Optimizing Mini LED for Higher Contrast Ratios

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED Technology Background and Objectives

Mini LED technology represents a significant advancement in display technology, bridging the gap between traditional LCD and OLED displays. Emerging in the mid-2010s, Mini LEDs are semiconductor light sources with dimensions typically ranging from 100 to 200 micrometers, substantially smaller than conventional LEDs but larger than microLEDs. This technology has evolved from traditional LED backlighting systems, offering enhanced control over local dimming zones and improved brightness capabilities.

The evolution of Mini LED technology has been driven by the increasing demand for higher display performance in consumer electronics, particularly in premium televisions, monitors, and mobile devices. The technology's development trajectory shows a consistent focus on reducing LED size while increasing the number of dimming zones, enabling more precise control over contrast and brightness across the display panel.

The primary objective in optimizing Mini LED for higher contrast ratios is to address the inherent limitations of LCD technology while providing a more cost-effective alternative to OLED displays. By increasing the number of individually controllable backlighting zones, Mini LED technology aims to minimize light leakage and achieve deeper blacks, thereby enhancing the overall contrast ratio of the display.

Current technical goals include reducing the physical size of Mini LEDs further to allow for more dimming zones within the same panel area, improving the algorithms that control local dimming to prevent blooming effects (light haloing around bright objects on dark backgrounds), and enhancing energy efficiency to make the technology viable for portable devices.

Another critical objective is to optimize the optical design of Mini LED backlighting systems to ensure uniform light distribution across the display while maintaining the ability to create high contrast between adjacent zones. This involves advancements in light guide plates, diffuser materials, and reflective surfaces within the display assembly.

The industry is also focused on developing more efficient manufacturing processes to reduce the cost of Mini LED displays, as current production methods contribute to their premium pricing. This includes innovations in mass transfer techniques, substrate materials, and automated quality control systems.

Looking forward, the technology roadmap for Mini LED displays indicates a convergence with quantum dot technology (known as Mini LED-QLED) to enhance color performance while maintaining the contrast advantages of Mini LED backlighting. This hybrid approach represents the next frontier in display technology, potentially offering OLED-like performance at more competitive price points.

The evolution of Mini LED technology has been driven by the increasing demand for higher display performance in consumer electronics, particularly in premium televisions, monitors, and mobile devices. The technology's development trajectory shows a consistent focus on reducing LED size while increasing the number of dimming zones, enabling more precise control over contrast and brightness across the display panel.

The primary objective in optimizing Mini LED for higher contrast ratios is to address the inherent limitations of LCD technology while providing a more cost-effective alternative to OLED displays. By increasing the number of individually controllable backlighting zones, Mini LED technology aims to minimize light leakage and achieve deeper blacks, thereby enhancing the overall contrast ratio of the display.

Current technical goals include reducing the physical size of Mini LEDs further to allow for more dimming zones within the same panel area, improving the algorithms that control local dimming to prevent blooming effects (light haloing around bright objects on dark backgrounds), and enhancing energy efficiency to make the technology viable for portable devices.

Another critical objective is to optimize the optical design of Mini LED backlighting systems to ensure uniform light distribution across the display while maintaining the ability to create high contrast between adjacent zones. This involves advancements in light guide plates, diffuser materials, and reflective surfaces within the display assembly.

The industry is also focused on developing more efficient manufacturing processes to reduce the cost of Mini LED displays, as current production methods contribute to their premium pricing. This includes innovations in mass transfer techniques, substrate materials, and automated quality control systems.

Looking forward, the technology roadmap for Mini LED displays indicates a convergence with quantum dot technology (known as Mini LED-QLED) to enhance color performance while maintaining the contrast advantages of Mini LED backlighting. This hybrid approach represents the next frontier in display technology, potentially offering OLED-like performance at more competitive price points.

Market Demand Analysis for High Contrast Displays

The display industry has witnessed a significant shift towards high contrast ratio technologies in recent years, driven primarily by consumer demand for more immersive viewing experiences. Market research indicates that the global high-contrast display market reached approximately $32 billion in 2022, with projections suggesting growth to $58 billion by 2027, representing a compound annual growth rate of 12.6%. This robust growth trajectory underscores the substantial market opportunity for Mini LED technology optimized for higher contrast ratios.

