Optimization of ICP-MS Detection Using Improved Plasma Control

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ICP-MS Technology Evolution and Objectives

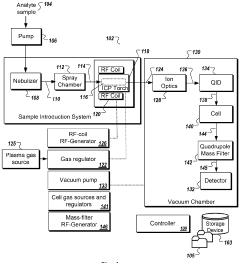

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) has evolved significantly since its commercial introduction in the early 1980s. This analytical technique combines the high-temperature ICP source with a mass spectrometer, enabling precise detection of metals and several non-metals at concentrations as low as one part per trillion. The evolution of ICP-MS technology has been driven by the increasing demand for more sensitive, accurate, and efficient elemental analysis across various industries including environmental monitoring, pharmaceutical research, and materials science.

The initial development of ICP-MS focused on establishing fundamental operational parameters and addressing basic interference issues. Early systems suffered from significant limitations in sensitivity, precision, and susceptibility to matrix effects. Throughout the 1990s, technological advancements led to the introduction of collision/reaction cells, which revolutionized the field by effectively reducing polyatomic interferences that had previously limited analytical capabilities.

The 2000s witnessed the integration of advanced plasma control mechanisms, including improved RF generators and plasma torch designs. These innovations enhanced plasma stability and energy transfer efficiency, resulting in better ionization rates and reduced matrix effects. Concurrently, mass analyzer technology progressed from quadrupole systems to high-resolution magnetic sector instruments and time-of-flight analyzers, each offering distinct advantages for specific analytical applications.

Recent technological developments have concentrated on optimizing plasma control parameters to enhance detection capabilities. Improved plasma control involves precise regulation of plasma temperature, ionization efficiency, and ion extraction dynamics. These advancements have been facilitated by sophisticated software algorithms and hardware innovations that enable real-time adjustments to plasma conditions based on sample characteristics and analytical requirements.

The primary objectives of current ICP-MS technology optimization efforts include reducing detection limits for challenging elements, minimizing spectral interferences, improving sample throughput, and enhancing instrument robustness for complex matrices. Researchers are particularly focused on developing plasma control strategies that can adapt to varying sample compositions without compromising analytical performance.

Looking forward, the trajectory of ICP-MS technology is moving toward more intelligent systems with adaptive plasma control capabilities. These systems aim to automatically optimize operational parameters based on real-time feedback from the analytical process. The integration of machine learning algorithms for plasma optimization represents a promising frontier, potentially enabling unprecedented levels of sensitivity and selectivity while reducing the expertise required for method development.

The ultimate goal of improved plasma control in ICP-MS is to establish a versatile analytical platform capable of handling diverse sample types with minimal method development, while consistently delivering accurate and precise results across the periodic table of elements.

The initial development of ICP-MS focused on establishing fundamental operational parameters and addressing basic interference issues. Early systems suffered from significant limitations in sensitivity, precision, and susceptibility to matrix effects. Throughout the 1990s, technological advancements led to the introduction of collision/reaction cells, which revolutionized the field by effectively reducing polyatomic interferences that had previously limited analytical capabilities.

The 2000s witnessed the integration of advanced plasma control mechanisms, including improved RF generators and plasma torch designs. These innovations enhanced plasma stability and energy transfer efficiency, resulting in better ionization rates and reduced matrix effects. Concurrently, mass analyzer technology progressed from quadrupole systems to high-resolution magnetic sector instruments and time-of-flight analyzers, each offering distinct advantages for specific analytical applications.

Recent technological developments have concentrated on optimizing plasma control parameters to enhance detection capabilities. Improved plasma control involves precise regulation of plasma temperature, ionization efficiency, and ion extraction dynamics. These advancements have been facilitated by sophisticated software algorithms and hardware innovations that enable real-time adjustments to plasma conditions based on sample characteristics and analytical requirements.

The primary objectives of current ICP-MS technology optimization efforts include reducing detection limits for challenging elements, minimizing spectral interferences, improving sample throughput, and enhancing instrument robustness for complex matrices. Researchers are particularly focused on developing plasma control strategies that can adapt to varying sample compositions without compromising analytical performance.

