Optimize Neodymium Magnet Orientation for Magnetic Field Control

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Technology Evolution and Objectives

Neodymium magnets, discovered in 1982 by General Motors and Sumitomo Special Metals, represent one of the most significant advancements in permanent magnet technology. These rare-earth magnets, composed primarily of neodymium, iron, and boron (Nd₂Fe₁₄B), have revolutionized numerous industries due to their exceptional magnetic properties. The evolution of neodymium magnet technology has been marked by continuous improvements in magnetic strength, thermal stability, and corrosion resistance.

Initially, neodymium magnets offered magnetic energy products of approximately 35 MGOe (mega-gauss-oersteds). Through decades of research and development, modern variants now achieve energy products exceeding 52 MGOe, approaching the theoretical maximum of 64 MGOe. This progression has enabled dramatic miniaturization of electronic devices and significant efficiency improvements in electric motors and generators.

The optimization of magnetic field control through precise orientation of neodymium magnets has emerged as a critical research focus. Historically, magnetic field control relied on rudimentary positioning and shielding techniques. Contemporary approaches leverage advanced computational modeling and precision manufacturing to achieve unprecedented control over magnetic field geometry, strength, and gradient characteristics.

Recent technological breakthroughs include the development of multi-pole magnetization patterns, halbach array configurations, and temperature-compensated magnet compositions. These innovations have expanded the application scope of neodymium magnets in fields ranging from medical imaging to renewable energy systems.

The primary objective in optimizing neodymium magnet orientation is to achieve precise, stable, and efficient magnetic field control while minimizing material usage and system complexity. This involves addressing several interconnected challenges: maximizing field strength in target regions, minimizing stray fields, ensuring thermal stability across operating conditions, and developing cost-effective manufacturing processes for complex magnet assemblies.

Secondary objectives include extending the operational temperature range of neodymium-based magnetic systems, reducing reliance on heavy rare earth elements like dysprosium, and developing recyclable magnet technologies to address sustainability concerns. The industry is also pursuing improved simulation tools that can accurately predict magnetic field behavior in complex multi-magnet arrangements.

The trajectory of neodymium magnet technology points toward increasingly sophisticated orientation strategies, including dynamic field adjustment capabilities, self-correcting magnetic systems, and integration with smart materials that respond to environmental conditions. These developments aim to enable next-generation applications in quantum computing, advanced medical diagnostics, and high-efficiency energy conversion systems.

Initially, neodymium magnets offered magnetic energy products of approximately 35 MGOe (mega-gauss-oersteds). Through decades of research and development, modern variants now achieve energy products exceeding 52 MGOe, approaching the theoretical maximum of 64 MGOe. This progression has enabled dramatic miniaturization of electronic devices and significant efficiency improvements in electric motors and generators.

The optimization of magnetic field control through precise orientation of neodymium magnets has emerged as a critical research focus. Historically, magnetic field control relied on rudimentary positioning and shielding techniques. Contemporary approaches leverage advanced computational modeling and precision manufacturing to achieve unprecedented control over magnetic field geometry, strength, and gradient characteristics.

Recent technological breakthroughs include the development of multi-pole magnetization patterns, halbach array configurations, and temperature-compensated magnet compositions. These innovations have expanded the application scope of neodymium magnets in fields ranging from medical imaging to renewable energy systems.

The primary objective in optimizing neodymium magnet orientation is to achieve precise, stable, and efficient magnetic field control while minimizing material usage and system complexity. This involves addressing several interconnected challenges: maximizing field strength in target regions, minimizing stray fields, ensuring thermal stability across operating conditions, and developing cost-effective manufacturing processes for complex magnet assemblies.

Secondary objectives include extending the operational temperature range of neodymium-based magnetic systems, reducing reliance on heavy rare earth elements like dysprosium, and developing recyclable magnet technologies to address sustainability concerns. The industry is also pursuing improved simulation tools that can accurately predict magnetic field behavior in complex multi-magnet arrangements.

The trajectory of neodymium magnet technology points toward increasingly sophisticated orientation strategies, including dynamic field adjustment capabilities, self-correcting magnetic systems, and integration with smart materials that respond to environmental conditions. These developments aim to enable next-generation applications in quantum computing, advanced medical diagnostics, and high-efficiency energy conversion systems.