Consumer electronics, particularly premium television and professional monitor segments, demonstrate the strongest demand for high contrast displays. In the television market, high-end models featuring enhanced contrast capabilities command price premiums of 30-40% compared to standard models, indicating consumers' willingness to pay for superior visual quality. The professional display market, including content creation, medical imaging, and industrial applications, similarly values high contrast ratios for accuracy and detail reproduction.

Market surveys reveal that contrast ratio ranks among the top three purchasing considerations for consumers acquiring premium displays, alongside resolution and color accuracy. This consumer preference has intensified competition among manufacturers to develop technologies that deliver deeper blacks and brighter highlights, with Mini LED emerging as a promising solution that balances performance and manufacturing scalability.

The automotive display market represents another rapidly expanding segment, with high-contrast displays increasingly featured in premium vehicle dashboards and entertainment systems. Industry analysts project this sector to grow at 15.8% annually through 2026, outpacing the broader display market and creating additional demand for Mini LED solutions.

Regional analysis shows Asia-Pacific leading market demand with 42% share, followed by North America (28%) and Europe (22%). China and South Korea are particularly significant markets due to their strong consumer electronics manufacturing base and domestic consumption patterns. The North American market demonstrates the highest premium segment penetration, with consumers showing greater willingness to invest in advanced display technologies.

Competitive landscape assessment reveals that traditional LCD displays with conventional backlighting are rapidly losing market share to technologies offering superior contrast, including OLED and Mini LED. While OLED currently dominates the ultra-premium segment, Mini LED's potential for higher brightness, reduced burn-in risk, and improving cost structure positions it favorably for significant market expansion, particularly in the mid-premium segment where price sensitivity remains a factor.

Consumer electronics, particularly premium television and professional monitor segments, demonstrate the strongest demand for high contrast displays. In the television market, high-end models featuring enhanced contrast capabilities command price premiums of 30-40% compared to standard models, indicating consumers' willingness to pay for superior visual quality. The professional display market, including content creation, medical imaging, and industrial applications, similarly values high contrast ratios for accuracy and detail reproduction.

Market surveys reveal that contrast ratio ranks among the top three purchasing considerations for consumers acquiring premium displays, alongside resolution and color accuracy. This consumer preference has intensified competition among manufacturers to develop technologies that deliver deeper blacks and brighter highlights, with Mini LED emerging as a promising solution that balances performance and manufacturing scalability.

The automotive display market represents another rapidly expanding segment, with high-contrast displays increasingly featured in premium vehicle dashboards and entertainment systems. Industry analysts project this sector to grow at 15.8% annually through 2026, outpacing the broader display market and creating additional demand for Mini LED solutions.

Regional analysis shows Asia-Pacific leading market demand with 42% share, followed by North America (28%) and Europe (22%). China and South Korea are particularly significant markets due to their strong consumer electronics manufacturing base and domestic consumption patterns. The North American market demonstrates the highest premium segment penetration, with consumers showing greater willingness to invest in advanced display technologies.

Competitive landscape assessment reveals that traditional LCD displays with conventional backlighting are rapidly losing market share to technologies offering superior contrast, including OLED and Mini LED. While OLED currently dominates the ultra-premium segment, Mini LED's potential for higher brightness, reduced burn-in risk, and improving cost structure positions it favorably for significant market expansion, particularly in the mid-premium segment where price sensitivity remains a factor.

Mini LED Technical Challenges and Limitations

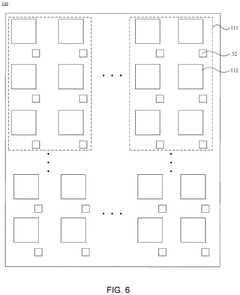

Despite the promising advancements in Mini LED technology, several significant technical challenges and limitations currently impede its optimization for achieving higher contrast ratios. The primary challenge lies in the precision control of local dimming zones. While Mini LEDs offer substantially more dimming zones than traditional LED backlighting, the number remains insufficient to completely eliminate blooming effects—where light from bright objects bleeds into adjacent dark areas, reducing contrast effectiveness.