Looking forward, the trajectory of ICP-MS technology is moving toward more intelligent systems with adaptive plasma control capabilities. These systems aim to automatically optimize operational parameters based on real-time feedback from the analytical process. The integration of machine learning algorithms for plasma optimization represents a promising frontier, potentially enabling unprecedented levels of sensitivity and selectivity while reducing the expertise required for method development.

The ultimate goal of improved plasma control in ICP-MS is to establish a versatile analytical platform capable of handling diverse sample types with minimal method development, while consistently delivering accurate and precise results across the periodic table of elements.

Market Applications and Analytical Demands

The ICP-MS (Inductively Coupled Plasma Mass Spectrometry) market has experienced significant growth in recent years, driven by increasing demands across multiple industries requiring precise elemental analysis. The global ICP-MS market was valued at approximately 1.2 billion USD in 2022 and is projected to grow at a compound annual growth rate of 7.8% through 2028, reflecting the expanding applications and analytical needs.

Environmental monitoring represents one of the largest application segments, with regulatory agencies worldwide implementing stricter guidelines for monitoring heavy metals and trace elements in water, soil, and air samples. The detection limits required by these regulations have become increasingly stringent, necessitating more sensitive and reliable analytical techniques like optimized ICP-MS systems.

The pharmaceutical and biotechnology sectors have emerged as rapidly growing markets for advanced ICP-MS technology. These industries require ultra-trace elemental analysis for quality control of raw materials, finished products, and detection of elemental impurities in accordance with USP <232>, <233>, and ICH Q3D guidelines. The demand for validated methods capable of detecting elements at parts-per-trillion levels has intensified the need for improved plasma control in ICP-MS systems.

Food safety testing represents another critical application area with growing demand. Regulatory bodies including the FDA, EFSA, and various national food safety authorities have established maximum allowable limits for toxic elements in food products. This has created substantial demand for high-throughput ICP-MS methods with enhanced sensitivity and reduced interference through optimized plasma conditions.

Clinical diagnostics and biomedical research applications are expanding rapidly, with ICP-MS being increasingly utilized for trace element analysis in biological samples, biomarkers research, and metallomics studies. The clinical laboratory market specifically requires systems with improved plasma stability to handle complex biological matrices while maintaining sensitivity and accuracy.

The semiconductor and electronics manufacturing industry demands ultra-pure materials analysis, where even minute elemental contamination can significantly impact product performance. This sector requires ICP-MS systems with exceptional detection limits and stability, driving innovation in plasma control technologies.

Mining, metallurgy, and materials science applications continue to represent substantial market segments, requiring robust analytical capabilities for ore characterization, process monitoring, and quality control. These applications often involve challenging sample matrices that benefit significantly from improved plasma control techniques.

Academic and research institutions constitute a stable market segment, utilizing ICP-MS for fundamental research across disciplines including geochemistry, environmental science, materials science, and biological systems. These users often pioneer new applications that eventually translate to industrial settings.

Environmental monitoring represents one of the largest application segments, with regulatory agencies worldwide implementing stricter guidelines for monitoring heavy metals and trace elements in water, soil, and air samples. The detection limits required by these regulations have become increasingly stringent, necessitating more sensitive and reliable analytical techniques like optimized ICP-MS systems.

The pharmaceutical and biotechnology sectors have emerged as rapidly growing markets for advanced ICP-MS technology. These industries require ultra-trace elemental analysis for quality control of raw materials, finished products, and detection of elemental impurities in accordance with USP <232>, <233>, and ICH Q3D guidelines. The demand for validated methods capable of detecting elements at parts-per-trillion levels has intensified the need for improved plasma control in ICP-MS systems.

Food safety testing represents another critical application area with growing demand. Regulatory bodies including the FDA, EFSA, and various national food safety authorities have established maximum allowable limits for toxic elements in food products. This has created substantial demand for high-throughput ICP-MS methods with enhanced sensitivity and reduced interference through optimized plasma conditions.

Clinical diagnostics and biomedical research applications are expanding rapidly, with ICP-MS being increasingly utilized for trace element analysis in biological samples, biomarkers research, and metallomics studies. The clinical laboratory market specifically requires systems with improved plasma stability to handle complex biological matrices while maintaining sensitivity and accuracy.