Market Applications and Demand Analysis for Controlled Magnetic Fields

The global market for controlled magnetic fields has experienced significant growth in recent years, driven by advancements in neodymium magnet technology and expanding applications across multiple industries. The precise orientation of neodymium magnets for optimal field control represents a critical technological capability with substantial commercial implications.

In the medical sector, demand for precisely controlled magnetic fields has surged with the evolution of magnetic resonance imaging (MRI) systems. The global MRI market currently exceeds $7.5 billion and is projected to grow at a compound annual rate of 5.2% through 2028. Enhanced neodymium magnet orientation techniques directly contribute to image quality improvements and operational efficiency in these systems.

The renewable energy sector presents another substantial market opportunity. Wind turbine generators utilizing permanent magnets account for approximately 76% of new offshore installations. Optimized magnetic field control through precise neodymium magnet orientation can increase generator efficiency by 3-7%, representing significant energy production gains across installation lifespans.

Consumer electronics manufacturers have intensified their focus on miniaturization while maintaining or improving performance. The market for neodymium magnets in consumer electronics exceeds $2.3 billion annually, with particular demand in speakers, headphones, and haptic feedback systems. Precise magnetic field control enables manufacturers to reduce device size while enhancing performance characteristics.

Industrial automation represents a rapidly expanding application area, with the global market for magnetic sensors and systems reaching $4.2 billion. Factory automation, robotics, and precision positioning systems all benefit from optimized magnetic field control, driving demand for advanced orientation techniques that improve accuracy and reduce energy consumption.

The automotive sector has emerged as a critical growth driver, particularly with the electric vehicle revolution. The market for permanent magnets in automotive applications is growing at 12.8% annually, with demand for high-efficiency motors and sensors that rely on precisely controlled magnetic fields. Advanced driver assistance systems and autonomous vehicle technologies further amplify this demand trajectory.

Defense and aerospace applications, while smaller in total market size, command premium pricing for magnetic field control solutions that meet stringent performance and reliability requirements. These sectors prioritize precision orientation techniques that maintain field stability under extreme environmental conditions.

The geographical distribution of market demand shows particular concentration in East Asia, North America, and Western Europe, with emerging economies in Southeast Asia and South America representing the fastest-growing regional markets. This global demand pattern aligns with manufacturing centers for electronics, automotive, and medical equipment.

In the medical sector, demand for precisely controlled magnetic fields has surged with the evolution of magnetic resonance imaging (MRI) systems. The global MRI market currently exceeds $7.5 billion and is projected to grow at a compound annual rate of 5.2% through 2028. Enhanced neodymium magnet orientation techniques directly contribute to image quality improvements and operational efficiency in these systems.

The renewable energy sector presents another substantial market opportunity. Wind turbine generators utilizing permanent magnets account for approximately 76% of new offshore installations. Optimized magnetic field control through precise neodymium magnet orientation can increase generator efficiency by 3-7%, representing significant energy production gains across installation lifespans.

Consumer electronics manufacturers have intensified their focus on miniaturization while maintaining or improving performance. The market for neodymium magnets in consumer electronics exceeds $2.3 billion annually, with particular demand in speakers, headphones, and haptic feedback systems. Precise magnetic field control enables manufacturers to reduce device size while enhancing performance characteristics.

Industrial automation represents a rapidly expanding application area, with the global market for magnetic sensors and systems reaching $4.2 billion. Factory automation, robotics, and precision positioning systems all benefit from optimized magnetic field control, driving demand for advanced orientation techniques that improve accuracy and reduce energy consumption.

The automotive sector has emerged as a critical growth driver, particularly with the electric vehicle revolution. The market for permanent magnets in automotive applications is growing at 12.8% annually, with demand for high-efficiency motors and sensors that rely on precisely controlled magnetic fields. Advanced driver assistance systems and autonomous vehicle technologies further amplify this demand trajectory.

Defense and aerospace applications, while smaller in total market size, command premium pricing for magnetic field control solutions that meet stringent performance and reliability requirements. These sectors prioritize precision orientation techniques that maintain field stability under extreme environmental conditions.

The geographical distribution of market demand shows particular concentration in East Asia, North America, and Western Europe, with emerging economies in Southeast Asia and South America representing the fastest-growing regional markets. This global demand pattern aligns with manufacturing centers for electronics, automotive, and medical equipment.