Manufacturing precision presents another critical limitation. The miniaturization of LED chips to dimensions below 200 micrometers introduces considerable production difficulties, including yield issues, placement accuracy, and uniformity control. These manufacturing constraints directly impact the achievable contrast ratio and overall display quality, particularly at mass production scales.

Thermal management emerges as a persistent challenge in Mini LED displays. The dense arrangement of numerous LED chips generates significant heat during operation, which can affect both performance and longevity. Without adequate thermal solutions, brightness consistency degrades over time, and color accuracy suffers, ultimately compromising the contrast ratio benefits.

Power efficiency remains suboptimal compared to emerging technologies like OLED. While Mini LED displays require less power than conventional LED-LCD systems, they still consume considerably more energy than self-emissive display technologies, especially when implementing sophisticated local dimming algorithms to enhance contrast ratios.

The complexity of driving circuits increases exponentially with the number of dimming zones. Current Mini LED displays with thousands of zones require sophisticated backplane technologies and control algorithms, adding to cost and design complexity while potentially introducing response time limitations that affect dynamic contrast performance.

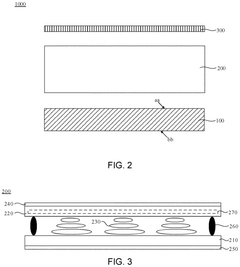

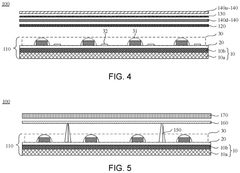

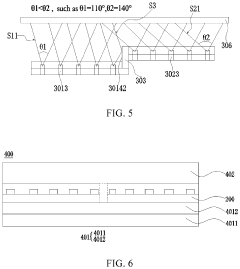

Optical stack optimization presents unique challenges. The distance between the Mini LED backlight layer and the LCD panel (optical distance) must be precisely controlled to minimize light spread. Additionally, diffuser designs must balance between light uniformity and maintaining the integrity of dimming zones—a delicate trade-off affecting contrast performance.

Cost factors significantly limit widespread adoption of high-performance Mini LED solutions. The expense associated with implementing tens of thousands of dimming zones necessary for OLED-competitive contrast ratios remains prohibitively high for many market segments, restricting the technology's penetration to premium product categories.

Algorithm development for intelligent local dimming represents another frontier challenge. Current algorithms struggle to optimize real-time dimming decisions that maximize contrast while minimizing artifacts, particularly during high-motion content where processing latency becomes critical.

Manufacturing precision presents another critical limitation. The miniaturization of LED chips to dimensions below 200 micrometers introduces considerable production difficulties, including yield issues, placement accuracy, and uniformity control. These manufacturing constraints directly impact the achievable contrast ratio and overall display quality, particularly at mass production scales.

Thermal management emerges as a persistent challenge in Mini LED displays. The dense arrangement of numerous LED chips generates significant heat during operation, which can affect both performance and longevity. Without adequate thermal solutions, brightness consistency degrades over time, and color accuracy suffers, ultimately compromising the contrast ratio benefits.

Power efficiency remains suboptimal compared to emerging technologies like OLED. While Mini LED displays require less power than conventional LED-LCD systems, they still consume considerably more energy than self-emissive display technologies, especially when implementing sophisticated local dimming algorithms to enhance contrast ratios.

The complexity of driving circuits increases exponentially with the number of dimming zones. Current Mini LED displays with thousands of zones require sophisticated backplane technologies and control algorithms, adding to cost and design complexity while potentially introducing response time limitations that affect dynamic contrast performance.

Optical stack optimization presents unique challenges. The distance between the Mini LED backlight layer and the LCD panel (optical distance) must be precisely controlled to minimize light spread. Additionally, diffuser designs must balance between light uniformity and maintaining the integrity of dimming zones—a delicate trade-off affecting contrast performance.

Cost factors significantly limit widespread adoption of high-performance Mini LED solutions. The expense associated with implementing tens of thousands of dimming zones necessary for OLED-competitive contrast ratios remains prohibitively high for many market segments, restricting the technology's penetration to premium product categories.