The semiconductor and electronics manufacturing industry demands ultra-pure materials analysis, where even minute elemental contamination can significantly impact product performance. This sector requires ICP-MS systems with exceptional detection limits and stability, driving innovation in plasma control technologies.

Mining, metallurgy, and materials science applications continue to represent substantial market segments, requiring robust analytical capabilities for ore characterization, process monitoring, and quality control. These applications often involve challenging sample matrices that benefit significantly from improved plasma control techniques.

Academic and research institutions constitute a stable market segment, utilizing ICP-MS for fundamental research across disciplines including geochemistry, environmental science, materials science, and biological systems. These users often pioneer new applications that eventually translate to industrial settings.

Current Plasma Control Limitations and Challenges

Despite significant advancements in ICP-MS technology, current plasma control systems face several critical limitations that impede optimal analytical performance. The primary challenge lies in maintaining plasma stability across varying sample matrices. When complex samples are introduced, plasma conditions can fluctuate dramatically, leading to signal drift and compromised detection limits. These fluctuations are particularly problematic when analyzing environmental samples with high dissolved solid content or biological specimens with complex organic matrices.

Temperature gradient control within the plasma represents another significant hurdle. Conventional systems struggle to maintain uniform temperature distribution, resulting in inconsistent ionization efficiency across different elements. This non-uniformity creates systematic biases in multi-element analyses, particularly affecting elements with high ionization potentials such as arsenic and selenium, which require precise plasma conditions for optimal detection.

Power supply instabilities contribute substantially to plasma control limitations. Current RF generators exhibit microsecond-level power fluctuations that, while seemingly minor, can significantly impact the detection of ultra-trace elements. These fluctuations become particularly problematic during extended analytical runs, where cumulative effects manifest as deteriorating precision over time.

Sample introduction systems present additional challenges to plasma stability. Conventional nebulizers and spray chambers create inherently variable aerosol delivery, resulting in plasma perturbations that affect ionization efficiency. This variability becomes especially pronounced when analyzing samples with high viscosity or salt content, where aerosol characteristics change dramatically during analysis.

Interface design limitations further complicate plasma control. The transition zone between atmospheric pressure plasma and the vacuum system creates turbulence and thermal gradients that are difficult to standardize. Current interface configurations struggle to maintain consistent ion extraction efficiency across varying plasma conditions, leading to matrix-dependent transmission biases.

Feedback control mechanisms in existing systems operate at insufficient speeds to compensate for rapid plasma fluctuations. Most commercial instruments employ relatively slow feedback loops that cannot respond to transient plasma disturbances occurring at millisecond timescales. This temporal mismatch between disturbance and correction results in residual instability that affects analytical precision.

Finally, current plasma diagnostic capabilities remain limited. Most systems rely on indirect measurements of plasma conditions rather than real-time, spatially resolved diagnostics. This information gap prevents the implementation of advanced adaptive control strategies that could otherwise compensate for plasma variations. The lack of comprehensive plasma monitoring represents a fundamental barrier to achieving the next generation of detection limits in ICP-MS technology.

Temperature gradient control within the plasma represents another significant hurdle. Conventional systems struggle to maintain uniform temperature distribution, resulting in inconsistent ionization efficiency across different elements. This non-uniformity creates systematic biases in multi-element analyses, particularly affecting elements with high ionization potentials such as arsenic and selenium, which require precise plasma conditions for optimal detection.

Power supply instabilities contribute substantially to plasma control limitations. Current RF generators exhibit microsecond-level power fluctuations that, while seemingly minor, can significantly impact the detection of ultra-trace elements. These fluctuations become particularly problematic during extended analytical runs, where cumulative effects manifest as deteriorating precision over time.

Sample introduction systems present additional challenges to plasma stability. Conventional nebulizers and spray chambers create inherently variable aerosol delivery, resulting in plasma perturbations that affect ionization efficiency. This variability becomes especially pronounced when analyzing samples with high viscosity or salt content, where aerosol characteristics change dramatically during analysis.

Interface design limitations further complicate plasma control. The transition zone between atmospheric pressure plasma and the vacuum system creates turbulence and thermal gradients that are difficult to standardize. Current interface configurations struggle to maintain consistent ion extraction efficiency across varying plasma conditions, leading to matrix-dependent transmission biases.

