Patent Landscape for Single-Atom Catalysis in Catalysts

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Single-Atom Catalysis Background and Objectives

Single-atom catalysis (SAC) represents a revolutionary frontier in heterogeneous catalysis that has emerged over the past decade. This innovative field focuses on the dispersion of isolated metal atoms on various supports, creating catalysts with maximum atom efficiency and unique catalytic properties. The concept was first formally introduced in 2011, though earlier studies had observed similar phenomena without explicitly defining the field.

The evolution of SAC technology has been driven by advances in characterization techniques, particularly aberration-corrected electron microscopy and X-ray absorption spectroscopy, which have enabled researchers to definitively identify and study isolated metal atoms on supports. This technological progression has transformed catalysis from traditional nanoparticle systems to precisely controlled single-atom architectures.

The development trajectory of SAC has been marked by several key milestones: initial proof-of-concept demonstrations, expansion of applicable metal elements beyond noble metals, diversification of support materials, and most recently, the creation of dual-atom and multi-atom sites with controlled configurations. Each advancement has expanded the potential applications and enhanced the performance metrics of these catalysts.

Current research trends in SAC focus on addressing stability challenges, understanding reaction mechanisms at the atomic level, and developing scalable synthesis methods. The field is moving toward rational design principles that can predict catalytic behavior based on metal-support interactions and electronic structures, rather than empirical trial-and-error approaches.

The primary technical objectives in SAC research include: enhancing catalyst stability under realistic reaction conditions; developing precise synthesis protocols for industrial-scale production; expanding the range of catalyzed reactions beyond current limitations; and creating multifunctional SACs capable of catalyzing cascade reactions in one-pot processes.

From a patent landscape perspective, SAC technology has seen exponential growth in patent filings since 2015, with particular concentration in energy conversion, environmental remediation, and fine chemical synthesis applications. The intellectual property ecosystem is increasingly competitive, with both academic institutions and industrial entities seeking to secure foundational patents in synthesis methods and application-specific implementations.

The ultimate goal of SAC research is to develop atom-efficient catalysts that can significantly reduce energy consumption and waste production in chemical processes, aligning with global sustainability objectives while enabling novel chemical transformations that are unattainable with conventional catalysts.

The evolution of SAC technology has been driven by advances in characterization techniques, particularly aberration-corrected electron microscopy and X-ray absorption spectroscopy, which have enabled researchers to definitively identify and study isolated metal atoms on supports. This technological progression has transformed catalysis from traditional nanoparticle systems to precisely controlled single-atom architectures.

The development trajectory of SAC has been marked by several key milestones: initial proof-of-concept demonstrations, expansion of applicable metal elements beyond noble metals, diversification of support materials, and most recently, the creation of dual-atom and multi-atom sites with controlled configurations. Each advancement has expanded the potential applications and enhanced the performance metrics of these catalysts.

Current research trends in SAC focus on addressing stability challenges, understanding reaction mechanisms at the atomic level, and developing scalable synthesis methods. The field is moving toward rational design principles that can predict catalytic behavior based on metal-support interactions and electronic structures, rather than empirical trial-and-error approaches.

The primary technical objectives in SAC research include: enhancing catalyst stability under realistic reaction conditions; developing precise synthesis protocols for industrial-scale production; expanding the range of catalyzed reactions beyond current limitations; and creating multifunctional SACs capable of catalyzing cascade reactions in one-pot processes.

From a patent landscape perspective, SAC technology has seen exponential growth in patent filings since 2015, with particular concentration in energy conversion, environmental remediation, and fine chemical synthesis applications. The intellectual property ecosystem is increasingly competitive, with both academic institutions and industrial entities seeking to secure foundational patents in synthesis methods and application-specific implementations.

The ultimate goal of SAC research is to develop atom-efficient catalysts that can significantly reduce energy consumption and waste production in chemical processes, aligning with global sustainability objectives while enabling novel chemical transformations that are unattainable with conventional catalysts.

