing environments. They support real-time data acquisition, signal processing, and performance analysis to validate controller behavior under various operating conditions.

- Model-based design tools for PID controller development: Open-source model-based design tools support the development of PID controllers through graphical programming interfaces and code generation capabilities. These tools allow engineers to create block diagrams representing control systems, simulate their behavior, and automatically generate code for implementation. They often include libraries of control components, analysis functions, and verification tools to ensure controller performance meets specifications.

- Real-time monitoring and validation tools for PID controllers: Open-source tools for real-time monitoring and validation of PID controllers provide capabilities for data logging, performance analysis, and visualization during operation. These tools allow engineers to observe controller behavior, identify issues, and make adjustments as needed. They often include features for comparing actual performance against simulated results, detecting anomalies, and generating reports to document controller verification.

02 PID tuning and optimization frameworks

Open-source frameworks specifically designed for tuning and optimizing PID controllers help engineers determine optimal controller parameters. These tools implement various tuning methodologies such as Ziegler-Nichols, Cohen-Coon, and more advanced algorithms including genetic algorithms and particle swarm optimization. They enable automatic parameter adjustment based on system response characteristics and performance criteria like settling time, overshoot, and steady-state error.Expand Specific Solutions03 Real-time verification and testing environments

Open-source environments for real-time verification and testing of PID controllers allow for hardware-in-the-loop testing and validation. These tools provide interfaces to connect simulated controllers with physical systems or emulators, enabling engineers to verify controller performance under realistic conditions. They often include data logging capabilities, performance metrics calculation, and tools for comparing actual system behavior against theoretical models.Expand Specific Solutions04 Educational and learning platforms for PID control

Open-source educational platforms focus on teaching PID control concepts through interactive simulations and exercises. These tools provide simplified interfaces with visual feedback to help students and engineers understand the effects of changing controller parameters. They often include pre-built examples of common control problems, step-by-step tutorials, and documentation explaining theoretical concepts alongside practical implementations.Expand Specific Solutions05 Integration frameworks for PID controllers in larger systems

Open-source integration frameworks enable PID controllers to be incorporated into larger control systems and industrial automation environments. These tools provide standardized interfaces for connecting controllers with sensors, actuators, and other system components. They support various communication protocols, offer middleware for distributed control systems, and include tools for system-wide monitoring and management of multiple controllers operating in coordination.Expand Specific Solutions

Leading Organizations in Open-Source Control Systems

The open-source PID controller tools market is currently in a growth phase, with increasing adoption across industrial automation sectors. The market size is expanding as more industries embrace digital transformation, with an estimated annual growth rate of 5-7%. Technologically, this field shows varying maturity levels, with established players like SUPCON Technology and Samsung Electronics offering sophisticated commercial solutions, while academic institutions including Zhejiang University and Harbin Engineering University drive innovation through research. Companies like Nanjing KEYUAN DRIVE TECHNOLOGY and Sciyon Wisdom Technology are developing specialized implementations for industrial applications. IBM provides enterprise-level frameworks, while smaller firms focus on niche applications. The ecosystem benefits from cross-pollination between academic research and industrial implementation, creating a dynamic competitive landscape balancing commercial interests with open-source collaboration.

SUPCON Technology Co., Ltd.

Technical Solution: SUPCON has developed SuperPID, an open-source industrial-grade PID controller design and verification platform tailored for process control applications. The platform integrates with their distributed control systems while maintaining an open architecture that allows integration with third-party systems. SuperPID features advanced auto-tuning algorithms based on relay feedback and pattern recognition techniques that can identify process dynamics without disrupting normal operations. The tool includes specialized modules for common industrial processes such as temperature, flow, and pressure control with pre-configured templates. SUPCON's solution incorporates real-time performance monitoring and adaptive tuning capabilities that automatically adjust parameters in response to changing process conditions. The verification component includes hardware-in-the-loop testing capabilities and comprehensive simulation tools that model various disturbance scenarios and process nonlinearities.