Feedback control mechanisms in existing systems operate at insufficient speeds to compensate for rapid plasma fluctuations. Most commercial instruments employ relatively slow feedback loops that cannot respond to transient plasma disturbances occurring at millisecond timescales. This temporal mismatch between disturbance and correction results in residual instability that affects analytical precision.

Finally, current plasma diagnostic capabilities remain limited. Most systems rely on indirect measurements of plasma conditions rather than real-time, spatially resolved diagnostics. This information gap prevents the implementation of advanced adaptive control strategies that could otherwise compensate for plasma variations. The lack of comprehensive plasma monitoring represents a fundamental barrier to achieving the next generation of detection limits in ICP-MS technology.

Current Plasma Optimization Methodologies

01 Sample introduction and ionization optimization

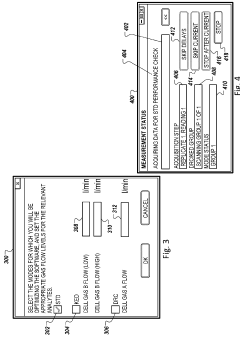

Optimization of sample introduction systems and ionization processes in ICP-MS is crucial for enhancing detection sensitivity and stability. This includes improvements in nebulizer design, spray chamber configurations, and plasma torch parameters to ensure efficient sample atomization and ionization. Advanced techniques focus on minimizing matrix effects and optimizing gas flow rates to achieve consistent ion production across various sample types.- Sample introduction and ionization optimization: Optimization of sample introduction systems and ionization processes in ICP-MS to enhance detection sensitivity and stability. This includes improvements in nebulizer design, spray chamber configurations, and plasma torch parameters to ensure efficient sample atomization and ionization. These optimizations help reduce matrix effects and improve the overall analytical performance of the ICP-MS system.

- Interface and ion optics enhancements: Advancements in the interface region and ion optics of ICP-MS systems to improve ion transmission and reduce interferences. This includes optimized designs for sampling cones, skimmer cones, and ion focusing lenses that enhance ion extraction from the plasma and transmission to the mass analyzer. These improvements lead to better sensitivity, lower detection limits, and reduced background noise.

- Mass analyzer and detector innovations: Innovations in mass analyzer technologies and detector systems for ICP-MS to improve mass resolution, sensitivity, and dynamic range. This includes advancements in quadrupole, time-of-flight, and sector field mass analyzers, as well as improvements in detector electronics and signal processing algorithms. These innovations enable more accurate quantification of trace elements and isotope ratio measurements.

- Interference reduction techniques: Development of methods to reduce or eliminate spectral and non-spectral interferences in ICP-MS analysis. This includes collision/reaction cell technologies, mathematical correction models, and sample preparation strategies to minimize polyatomic interferences, isobaric overlaps, and matrix effects. These techniques improve the accuracy and precision of trace element analysis in complex sample matrices.

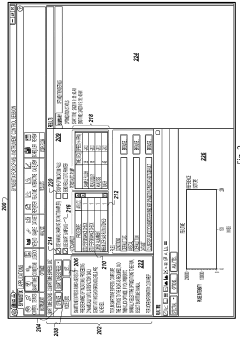

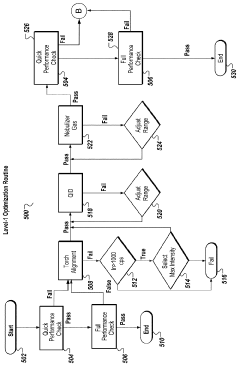

- Automated calibration and quality control systems: Implementation of automated calibration procedures and quality control systems to enhance the reliability and reproducibility of ICP-MS measurements. This includes intelligent software algorithms for instrument tuning, drift correction, and data processing, as well as integrated quality control protocols for method validation and uncertainty estimation. These systems improve laboratory efficiency and ensure consistent analytical performance.

