Optimizing Neodymium Magnet Use in Flexible Circuit Designs

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnets in Flexible Circuits: Background and Objectives

Neodymium magnets have revolutionized the electronics industry since their commercial introduction in the 1980s. These rare-earth magnets, composed primarily of neodymium, iron, and boron (NdFeB), offer unprecedented magnetic strength-to-size ratios, making them invaluable for applications requiring powerful yet compact magnetic components. The evolution of these magnets has closely paralleled advancements in miniaturization across the electronics sector, with significant milestones including increased temperature stability and improved corrosion resistance through specialized coatings.

The integration of neodymium magnets with flexible circuit technology represents a relatively recent technological convergence. Flexible circuits, which emerged in the 1950s and gained widespread adoption in the 1990s, have traditionally relied on mechanical fasteners or adhesives for component attachment. The introduction of magnetic mounting solutions using neodymium magnets presents a paradigm shift in design methodology, offering both secure attachment and the possibility of reconfigurable components.

Current technological trends indicate a growing demand for more adaptable, modular electronic systems that can be easily modified or upgraded. This trend aligns perfectly with the potential benefits of optimized neodymium magnet implementation in flexible circuits. Additionally, the push toward wearable technology and Internet of Things (IoT) devices has accelerated interest in flexible electronic systems that can conform to irregular surfaces while maintaining robust component connections.

The primary technical objectives for optimizing neodymium magnet use in flexible circuit designs encompass several dimensions. First, there is a need to develop mounting configurations that maximize magnetic coupling strength while minimizing interference with circuit functionality. Second, researchers aim to address challenges related to thermal management, as neodymium magnets lose magnetic properties at elevated temperatures (typically above 80°C). Third, there is significant interest in developing manufacturing processes that allow for precise placement and secure bonding of magnets to flexible substrates.

Long-term technological goals include the development of composite materials that combine magnetic and conductive properties, potentially eliminating the need for discrete magnetic components altogether. There is also substantial research focused on creating programmable magnetic interfaces that could allow for dynamic reconfiguration of circuit layouts through controlled magnetization patterns.

The optimization of neodymium magnet implementation in flexible circuits represents a critical enabling technology for next-generation electronic devices, particularly in medical implants, wearable computing, and aerospace applications where weight, space, and reliability constraints are paramount. As such, this technological domain sits at the intersection of materials science, electrical engineering, and manufacturing innovation, with significant potential to enable new product categories and capabilities.

The integration of neodymium magnets with flexible circuit technology represents a relatively recent technological convergence. Flexible circuits, which emerged in the 1950s and gained widespread adoption in the 1990s, have traditionally relied on mechanical fasteners or adhesives for component attachment. The introduction of magnetic mounting solutions using neodymium magnets presents a paradigm shift in design methodology, offering both secure attachment and the possibility of reconfigurable components.

Current technological trends indicate a growing demand for more adaptable, modular electronic systems that can be easily modified or upgraded. This trend aligns perfectly with the potential benefits of optimized neodymium magnet implementation in flexible circuits. Additionally, the push toward wearable technology and Internet of Things (IoT) devices has accelerated interest in flexible electronic systems that can conform to irregular surfaces while maintaining robust component connections.

The primary technical objectives for optimizing neodymium magnet use in flexible circuit designs encompass several dimensions. First, there is a need to develop mounting configurations that maximize magnetic coupling strength while minimizing interference with circuit functionality. Second, researchers aim to address challenges related to thermal management, as neodymium magnets lose magnetic properties at elevated temperatures (typically above 80°C). Third, there is significant interest in developing manufacturing processes that allow for precise placement and secure bonding of magnets to flexible substrates.

Long-term technological goals include the development of composite materials that combine magnetic and conductive properties, potentially eliminating the need for discrete magnetic components altogether. There is also substantial research focused on creating programmable magnetic interfaces that could allow for dynamic reconfiguration of circuit layouts through controlled magnetization patterns.

The optimization of neodymium magnet implementation in flexible circuits represents a critical enabling technology for next-generation electronic devices, particularly in medical implants, wearable computing, and aerospace applications where weight, space, and reliability constraints are paramount. As such, this technological domain sits at the intersection of materials science, electrical engineering, and manufacturing innovation, with significant potential to enable new product categories and capabilities.

