Optimization Of Thermoelectric Generators For Urban Renewable Networks

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Generation Background and Objectives

Thermoelectric generation technology has evolved significantly since its discovery in the early 19th century, based on the Seebeck effect where temperature differences between two dissimilar electrical conductors produce a voltage difference. The development trajectory has moved from basic scientific understanding to practical applications, with notable acceleration in the last two decades due to advancements in material science and increasing focus on renewable energy solutions.

Urban environments present unique opportunities for thermoelectric generation due to abundant waste heat sources including industrial processes, transportation systems, building HVAC systems, and underground infrastructure. These thermal gradients, often overlooked in conventional energy harvesting approaches, represent a significant untapped energy resource that could contribute to urban renewable networks.

The primary objective of optimizing thermoelectric generators (TEGs) for urban renewable networks is to develop highly efficient, cost-effective, and scalable systems that can convert urban waste heat into usable electricity. This involves enhancing the figure of merit (ZT) of thermoelectric materials, improving thermal management systems, and developing innovative integration strategies within existing urban infrastructure.

Current thermoelectric materials typically achieve ZT values between 1-2, limiting conversion efficiency to approximately 5-8%. A key technical goal is to develop materials with ZT values exceeding 3, which could potentially double conversion efficiency and significantly improve economic viability for widespread urban deployment.

The technology evolution trend indicates a shift from traditional bismuth telluride-based materials toward more abundant, environmentally friendly alternatives such as silicides, skutterudites, and organic thermoelectric materials. Concurrently, there is growing interest in flexible and modular TEG designs that can adapt to diverse urban heat sources and spatial constraints.

Integration with smart grid technologies represents another important objective, enabling TEG systems to contribute to grid stability and respond dynamically to urban energy demands. This includes developing advanced power management electronics and predictive algorithms to optimize energy harvesting under fluctuating urban thermal conditions.

Sustainability considerations are increasingly shaping research directions, with emphasis on reducing rare earth element dependency, minimizing environmental impact throughout the lifecycle, and ensuring long-term durability in urban environments characterized by pollution, vibration, and variable weather conditions.

The ultimate goal is to establish thermoelectric generation as a viable component of distributed urban energy systems, complementing other renewable technologies and contributing to urban energy resilience, carbon reduction targets, and circular economy principles through effective waste heat utilization.

Urban environments present unique opportunities for thermoelectric generation due to abundant waste heat sources including industrial processes, transportation systems, building HVAC systems, and underground infrastructure. These thermal gradients, often overlooked in conventional energy harvesting approaches, represent a significant untapped energy resource that could contribute to urban renewable networks.

The primary objective of optimizing thermoelectric generators (TEGs) for urban renewable networks is to develop highly efficient, cost-effective, and scalable systems that can convert urban waste heat into usable electricity. This involves enhancing the figure of merit (ZT) of thermoelectric materials, improving thermal management systems, and developing innovative integration strategies within existing urban infrastructure.

Current thermoelectric materials typically achieve ZT values between 1-2, limiting conversion efficiency to approximately 5-8%. A key technical goal is to develop materials with ZT values exceeding 3, which could potentially double conversion efficiency and significantly improve economic viability for widespread urban deployment.

The technology evolution trend indicates a shift from traditional bismuth telluride-based materials toward more abundant, environmentally friendly alternatives such as silicides, skutterudites, and organic thermoelectric materials. Concurrently, there is growing interest in flexible and modular TEG designs that can adapt to diverse urban heat sources and spatial constraints.

Integration with smart grid technologies represents another important objective, enabling TEG systems to contribute to grid stability and respond dynamically to urban energy demands. This includes developing advanced power management electronics and predictive algorithms to optimize energy harvesting under fluctuating urban thermal conditions.

Sustainability considerations are increasingly shaping research directions, with emphasis on reducing rare earth element dependency, minimizing environmental impact throughout the lifecycle, and ensuring long-term durability in urban environments characterized by pollution, vibration, and variable weather conditions.

The ultimate goal is to establish thermoelectric generation as a viable component of distributed urban energy systems, complementing other renewable technologies and contributing to urban energy resilience, carbon reduction targets, and circular economy principles through effective waste heat utilization.