02 Interface and ion optics enhancements

Enhancements to the interface region and ion optics significantly improve ion transmission efficiency in ICP-MS systems. These innovations include optimized cone designs, improved vacuum systems, and advanced ion focusing technologies that reduce signal loss between the plasma and mass analyzer. Such developments help maintain signal integrity while minimizing interferences, leading to better detection limits and analytical precision.Expand Specific Solutions03 Mass analyzer and detector improvements

Advancements in mass analyzer technology and detector systems have substantially enhanced ICP-MS performance. These include high-resolution quadrupole designs, time-of-flight systems, and improved detector electronics that extend dynamic range and reduce background noise. Such improvements allow for better isotope discrimination, lower detection limits, and more accurate quantification across a wider concentration range.Expand Specific Solutions04 Interference reduction techniques

Various techniques have been developed to minimize spectral and non-spectral interferences in ICP-MS analysis. These include collision/reaction cell technologies, mathematical correction models, and specialized sample preparation methods. By effectively reducing polyatomic and isobaric interferences, these approaches improve measurement accuracy for challenging elements and complex matrices, enabling more reliable trace element analysis.Expand Specific Solutions05 Automated calibration and quality control systems

Integration of automated calibration procedures and quality control systems enhances the reliability and efficiency of ICP-MS analysis. These systems include intelligent software for instrument optimization, automated standard preparation, and real-time monitoring of analytical performance. Such advancements reduce operator intervention, minimize systematic errors, and ensure consistent analytical quality across different sample types and concentration ranges.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The ICP-MS detection optimization market is currently in a growth phase, characterized by increasing demand for enhanced plasma control technologies. The market size is expanding due to applications in environmental monitoring, pharmaceuticals, and semiconductor industries. Technologically, the field is moderately mature but experiencing innovation-driven evolution. Leading players include Agilent Technologies and Thermo Fisher Scientific, who dominate with comprehensive solutions, while specialized innovators like Kimia Analytics and Elemental Scientific focus on niche improvements in plasma stability and sample introduction. Academic institutions such as ETH Zurich and EPFL contribute fundamental research, while regional competitors from Asia, including Jiangsu Skyray and Ruilaipu Medical Technology, are gaining market share with cost-effective alternatives, creating a dynamic competitive landscape.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has developed a comprehensive plasma control system for ICP-MS that incorporates advanced RF generator technology with real-time impedance matching. Their Ultra High Matrix Introduction (UHMI) technology allows for dilution of the sample aerosol with argon gas before it enters the plasma, enabling analysis of samples with up to 25% total dissolved solids without manual dilution. The system employs a unique helium collision cell technology (HMI) that effectively removes polyatomic interferences while maintaining sensitivity. Agilent's latest ICP-MS systems feature automated plasma optimization routines that continuously monitor and adjust plasma conditions based on sample composition, ensuring optimal ionization efficiency and signal stability across diverse sample matrices. The integration of their Advanced Temperature Control system maintains consistent plasma temperature regardless of sample load variations, significantly improving long-term analytical precision.

Strengths: Superior matrix tolerance allowing direct analysis of complex samples; excellent interference removal while maintaining sensitivity; automated optimization reduces operator intervention. Weaknesses: Higher initial investment cost compared to some competitors; proprietary consumables may increase operational costs; requires more extensive training for operators to fully utilize advanced features.

Thermo Fisher Scientific (Bremen) GmbH

Technical Solution: Thermo Fisher Scientific has pioneered the Enhanced Sensitivity Interface (ESI) technology for ICP-MS, featuring a unique plasma-sampling interface design that significantly improves ion transmission efficiency. Their proprietary QCell collision/reaction cell technology employs a quadrupole-based design with precise control of kinetic energy discrimination parameters, allowing selective removal of interferences while preserving analyte signals. The company's latest innovation includes the Advanced Plasma Robustness System that incorporates a vertical torch design with digital RF generator providing exceptional plasma stability even for volatile organic solvents. Their plasma control system features dynamic gas blending technology that automatically adjusts nebulizer gas flow, auxiliary gas flow, and RF power based on real-time monitoring of plasma conditions. This approach enables optimization for different sample types without manual recalibration. Thermo Fisher has also developed specialized software algorithms that continuously monitor plasma performance parameters and implement corrective actions to maintain optimal conditions.

Strengths: Exceptional sensitivity and detection limits; superior plasma stability for organic matrices; comprehensive interference management system. Weaknesses: Complex system requires higher level of expertise to operate optimally; higher gas consumption compared to some competing systems; more extensive maintenance requirements for high-performance components.