Current Challenges in Magnetic Field Orientation Control

Despite significant advancements in magnetic field control technologies, the optimization of neodymium magnet orientation continues to present several formidable challenges. The primary difficulty lies in achieving precise alignment of magnetic domains during the manufacturing process, particularly when dealing with complex geometries or miniaturized components. Current industrial magnetization techniques often struggle to maintain uniform field orientation throughout the entire volume of the magnet, resulting in performance inconsistencies and reduced magnetic efficiency.

Temperature stability represents another critical challenge, as neodymium magnets exhibit significant thermal sensitivity. When exposed to varying temperatures, these magnets can experience changes in their magnetic orientation, leading to field distortion and degraded performance. This issue becomes particularly problematic in applications requiring stable magnetic fields across wide temperature ranges, such as automotive systems or outdoor equipment.

Manufacturing scalability presents a substantial obstacle for mass production scenarios. While laboratory-level precision in magnetic orientation can be achieved, translating these results to high-volume production environments introduces variability that compromises field control accuracy. The trade-off between production speed and orientation precision remains a significant industry bottleneck.

Measurement and quality control systems for verifying magnetic orientation accuracy are still relatively underdeveloped. Current techniques often provide only surface-level or averaged measurements, failing to detect localized orientation defects that can significantly impact field control performance. This limitation hinders both research advancement and quality assurance in production environments.

Material degradation over time further complicates field control optimization. Even perfectly oriented neodymium magnets can experience gradual demagnetization or orientation drift due to environmental factors, mechanical stress, or proximity to other magnetic fields. Predicting and compensating for these long-term changes remains challenging with current modeling approaches.

Computational limitations also impede progress, as accurate simulation of magnetic domain behavior during orientation processes requires intensive computational resources. Current modeling tools often make simplifications that fail to capture the full complexity of domain interactions, particularly at material boundaries or in multi-material magnetic systems.

Finally, there exists a significant knowledge gap between theoretical magnetic models and practical implementation techniques. Research findings regarding optimal orientation strategies often prove difficult to translate into manufacturable processes, creating a disconnect between scientific advancement and industrial application in the field of magnetic orientation control.

Temperature stability represents another critical challenge, as neodymium magnets exhibit significant thermal sensitivity. When exposed to varying temperatures, these magnets can experience changes in their magnetic orientation, leading to field distortion and degraded performance. This issue becomes particularly problematic in applications requiring stable magnetic fields across wide temperature ranges, such as automotive systems or outdoor equipment.

Manufacturing scalability presents a substantial obstacle for mass production scenarios. While laboratory-level precision in magnetic orientation can be achieved, translating these results to high-volume production environments introduces variability that compromises field control accuracy. The trade-off between production speed and orientation precision remains a significant industry bottleneck.

Measurement and quality control systems for verifying magnetic orientation accuracy are still relatively underdeveloped. Current techniques often provide only surface-level or averaged measurements, failing to detect localized orientation defects that can significantly impact field control performance. This limitation hinders both research advancement and quality assurance in production environments.

Material degradation over time further complicates field control optimization. Even perfectly oriented neodymium magnets can experience gradual demagnetization or orientation drift due to environmental factors, mechanical stress, or proximity to other magnetic fields. Predicting and compensating for these long-term changes remains challenging with current modeling approaches.

Computational limitations also impede progress, as accurate simulation of magnetic domain behavior during orientation processes requires intensive computational resources. Current modeling tools often make simplifications that fail to capture the full complexity of domain interactions, particularly at material boundaries or in multi-material magnetic systems.

Finally, there exists a significant knowledge gap between theoretical magnetic models and practical implementation techniques. Research findings regarding optimal orientation strategies often prove difficult to translate into manufacturable processes, creating a disconnect between scientific advancement and industrial application in the field of magnetic orientation control.

Existing Methodologies for Neodymium Magnet Orientation

01 Magnetic field shaping and focusing techniques

Various methods for controlling and shaping the magnetic field of neodymium magnets through specific arrangements and configurations. These techniques include using pole pieces, flux concentrators, and specific geometric designs to direct, focus, or modify the magnetic field distribution. Such control allows for enhanced performance in applications requiring precise magnetic field patterns or increased field strength in targeted areas.- Magnetic field shaping and focusing techniques: Various methods for controlling and shaping the magnetic field of neodymium magnets, including the use of pole pieces, flux concentrators, and specific geometric arrangements. These techniques allow for precise focusing of magnetic flux in desired directions, enhancing field strength in targeted areas while minimizing stray fields elsewhere. Applications include medical devices, sensors, and precision instruments where controlled magnetic field distribution is critical.