Market Analysis for Magnetic Flexible Circuit Applications

The magnetic flexible circuit market is experiencing robust growth, driven by increasing demand for miniaturized electronic devices across multiple industries. Current market valuations place this sector at approximately 3.2 billion USD in 2023, with projections indicating a compound annual growth rate of 7.8% through 2028. This growth trajectory is particularly evident in consumer electronics, automotive applications, and medical devices, where space constraints and design flexibility are critical factors.

Consumer electronics represents the largest application segment, accounting for roughly 42% of the total market share. The proliferation of wearable technology, smartphones, and ultra-thin computing devices has created substantial demand for flexible circuit solutions incorporating neodymium magnets. These components enable secure connections, improved haptic feedback, and novel form factors that enhance user experience while maintaining device reliability.

The automotive sector follows as the second-largest market segment at 27% market share, with applications ranging from advanced driver assistance systems (ADAS) to electric vehicle battery management systems. The transition toward electric and autonomous vehicles has accelerated the adoption of flexible magnetic circuits that can withstand harsh operating environments while providing space-efficient solutions for increasingly complex vehicle electronics.

Medical device applications constitute approximately 18% of the market, with significant growth potential due to increasing demand for portable diagnostic equipment, implantable devices, and wearable health monitors. The unique properties of neodymium magnets in flexible circuits enable non-invasive attachment methods, improved signal transmission, and enhanced device functionality in critical healthcare applications.

Regional analysis reveals that Asia-Pacific dominates the market with 48% share, led by manufacturing powerhouses in China, Japan, and South Korea. North America follows at 29%, with particular strength in medical and aerospace applications, while Europe accounts for 19% of the global market with strong automotive sector implementation.

Supply chain considerations have become increasingly important, with recent disruptions highlighting vulnerabilities in rare earth element sourcing. China currently controls approximately 85% of global neodymium production, creating potential bottlenecks and price volatility that impact downstream manufacturing. This has prompted increased investment in alternative sourcing strategies and recycling technologies to ensure sustainable supply for growing market demands.

Customer requirements analysis indicates a clear trend toward higher performance in smaller form factors, with particular emphasis on thermal management, electromagnetic interference mitigation, and mechanical durability. These requirements are driving innovation in neodymium magnet integration techniques that optimize magnetic field strength while minimizing material usage.

Consumer electronics represents the largest application segment, accounting for roughly 42% of the total market share. The proliferation of wearable technology, smartphones, and ultra-thin computing devices has created substantial demand for flexible circuit solutions incorporating neodymium magnets. These components enable secure connections, improved haptic feedback, and novel form factors that enhance user experience while maintaining device reliability.

The automotive sector follows as the second-largest market segment at 27% market share, with applications ranging from advanced driver assistance systems (ADAS) to electric vehicle battery management systems. The transition toward electric and autonomous vehicles has accelerated the adoption of flexible magnetic circuits that can withstand harsh operating environments while providing space-efficient solutions for increasingly complex vehicle electronics.

Medical device applications constitute approximately 18% of the market, with significant growth potential due to increasing demand for portable diagnostic equipment, implantable devices, and wearable health monitors. The unique properties of neodymium magnets in flexible circuits enable non-invasive attachment methods, improved signal transmission, and enhanced device functionality in critical healthcare applications.

Regional analysis reveals that Asia-Pacific dominates the market with 48% share, led by manufacturing powerhouses in China, Japan, and South Korea. North America follows at 29%, with particular strength in medical and aerospace applications, while Europe accounts for 19% of the global market with strong automotive sector implementation.

Supply chain considerations have become increasingly important, with recent disruptions highlighting vulnerabilities in rare earth element sourcing. China currently controls approximately 85% of global neodymium production, creating potential bottlenecks and price volatility that impact downstream manufacturing. This has prompted increased investment in alternative sourcing strategies and recycling technologies to ensure sustainable supply for growing market demands.

Customer requirements analysis indicates a clear trend toward higher performance in smaller form factors, with particular emphasis on thermal management, electromagnetic interference mitigation, and mechanical durability. These requirements are driving innovation in neodymium magnet integration techniques that optimize magnetic field strength while minimizing material usage.

Technical Challenges in Neodymium Magnet Integration

The integration of neodymium magnets into flexible circuit designs presents significant technical challenges that require innovative solutions. The primary obstacle lies in the inherent brittleness of neodymium magnets, which contrasts sharply with the malleable nature of flexible circuits. When these magnets are subjected to bending or flexing forces, they tend to crack or shatter, compromising both their magnetic properties and the structural integrity of the circuit.