Urban Energy Market Demand Analysis

The global urban energy market is experiencing a significant shift towards renewable and sustainable energy solutions, creating a fertile ground for thermoelectric generator (TEG) technologies. Current market analysis indicates that urban areas consume approximately 75% of the world's primary energy while generating over 70% of global carbon emissions. This concentration of energy consumption presents both a challenge and an opportunity for TEG implementation in urban renewable networks.

Market research reveals growing demand for decentralized energy generation systems in urban environments, with the global distributed energy generation market projected to reach $573 billion by 2026, growing at a CAGR of 11.8%. Thermoelectric generators, which convert waste heat directly into electricity, are positioned to capture a significant portion of this market due to their ability to operate in diverse urban settings without moving parts, minimal maintenance requirements, and long operational lifespans.

Urban infrastructure presents numerous potential heat sources for TEG applications, including industrial processes, building HVAC systems, transportation networks, and even human-occupied spaces. The waste heat recovery market specifically is expanding at 8.5% annually, indicating strong potential for TEG technologies that can effectively capture and convert this otherwise lost energy resource.

Consumer and municipal demand for energy resilience is another significant market driver. Urban power outages cost businesses billions annually, creating demand for supplementary power generation systems. TEGs integrated into renewable networks can provide critical backup power capabilities while simultaneously improving overall energy efficiency during normal operations.

Policy landscapes are increasingly favorable for TEG adoption. Over 170 countries have established renewable energy targets, with many major urban centers implementing specific policies to reduce carbon emissions and increase renewable energy utilization. Financial incentives, including tax credits, grants, and favorable utility rate structures for distributed generation, further enhance the market potential for optimized TEG systems.

Market segmentation analysis indicates particularly strong growth potential in smart city initiatives, commercial building energy management, industrial waste heat recovery, and urban microgrid development. Each segment presents unique requirements for TEG optimization, from high-temperature industrial applications to lower-temperature building integration scenarios.

The urban energy market also shows increasing willingness to pay premium prices for technologies that offer multiple benefits beyond simple energy generation. TEGs that can simultaneously provide heating, cooling, and electricity generation while reducing carbon footprints command higher market valuations, with consumers demonstrating up to 20% higher willingness to pay for multi-functional energy solutions.

Market research reveals growing demand for decentralized energy generation systems in urban environments, with the global distributed energy generation market projected to reach $573 billion by 2026, growing at a CAGR of 11.8%. Thermoelectric generators, which convert waste heat directly into electricity, are positioned to capture a significant portion of this market due to their ability to operate in diverse urban settings without moving parts, minimal maintenance requirements, and long operational lifespans.

Urban infrastructure presents numerous potential heat sources for TEG applications, including industrial processes, building HVAC systems, transportation networks, and even human-occupied spaces. The waste heat recovery market specifically is expanding at 8.5% annually, indicating strong potential for TEG technologies that can effectively capture and convert this otherwise lost energy resource.

Consumer and municipal demand for energy resilience is another significant market driver. Urban power outages cost businesses billions annually, creating demand for supplementary power generation systems. TEGs integrated into renewable networks can provide critical backup power capabilities while simultaneously improving overall energy efficiency during normal operations.

Policy landscapes are increasingly favorable for TEG adoption. Over 170 countries have established renewable energy targets, with many major urban centers implementing specific policies to reduce carbon emissions and increase renewable energy utilization. Financial incentives, including tax credits, grants, and favorable utility rate structures for distributed generation, further enhance the market potential for optimized TEG systems.

Market segmentation analysis indicates particularly strong growth potential in smart city initiatives, commercial building energy management, industrial waste heat recovery, and urban microgrid development. Each segment presents unique requirements for TEG optimization, from high-temperature industrial applications to lower-temperature building integration scenarios.

The urban energy market also shows increasing willingness to pay premium prices for technologies that offer multiple benefits beyond simple energy generation. TEGs that can simultaneously provide heating, cooling, and electricity generation while reducing carbon footprints command higher market valuations, with consumers demonstrating up to 20% higher willingness to pay for multi-functional energy solutions.

TEG Technology Status and Challenges

Thermoelectric generators (TEGs) have gained significant attention globally as a promising technology for urban renewable energy networks. Currently, TEG technology has reached commercial viability in niche applications but faces substantial challenges for widespread urban implementation. The global market for TEGs was valued at approximately $460 million in 2022, with projections indicating growth to $1.2 billion by 2030, demonstrating increasing interest despite technical limitations.