Market Demand Analysis for Single-Atom Catalysts

The global market for single-atom catalysts (SACs) has witnessed significant growth in recent years, driven by increasing demand for more efficient and sustainable catalytic processes across various industries. The unique properties of SACs, including their maximized atom utilization efficiency and exceptional catalytic performance, position them as highly valuable materials in addressing critical industrial and environmental challenges.

The energy sector represents one of the largest market segments for SACs, with applications in fuel cells, hydrogen production, and renewable energy conversion. The global push towards hydrogen economy has particularly accelerated demand for platinum-group metal (PGM) based SACs, which offer superior performance in hydrogen evolution reaction (HER) and oxygen reduction reaction (ORR) while using minimal amounts of precious metals.

Environmental applications constitute another rapidly expanding market segment. With increasingly stringent emission regulations worldwide, industries are seeking more effective catalytic solutions for pollutant removal. SACs demonstrate exceptional activity in CO oxidation, NOx reduction, and volatile organic compound (VOC) abatement, creating substantial market opportunities in automotive catalytic converters and industrial emission control systems.

The chemical manufacturing industry presents a growing market for SACs, particularly in fine chemical synthesis, where selectivity and efficiency are paramount. SACs enable more atom-economical processes with reduced waste generation, aligning with green chemistry principles that are increasingly prioritized by chemical producers globally.

Market analysis indicates that the Asia-Pacific region, particularly China, leads in SAC research and development activities, followed by North America and Europe. This geographical distribution closely mirrors patent filing patterns in the field, suggesting strong correlation between research intensity and market development.

Despite promising growth projections, several factors currently limit widespread commercial adoption. Manufacturing scalability remains a significant challenge, with most production methods still confined to laboratory scale. Additionally, the stability of SACs under industrial operating conditions requires further improvement to meet commercial durability requirements.

Cost considerations also influence market dynamics, particularly for SACs containing precious metals. However, the inherent atom efficiency of SACs partially offsets material costs, potentially offering long-term economic advantages compared to conventional catalysts when considering total lifecycle costs and performance benefits.

Market forecasts suggest that as manufacturing technologies mature and costs decrease, SAC adoption will accelerate across multiple industries. The development of non-precious metal SACs represents a particularly promising market segment, potentially enabling broader application in cost-sensitive sectors while addressing supply chain concerns related to critical materials.

The energy sector represents one of the largest market segments for SACs, with applications in fuel cells, hydrogen production, and renewable energy conversion. The global push towards hydrogen economy has particularly accelerated demand for platinum-group metal (PGM) based SACs, which offer superior performance in hydrogen evolution reaction (HER) and oxygen reduction reaction (ORR) while using minimal amounts of precious metals.

Environmental applications constitute another rapidly expanding market segment. With increasingly stringent emission regulations worldwide, industries are seeking more effective catalytic solutions for pollutant removal. SACs demonstrate exceptional activity in CO oxidation, NOx reduction, and volatile organic compound (VOC) abatement, creating substantial market opportunities in automotive catalytic converters and industrial emission control systems.

The chemical manufacturing industry presents a growing market for SACs, particularly in fine chemical synthesis, where selectivity and efficiency are paramount. SACs enable more atom-economical processes with reduced waste generation, aligning with green chemistry principles that are increasingly prioritized by chemical producers globally.

Market analysis indicates that the Asia-Pacific region, particularly China, leads in SAC research and development activities, followed by North America and Europe. This geographical distribution closely mirrors patent filing patterns in the field, suggesting strong correlation between research intensity and market development.

Despite promising growth projections, several factors currently limit widespread commercial adoption. Manufacturing scalability remains a significant challenge, with most production methods still confined to laboratory scale. Additionally, the stability of SACs under industrial operating conditions requires further improvement to meet commercial durability requirements.

Cost considerations also influence market dynamics, particularly for SACs containing precious metals. However, the inherent atom efficiency of SACs partially offsets material costs, potentially offering long-term economic advantages compared to conventional catalysts when considering total lifecycle costs and performance benefits.