Miniaturization requirements further complicate integration efforts. As flexible circuits are increasingly designed for compact applications such as wearable technology and medical devices, the need to incorporate smaller yet powerful magnets becomes paramount. However, reducing magnet size while maintaining sufficient magnetic field strength represents a delicate engineering balance that has not been fully resolved.

Thermal management poses another significant challenge. Neodymium magnets exhibit temperature-dependent behavior, with magnetic properties degrading at elevated temperatures (typically above 80°C). Flexible circuits in operation can generate considerable heat, particularly in densely packed configurations, potentially causing demagnetization or reduced performance of integrated magnets.

Adhesion and mounting mechanisms present technical hurdles as well. Traditional bonding methods often fail to provide reliable attachment between rigid magnets and flexible substrates during repeated flexing cycles. The differential expansion rates between these dissimilar materials under thermal cycling can lead to delamination or mechanical failure over time.

Electromagnetic interference (EMI) issues arise when neodymium magnets are placed in proximity to sensitive electronic components. The strong magnetic fields can disrupt signal integrity, induce currents in nearby conductors, and interfere with the operation of sensors or communication modules within the flexible circuit assembly.

Corrosion protection represents another technical challenge, as neodymium magnets are highly susceptible to oxidation. The typical operating environments for flexible circuits—which may include exposure to humidity, sweat, or other corrosive elements—can rapidly degrade unprotected magnets. While protective coatings exist, applying them uniformly to magnets intended for flexible circuit integration without compromising the circuit's flexibility remains problematic.

Manufacturing scalability also presents significant obstacles. Current production methods for integrating magnets into flexible circuits often involve manual placement and bonding, which limits throughput and increases costs. Developing automated processes that can precisely position and secure magnets within flexible substrates at high production volumes continues to challenge engineers and manufacturers in this field.

Miniaturization requirements further complicate integration efforts. As flexible circuits are increasingly designed for compact applications such as wearable technology and medical devices, the need to incorporate smaller yet powerful magnets becomes paramount. However, reducing magnet size while maintaining sufficient magnetic field strength represents a delicate engineering balance that has not been fully resolved.

Thermal management poses another significant challenge. Neodymium magnets exhibit temperature-dependent behavior, with magnetic properties degrading at elevated temperatures (typically above 80°C). Flexible circuits in operation can generate considerable heat, particularly in densely packed configurations, potentially causing demagnetization or reduced performance of integrated magnets.

Adhesion and mounting mechanisms present technical hurdles as well. Traditional bonding methods often fail to provide reliable attachment between rigid magnets and flexible substrates during repeated flexing cycles. The differential expansion rates between these dissimilar materials under thermal cycling can lead to delamination or mechanical failure over time.

Electromagnetic interference (EMI) issues arise when neodymium magnets are placed in proximity to sensitive electronic components. The strong magnetic fields can disrupt signal integrity, induce currents in nearby conductors, and interfere with the operation of sensors or communication modules within the flexible circuit assembly.

Corrosion protection represents another technical challenge, as neodymium magnets are highly susceptible to oxidation. The typical operating environments for flexible circuits—which may include exposure to humidity, sweat, or other corrosive elements—can rapidly degrade unprotected magnets. While protective coatings exist, applying them uniformly to magnets intended for flexible circuit integration without compromising the circuit's flexibility remains problematic.

Manufacturing scalability also presents significant obstacles. Current production methods for integrating magnets into flexible circuits often involve manual placement and bonding, which limits throughput and increases costs. Developing automated processes that can precisely position and secure magnets within flexible substrates at high production volumes continues to challenge engineers and manufacturers in this field.

Current Integration Methods for Neodymium Magnets

01 Composition optimization for neodymium magnets

Optimizing the composition of neodymium magnets involves adjusting the ratios of rare earth elements, transition metals, and other additives to enhance magnetic properties. This includes precise control of neodymium, iron, and boron content, as well as incorporating elements like dysprosium or terbium to improve high-temperature performance and coercivity. The manufacturing process often involves careful alloying, melting, and casting techniques to ensure homogeneous distribution of elements throughout the material.- Composition optimization for neodymium magnets: Optimizing the chemical composition of neodymium magnets can significantly enhance their magnetic properties. This includes adjusting the ratios of neodymium, iron, and boron, as well as adding specific rare earth elements or other additives to improve coercivity, remanence, and temperature stability. These compositional modifications can lead to magnets with higher energy products and better performance in various applications.