The fundamental operating principle of TEGs relies on the Seebeck effect, converting temperature differentials directly into electrical energy. Contemporary commercial TEGs typically achieve conversion efficiencies between 5-8%, significantly lower than other renewable technologies like photovoltaics (15-22%) or wind turbines (30-45%). This efficiency limitation represents the primary technical challenge facing widespread TEG adoption in urban environments.

Material constraints constitute another significant barrier. Current state-of-the-art TEGs predominantly utilize bismuth telluride (Bi₂Te₃) for near-ambient temperature applications, which presents sustainability concerns due to tellurium's scarcity. Research into alternative materials such as skutterudites, half-Heusler alloys, and silicides shows promise but remains in early development stages for commercial applications.

Geographically, TEG technology development demonstrates distinct regional characteristics. North America and Europe lead in research innovation, with significant patent activities from institutions like NASA, MIT, and the Fraunhofer Institute. Meanwhile, manufacturing capacity is concentrated in East Asia, particularly Japan, South Korea, and China, creating a global innovation-production ecosystem.

Integration challenges within existing urban infrastructure present additional complications. Current TEG systems often require customized design solutions for specific waste heat sources, limiting standardization and increasing implementation costs. The absence of plug-and-play solutions has restricted adoption to specialized applications rather than widespread urban deployment.

Scalability issues further complicate urban implementation. Laboratory-scale TEG systems have demonstrated promising performance, but maintaining efficiency at larger scales remains problematic. Heat distribution uniformity across larger TEG arrays and effective heat dissipation mechanisms represent unresolved engineering challenges for urban-scale applications.

Regulatory frameworks and standardization also lag behind technological development. Unlike established renewable technologies, TEGs lack comprehensive performance standards and certification processes, creating market uncertainty and hindering investment. This regulatory gap particularly affects urban implementation where safety standards and building codes require clear compliance pathways.

AI and IoT integration represents an emerging opportunity, with smart TEG systems demonstrating 15-30% performance improvements through dynamic load management and predictive maintenance. However, these advanced control systems remain in early adoption phases for urban network applications.

The fundamental operating principle of TEGs relies on the Seebeck effect, converting temperature differentials directly into electrical energy. Contemporary commercial TEGs typically achieve conversion efficiencies between 5-8%, significantly lower than other renewable technologies like photovoltaics (15-22%) or wind turbines (30-45%). This efficiency limitation represents the primary technical challenge facing widespread TEG adoption in urban environments.

Material constraints constitute another significant barrier. Current state-of-the-art TEGs predominantly utilize bismuth telluride (Bi₂Te₃) for near-ambient temperature applications, which presents sustainability concerns due to tellurium's scarcity. Research into alternative materials such as skutterudites, half-Heusler alloys, and silicides shows promise but remains in early development stages for commercial applications.

Geographically, TEG technology development demonstrates distinct regional characteristics. North America and Europe lead in research innovation, with significant patent activities from institutions like NASA, MIT, and the Fraunhofer Institute. Meanwhile, manufacturing capacity is concentrated in East Asia, particularly Japan, South Korea, and China, creating a global innovation-production ecosystem.

Integration challenges within existing urban infrastructure present additional complications. Current TEG systems often require customized design solutions for specific waste heat sources, limiting standardization and increasing implementation costs. The absence of plug-and-play solutions has restricted adoption to specialized applications rather than widespread urban deployment.

Scalability issues further complicate urban implementation. Laboratory-scale TEG systems have demonstrated promising performance, but maintaining efficiency at larger scales remains problematic. Heat distribution uniformity across larger TEG arrays and effective heat dissipation mechanisms represent unresolved engineering challenges for urban-scale applications.

Regulatory frameworks and standardization also lag behind technological development. Unlike established renewable technologies, TEGs lack comprehensive performance standards and certification processes, creating market uncertainty and hindering investment. This regulatory gap particularly affects urban implementation where safety standards and building codes require clear compliance pathways.

AI and IoT integration represents an emerging opportunity, with smart TEG systems demonstrating 15-30% performance improvements through dynamic load management and predictive maintenance. However, these advanced control systems remain in early adoption phases for urban network applications.