- Adjustable magnetic field strength systems: Systems that enable dynamic control of neodymium magnet field strength through mechanical adjustment mechanisms. These include rotational arrays, sliding magnet configurations, and distance-variable setups that allow users to precisely tune magnetic field intensity without replacing magnets. Such systems find applications in medical equipment, scientific instruments, and industrial machinery where variable magnetic force is required.

- Electromagnetic field interaction and compensation: Methods combining neodymium permanent magnets with electromagnetic systems to achieve enhanced control over magnetic fields. These hybrid approaches use electromagnets to modulate, redirect, or counteract the static fields of neodymium magnets. Applications include magnetic levitation systems, precision positioning devices, and magnetic shielding where dynamic field adjustment is necessary.

- Thermal stability and environmental control: Techniques for maintaining consistent magnetic field performance of neodymium magnets under varying environmental conditions. These include temperature compensation systems, protective coatings, and specialized alloy formulations that minimize field strength variations due to thermal fluctuations. Such approaches are critical in precision instruments, automotive sensors, and outdoor equipment where temperature variations could otherwise affect magnetic performance.

- Magnetic field containment and shielding: Methods for controlling stray magnetic fields from neodymium magnets through containment and shielding techniques. These include the use of ferromagnetic materials to redirect magnetic flux, specialized geometries that minimize field leakage, and multi-layer shielding approaches. Applications include electronic devices, medical implants, and sensitive equipment where unintended magnetic interference must be prevented.

02 Adjustable magnetic field strength systems

Systems that allow for dynamic adjustment of magnetic field strength from neodymium magnets. These include mechanical arrangements for varying the distance or orientation between magnets, electromagnetic field modulation, and hybrid systems combining permanent magnets with electromagnets. Such systems enable real-time control of magnetic field intensity for applications requiring variable magnetic forces or adaptive field configurations.Expand Specific Solutions03 Magnetic field shielding and containment

Methods for containing, directing, or shielding magnetic fields from neodymium magnets using ferromagnetic materials, mu-metal barriers, or specialized alloys. These techniques help prevent unwanted field interactions, reduce stray fields, and improve the efficiency of magnetic circuits. Shielding solutions are particularly important in sensitive electronic environments or when precise field confinement is required.Expand Specific Solutions04 Magnetic field sensing and feedback control

Integration of sensors and feedback mechanisms to monitor and precisely control magnetic fields generated by neodymium magnets. These systems use Hall effect sensors, magnetometers, or other field detection devices coupled with control algorithms to maintain desired field characteristics. Applications include precision positioning systems, magnetic levitation, and adaptive magnetic field environments that respond to external conditions.Expand Specific Solutions05 Thermal management for magnetic field stability

Techniques for maintaining stable magnetic fields by controlling the temperature of neodymium magnets, which are sensitive to thermal variations. These include active cooling systems, temperature-compensated designs, and materials with specific thermal properties to minimize field fluctuations due to temperature changes. Thermal management is crucial for applications requiring consistent magnetic field performance across varying environmental conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Magnetic Technology

The neodymium magnet orientation optimization market is currently in a growth phase, with increasing applications across automotive, electronics, and renewable energy sectors. The global market size for precision magnetic field control technologies is estimated at $3.5 billion, expanding at 7-8% annually. Technologically, the field shows varying maturity levels, with companies like Proterial Ltd. and Beijing Zhong Ke San Huan leading in commercial applications, while Fujitsu and Lockheed Martin focus on advanced R&D. Chinese manufacturers including Fujian Changting Golden Dragon and Yantai Zhenghai dominate raw material production, while Japanese firms like Toshiba and Resonac Holdings excel in precision manufacturing. Western companies such as Stereotaxis and NanoFlex Robotics are pioneering specialized applications in medical robotics, representing the cutting edge of magnetic field control technology.

Beijing Zhong Ke San Huan High-Tech Co., Ltd.