Strengths: Purpose-built for industrial applications with robust implementation features and integration with existing control systems. The specialized modules for common processes reduce implementation time. Weaknesses: May have a steeper learning curve for users without process control background, and some advanced features may require proprietary hardware.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed TinyControl, an open-source lightweight PID controller framework designed specifically for IoT devices and consumer electronics. The framework is optimized for resource-constrained environments, with minimal memory footprint and efficient computational algorithms. TinyControl includes specialized tuning methods for thermal management systems commonly found in consumer electronics, with particular emphasis on balancing performance with energy efficiency. The toolkit provides cross-platform support across various microcontrollers and operating systems, making it versatile for different product lines. Samsung's solution includes a simulation environment that allows developers to test controller performance under various operating conditions before deployment. The verification tools include automated test suites that validate controller behavior against predefined performance criteria and stability requirements. TinyControl also features over-the-air update capabilities for PID parameters, enabling remote optimization of deployed devices.

Strengths: Highly optimized for resource-constrained environments with minimal computational overhead. The specialized focus on consumer electronics provides ready-to-use solutions for common applications. Weaknesses: May lack some advanced features found in more comprehensive industrial control packages, and optimization for low resource usage might limit complexity of implementable control strategies.

Critical Algorithms and Methods in Modern PID Implementation

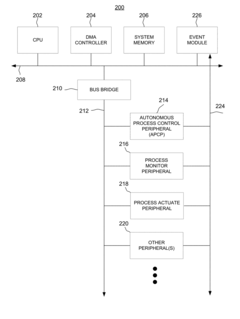

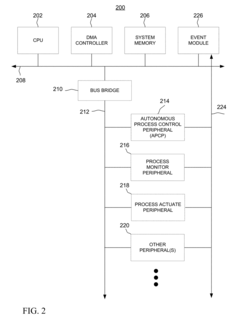

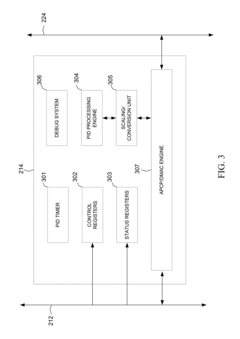

Autonomous process control peripheral

PatentActiveUS20180188699A1

Innovation

- An autonomous process control peripheral (APCP) is implemented in hardware within a microcontroller system, capable of obtaining process variables from a monitor peripheral, updating control variables using a control law, and adjusting the process without CPU intervention, thereby reducing errors and improving system reliability.

Automatic generation of PID parameters for a scanning probe microscope

PatentInactiveUS7987006B2

Innovation

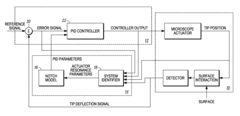

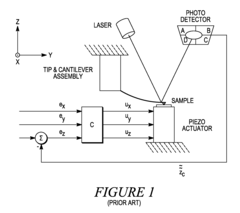

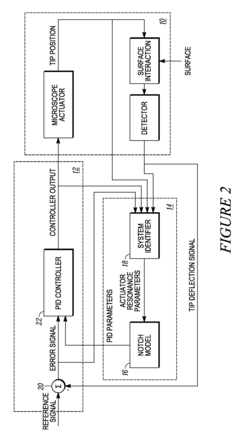

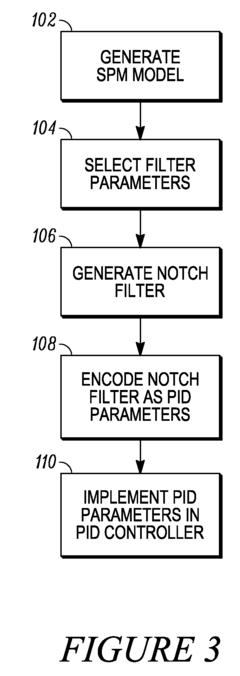

- The implementation of a notch filter-based PID controller design that uses a system identifier to generate PID parameters, allowing for the adjustment of actuator resonance and enabling control at frequencies beyond the main resonant frequency by modeling the dynamics of the SPM and incorporating a notch filter to shape the controller response.