Current Urban TEG Implementation Solutions

01 Material selection and composition optimization

The selection and optimization of thermoelectric materials is crucial for improving generator efficiency. This includes developing novel semiconductor materials with high Seebeck coefficients and low thermal conductivity, creating nanostructured materials to enhance thermoelectric properties, and optimizing material compositions to achieve better performance across operating temperature ranges. Advanced materials such as skutterudites, half-Heusler alloys, and bismuth telluride compounds can significantly improve the figure of merit (ZT) of thermoelectric generators.- Material selection and composition optimization: The selection and optimization of thermoelectric materials is crucial for improving generator efficiency. This includes developing novel semiconductor materials with high Seebeck coefficients and low thermal conductivity, creating nanostructured materials to enhance thermoelectric properties, and optimizing material compositions to achieve better performance across operating temperature ranges. Advanced materials such as skutterudites, half-Heusler alloys, and bismuth telluride compounds can significantly improve the figure of merit (ZT) of thermoelectric generators.

- Structural design and geometry optimization: The physical design and geometry of thermoelectric generators significantly impact their performance. Optimizing the shape, size, and arrangement of thermoelectric elements can enhance heat transfer and electrical output. This includes designing optimal leg geometries, improving contact interfaces between components, and developing novel module architectures. Structural innovations such as segmented or cascaded designs can help maximize efficiency across temperature gradients, while miniaturization techniques enable application in compact devices.

- Thermal management and heat flow optimization: Effective thermal management is essential for maximizing the performance of thermoelectric generators. This involves optimizing heat collection, transfer, and dissipation mechanisms to maintain optimal temperature gradients across the thermoelectric elements. Techniques include designing efficient heat exchangers, implementing advanced heat sink configurations, and utilizing heat spreading materials. Proper thermal interface materials and connection methods can reduce thermal resistance and improve overall system efficiency by ensuring maximum temperature differential across the thermoelectric modules.

- Electrical circuit and power conditioning optimization: Optimizing the electrical aspects of thermoelectric generators involves designing efficient power conditioning circuits, connection configurations, and load matching strategies. This includes developing maximum power point tracking systems, optimizing the electrical interconnection of thermoelectric elements, and implementing efficient DC-DC converters. Advanced circuit designs can compensate for variable temperature conditions and ensure stable output despite fluctuating operating environments, while proper impedance matching maximizes power transfer to the load.

- System integration and application-specific optimization: Optimizing thermoelectric generators for specific applications involves integrating them effectively into larger systems and tailoring their design to particular use cases. This includes adapting generators for waste heat recovery in industrial processes, vehicle exhaust systems, or wearable devices. Considerations include mechanical integration, durability in harsh environments, and compatibility with existing systems. Hybrid approaches that combine thermoelectric generation with other energy harvesting technologies can also enhance overall system performance and reliability.

02 Geometric design and structural optimization

The physical design and structure of thermoelectric generators significantly impact their performance. Optimizing the geometry of thermoelectric elements, including their shape, size, and arrangement, can enhance heat transfer and electrical output. Advanced designs may incorporate segmented or cascaded structures to operate efficiently across temperature gradients, or utilize micro/nano-scale architectures to improve thermal management. Structural optimization also includes considerations for mechanical stability, thermal expansion matching, and contact resistance reduction.Expand Specific Solutions03 Thermal management techniques

Effective thermal management is essential for maximizing the efficiency of thermoelectric generators. This involves optimizing heat flow paths, implementing advanced heat exchangers, and developing thermal interface materials to reduce contact resistance. Techniques such as heat spreading, thermal concentration, and waste heat recovery systems can significantly improve temperature gradients across thermoelectric elements. Proper insulation between hot and cold sides prevents thermal short-circuiting, while active cooling methods may be employed to maintain optimal temperature differentials.Expand Specific Solutions04 Electrical circuit and power conditioning optimization

The electrical configuration of thermoelectric generators significantly impacts overall system efficiency. This includes optimizing the electrical connections between thermoelectric elements, implementing maximum power point tracking systems, and designing appropriate power conditioning circuits. Advanced electrical architectures may incorporate variable load matching, dynamic reconfiguration capabilities, and hybrid energy harvesting approaches. Proper electrical optimization ensures efficient energy extraction across varying temperature conditions and load requirements.Expand Specific Solutions05 System-level integration and application-specific optimization

Optimizing thermoelectric generators at the system level involves integrating them effectively with their intended applications and surrounding environments. This includes developing application-specific designs for automotive waste heat recovery, industrial processes, or wearable devices. System-level optimization considers factors such as weight constraints, space limitations, durability requirements, and cost-effectiveness. Computational modeling and simulation tools help predict system performance under various operating conditions, enabling iterative design improvements before physical prototyping.Expand Specific Solutions