Algorithm development for intelligent local dimming represents another frontier challenge. Current algorithms struggle to optimize real-time dimming decisions that maximize contrast while minimizing artifacts, particularly during high-motion content where processing latency becomes critical.

Current Contrast Ratio Enhancement Solutions

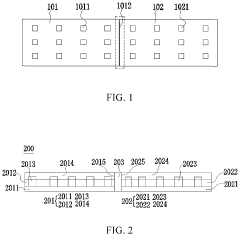

01 Mini LED backlight technology for improved contrast ratios

Mini LED backlight technology enables significantly improved contrast ratios in display devices by providing more precise local dimming capabilities. The smaller size of mini LEDs allows for more dimming zones compared to traditional LED backlights, resulting in better control of bright and dark areas on the screen. This technology reduces light leakage and enhances the dynamic range of the display, leading to deeper blacks and more vibrant images.- Local dimming techniques for enhancing contrast ratios: Mini LED displays utilize local dimming technology to enhance contrast ratios by selectively controlling the brightness of different zones of the display. This allows for deeper blacks in dark areas while maintaining brightness in light areas, significantly improving the overall contrast ratio. The technique involves dividing the backlight into numerous independently controllable zones, enabling precise light control that traditional LED displays cannot achieve.

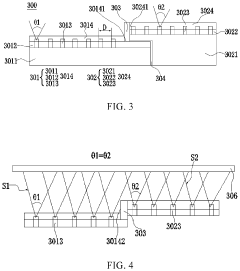

- Backlight structure optimization for Mini LED displays: The physical arrangement and structure of Mini LED backlights significantly impact contrast ratio performance. Optimized designs include specific spacing between LED units, reflective materials to prevent light leakage, and optical films that direct light more efficiently. These structural improvements help minimize light bleeding between zones, resulting in sharper contrast between bright and dark areas of the display.

- Driving circuit and control algorithms for contrast enhancement: Advanced driving circuits and control algorithms are essential for maximizing Mini LED contrast ratios. These systems dynamically adjust the brightness of individual LED zones based on image content analysis, applying sophisticated algorithms to determine optimal brightness levels. The control systems can process real-time image data to identify areas requiring higher contrast and adjust power distribution accordingly, resulting in improved perceived contrast ratios.

- Optical film and layer configurations for contrast improvement: Specialized optical films and layer configurations are used in Mini LED displays to enhance contrast ratios. These include diffusion films that evenly distribute light, quantum dot enhancement films that improve color purity, and anti-reflection coatings that reduce ambient light reflection. The strategic placement and combination of these optical elements help to maximize the perceived contrast ratio by managing light transmission and reflection within the display panel.

- Image processing techniques for contrast enhancement: Advanced image processing algorithms specifically designed for Mini LED displays can significantly improve perceived contrast ratios. These techniques include adaptive tone mapping, dynamic range expansion, and content-aware brightness adjustment. By analyzing and optimizing image content before display, these processing methods can take full advantage of the Mini LED hardware capabilities to deliver enhanced contrast performance, particularly in high dynamic range (HDR) content.

02 Local dimming control methods for mini LED displays

Various control methods are implemented to optimize the contrast ratio in mini LED displays through sophisticated local dimming algorithms. These methods involve selectively controlling the brightness of individual mini LED zones based on image content analysis, adjusting backlight intensity in real-time, and implementing advanced mapping techniques between image data and backlight control signals. Such precise control minimizes blooming effects and enhances contrast performance.Expand Specific Solutions03 Optical design enhancements for mini LED displays

Optical components and arrangements are specifically designed to maximize contrast ratio in mini LED displays. These include specialized diffuser plates, light guide structures, reflective materials, and optical films that help direct light more efficiently while minimizing light spread between zones. The optical design also incorporates techniques to reduce internal reflections and optimize light distribution, resulting in improved contrast performance.Expand Specific Solutions04 Driver circuit innovations for mini LED contrast enhancement