- Manufacturing process improvements: Advancements in manufacturing processes can optimize the performance of neodymium magnets. These include refined sintering techniques, improved powder metallurgy methods, precise heat treatment protocols, and controlled cooling processes. Such manufacturing optimizations can enhance grain alignment, reduce defects, and create more uniform magnetic domains, resulting in magnets with superior magnetic properties and mechanical strength.

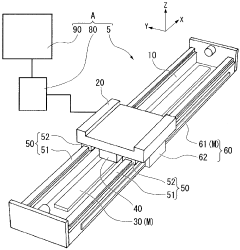

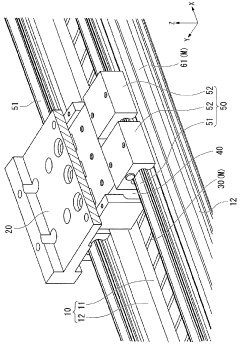

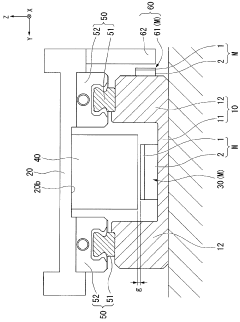

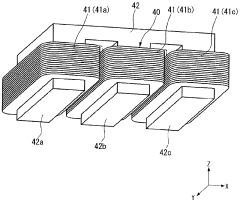

- Structural design optimization: The structural design of neodymium magnet systems can be optimized to maximize magnetic field strength and distribution. This includes innovative shapes, arrays, and configurations that enhance magnetic flux concentration and direction. Halbach arrays, multi-pole designs, and specialized geometries can be employed to focus magnetic fields where needed and minimize stray fields, improving overall system efficiency and performance.

- Coating and surface treatment technologies: Various coating and surface treatment technologies can be applied to neodymium magnets to enhance their corrosion resistance, thermal stability, and durability. These include nickel, zinc, epoxy, and specialized polymer coatings, as well as surface passivation treatments. Such protective layers prevent oxidation and degradation of the magnetic material, extending the lifespan of the magnets while maintaining their magnetic properties in harsh environments.

- Testing and quality control methods: Advanced testing and quality control methods are essential for optimizing neodymium magnets. These include sophisticated magnetic field measurement techniques, material characterization methods, accelerated aging tests, and non-destructive evaluation procedures. Implementing comprehensive quality control systems ensures consistency in magnetic properties, identifies defects early in the production process, and verifies that magnets meet the required specifications for specific applications.

02 Manufacturing process improvements for neodymium magnets

Advanced manufacturing processes can significantly optimize neodymium magnet performance. These include refined powder metallurgy techniques, improved sintering processes, and precise heat treatment protocols. Innovations in grain boundary diffusion processes allow for more efficient use of heavy rare earth elements, while controlled cooling rates during manufacturing help achieve optimal microstructure. These process improvements result in magnets with enhanced magnetic properties, better thermal stability, and increased resistance to demagnetization.Expand Specific Solutions03 Structural design optimization for magnetic assemblies

The structural design of magnetic assemblies using neodymium magnets can be optimized through various configurations and arrangements. This includes the use of Halbach arrays, magnetic circuits with pole pieces, and strategic positioning of multiple magnets to focus or direct magnetic flux. Computer modeling and simulation tools help predict magnetic field distributions and optimize magnet shapes, sizes, and orientations for specific applications. These design optimizations maximize magnetic field strength while minimizing the volume of expensive magnetic material required.Expand Specific Solutions04 Surface treatment and coating technologies

Surface treatments and coatings are essential for optimizing neodymium magnet performance and longevity. Various coating methods including nickel plating, zinc plating, epoxy coating, and parylene coating protect against corrosion and oxidation. Advanced surface passivation techniques improve chemical stability, while specialized coatings can enhance thermal conductivity or provide electrical insulation. These treatments extend magnet lifespan in harsh environments and prevent degradation of magnetic properties over time.Expand Specific Solutions05 Testing and quality control methods