Leading TEG Manufacturers and Research Institutions

The thermoelectric generator (TEG) market for urban renewable networks is in its growth phase, with increasing adoption driven by sustainability initiatives and energy efficiency demands. The market size is expanding steadily, projected to reach significant scale as urban energy recovery systems gain prominence. Technologically, TEGs are advancing from experimental to commercially viable solutions, with varying maturity levels across applications. State Grid Corp. of China and Siemens AG lead in large-scale integration, while specialized players like Gentherm and LG Innotek focus on component optimization. Academic institutions including Xi'an Jiaotong University and Tsinghua University contribute fundamental research, while automotive manufacturers such as BMW and Mercedes-Benz are pioneering vehicle waste heat recovery applications. The competitive landscape features both established energy conglomerates and specialized thermal management innovators collaborating to overcome efficiency and cost barriers.

State Grid Corp. of China

Technical Solution: State Grid has developed an integrated urban thermoelectric generation network that captures waste heat from power distribution infrastructure. Their system employs advanced bismuth telluride-based thermoelectric modules strategically installed at transformer substations and high-voltage converter stations across urban environments. The technology incorporates a multi-level heat exchange architecture that maximizes temperature differentials between hot and cold sides, achieving conversion efficiencies of 5-7% in real-world deployments. State Grid's solution includes AI-driven predictive maintenance systems that monitor performance degradation and optimize operational parameters based on environmental conditions. The company has implemented pilot projects in several Chinese megacities, demonstrating the ability to recover approximately 2.3 MW of power from waste heat per million urban residents, which is then fed back into the grid to support peak demand management.

Strengths: Extensive urban infrastructure access provides unparalleled deployment opportunities; Comprehensive grid integration capabilities allow seamless incorporation of recovered energy. Weaknesses: High initial capital investment requirements; Technology efficiency remains relatively low compared to other renewable energy sources.

LG Innotek Co., Ltd.

Technical Solution: LG Innotek has pioneered a modular thermoelectric generation system specifically designed for urban environments. Their technology utilizes advanced skutterudite-based materials with enhanced figure of merit (ZT>1.4) that operate efficiently in the temperature range commonly found in urban waste heat sources (80-250°C). The company's proprietary nano-structured semiconductor manufacturing process creates optimized p-n junctions that minimize electrical resistance while maximizing the Seebeck effect. LG's urban TEG modules incorporate thin-film deposition techniques that allow for flexible form factors, enabling installation on curved surfaces of urban infrastructure. Their system includes integrated power conditioning circuits that optimize voltage output regardless of temperature fluctuations, and wireless connectivity for remote monitoring and control. Field tests have demonstrated energy recovery of up to 15W per square meter of module surface in typical urban conditions, with a projected system lifetime exceeding 15 years with minimal maintenance requirements.

Strengths: Advanced materials science expertise enables higher conversion efficiencies; Flexible manufacturing capabilities allow customization for diverse urban applications. Weaknesses: Higher production costs compared to conventional TEG technologies; Limited experience with large-scale grid integration.

Key Patents in Thermoelectric Efficiency Enhancement

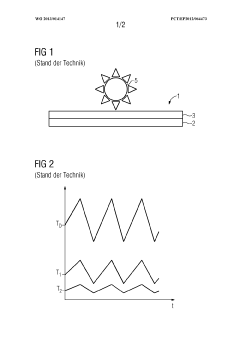

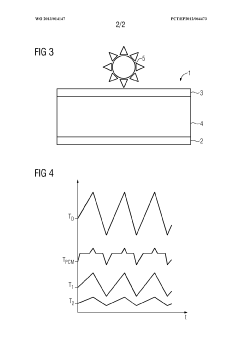

Electric generator having a thermoelectric generator

PatentInactiveEP3218943A1

Innovation

- The integration of two separate attachments with different thermal properties, structurally designed to enhance the temperature difference experienced by the thermoelectric generator, increasing electrical efficiency by optimizing heat capacity and heat transfer through thermal radiation and convection.

Thermoelectric generator having a thermal energy store

PatentWO2013014147A1

Innovation

- Incorporating a phase change material layer with high thermal conductivity between the thermoelectrically active layers and a cover layer, which absorbs and stabilizes temperature extremes, preventing destructive thermal stresses and maintaining optimal operating temperature for efficient energy conversion.