Integration Capabilities with Industrial Automation Systems

The integration of open-source PID controller tools with industrial automation systems represents a critical aspect of modern manufacturing and process control environments. Most open-source PID controller design tools offer various integration capabilities that enable seamless communication with existing industrial automation infrastructure. These integration capabilities typically include support for standard industrial protocols such as Modbus, OPC UA (Open Platform Communications Unified Architecture), PROFINET, and EtherCAT, allowing for real-time data exchange between the PID controllers and other components of the automation system.

Many open-source tools provide API (Application Programming Interface) libraries that facilitate integration with SCADA (Supervisory Control and Data Acquisition) systems, DCS (Distributed Control Systems), and PLC (Programmable Logic Controller) platforms. For instance, tools like OpenPLC and ScadaBR offer built-in interfaces for connecting with industrial hardware and software systems, enabling engineers to implement PID control strategies within broader automation frameworks.

The integration capabilities also extend to data logging and historian systems, which are essential for performance monitoring and analysis. Open-source tools like EtherLab and EPICS (Experimental Physics and Industrial Control System) provide mechanisms for storing controller performance data in standard database formats, facilitating long-term trend analysis and system optimization.

Containerization and virtualization support has emerged as another significant integration feature in modern open-source PID controller tools. Solutions like Docker-based PID controller implementations allow for portable deployment across different industrial computing platforms while maintaining consistent performance characteristics. This approach simplifies the integration of PID control systems into existing IT infrastructure and supports Industry 4.0 initiatives.

Cloud connectivity represents an evolving dimension of integration capabilities. Open-source tools increasingly offer options for secure cloud-based monitoring and parameter adjustment, enabling remote access to PID controllers. Platforms like Node-RED and Eclipse Mosquitto provide MQTT (Message Queuing Telemetry Transport) broker functionality that can connect PID controllers to cloud services while maintaining appropriate security measures for industrial systems.

Interoperability with simulation environments constitutes another valuable integration aspect. Many open-source PID tools can interface with simulation platforms like Modelica, OpenModelica, or Python-based simulation libraries, allowing for virtual commissioning and testing before deployment to physical systems. This capability significantly reduces implementation risks and shortens commissioning time in industrial settings.

Many open-source tools provide API (Application Programming Interface) libraries that facilitate integration with SCADA (Supervisory Control and Data Acquisition) systems, DCS (Distributed Control Systems), and PLC (Programmable Logic Controller) platforms. For instance, tools like OpenPLC and ScadaBR offer built-in interfaces for connecting with industrial hardware and software systems, enabling engineers to implement PID control strategies within broader automation frameworks.

The integration capabilities also extend to data logging and historian systems, which are essential for performance monitoring and analysis. Open-source tools like EtherLab and EPICS (Experimental Physics and Industrial Control System) provide mechanisms for storing controller performance data in standard database formats, facilitating long-term trend analysis and system optimization.

Containerization and virtualization support has emerged as another significant integration feature in modern open-source PID controller tools. Solutions like Docker-based PID controller implementations allow for portable deployment across different industrial computing platforms while maintaining consistent performance characteristics. This approach simplifies the integration of PID control systems into existing IT infrastructure and supports Industry 4.0 initiatives.

Cloud connectivity represents an evolving dimension of integration capabilities. Open-source tools increasingly offer options for secure cloud-based monitoring and parameter adjustment, enabling remote access to PID controllers. Platforms like Node-RED and Eclipse Mosquitto provide MQTT (Message Queuing Telemetry Transport) broker functionality that can connect PID controllers to cloud services while maintaining appropriate security measures for industrial systems.