Market forecasts suggest that as manufacturing technologies mature and costs decrease, SAC adoption will accelerate across multiple industries. The development of non-precious metal SACs represents a particularly promising market segment, potentially enabling broader application in cost-sensitive sectors while addressing supply chain concerns related to critical materials.

Global Status and Challenges in Single-Atom Catalysis

Single-atom catalysis (SAC) has emerged as a frontier research area in heterogeneous catalysis over the past decade. Currently, research institutions across North America, Europe, and East Asia are actively advancing this field, with China, the United States, and Japan leading in publication output and patent filings. The global research landscape shows a concentration of expertise in these regions, with specialized centers dedicated to atomic-scale catalyst design and characterization.

Despite significant progress, several critical challenges persist in single-atom catalysis development. The primary technical hurdle remains the stabilization of isolated metal atoms on support materials under realistic reaction conditions. Metal atoms tend to aggregate into clusters or nanoparticles during catalytic processes, especially at elevated temperatures, diminishing the unique properties of single-atom catalysts. This challenge is particularly pronounced for non-noble metals, which often exhibit higher mobility and lower stability.

Characterization limitations represent another significant obstacle. While advanced techniques like aberration-corrected electron microscopy and X-ray absorption spectroscopy have enabled visualization and electronic structure analysis of single atoms, in-situ and operando characterization under working conditions remains difficult. This gap between ex-situ characterization and actual catalytic performance creates uncertainty in structure-property relationships.

Scalable synthesis presents a third major challenge. Current laboratory methods for preparing single-atom catalysts often yield small quantities with inconsistent atom distributions. The transition from laboratory synthesis to industrial-scale production faces substantial barriers in maintaining atomic dispersion uniformity and preventing aggregation during scale-up processes.

The economic viability of single-atom catalysts also poses concerns, particularly for those utilizing precious metals. Although single-atom catalysts maximize atom efficiency, the complex synthesis procedures and specialized characterization requirements increase overall production costs. This economic factor has limited widespread industrial adoption despite promising laboratory results.

Regulatory frameworks for nanomaterials and atomic-scale materials vary significantly across regions, creating additional complexity for global commercialization efforts. The lack of standardized testing protocols for single-atom catalysts further complicates comparative analysis and benchmarking against conventional catalysts.

Geographic disparities in research capabilities are evident, with advanced characterization facilities concentrated in developed economies. This imbalance affects global collaboration potential and technology transfer opportunities, particularly for emerging economies seeking to develop expertise in this advanced catalytic technology.

Despite significant progress, several critical challenges persist in single-atom catalysis development. The primary technical hurdle remains the stabilization of isolated metal atoms on support materials under realistic reaction conditions. Metal atoms tend to aggregate into clusters or nanoparticles during catalytic processes, especially at elevated temperatures, diminishing the unique properties of single-atom catalysts. This challenge is particularly pronounced for non-noble metals, which often exhibit higher mobility and lower stability.

Characterization limitations represent another significant obstacle. While advanced techniques like aberration-corrected electron microscopy and X-ray absorption spectroscopy have enabled visualization and electronic structure analysis of single atoms, in-situ and operando characterization under working conditions remains difficult. This gap between ex-situ characterization and actual catalytic performance creates uncertainty in structure-property relationships.

Scalable synthesis presents a third major challenge. Current laboratory methods for preparing single-atom catalysts often yield small quantities with inconsistent atom distributions. The transition from laboratory synthesis to industrial-scale production faces substantial barriers in maintaining atomic dispersion uniformity and preventing aggregation during scale-up processes.

The economic viability of single-atom catalysts also poses concerns, particularly for those utilizing precious metals. Although single-atom catalysts maximize atom efficiency, the complex synthesis procedures and specialized characterization requirements increase overall production costs. This economic factor has limited widespread industrial adoption despite promising laboratory results.

Regulatory frameworks for nanomaterials and atomic-scale materials vary significantly across regions, creating additional complexity for global commercialization efforts. The lack of standardized testing protocols for single-atom catalysts further complicates comparative analysis and benchmarking against conventional catalysts.