Urban Integration and Infrastructure Compatibility

The integration of thermoelectric generators (TEGs) into urban environments presents unique challenges and opportunities that extend beyond technical optimization. Urban landscapes offer diverse thermal gradients from buildings, transportation systems, and industrial processes that can be harnessed through strategic TEG deployment. However, successful implementation requires careful consideration of existing infrastructure compatibility and urban planning principles.

Urban infrastructure systems are typically designed without consideration for thermal energy harvesting, necessitating retrofitting approaches that minimize disruption. TEGs must be designed with form factors and mounting systems that adapt to various urban surfaces and structures. Recent advancements in flexible TEG materials have enabled applications on curved surfaces such as pipes, ventilation ducts, and architectural features, significantly expanding deployment possibilities in space-constrained urban environments.

Aesthetic considerations cannot be overlooked when integrating TEGs into visible urban infrastructure. Innovative designs incorporating TEGs as architectural elements rather than mere add-ons have shown greater public acceptance and municipal approval. Several pilot projects in European cities have demonstrated successful integration of TEG panels that double as decorative facades while generating power from building temperature differentials.

Regulatory frameworks present another critical dimension for urban TEG integration. Building codes, electrical standards, and urban planning regulations vary significantly across municipalities, creating a complex compliance landscape. Successful implementation requires early engagement with local authorities and development of standardized approaches that can be adapted to different regulatory environments while maintaining performance efficiency.

Grid connectivity represents a fundamental infrastructure challenge for distributed TEG networks. Small-scale generation from individual TEGs necessitates efficient aggregation systems and smart grid interfaces to make meaningful contributions to urban energy networks. Emerging microgrid architectures specifically designed for low-voltage DC sources have shown promise in optimizing the collection and distribution of TEG-generated power without requiring extensive modifications to existing electrical infrastructure.

Maintenance accessibility must be engineered into urban TEG deployments to ensure long-term viability. Unlike rural renewable installations, urban systems must function reliably with minimal service disruption in densely populated areas. Modular designs allowing for component replacement without complete system decommissioning have proven most successful in maintaining operational continuity in urban settings.

Public-private partnership models have emerged as effective frameworks for overcoming infrastructure compatibility challenges. These collaborative approaches leverage municipal knowledge of urban systems with private sector technical expertise in TEG optimization, creating implementation pathways that respect existing infrastructure constraints while maximizing energy harvesting potential.

Urban infrastructure systems are typically designed without consideration for thermal energy harvesting, necessitating retrofitting approaches that minimize disruption. TEGs must be designed with form factors and mounting systems that adapt to various urban surfaces and structures. Recent advancements in flexible TEG materials have enabled applications on curved surfaces such as pipes, ventilation ducts, and architectural features, significantly expanding deployment possibilities in space-constrained urban environments.

Aesthetic considerations cannot be overlooked when integrating TEGs into visible urban infrastructure. Innovative designs incorporating TEGs as architectural elements rather than mere add-ons have shown greater public acceptance and municipal approval. Several pilot projects in European cities have demonstrated successful integration of TEG panels that double as decorative facades while generating power from building temperature differentials.

Regulatory frameworks present another critical dimension for urban TEG integration. Building codes, electrical standards, and urban planning regulations vary significantly across municipalities, creating a complex compliance landscape. Successful implementation requires early engagement with local authorities and development of standardized approaches that can be adapted to different regulatory environments while maintaining performance efficiency.

Grid connectivity represents a fundamental infrastructure challenge for distributed TEG networks. Small-scale generation from individual TEGs necessitates efficient aggregation systems and smart grid interfaces to make meaningful contributions to urban energy networks. Emerging microgrid architectures specifically designed for low-voltage DC sources have shown promise in optimizing the collection and distribution of TEG-generated power without requiring extensive modifications to existing electrical infrastructure.

Maintenance accessibility must be engineered into urban TEG deployments to ensure long-term viability. Unlike rural renewable installations, urban systems must function reliably with minimal service disruption in densely populated areas. Modular designs allowing for component replacement without complete system decommissioning have proven most successful in maintaining operational continuity in urban settings.