Interoperability with simulation environments constitutes another valuable integration aspect. Many open-source PID tools can interface with simulation platforms like Modelica, OpenModelica, or Python-based simulation libraries, allowing for virtual commissioning and testing before deployment to physical systems. This capability significantly reduces implementation risks and shortens commissioning time in industrial settings.

Performance Benchmarking Methodologies for PID Controllers

Establishing standardized benchmarking methodologies for PID controllers is essential for objective performance evaluation across different open-source tools. The benchmarking process typically begins with defining key performance metrics that accurately reflect controller effectiveness. These metrics commonly include rise time, settling time, overshoot percentage, steady-state error, and integral performance indices such as IAE (Integral of Absolute Error), ISE (Integral of Squared Error), and ITAE (Integral of Time-weighted Absolute Error). Each metric provides unique insights into controller behavior under different operational conditions.

Test scenarios must be carefully designed to evaluate PID controller performance across various conditions. Standard test signals include step inputs, ramp inputs, sinusoidal inputs, and disturbance rejection tests. More sophisticated benchmarking approaches incorporate robustness tests that introduce parameter variations, noise, and time delays to assess controller stability under uncertain conditions. This multi-scenario testing ensures comprehensive performance evaluation beyond ideal conditions.

Reference systems play a crucial role in benchmarking by providing standardized platforms for comparison. Common reference models include first-order plus dead time (FOPDT) systems, second-order systems, and industry-specific process models. These reference systems allow for consistent evaluation across different PID implementation tools and tuning methods, establishing a common baseline for performance assessment.

Computational efficiency metrics are increasingly important in modern control applications, particularly for embedded systems with limited resources. These metrics include algorithm execution time, memory usage, and CPU load. For real-time applications, deterministic behavior becomes critical, necessitating measurements of worst-case execution time and jitter characteristics of the PID implementation.

Documentation standards for benchmarking results ensure reproducibility and transparency. Comprehensive documentation should include detailed descriptions of the test environment, hardware specifications, software versions, parameter settings, and raw performance data. Many open-source communities have developed standardized reporting templates that facilitate direct comparison between different tools and implementations.

Cross-platform validation represents an advanced benchmarking approach that evaluates PID controller performance across multiple hardware and software environments. This methodology tests the portability and consistency of controller behavior when deployed on different operating systems, microcontrollers, or industrial control systems. Such validation is particularly valuable for open-source tools intended for diverse application environments, ensuring reliable performance regardless of the deployment platform.

Test scenarios must be carefully designed to evaluate PID controller performance across various conditions. Standard test signals include step inputs, ramp inputs, sinusoidal inputs, and disturbance rejection tests. More sophisticated benchmarking approaches incorporate robustness tests that introduce parameter variations, noise, and time delays to assess controller stability under uncertain conditions. This multi-scenario testing ensures comprehensive performance evaluation beyond ideal conditions.

Reference systems play a crucial role in benchmarking by providing standardized platforms for comparison. Common reference models include first-order plus dead time (FOPDT) systems, second-order systems, and industry-specific process models. These reference systems allow for consistent evaluation across different PID implementation tools and tuning methods, establishing a common baseline for performance assessment.

Computational efficiency metrics are increasingly important in modern control applications, particularly for embedded systems with limited resources. These metrics include algorithm execution time, memory usage, and CPU load. For real-time applications, deterministic behavior becomes critical, necessitating measurements of worst-case execution time and jitter characteristics of the PID implementation.

Documentation standards for benchmarking results ensure reproducibility and transparency. Comprehensive documentation should include detailed descriptions of the test environment, hardware specifications, software versions, parameter settings, and raw performance data. Many open-source communities have developed standardized reporting templates that facilitate direct comparison between different tools and implementations.

Cross-platform validation represents an advanced benchmarking approach that evaluates PID controller performance across multiple hardware and software environments. This methodology tests the portability and consistency of controller behavior when deployed on different operating systems, microcontrollers, or industrial control systems. Such validation is particularly valuable for open-source tools intended for diverse application environments, ensuring reliable performance regardless of the deployment platform.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!