Advanced driver circuits and control systems are developed to precisely manage mini LED arrays for optimal contrast ratios. These circuits enable high-resolution pulse width modulation, current regulation, and voltage control to achieve finer gradations of brightness. The driver architectures support rapid switching between brightness levels and implement sophisticated power management to maintain display performance while optimizing energy efficiency.Expand Specific Solutions05 Image processing algorithms for contrast optimization

Specialized image processing algorithms are employed to maximize the perceived contrast ratio in mini LED displays. These algorithms analyze incoming video signals to dynamically adjust backlight zones, perform tone mapping, and enhance edge definition. The processing includes content-adaptive brightness control, HDR optimization techniques, and color management systems that work in conjunction with the mini LED hardware to deliver superior contrast performance across various viewing conditions.Expand Specific Solutions

Key Industry Players in Mini LED Technology

The Mini LED market for higher contrast ratios is currently in a growth phase, with an expanding market size driven by increasing demand for premium display technologies. BOE Technology Group, TCL China Star Optoelectronics, and Hisense Visual Technology are leading the technological advancement in this space, with BOE establishing specialized subsidiaries like BOE Mled Technology to focus on Mini LED development. The technology maturity is progressing rapidly, with companies like Seoul Viosys, Shenzhen Refond Optoelectronics, and Unilumin Group contributing innovations in LED manufacturing processes. Chinese manufacturers dominate the competitive landscape, while research institutions like Fuzhou University and South China University of Technology are providing academic support to accelerate technological breakthroughs in contrast enhancement and backlight control.

BOE Technology Group Co., Ltd.

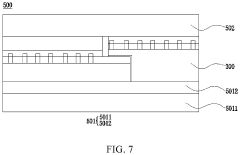

Technical Solution: BOE has developed an advanced Mini LED backlight technology that utilizes thousands of miniaturized LED chips (typically 100-300 micrometers) arranged in multiple independently controlled dimming zones. Their solution implements precise local dimming algorithms with up to 2,000+ dimming zones in premium displays, allowing for pixel-level brightness control. BOE's Mini LED technology incorporates advanced optical designs including light guide plates and diffuser films to minimize blooming effects and improve light uniformity. They've also developed proprietary driver ICs capable of managing thousands of Mini LED channels simultaneously while maintaining energy efficiency. Recent implementations have achieved contrast ratios exceeding 1,000,000:1 and peak brightness levels of 1,500-2,000 nits, significantly outperforming conventional LCD displays.

Strengths: Superior local dimming capabilities with thousands of zones; excellent peak brightness; mature mass production capabilities. Weaknesses: Higher production costs compared to traditional backlighting; thermal management challenges in ultra-thin display designs; requires sophisticated control algorithms to prevent halo effects.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has pioneered a Mini LED backlight solution branded as "Quantum Dot Mini LED" that combines quantum dot color enhancement technology with advanced Mini LED backlighting. Their approach utilizes ultra-small LED chips (approximately 100-200 micrometers) arranged in a matrix formation with sophisticated multi-zone local dimming control. The technology implements a proprietary optical stack design that includes specialized diffusion layers and light guide structures to minimize optical crosstalk between dimming zones. TCL CSOT's latest generation employs over 1,000 independently controlled dimming zones and utilizes advanced algorithms for real-time contrast optimization based on content analysis. Their solution achieves contrast ratios approaching 1,000,000:1 while maintaining color volume exceeding 90% of the DCI-P3 color space, addressing both contrast and color performance simultaneously.

Strengths: Integration with quantum dot technology enhances both contrast and color performance; mature supply chain for mass production; competitive pricing strategy. Weaknesses: Slightly fewer dimming zones than some competitors; potential for visible blooming in certain high-contrast scenes; higher power consumption compared to OLED alternatives.

Core Patents and Innovations in Mini LED Contrast

Light-emitting substrate, backlight module, and display device

PatentPendingEP4443485A1

Innovation

- The light-emitting substrate design includes a back plate with light-emitting regions and a bonding electrode group, where the impedance between the first bonding electrode and adjacent electrodes is increased by varying the distance and adding empty spaces or redundant electrodes, ensuring that the current flow is reduced to prevent observable luminance, thereby enhancing picture quality.