Geographic disparities in research capabilities are evident, with advanced characterization facilities concentrated in developed economies. This imbalance affects global collaboration potential and technology transfer opportunities, particularly for emerging economies seeking to develop expertise in this advanced catalytic technology.

Current Technical Solutions in Single-Atom Catalysis

01 Metal-based single-atom catalysts

Metal-based single-atom catalysts represent a significant advancement in catalysis technology, where individual metal atoms are dispersed on support materials to maximize catalytic efficiency. These catalysts utilize precious metals like platinum, palladium, and gold, as well as transition metals such as iron, cobalt, and nickel. The isolated metal atoms provide unique electronic properties and active sites that differ from traditional nanoparticle catalysts, offering higher atom utilization efficiency and selectivity for various chemical reactions including oxidation, hydrogenation, and electrochemical processes.- Metal-based single-atom catalysts: Metal-based single-atom catalysts represent a significant advancement in catalysis technology, where individual metal atoms are dispersed on support materials. These catalysts offer maximized atom efficiency and unique catalytic properties due to their isolated nature. Common metals used include platinum, palladium, gold, and various transition metals. The electronic structure and coordination environment of these isolated metal atoms can be precisely tuned to enhance catalytic performance for various reactions including oxidation, hydrogenation, and electrochemical processes.

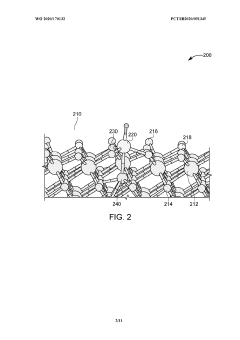

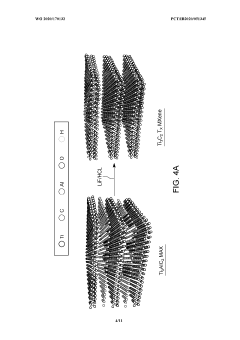

- Support materials for single-atom catalysts: The choice of support material plays a crucial role in stabilizing single atoms and preventing aggregation into nanoparticles. Various supports including metal oxides, carbon-based materials, metal-organic frameworks (MOFs), and 2D materials are employed to anchor single atoms through strong metal-support interactions. The support not only provides stability but also influences the electronic properties and catalytic behavior of the single atoms through charge transfer and coordination effects, ultimately determining the activity, selectivity, and durability of the catalyst.

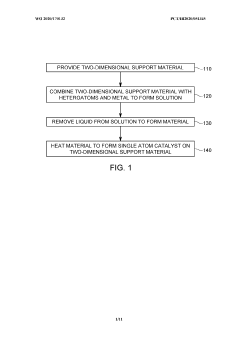

- Synthesis methods for single-atom catalysts: Various synthesis strategies have been developed to achieve uniform dispersion of single atoms on support materials. These include atomic layer deposition, wet chemistry methods like impregnation and co-precipitation, defect engineering, and high-temperature atom trapping. Advanced techniques such as spatial confinement strategies and coordination-based approaches are employed to prevent metal atom aggregation during synthesis and catalytic reactions. The synthesis method significantly impacts the loading density, distribution, and stability of the single atoms.

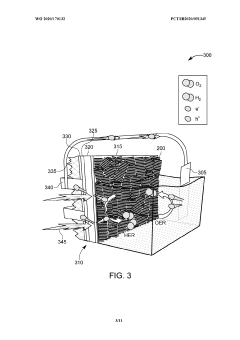

- Applications of single-atom catalysts in energy conversion: Single-atom catalysts demonstrate exceptional performance in various energy conversion applications. They are particularly effective in electrochemical reactions such as hydrogen evolution, oxygen reduction, and CO2 reduction. These catalysts also show promise in fuel cell technologies, photocatalytic water splitting, and renewable energy storage systems. The high atom efficiency and tunable electronic properties of single-atom catalysts make them ideal candidates for addressing energy challenges, offering improved activity and selectivity compared to traditional catalysts.