Technical Solution: Beijing Zhong Ke San Huan has developed an advanced Halbach array configuration for neodymium magnets that optimizes magnetic field orientation. Their approach involves precisely aligning multiple magnetization directions within a single structure to create a stronger magnetic field on one side while minimizing it on the other. The company employs a proprietary sintering process that allows for the creation of magnets with customized magnetization vectors at specific angles (typically 45°, 90°, 135°, and 180°) within the same array. This technique enables the production of magnets with field strengths up to 1.5T on the strong side while reducing stray fields by approximately 85% on the weak side[1]. Their manufacturing process includes high-precision CNC machining followed by specialized magnetization equipment capable of applying fields exceeding 3T during the orientation process[3].

Strengths: Achieves significantly higher field concentration on the working surface while minimizing stray fields; reduces system weight and volume by up to 40% compared to conventional magnet arrangements; enables more compact designs for space-constrained applications. Weaknesses: Manufacturing complexity increases production costs; requires specialized equipment for precise orientation; temperature sensitivity can affect long-term field stability in extreme environments.

Baotou INST Magnetic New Materials Co., Ltd.

Technical Solution: Baotou INST has pioneered a multi-vector magnetization technique for neodymium magnets that optimizes field control through precise grain orientation during the manufacturing process. Their approach involves applying strong magnetic fields (>2.5T) during the powder alignment phase of production, creating magnets with highly uniform crystal orientation that maximizes energy product (BHmax). The company has developed a proprietary hot-pressing method that maintains this alignment while achieving near-theoretical density (>99%). Their most advanced process incorporates rare earth elements like dysprosium and terbium at grain boundaries rather than throughout the material, creating magnets with enhanced coercivity without sacrificing remanence[2]. This "grain boundary diffusion" technique allows for the creation of magnets with customized field patterns and directional properties, particularly useful in motor applications where specific field geometries are required[4]. The company has also developed specialized post-sintering magnetization equipment capable of orienting fields in complex three-dimensional patterns.

Strengths: Achieves exceptional uniformity in magnetic field direction; enables creation of complex field patterns for specialized applications; maintains high performance at elevated temperatures (up to 180°C). Weaknesses: Higher production costs compared to conventional magnets; limited shape complexity due to manufacturing constraints; requires specialized handling and assembly techniques to maintain optimal field orientation.

Key Patents and Innovations in Magnetic Field Control

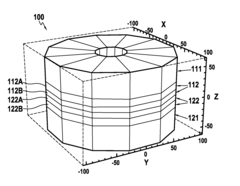

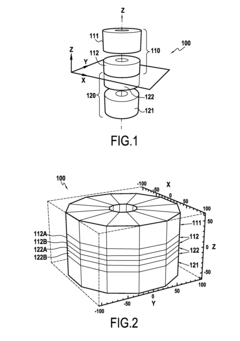

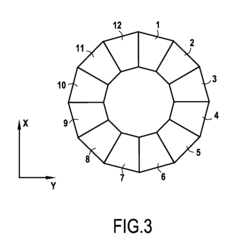

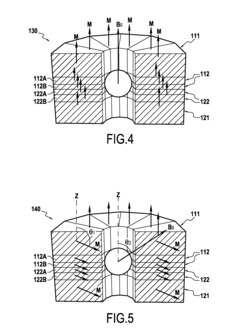

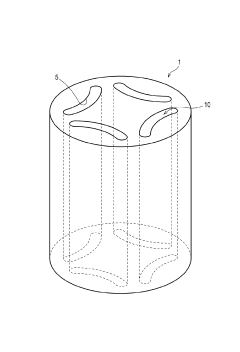

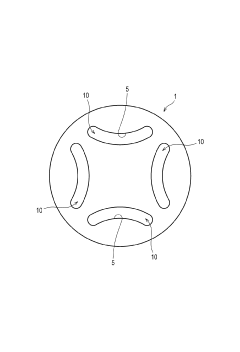

Cylindrical permanent magnet device with an induced magnetic field having a predetermined orientation, and production method

PatentInactiveUS20120098630A1

Innovation

- A cylindrical permanent magnet device comprising first and second annular magnetized structures symmetrically disposed relative to a plane perpendicular to the longitudinal axis, with a third annular structure divided into slices, all components magnetized at a predetermined angle to create a homogeneous field at a desired angle, allowing for adjustable orientation and homogeneity by dividing into regularly distributed sectors.