Sophisticated testing and quality control methods ensure optimal performance of neodymium magnets. These include magnetic property measurements using hysteresisgraphs, vibrating sample magnetometers, and Helmholtz coils to verify magnetic flux density and coercivity. Physical testing methods assess mechanical strength, dimensional accuracy, and coating quality. Advanced techniques like scanning electron microscopy and X-ray diffraction analyze microstructure and phase composition. Implementing statistical process control and automated inspection systems helps maintain consistent quality across production batches.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The flexible circuit design market utilizing neodymium magnets is in a growth phase, with increasing demand driven by miniaturization trends in electronics and automotive applications. The market is expected to reach significant scale as companies like Beijing Zhong Ke San Huan High-Tech and Hengdian Group DMEGC Magnetics lead in magnetic material production, while Apple, Bosch, and Nidec drive application innovation. Technology maturity varies across sectors, with established players like Valeo and Continental Automotive demonstrating advanced implementation in automotive electronics, while newer entrants like Heye Health Technology explore emerging healthcare applications. Research institutions including Zhejiang University and CNRS are advancing fundamental technologies to overcome current limitations in flexible circuit integration with magnetic components.

Beijing Zhong Ke San Huan High-Tech Co., Ltd.

Technical Solution: Beijing Zhong Ke San Huan has developed a proprietary NdFeB magnet manufacturing process specifically optimized for flexible circuit applications. Their technology involves creating ultra-thin (sub-0.5mm) sintered neodymium magnets with specialized coatings that resist delamination when integrated with flexible substrates. The company has pioneered a "gradient magnetization" technique that allows for precise magnetic field distribution across curved or bent surfaces, maintaining consistent magnetic performance even when the circuit is flexed. Their patented process reduces eddy current losses by up to 40% compared to conventional magnets when used in flexible circuit designs, enabling higher frequency operation without excessive heating. Additionally, they've developed specialized bonding techniques using temperature-resistant adhesives that maintain integrity across the full operating temperature range (-40°C to +150°C) of flexible circuits, ensuring reliable performance in automotive and industrial applications.

Strengths: Industry-leading thin magnet manufacturing capability with excellent mechanical properties for flexible applications; proprietary coating technology provides superior corrosion resistance while maintaining flexibility. Weaknesses: Higher production costs compared to standard magnets; limited production capacity for ultra-specialized designs; requires careful handling during circuit assembly to prevent damage to the thinnest magnet variants.

Robert Bosch GmbH

Technical Solution: Bosch has developed a sophisticated approach to neodymium magnet optimization for flexible circuits through their "FlexMag" technology platform. This system employs a multi-layered design philosophy where specially engineered NdFeB magnets are integrated with compliant mounting structures that accommodate the mechanical stress of flexing circuits. Their proprietary manufacturing process creates magnets with anisotropic properties that maintain consistent magnetic field strength even when subjected to bending forces. Bosch has pioneered a micro-segmentation technique that distributes smaller, precisely positioned magnets throughout flexible circuit designs, reducing weight by approximately 30% while maintaining equivalent magnetic performance. Their advanced simulation tools allow for precise magnetic field modeling in dynamic flexible environments, optimizing magnet placement and orientation for specific applications. Additionally, Bosch has developed specialized encapsulation methods using nano-composite materials that protect neodymium magnets from environmental factors while preserving flexibility, extending operational lifespan by up to 40% in automotive applications. The company has successfully implemented these technologies in sensor systems for advanced driver assistance systems (ADAS) and industrial automation.

Strengths: Comprehensive system-level approach that considers both magnetic and mechanical aspects; extensive experience in automotive-grade reliability requirements; advanced simulation capabilities for optimizing magnetic field distribution. Weaknesses: Solutions tend to be more expensive than competitors; primarily focused on automotive and industrial applications rather than consumer electronics; requires specialized manufacturing equipment for implementation.

Key Patents and Research on Magnetic Flexible Circuits

Flexible magnet, method for manufacturing flexible magnet, magnetic encoder, and actuator

PatentWO2012073755A1

Innovation

- A flexible magnet comprising a first sheet with rare earth magnetic powder in resin, magnetized with N and S poles on the surface, and a second sheet with ferrite magnetic powder in resin on the back, acting as a reinforcing member to prevent cracking or tearing when bent, and maintaining high magnetic force.