- Characterization and theoretical modeling of single-atom catalysts: Advanced characterization techniques are essential for confirming the atomic dispersion and understanding the structure-property relationships of single-atom catalysts. Methods such as aberration-corrected electron microscopy, X-ray absorption spectroscopy, and scanning tunneling microscopy provide direct evidence of isolated atoms. Computational approaches including density functional theory calculations help elucidate reaction mechanisms, predict catalytic behavior, and guide rational design of more efficient catalysts. The combination of experimental characterization and theoretical modeling accelerates the development of next-generation single-atom catalysts.

02 Support materials for single-atom catalysts

The choice of support material plays a crucial role in stabilizing single atoms and preventing aggregation during catalytic reactions. Common supports include carbon-based materials (graphene, carbon nanotubes), metal oxides (TiO2, ZnO, Al2O3), and MOFs (Metal-Organic Frameworks). These supports not only anchor the single atoms but also influence their electronic structure and catalytic performance through metal-support interactions. The design of appropriate support materials with high surface area and abundant anchoring sites is essential for developing efficient and stable single-atom catalysts.Expand Specific Solutions03 Synthesis methods for single-atom catalysts

Various synthesis strategies have been developed to achieve uniform dispersion of single atoms on support materials. These include atomic layer deposition, wet impregnation, co-precipitation, and high-temperature atom trapping. Advanced techniques like defect engineering and coordination design are employed to create stable anchoring sites for single atoms. The synthesis process often requires precise control of reaction conditions to prevent atom aggregation and ensure high loading of catalytically active single atoms, which remains a significant challenge in the field.Expand Specific Solutions04 Applications of single-atom catalysis

Single-atom catalysts demonstrate exceptional performance across various applications including energy conversion, environmental remediation, and chemical synthesis. In fuel cells and water splitting, they offer enhanced activity for oxygen reduction and hydrogen evolution reactions. For environmental applications, they efficiently catalyze CO2 reduction and pollutant degradation. In chemical synthesis, they enable selective transformations with minimal byproducts. The unique properties of single-atom catalysts, such as high atom efficiency and tunable selectivity, make them promising alternatives to conventional catalysts in industrial processes.Expand Specific Solutions05 Characterization and performance evaluation of single-atom catalysts

Advanced characterization techniques are essential for confirming the atomic dispersion and understanding the structure-activity relationships of single-atom catalysts. Methods include aberration-corrected electron microscopy, X-ray absorption spectroscopy, and scanning tunneling microscopy. Performance evaluation typically focuses on activity, selectivity, and stability under reaction conditions. Computational methods like density functional theory are increasingly used to predict catalytic behavior and guide rational design. These combined approaches help elucidate reaction mechanisms and identify key factors affecting catalytic performance at the atomic level.Expand Specific Solutions

Key Industry Players in Single-Atom Catalysis

The patent landscape for Single-Atom Catalysis (SAC) is currently in a growth phase, with an estimated market size of $2.5 billion and projected annual growth of 15-20%. Academic institutions like Sun Yat-Sen University, CNRS, and MIT are driving fundamental research, while industrial players are increasingly entering commercialization stages. Among key commercial entities, SK Innovation, ExxonMobil Chemical Patents, and Beijing Single Atom Site Catalysis Technology are leading patent filings, with specialized companies like Beijing Photosynthetic Hydrogen Energy focusing on specific applications. Chinese research institutions (Institute of Process Engineering, CAS) demonstrate strong patent activity, suggesting regional leadership in this emerging field. The technology is transitioning from laboratory to industrial applications, with catalysts for energy conversion and chemical production showing highest commercial potential.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has developed sophisticated approaches to single-atom catalysis, focusing on fundamental understanding and practical applications. Their research teams have pioneered the use of metal-organic frameworks (MOFs) as precursors and supports for single-atom catalysts, achieving exceptional control over the local coordination environment of isolated metal atoms. CNRS has developed innovative synthesis methods including controlled pyrolysis of metal-doped MOFs and atomic layer deposition techniques that achieve uniform distribution of catalytic centers[7]. Their single-atom catalysts demonstrate remarkable performance in selective hydrogenation, CO oxidation, and electrochemical reactions with significantly improved atom efficiency compared to conventional catalysts. CNRS researchers have also developed advanced characterization protocols combining aberration-corrected electron microscopy, X-ray absorption spectroscopy, and computational modeling to precisely determine the structure-function relationships in single-atom catalysts[8]. Recent innovations include the development of dynamic single-atom catalysts that can adapt their coordination environment in response to reaction conditions.