Key Patents in Plasma Control Technology

Systems and methods for automated optimization of a multi-mode inductively coupled plasma mass spectrometer

PatentActiveCA2938675C

Innovation

- An automated optimization system for multi-mode ICP-MS that allows for 'single click' operation, using a processor and non-transitory computer-readable medium to execute user inputs for automated tuning routines, including performance assessments and dynamic range optimization, to adjust settings such as torch alignment, quadrupole ion deflector calibration, and nebulizer gas flow, ensuring optimal instrument performance across various modes.

Environmental and Safety Considerations

The operation of ICP-MS systems presents several significant environmental and safety considerations that must be addressed through comprehensive protocols and engineering controls. Plasma generation in ICP-MS requires substantial energy input and produces high temperatures (6,000-10,000K), creating potential thermal hazards for operators. Modern systems incorporate multiple safety interlocks and cooling mechanisms to mitigate these risks, including automatic shutdown features that activate when system parameters exceed safe thresholds.

Argon gas consumption represents a notable environmental concern in ICP-MS operations. Conventional systems typically consume 15-20 L/min of argon, contributing to resource depletion and operational costs. Recent advancements in plasma control technology have reduced this consumption by 30-40% through optimized torch designs and improved gas flow management. These innovations not only decrease environmental impact but also enhance operational efficiency and reduce laboratory expenses.

Waste management constitutes another critical environmental consideration. ICP-MS analysis generates liquid waste containing various metals and acids that require proper disposal protocols. Advanced plasma control systems minimize sample consumption, thereby reducing waste generation by up to 25% compared to conventional methods. Additionally, modern sample introduction systems with improved nebulization efficiency further decrease sample requirements and subsequent waste production.

Electromagnetic radiation and UV emissions from the plasma source present potential health hazards to operators. Enhanced shielding designs in current ICP-MS instruments effectively contain these emissions, while improved plasma stability through advanced RF generators reduces the risk of unexpected radiation exposure. Regular monitoring and maintenance protocols are essential to ensure continued effectiveness of these protective measures.

Energy efficiency has become increasingly important in laboratory instrumentation design. Improved plasma control technologies have reduced power consumption by approximately 15-20% through more efficient RF coupling and optimized plasma ignition sequences. These enhancements align with broader sustainability initiatives while simultaneously improving analytical performance through more stable plasma conditions.

Noise pollution, often overlooked in laboratory settings, can cause operator fatigue and potential hearing damage over extended periods. Modern ICP-MS systems incorporate acoustic insulation and redesigned vacuum pumps that reduce operational noise levels by 5-10 decibels compared to earlier generations, creating a more ergonomic and less stressful working environment while maintaining analytical performance.

Argon gas consumption represents a notable environmental concern in ICP-MS operations. Conventional systems typically consume 15-20 L/min of argon, contributing to resource depletion and operational costs. Recent advancements in plasma control technology have reduced this consumption by 30-40% through optimized torch designs and improved gas flow management. These innovations not only decrease environmental impact but also enhance operational efficiency and reduce laboratory expenses.

Waste management constitutes another critical environmental consideration. ICP-MS analysis generates liquid waste containing various metals and acids that require proper disposal protocols. Advanced plasma control systems minimize sample consumption, thereby reducing waste generation by up to 25% compared to conventional methods. Additionally, modern sample introduction systems with improved nebulization efficiency further decrease sample requirements and subsequent waste production.

Electromagnetic radiation and UV emissions from the plasma source present potential health hazards to operators. Enhanced shielding designs in current ICP-MS instruments effectively contain these emissions, while improved plasma stability through advanced RF generators reduces the risk of unexpected radiation exposure. Regular monitoring and maintenance protocols are essential to ensure continued effectiveness of these protective measures.

Energy efficiency has become increasingly important in laboratory instrumentation design. Improved plasma control technologies have reduced power consumption by approximately 15-20% through more efficient RF coupling and optimized plasma ignition sequences. These enhancements align with broader sustainability initiatives while simultaneously improving analytical performance through more stable plasma conditions.

Noise pollution, often overlooked in laboratory settings, can cause operator fatigue and potential hearing damage over extended periods. Modern ICP-MS systems incorporate acoustic insulation and redesigned vacuum pumps that reduce operational noise levels by 5-10 decibels compared to earlier generations, creating a more ergonomic and less stressful working environment while maintaining analytical performance.