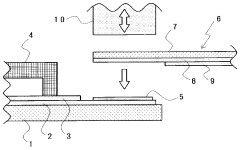

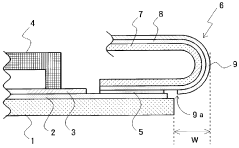

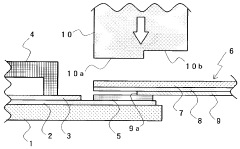

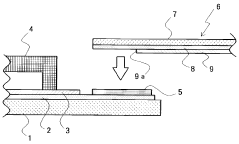

Flexible circuit board module and its manufacturing method

PatentWO2010001448A1

Innovation

- The FPC is connected to the substrate body using an anisotropic conductive film (ACF) with a protruding portion that covers part of the coverlay, allowing for a controlled bending process to disperse stress, reducing the occurrence of wiring breakage and peeling by using a thermocompression bonding head with different surfaces for electrical and mechanical connection.

Material Compatibility and Durability Considerations

When integrating neodymium magnets into flexible circuit designs, material compatibility and durability considerations become paramount for ensuring long-term reliability and performance. Neodymium magnets (Nd2Fe14B) are highly susceptible to corrosion, particularly in environments with high humidity or temperature fluctuations. This vulnerability necessitates careful selection of protective coatings such as nickel-copper-nickel plating, epoxy resin, or parylene conformal coating to prevent degradation when in contact with flexible circuit materials.

The thermal expansion coefficient mismatch between neodymium magnets and flexible substrate materials presents a significant challenge. While flexible circuits typically utilize polyimide or polyester substrates with thermal expansion coefficients ranging from 17-20 ppm/°C, neodymium magnets exhibit much lower rates at approximately 4-8 ppm/°C. This disparity can lead to mechanical stress during thermal cycling, potentially causing delamination or cracking at interface points.

Galvanic corrosion risk must be carefully evaluated when neodymium magnets come into contact with conductive traces on flexible circuits. The electrochemical potential difference between the neodymium alloy and copper or silver traces can accelerate corrosion in the presence of moisture. Implementing isolation layers or selecting compatible metallization for circuit traces becomes essential for mitigating this risk.

Mechanical stress resistance represents another critical consideration. Flexible circuits, by definition, undergo repeated bending and flexing during operation. The brittle nature of sintered neodymium magnets makes them susceptible to fracturing under such conditions. Bonding techniques must accommodate the differential movement between the rigid magnet and flexible substrate while maintaining secure attachment.

Long-term magnetic field stability must be preserved despite environmental challenges. Neodymium magnets can experience flux loss when exposed to temperatures exceeding 80°C, which may occur in certain flexible circuit applications. Additionally, mechanical shock and vibration can gradually demagnetize these components over time. Implementing design features that shield magnets from extreme conditions helps maintain magnetic performance throughout the product lifecycle.

Chemical compatibility between adhesives used for magnet attachment and flexible circuit materials requires thorough evaluation. Certain adhesives may contain solvents or curing agents that could degrade either the magnet coating or the flexible substrate. Silicone-based adhesives often provide the optimal balance of flexibility and chemical inertness for these applications, though they typically offer lower bond strength than epoxy alternatives.

The thermal expansion coefficient mismatch between neodymium magnets and flexible substrate materials presents a significant challenge. While flexible circuits typically utilize polyimide or polyester substrates with thermal expansion coefficients ranging from 17-20 ppm/°C, neodymium magnets exhibit much lower rates at approximately 4-8 ppm/°C. This disparity can lead to mechanical stress during thermal cycling, potentially causing delamination or cracking at interface points.

Galvanic corrosion risk must be carefully evaluated when neodymium magnets come into contact with conductive traces on flexible circuits. The electrochemical potential difference between the neodymium alloy and copper or silver traces can accelerate corrosion in the presence of moisture. Implementing isolation layers or selecting compatible metallization for circuit traces becomes essential for mitigating this risk.

Mechanical stress resistance represents another critical consideration. Flexible circuits, by definition, undergo repeated bending and flexing during operation. The brittle nature of sintered neodymium magnets makes them susceptible to fracturing under such conditions. Bonding techniques must accommodate the differential movement between the rigid magnet and flexible substrate while maintaining secure attachment.

Long-term magnetic field stability must be preserved despite environmental challenges. Neodymium magnets can experience flux loss when exposed to temperatures exceeding 80°C, which may occur in certain flexible circuit applications. Additionally, mechanical shock and vibration can gradually demagnetize these components over time. Implementing design features that shield magnets from extreme conditions helps maintain magnetic performance throughout the product lifecycle.