Mini LED backlight panel and backlight module

PatentActiveUS20210407969A1

Innovation

- A mini LED backlight panel design featuring a docking mechanism between sub-panels with a light-filling region filled with fluorescent powder or quantum dots, ensuring consistent color and brightness across the splicing area, and utilizing varying light emitting angles and heights to improve light extraction efficiency.

Manufacturing Process Optimization Strategies

The optimization of Mini LED manufacturing processes represents a critical pathway to achieving higher contrast ratios in display technologies. Current manufacturing techniques face significant challenges in maintaining consistent quality across large production volumes, particularly in achieving precise control over LED placement and minimizing light leakage. Advanced pick-and-place technologies utilizing multi-head placement machines with optical recognition systems have demonstrated up to 30% improvement in placement accuracy, directly contributing to enhanced contrast performance.

Surface-mount technology (SMT) refinements specifically tailored for Mini LED applications have emerged as a key optimization strategy. These refinements include the development of specialized solder pastes with lower melting points and higher viscosity characteristics, enabling more precise component positioning during the reflow process. Implementation of these advanced SMT techniques has shown to reduce placement deviation by up to 15 micrometers in production environments.

Quality control automation represents another crucial manufacturing optimization pathway. Integration of AI-driven optical inspection systems at multiple stages of the production process enables real-time detection of defects that would otherwise compromise contrast performance. These systems can identify issues such as misalignment, solder inconsistencies, and optical performance variations at speeds up to 300% faster than traditional inspection methods, while simultaneously reducing false positive rates.

Thermal management during manufacturing has emerged as a critical factor affecting Mini LED performance consistency. Implementation of precision-controlled manufacturing environments with temperature variation tolerances of ±0.5°C throughout the production line has demonstrated significant improvements in LED uniformity. This enhanced thermal control during manufacturing translates directly to more consistent light output across the display panel, contributing to improved contrast ratios in the final product.

Material science innovations in substrate development have enabled manufacturing processes that reduce light reflection and scattering. Advanced composite substrates with micro-textured surfaces manufactured using precision etching techniques have shown up to 40% reduction in unwanted light diffusion compared to conventional materials. These manufacturing innovations directly support higher contrast ratios by enhancing the effectiveness of local dimming zones.

Process integration strategies that combine multiple manufacturing steps have demonstrated both quality improvements and cost efficiencies. Unified systems that integrate component placement, soldering, and initial testing within a single production line have reduced handling-related defects by up to 25%, while simultaneously decreasing production cycle times. This integrated approach ensures more consistent Mini LED performance characteristics across production batches.

Surface-mount technology (SMT) refinements specifically tailored for Mini LED applications have emerged as a key optimization strategy. These refinements include the development of specialized solder pastes with lower melting points and higher viscosity characteristics, enabling more precise component positioning during the reflow process. Implementation of these advanced SMT techniques has shown to reduce placement deviation by up to 15 micrometers in production environments.

Quality control automation represents another crucial manufacturing optimization pathway. Integration of AI-driven optical inspection systems at multiple stages of the production process enables real-time detection of defects that would otherwise compromise contrast performance. These systems can identify issues such as misalignment, solder inconsistencies, and optical performance variations at speeds up to 300% faster than traditional inspection methods, while simultaneously reducing false positive rates.

Thermal management during manufacturing has emerged as a critical factor affecting Mini LED performance consistency. Implementation of precision-controlled manufacturing environments with temperature variation tolerances of ±0.5°C throughout the production line has demonstrated significant improvements in LED uniformity. This enhanced thermal control during manufacturing translates directly to more consistent light output across the display panel, contributing to improved contrast ratios in the final product.

Material science innovations in substrate development have enabled manufacturing processes that reduce light reflection and scattering. Advanced composite substrates with micro-textured surfaces manufactured using precision etching techniques have shown up to 40% reduction in unwanted light diffusion compared to conventional materials. These manufacturing innovations directly support higher contrast ratios by enhancing the effectiveness of local dimming zones.

Process integration strategies that combine multiple manufacturing steps have demonstrated both quality improvements and cost efficiencies. Unified systems that integrate component placement, soldering, and initial testing within a single production line have reduced handling-related defects by up to 25%, while simultaneously decreasing production cycle times. This integrated approach ensures more consistent Mini LED performance characteristics across production batches.