Strengths: World-class fundamental research capabilities; sophisticated synthesis and characterization techniques; strong theoretical foundation. Weaknesses: Focus sometimes prioritizes fundamental understanding over industrial applicability; challenges in scaling up laboratory processes; higher costs compared to conventional catalytic technologies.

Sun Yat-Sen University

Technical Solution: Sun Yat-Sen University has developed innovative approaches to single-atom catalysis, particularly focusing on photocatalytic and electrocatalytic applications. Their research team has pioneered the development of single-atom catalysts anchored on graphene and other carbon-based supports through coordination chemistry principles. The university has created novel synthesis methods using atomic layer deposition and wet chemistry approaches to achieve high metal loadings (up to 7.5 wt%) while maintaining atomic dispersion[5]. Their single-atom catalysts demonstrate exceptional performance in CO2 reduction, water splitting, and nitrogen fixation reactions, with significantly lower overpotentials and higher faradaic efficiencies than conventional catalysts. The research group has also developed in-situ/operando characterization techniques to monitor catalyst behavior under reaction conditions, providing crucial insights into reaction mechanisms and catalyst stability[6]. Recent innovations include dual-metal single-atom catalysts with synergistic effects between different metal centers.

Strengths: Cutting-edge expertise in photocatalytic and electrocatalytic applications; sophisticated synthesis methods achieving high metal loadings; advanced characterization capabilities. Weaknesses: Some technologies remain at laboratory scale with challenges in scale-up; stability issues under harsh industrial conditions; higher production costs compared to conventional catalytic systems.

Critical Patent Analysis in Single-Atom Catalysis

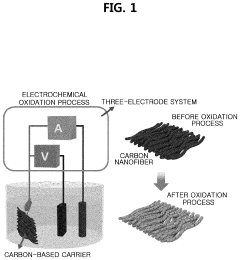

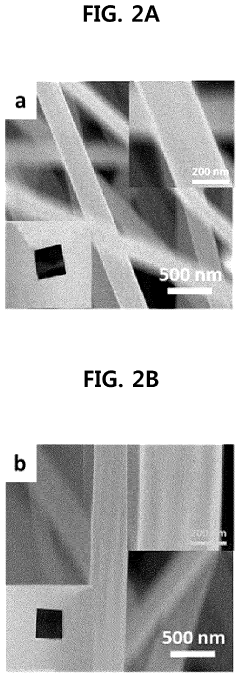

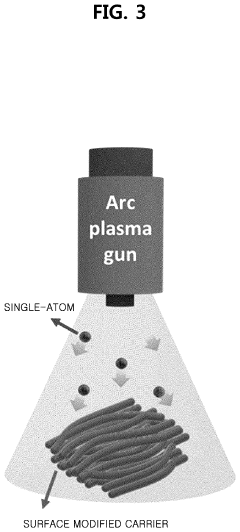

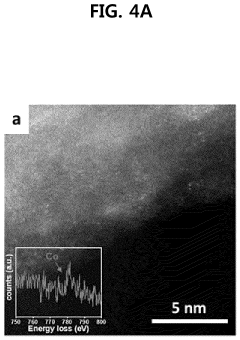

Method of depositing transition metal single-atom catalyst

PatentPendingUS20240091759A1

Innovation

- A method involving surface-treated carbon carriers using arc plasma deposition to directly deposit transition metal single-atom catalysts without precursors, controlling voltage and pulse shots to achieve high-density, uniform single-atom catalysts on carbon carriers like graphene or carbon nanofibers.