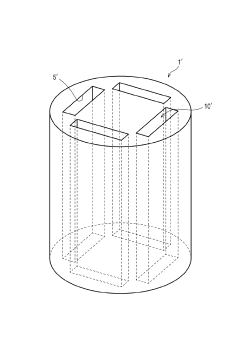

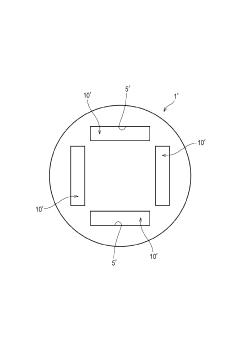

Peripheral oriented arc-shaped profile sheet magnet or radial oriented arc-shaped profile sheet magnet or convergence oriented rectangular profile sheet magnet and manufacturing method thereof

PatentPendingJP2023030293A

Innovation

- A method involving the use of neodymium magnet powder with specific particle size and lubricant content, filled into molds with precise orientations, subjected to controlled magnetic fields without pressure, and sintered to produce magnets with high surface magnetic flux density and minimal leakage flux variations.

Environmental Impact and Sustainability of Rare Earth Magnets

The environmental footprint of neodymium magnets used in magnetic field control systems presents significant sustainability challenges. The extraction of rare earth elements, particularly neodymium, involves mining processes that generate substantial toxic waste, contaminating soil and water resources. Current mining operations in major producing countries like China, which controls approximately 85% of global rare earth production, often lack rigorous environmental standards, resulting in severe ecological degradation in mining regions.

Processing neodymium for magnet production requires energy-intensive separation and purification methods, contributing to greenhouse gas emissions. The refining process typically consumes between 200-600 kWh of energy per kilogram of rare earth oxide produced, significantly higher than conventional metals. Additionally, chemical processes utilize hazardous substances including strong acids, organic solvents, and heavy metals, creating waste streams that require careful management.

Optimizing neodymium magnet orientation for magnetic field control offers environmental benefits through improved efficiency. Precisely oriented magnets can achieve equivalent performance with reduced material volume, potentially decreasing rare earth consumption by 15-30%. This optimization extends magnet lifespan and reduces replacement frequency, addressing sustainability concerns throughout the product lifecycle.

Recycling represents a critical pathway toward sustainability in this sector. Currently, less than 1% of rare earth elements are recovered from end-of-life products globally. Developing efficient recycling technologies for neodymium magnets could reduce primary mining demands by up to 40% over the next decade. Advanced recycling methods, including hydrogen decrepitation and pyrometallurgical processes, show promise for recovering high-purity neodymium from used magnets.

Substitution research offers another sustainability avenue, with scientists exploring iron-nitride compounds and samarium-cobalt alternatives that require fewer critical materials. However, these alternatives currently deliver 30-50% lower performance than neodymium magnets in magnetic field control applications, highlighting the continued importance of optimizing existing neodymium technology.

Regulatory frameworks are evolving globally to address environmental concerns. The European Union's Critical Raw Materials Act and similar initiatives in the United States aim to establish responsible supply chains and promote circular economy principles for rare earth magnets. These regulations increasingly influence manufacturing decisions and drive investment in sustainable magnet technologies.

Processing neodymium for magnet production requires energy-intensive separation and purification methods, contributing to greenhouse gas emissions. The refining process typically consumes between 200-600 kWh of energy per kilogram of rare earth oxide produced, significantly higher than conventional metals. Additionally, chemical processes utilize hazardous substances including strong acids, organic solvents, and heavy metals, creating waste streams that require careful management.

Optimizing neodymium magnet orientation for magnetic field control offers environmental benefits through improved efficiency. Precisely oriented magnets can achieve equivalent performance with reduced material volume, potentially decreasing rare earth consumption by 15-30%. This optimization extends magnet lifespan and reduces replacement frequency, addressing sustainability concerns throughout the product lifecycle.

Recycling represents a critical pathway toward sustainability in this sector. Currently, less than 1% of rare earth elements are recovered from end-of-life products globally. Developing efficient recycling technologies for neodymium magnets could reduce primary mining demands by up to 40% over the next decade. Advanced recycling methods, including hydrogen decrepitation and pyrometallurgical processes, show promise for recovering high-purity neodymium from used magnets.