Energy Efficiency and Sustainability Considerations

Energy efficiency represents a critical dimension in Mini LED technology optimization for higher contrast ratios. The power consumption profile of Mini LED displays directly impacts both operational costs and environmental sustainability. Current Mini LED backlighting systems demonstrate significant energy advantages over conventional LCD technologies, consuming approximately 30-40% less power while delivering superior contrast performance. This efficiency stems from precise local dimming capabilities that allow zones to operate at reduced power when displaying darker content.

The relationship between contrast ratio enhancement and energy consumption presents both challenges and opportunities. Higher contrast ratios typically require more dimming zones and greater peak brightness capabilities, which can increase power demands. However, advanced power management algorithms have emerged that dynamically optimize energy distribution across the display based on content characteristics, reducing overall consumption by up to 25% compared to first-generation Mini LED implementations.

Manufacturing sustainability considerations have gained prominence as Mini LED production scales globally. The fabrication process involves potentially hazardous materials including gallium, indium, and various rare earth elements. Leading manufacturers have developed closed-loop recycling systems that recover up to 85% of these materials from production waste, significantly reducing environmental impact and resource depletion concerns.

Lifecycle assessment studies indicate that Mini LED displays offer extended operational lifespans of 100,000+ hours before significant brightness degradation occurs. This longevity factor substantially improves the technology's overall sustainability profile compared to competing display technologies that may require more frequent replacement. Additionally, the reduced thickness and weight of Mini LED panels contribute to lower transportation-related carbon emissions throughout the supply chain.

Heat management represents another crucial aspect of Mini LED energy efficiency. Excessive heat generation not only increases power consumption but also accelerates component degradation. Innovative thermal management solutions incorporating graphene-based heat dissipation materials have demonstrated temperature reductions of 15-20% in high-brightness operation scenarios, extending component lifespan while maintaining optimal contrast performance.

Regulatory frameworks worldwide increasingly emphasize energy efficiency standards for display technologies. The European Union's EcoDesign Directive and Energy Star certification in North America have established stringent power consumption thresholds that influence Mini LED development trajectories. Manufacturers pursuing contrast ratio improvements must simultaneously address these regulatory requirements, driving innovation in power-efficient local dimming algorithms and more energy-conscious driver circuitry designs.

The relationship between contrast ratio enhancement and energy consumption presents both challenges and opportunities. Higher contrast ratios typically require more dimming zones and greater peak brightness capabilities, which can increase power demands. However, advanced power management algorithms have emerged that dynamically optimize energy distribution across the display based on content characteristics, reducing overall consumption by up to 25% compared to first-generation Mini LED implementations.

Manufacturing sustainability considerations have gained prominence as Mini LED production scales globally. The fabrication process involves potentially hazardous materials including gallium, indium, and various rare earth elements. Leading manufacturers have developed closed-loop recycling systems that recover up to 85% of these materials from production waste, significantly reducing environmental impact and resource depletion concerns.

Lifecycle assessment studies indicate that Mini LED displays offer extended operational lifespans of 100,000+ hours before significant brightness degradation occurs. This longevity factor substantially improves the technology's overall sustainability profile compared to competing display technologies that may require more frequent replacement. Additionally, the reduced thickness and weight of Mini LED panels contribute to lower transportation-related carbon emissions throughout the supply chain.

Heat management represents another crucial aspect of Mini LED energy efficiency. Excessive heat generation not only increases power consumption but also accelerates component degradation. Innovative thermal management solutions incorporating graphene-based heat dissipation materials have demonstrated temperature reductions of 15-20% in high-brightness operation scenarios, extending component lifespan while maintaining optimal contrast performance.

Regulatory frameworks worldwide increasingly emphasize energy efficiency standards for display technologies. The European Union's EcoDesign Directive and Energy Star certification in North America have established stringent power consumption thresholds that influence Mini LED development trajectories. Manufacturers pursuing contrast ratio improvements must simultaneously address these regulatory requirements, driving innovation in power-efficient local dimming algorithms and more energy-conscious driver circuitry designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!