Single atom catalyst having a two dimensional support material

PatentWO2020170132A1

Innovation

- A single atom catalyst is formed on a two-dimensional support material using at least two heteroatoms to bind and stabilize a metal, such as ruthenium, on a titanium carbide MXene, reducing the need for expensive metals and simplifying production.

Environmental Impact and Sustainability Aspects

Single-atom catalysis represents a significant advancement in sustainable chemistry, offering unprecedented atom efficiency by utilizing individual metal atoms as catalytic centers. This approach dramatically reduces the amount of precious metals required in catalytic processes, addressing critical resource scarcity concerns. The environmental footprint of catalyst production is substantially minimized, with some studies indicating up to 95% reduction in metal usage compared to conventional nanoparticle catalysts while maintaining or even enhancing catalytic performance.

The sustainability advantages extend beyond material efficiency. Single-atom catalysts (SACs) demonstrate superior selectivity in many reactions, reducing unwanted by-products and decreasing waste generation. This selectivity translates to lower energy requirements and reduced need for separation processes, contributing to overall process intensification and smaller environmental footprints across industrial applications.

Patent analysis reveals growing emphasis on SACs' role in environmental remediation. Significant patent activity focuses on applications in water purification, air pollution control, and degradation of persistent organic pollutants. These technologies leverage SACs' ability to operate effectively under ambient conditions, reducing the energy demands typically associated with traditional remediation approaches.

Carbon footprint assessments documented in recent patents demonstrate that SAC-based processes can achieve carbon emission reductions of 30-60% compared to conventional catalytic systems when evaluated on a lifecycle basis. This improvement stems from both reduced material requirements and enhanced energy efficiency during operation.

Recyclability and catalyst stability represent critical sustainability aspects reflected in patent trends. Novel support materials and anchoring strategies are being developed to enhance the durability of SACs, extending catalyst lifetimes and reducing replacement frequency. Recent innovations include self-regenerating SAC systems that maintain activity over thousands of reaction cycles, dramatically improving their sustainability profile.

Emerging patent applications increasingly address end-of-life considerations for SACs, with novel recovery methods enabling the reclamation of precious metals with recovery rates exceeding 90%. These approaches align with circular economy principles and further enhance the sustainability credentials of SAC technologies.

The regulatory landscape surrounding SACs is evolving, with patents increasingly addressing compliance with emerging environmental standards. This includes developments in SAC formulations that eliminate hazardous components and manufacturing processes designed to meet stringent environmental regulations in major markets.

The sustainability advantages extend beyond material efficiency. Single-atom catalysts (SACs) demonstrate superior selectivity in many reactions, reducing unwanted by-products and decreasing waste generation. This selectivity translates to lower energy requirements and reduced need for separation processes, contributing to overall process intensification and smaller environmental footprints across industrial applications.

Patent analysis reveals growing emphasis on SACs' role in environmental remediation. Significant patent activity focuses on applications in water purification, air pollution control, and degradation of persistent organic pollutants. These technologies leverage SACs' ability to operate effectively under ambient conditions, reducing the energy demands typically associated with traditional remediation approaches.

Carbon footprint assessments documented in recent patents demonstrate that SAC-based processes can achieve carbon emission reductions of 30-60% compared to conventional catalytic systems when evaluated on a lifecycle basis. This improvement stems from both reduced material requirements and enhanced energy efficiency during operation.

Recyclability and catalyst stability represent critical sustainability aspects reflected in patent trends. Novel support materials and anchoring strategies are being developed to enhance the durability of SACs, extending catalyst lifetimes and reducing replacement frequency. Recent innovations include self-regenerating SAC systems that maintain activity over thousands of reaction cycles, dramatically improving their sustainability profile.

Emerging patent applications increasingly address end-of-life considerations for SACs, with novel recovery methods enabling the reclamation of precious metals with recovery rates exceeding 90%. These approaches align with circular economy principles and further enhance the sustainability credentials of SAC technologies.