Calibration and Quality Assurance Protocols

Calibration and quality assurance protocols form the cornerstone of reliable ICP-MS detection systems with improved plasma control. Establishing robust calibration procedures begins with the selection of appropriate reference materials that match the matrix composition of analytical samples. Multi-element calibration standards with certified concentrations spanning the expected analytical range should be utilized to construct calibration curves with at least five concentration points. For optimal plasma control, these calibration procedures must be performed under standardized plasma conditions, with documented forward power settings, gas flow rates, and torch positions.

Daily performance verification protocols are essential for maintaining analytical integrity. These should include measurements of sensitivity, oxide formation rates, and doubly charged ion ratios using tuning solutions containing elements across the mass range (e.g., Li, Y, Ce, and Tl). Establishing control charts for these parameters enables early detection of plasma instability or instrument drift. Modern ICP-MS systems benefit from automated quality control routines that monitor plasma conditions in real-time, adjusting parameters to maintain optimal performance.

Internal standardization represents a critical quality assurance technique for compensating for matrix effects and signal drift. Elements such as Sc, Y, In, Tb, and Bi, covering different mass ranges, should be added to all samples, blanks, and standards at consistent concentrations. The selection of internal standards should be based on ionization potentials and masses similar to the analytes of interest, ensuring effective correction across the analytical run.

Method validation protocols must include determinations of detection limits, quantification limits, precision, accuracy, and linear dynamic range under the optimized plasma conditions. Certified reference materials that closely match sample matrices should be analyzed regularly to verify method accuracy. For complex matrices, standard addition methods or isotope dilution techniques may be necessary to overcome matrix-induced interferences that persist despite optimized plasma control.

Interlaboratory comparison programs provide external validation of calibration and quality assurance protocols. Participation in proficiency testing schemes specific to ICP-MS applications helps identify systematic biases and validates the effectiveness of plasma optimization strategies. Documentation of all calibration procedures, quality control results, and corrective actions taken when acceptance criteria are not met is essential for regulatory compliance and method defensibility.

Advanced plasma control systems now incorporate automated calibration verification routines that continuously monitor plasma stability parameters and flag deviations from established performance criteria. These systems can implement real-time corrections to plasma conditions, ensuring consistent analytical performance even during extended analytical sequences or when analyzing challenging sample matrices.

Daily performance verification protocols are essential for maintaining analytical integrity. These should include measurements of sensitivity, oxide formation rates, and doubly charged ion ratios using tuning solutions containing elements across the mass range (e.g., Li, Y, Ce, and Tl). Establishing control charts for these parameters enables early detection of plasma instability or instrument drift. Modern ICP-MS systems benefit from automated quality control routines that monitor plasma conditions in real-time, adjusting parameters to maintain optimal performance.

Internal standardization represents a critical quality assurance technique for compensating for matrix effects and signal drift. Elements such as Sc, Y, In, Tb, and Bi, covering different mass ranges, should be added to all samples, blanks, and standards at consistent concentrations. The selection of internal standards should be based on ionization potentials and masses similar to the analytes of interest, ensuring effective correction across the analytical run.

Method validation protocols must include determinations of detection limits, quantification limits, precision, accuracy, and linear dynamic range under the optimized plasma conditions. Certified reference materials that closely match sample matrices should be analyzed regularly to verify method accuracy. For complex matrices, standard addition methods or isotope dilution techniques may be necessary to overcome matrix-induced interferences that persist despite optimized plasma control.

Interlaboratory comparison programs provide external validation of calibration and quality assurance protocols. Participation in proficiency testing schemes specific to ICP-MS applications helps identify systematic biases and validates the effectiveness of plasma optimization strategies. Documentation of all calibration procedures, quality control results, and corrective actions taken when acceptance criteria are not met is essential for regulatory compliance and method defensibility.

Advanced plasma control systems now incorporate automated calibration verification routines that continuously monitor plasma stability parameters and flag deviations from established performance criteria. These systems can implement real-time corrections to plasma conditions, ensuring consistent analytical performance even during extended analytical sequences or when analyzing challenging sample matrices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!