Chemical compatibility between adhesives used for magnet attachment and flexible circuit materials requires thorough evaluation. Certain adhesives may contain solvents or curing agents that could degrade either the magnet coating or the flexible substrate. Silicone-based adhesives often provide the optimal balance of flexibility and chemical inertness for these applications, though they typically offer lower bond strength than epoxy alternatives.

Environmental Impact and Recycling Strategies

The environmental impact of neodymium magnets in flexible circuit designs presents significant sustainability challenges that require comprehensive assessment and strategic solutions. The mining and processing of rare earth elements, particularly neodymium, involves extensive land disruption, water pollution, and toxic waste generation. Studies indicate that for every ton of rare earth elements produced, approximately 2,000 tons of toxic waste may be generated, creating substantial environmental liabilities.

In flexible circuit applications, the miniaturization trend has increased the concentration of these materials, complicating end-of-life management. Current disposal practices often result in valuable neodymium resources entering landfills, where they not only represent lost economic value but also pose potential groundwater contamination risks through leaching of heavy metals.

Advanced recycling technologies are emerging as critical solutions to mitigate these environmental concerns. Hydrometallurgical processes using selective leaching agents have demonstrated recovery rates of up to 95% for neodymium from end-of-life electronics. These methods offer significantly reduced energy consumption compared to primary production, with some studies indicating energy savings of 75-80% when using recycled materials.

Pyrometallurgical approaches provide complementary recycling pathways, particularly suitable for processing mixed electronic waste containing neodymium magnets. These high-temperature processes can effectively separate rare earth elements from other materials, though they typically require substantial energy inputs and sophisticated emissions control systems.

Design-for-recycling strategies represent a proactive approach to environmental management. Incorporating easily separable magnet components in flexible circuit designs can increase recovery rates by 40-60% compared to conventional designs. Several manufacturers have pioneered snap-fit assemblies and reversible adhesives that maintain performance while facilitating end-of-life disassembly.

Regulatory frameworks are increasingly influencing industry practices, with the European Union's WEEE Directive and similar legislation in Japan and China establishing extended producer responsibility for electronic waste. These regulations are driving innovation in both recycling technologies and product design approaches that minimize environmental impact throughout the product lifecycle.

Industry-academic partnerships have accelerated the development of novel recycling methods, including bioleaching techniques that utilize specialized microorganisms to extract rare earth elements from waste materials. These approaches offer potentially lower environmental footprints than conventional chemical processes, though they remain in early development stages with commercial implementation expected within the next 5-7 years.

In flexible circuit applications, the miniaturization trend has increased the concentration of these materials, complicating end-of-life management. Current disposal practices often result in valuable neodymium resources entering landfills, where they not only represent lost economic value but also pose potential groundwater contamination risks through leaching of heavy metals.

Advanced recycling technologies are emerging as critical solutions to mitigate these environmental concerns. Hydrometallurgical processes using selective leaching agents have demonstrated recovery rates of up to 95% for neodymium from end-of-life electronics. These methods offer significantly reduced energy consumption compared to primary production, with some studies indicating energy savings of 75-80% when using recycled materials.

Pyrometallurgical approaches provide complementary recycling pathways, particularly suitable for processing mixed electronic waste containing neodymium magnets. These high-temperature processes can effectively separate rare earth elements from other materials, though they typically require substantial energy inputs and sophisticated emissions control systems.

Design-for-recycling strategies represent a proactive approach to environmental management. Incorporating easily separable magnet components in flexible circuit designs can increase recovery rates by 40-60% compared to conventional designs. Several manufacturers have pioneered snap-fit assemblies and reversible adhesives that maintain performance while facilitating end-of-life disassembly.

Regulatory frameworks are increasingly influencing industry practices, with the European Union's WEEE Directive and similar legislation in Japan and China establishing extended producer responsibility for electronic waste. These regulations are driving innovation in both recycling technologies and product design approaches that minimize environmental impact throughout the product lifecycle.

Industry-academic partnerships have accelerated the development of novel recycling methods, including bioleaching techniques that utilize specialized microorganisms to extract rare earth elements from waste materials. These approaches offer potentially lower environmental footprints than conventional chemical processes, though they remain in early development stages with commercial implementation expected within the next 5-7 years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!