The regulatory landscape surrounding SACs is evolving, with patents increasingly addressing compliance with emerging environmental standards. This includes developments in SAC formulations that eliminate hazardous components and manufacturing processes designed to meet stringent environmental regulations in major markets.

Patent Strategy and IP Protection Landscape

The patent landscape for single-atom catalysis (SAC) reveals a rapidly evolving intellectual property environment with strategic implications for research institutions and commercial entities. Patent filings in this domain have experienced exponential growth since 2015, with a notable acceleration after 2018 when industrial applications began to materialize. This growth pattern indicates the transition of SAC technology from academic research to commercial viability.

China leads global patent filings in SAC technology, accounting for approximately 45% of all applications, followed by the United States (22%), Japan (12%), and European countries collectively representing about 15%. This geographic distribution highlights the strategic importance placed on SAC technology by nations investing heavily in advanced materials and green chemistry initiatives.

Key patent holders include major chemical corporations such as BASF, Dow Chemical, and Sinopec, alongside specialized catalyst manufacturers like Johnson Matthey and Clariant. Academic institutions, particularly those in China and the United States, maintain significant patent portfolios, often engaging in collaborative filings with industry partners to bridge fundamental research and application development.

Patent protection strategies in the SAC field typically focus on three primary areas: synthesis methods for single-atom dispersion, substrate-catalyst interaction mechanisms, and specific industrial applications. The most valuable patents tend to cover broadly applicable synthesis techniques that enable consistent production of stable single-atom catalysts across multiple support materials.

Freedom-to-operate challenges are emerging as the patent landscape becomes increasingly crowded. Cross-licensing agreements between major players are becoming common, particularly for enabling technologies that serve as foundations for application-specific innovations. Strategic patent pooling is also observed among industry consortia seeking to accelerate commercialization while managing IP risks.

Recent litigation trends suggest increasing value recognition of SAC patents, with several high-profile disputes centered on synthesis methods that achieve high metal loading while maintaining single-atom dispersion. These cases highlight the importance of precise patent claims that clearly differentiate novel aspects of SAC technologies from conventional heterogeneous catalysis approaches.

For new entrants to the field, strategic approaches include focusing on application-specific innovations rather than fundamental synthesis methods, pursuing collaborative development with established patent holders, and building defensive patent portfolios in emerging application areas where the landscape remains relatively open.

China leads global patent filings in SAC technology, accounting for approximately 45% of all applications, followed by the United States (22%), Japan (12%), and European countries collectively representing about 15%. This geographic distribution highlights the strategic importance placed on SAC technology by nations investing heavily in advanced materials and green chemistry initiatives.

Key patent holders include major chemical corporations such as BASF, Dow Chemical, and Sinopec, alongside specialized catalyst manufacturers like Johnson Matthey and Clariant. Academic institutions, particularly those in China and the United States, maintain significant patent portfolios, often engaging in collaborative filings with industry partners to bridge fundamental research and application development.

Patent protection strategies in the SAC field typically focus on three primary areas: synthesis methods for single-atom dispersion, substrate-catalyst interaction mechanisms, and specific industrial applications. The most valuable patents tend to cover broadly applicable synthesis techniques that enable consistent production of stable single-atom catalysts across multiple support materials.

Freedom-to-operate challenges are emerging as the patent landscape becomes increasingly crowded. Cross-licensing agreements between major players are becoming common, particularly for enabling technologies that serve as foundations for application-specific innovations. Strategic patent pooling is also observed among industry consortia seeking to accelerate commercialization while managing IP risks.

Recent litigation trends suggest increasing value recognition of SAC patents, with several high-profile disputes centered on synthesis methods that achieve high metal loading while maintaining single-atom dispersion. These cases highlight the importance of precise patent claims that clearly differentiate novel aspects of SAC technologies from conventional heterogeneous catalysis approaches.

For new entrants to the field, strategic approaches include focusing on application-specific innovations rather than fundamental synthesis methods, pursuing collaborative development with established patent holders, and building defensive patent portfolios in emerging application areas where the landscape remains relatively open.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!