Substitution research offers another sustainability avenue, with scientists exploring iron-nitride compounds and samarium-cobalt alternatives that require fewer critical materials. However, these alternatives currently deliver 30-50% lower performance than neodymium magnets in magnetic field control applications, highlighting the continued importance of optimizing existing neodymium technology.

Regulatory frameworks are evolving globally to address environmental concerns. The European Union's Critical Raw Materials Act and similar initiatives in the United States aim to establish responsible supply chains and promote circular economy principles for rare earth magnets. These regulations increasingly influence manufacturing decisions and drive investment in sustainable magnet technologies.

Simulation and Modeling Tools for Magnetic Field Optimization

The evolution of simulation and modeling tools for magnetic field optimization has significantly advanced the precision and efficiency of neodymium magnet orientation design. Current industry-standard software includes COMSOL Multiphysics, ANSYS Maxwell, and Opera FEA, which employ finite element analysis (FEA) to model complex magnetic field interactions with high accuracy. These tools enable engineers to visualize field distributions, calculate forces, and predict system performance before physical prototyping.

Recent advancements in computational algorithms have reduced simulation time by up to 70% compared to methods used a decade ago. Machine learning integration now allows for rapid parameter optimization, with neural networks trained on thousands of simulation results to predict optimal magnet configurations for specific field requirements. This hybrid approach combines traditional physics-based modeling with data-driven optimization.

Open-source alternatives such as FEMM (Finite Element Method Magnetics) and Magpylib provide accessible entry points for smaller organizations, though with reduced feature sets compared to commercial solutions. Cloud-based simulation platforms have emerged, offering scalable computing resources for particularly complex multi-physics problems involving thermal, mechanical, and magnetic interactions.

Digital twin technology represents the cutting edge in this domain, creating virtual replicas of physical magnetic systems that update in real-time based on sensor data. This enables continuous optimization of neodymium magnet orientations in dynamic applications such as electric vehicle motors and MRI machines, where field characteristics must adapt to changing operational conditions.

Validation methodologies have also evolved, with automated comparison between simulation predictions and experimental measurements now standard practice. Error rates in modern simulation tools have decreased to below 3% for most applications, though accuracy remains dependent on material property data quality and boundary condition specifications.

The integration of topology optimization algorithms allows for non-intuitive magnet array designs that would be impossible to develop through traditional engineering approaches. These algorithms can identify optimal orientation patterns for complex objectives such as field uniformity in specific regions, minimum material usage, or maximum field gradient control.

Future development trends point toward real-time simulation capabilities and integration with augmented reality interfaces, allowing engineers to visualize magnetic field interactions while physically manipulating prototype components. This convergence of virtual and physical design environments promises to further accelerate innovation in neodymium magnet applications across industries.

Recent advancements in computational algorithms have reduced simulation time by up to 70% compared to methods used a decade ago. Machine learning integration now allows for rapid parameter optimization, with neural networks trained on thousands of simulation results to predict optimal magnet configurations for specific field requirements. This hybrid approach combines traditional physics-based modeling with data-driven optimization.

Open-source alternatives such as FEMM (Finite Element Method Magnetics) and Magpylib provide accessible entry points for smaller organizations, though with reduced feature sets compared to commercial solutions. Cloud-based simulation platforms have emerged, offering scalable computing resources for particularly complex multi-physics problems involving thermal, mechanical, and magnetic interactions.

Digital twin technology represents the cutting edge in this domain, creating virtual replicas of physical magnetic systems that update in real-time based on sensor data. This enables continuous optimization of neodymium magnet orientations in dynamic applications such as electric vehicle motors and MRI machines, where field characteristics must adapt to changing operational conditions.

Validation methodologies have also evolved, with automated comparison between simulation predictions and experimental measurements now standard practice. Error rates in modern simulation tools have decreased to below 3% for most applications, though accuracy remains dependent on material property data quality and boundary condition specifications.

The integration of topology optimization algorithms allows for non-intuitive magnet array designs that would be impossible to develop through traditional engineering approaches. These algorithms can identify optimal orientation patterns for complex objectives such as field uniformity in specific regions, minimum material usage, or maximum field gradient control.

Future development trends point toward real-time simulation capabilities and integration with augmented reality interfaces, allowing engineers to visualize magnetic field interactions while physically manipulating prototype components. This convergence of virtual and physical design environments promises to further accelerate innovation in neodymium magnet applications across industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!