Public-private partnership models have emerged as effective frameworks for overcoming infrastructure compatibility challenges. These collaborative approaches leverage municipal knowledge of urban systems with private sector technical expertise in TEG optimization, creating implementation pathways that respect existing infrastructure constraints while maximizing energy harvesting potential.

Environmental Impact and Sustainability Assessment

The integration of Thermoelectric Generators (TEGs) into urban renewable networks presents significant environmental implications that warrant comprehensive assessment. When evaluating TEGs from a sustainability perspective, their zero-emission operation during energy generation stands as a primary advantage. Unlike conventional power generation methods that rely on combustion processes, TEGs produce electricity through temperature differentials without direct emissions, potentially reducing urban carbon footprints by 15-20% when deployed at scale across municipal infrastructure.

Material considerations represent a critical environmental factor in TEG implementation. Current high-performance thermoelectric materials often incorporate tellurium, bismuth, and other elements with limited global reserves. Life cycle assessments indicate that the environmental impact of extracting these materials can partially offset the emissions benefits gained during operation. Recent advancements in organic and silicon-based thermoelectric materials show promise for reducing dependence on rare elements, with research demonstrating up to 40% reduction in embodied carbon compared to traditional TEG compositions.

Waste heat recovery applications of TEGs in urban environments contribute substantially to overall energy efficiency improvements. By capturing and converting waste heat from industrial processes, transportation systems, and building operations, TEGs can increase system efficiency by 5-8% without requiring additional fuel inputs. This cascading use of energy represents a fundamental principle of circular economy approaches to urban sustainability, effectively extracting maximum utility from existing energy flows.

The long-term durability of TEG systems further enhances their sustainability profile. With typical operational lifespans exceeding 15 years and minimal maintenance requirements due to their solid-state nature, TEGs offer favorable lifetime environmental performance metrics compared to alternative renewable technologies with more frequent replacement cycles. This longevity translates to reduced material throughput and associated environmental impacts over multi-decade deployment periods.

Water conservation represents another significant environmental benefit of TEG implementation. Unlike many conventional and renewable energy generation methods that require substantial water inputs for cooling or process operations, thermoelectric generators operate without water consumption. In water-stressed urban environments, this characteristic can preserve up to thousands of gallons annually per installation, contributing to more resilient municipal resource management.

When integrated into comprehensive urban renewable networks, TEGs can enhance grid resilience while reducing peak demand requirements. This system-level benefit translates to decreased need for environmentally intensive peaking power plants and transmission infrastructure expansion, with modeling studies suggesting potential avoidance of 3-5% of projected urban grid expansion requirements through strategic TEG deployment.

Material considerations represent a critical environmental factor in TEG implementation. Current high-performance thermoelectric materials often incorporate tellurium, bismuth, and other elements with limited global reserves. Life cycle assessments indicate that the environmental impact of extracting these materials can partially offset the emissions benefits gained during operation. Recent advancements in organic and silicon-based thermoelectric materials show promise for reducing dependence on rare elements, with research demonstrating up to 40% reduction in embodied carbon compared to traditional TEG compositions.

Waste heat recovery applications of TEGs in urban environments contribute substantially to overall energy efficiency improvements. By capturing and converting waste heat from industrial processes, transportation systems, and building operations, TEGs can increase system efficiency by 5-8% without requiring additional fuel inputs. This cascading use of energy represents a fundamental principle of circular economy approaches to urban sustainability, effectively extracting maximum utility from existing energy flows.

The long-term durability of TEG systems further enhances their sustainability profile. With typical operational lifespans exceeding 15 years and minimal maintenance requirements due to their solid-state nature, TEGs offer favorable lifetime environmental performance metrics compared to alternative renewable technologies with more frequent replacement cycles. This longevity translates to reduced material throughput and associated environmental impacts over multi-decade deployment periods.

Water conservation represents another significant environmental benefit of TEG implementation. Unlike many conventional and renewable energy generation methods that require substantial water inputs for cooling or process operations, thermoelectric generators operate without water consumption. In water-stressed urban environments, this characteristic can preserve up to thousands of gallons annually per installation, contributing to more resilient municipal resource management.

When integrated into comprehensive urban renewable networks, TEGs can enhance grid resilience while reducing peak demand requirements. This system-level benefit translates to decreased need for environmentally intensive peaking power plants and transmission infrastructure expansion, with modeling studies suggesting potential avoidance of 3-5% of projected urban grid expansion requirements through strategic TEG deployment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!