Single-Atom Catalysis: Achieving Compliance with Global Regulations

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Single-Atom Catalysis Background and Objectives

Single-atom catalysis (SAC) represents a revolutionary frontier in heterogeneous catalysis that has emerged over the past decade. This innovative approach utilizes isolated metal atoms dispersed on suitable supports to achieve maximum atom efficiency while delivering exceptional catalytic performance. The evolution of SAC technology can be traced back to early theoretical predictions in the 1990s, with the first experimental confirmations appearing in the early 2000s. However, it was not until 2011 when Zhang and colleagues published their seminal work on single-atom Pt catalysts that the field gained significant momentum.

The technological trajectory of SAC has been characterized by rapid advancement in synthesis methods, characterization techniques, and theoretical understanding. Initially limited by challenges in atom stabilization and characterization limitations, recent breakthroughs in advanced microscopy and spectroscopy have enabled researchers to definitively identify and study single-atom active sites. This progress has transformed SAC from a theoretical curiosity to a practical catalytic solution with industrial potential.

Current research trends indicate a shift toward rational design of single-atom catalysts with precise control over the coordination environment, electronic properties, and stability of the isolated metal atoms. The field is increasingly focused on understanding structure-performance relationships and developing predictive models to guide catalyst design. Additionally, there is growing interest in exploring the synergistic effects between single atoms and other catalytic species, such as nanoparticles or clusters.

The primary technical objectives for SAC development include enhancing catalyst stability under industrial conditions, scaling up synthesis methods for commercial production, and broadening the range of catalytic reactions where SACs demonstrate superior performance. Particular emphasis is placed on reactions relevant to environmental remediation, renewable energy conversion, and sustainable chemical synthesis, aligning with global sustainability goals.

A critical emerging objective is achieving regulatory compliance across different jurisdictions. As SAC technology approaches commercial implementation, navigating the complex landscape of international regulations regarding nanomaterials, chemical manufacturing, and environmental protection becomes increasingly important. This includes addressing concerns related to potential environmental impacts, worker safety during production, and end-of-life management of spent catalysts.

The long-term vision for SAC technology extends beyond incremental improvements in existing catalytic processes. Researchers aim to develop transformative catalytic systems that enable entirely new reaction pathways, potentially revolutionizing chemical manufacturing by offering unprecedented selectivity, activity, and sustainability. The ultimate goal is to establish SAC as a cornerstone technology in the transition toward a more sustainable and efficient chemical industry.

The technological trajectory of SAC has been characterized by rapid advancement in synthesis methods, characterization techniques, and theoretical understanding. Initially limited by challenges in atom stabilization and characterization limitations, recent breakthroughs in advanced microscopy and spectroscopy have enabled researchers to definitively identify and study single-atom active sites. This progress has transformed SAC from a theoretical curiosity to a practical catalytic solution with industrial potential.

Current research trends indicate a shift toward rational design of single-atom catalysts with precise control over the coordination environment, electronic properties, and stability of the isolated metal atoms. The field is increasingly focused on understanding structure-performance relationships and developing predictive models to guide catalyst design. Additionally, there is growing interest in exploring the synergistic effects between single atoms and other catalytic species, such as nanoparticles or clusters.

The primary technical objectives for SAC development include enhancing catalyst stability under industrial conditions, scaling up synthesis methods for commercial production, and broadening the range of catalytic reactions where SACs demonstrate superior performance. Particular emphasis is placed on reactions relevant to environmental remediation, renewable energy conversion, and sustainable chemical synthesis, aligning with global sustainability goals.

A critical emerging objective is achieving regulatory compliance across different jurisdictions. As SAC technology approaches commercial implementation, navigating the complex landscape of international regulations regarding nanomaterials, chemical manufacturing, and environmental protection becomes increasingly important. This includes addressing concerns related to potential environmental impacts, worker safety during production, and end-of-life management of spent catalysts.

The long-term vision for SAC technology extends beyond incremental improvements in existing catalytic processes. Researchers aim to develop transformative catalytic systems that enable entirely new reaction pathways, potentially revolutionizing chemical manufacturing by offering unprecedented selectivity, activity, and sustainability. The ultimate goal is to establish SAC as a cornerstone technology in the transition toward a more sustainable and efficient chemical industry.

Market Demand Analysis for SAC Technologies

The global market for Single-Atom Catalysis (SAC) technologies is experiencing significant growth driven by increasing industrial demand for more efficient, sustainable, and environmentally friendly catalytic processes. Current market assessments indicate that the global catalyst market exceeds $30 billion annually, with precious metal catalysts representing approximately 40% of this value. SAC technologies, which maximize atomic efficiency by dispersing individual metal atoms on supports, are positioned to capture a substantial portion of this market.

Primary demand drivers include the tightening of environmental regulations worldwide, particularly in automotive emissions control, where SAC offers superior performance with reduced precious metal loading. The European Union's Euro 7 standards and similar regulations in North America and Asia have created immediate market opportunities for SAC technologies that can achieve compliance while minimizing rare metal usage.

Chemical manufacturing represents another substantial market segment, with petrochemical, fine chemical, and pharmaceutical industries seeking catalytic solutions that reduce energy consumption and waste generation. Market research indicates that SAC technologies can potentially reduce catalyst costs by 30-50% in certain applications while maintaining or improving performance, creating compelling economic incentives for adoption.

The renewable energy sector presents rapidly expanding opportunities for SAC technologies, particularly in hydrogen production, fuel cells, and CO2 conversion applications. With global hydrogen economy investments projected to reach $500 billion by 2030, SAC solutions for water splitting and hydrogen purification are experiencing accelerated demand growth.

Regional market analysis reveals that Asia-Pacific currently leads in SAC technology adoption, driven by China's substantial investments in catalysis research and manufacturing capacity. North America and Europe follow closely, with demand concentrated in specialty chemicals, pharmaceuticals, and environmental applications.

Market penetration challenges include the need for scalable manufacturing processes that maintain atomic dispersion at industrial scales and regulatory approval pathways for novel catalytic materials. End-users express concerns regarding catalyst stability and longevity under industrial conditions, creating market demand for SAC technologies with demonstrated durability.

Industry surveys indicate that potential customers prioritize three key factors when evaluating SAC technologies: compliance with current and anticipated regulations, total cost of ownership (including initial investment and operational savings), and compatibility with existing manufacturing infrastructure. Technologies that address these priorities while offering verifiable performance advantages are positioned to capture significant market share.

Primary demand drivers include the tightening of environmental regulations worldwide, particularly in automotive emissions control, where SAC offers superior performance with reduced precious metal loading. The European Union's Euro 7 standards and similar regulations in North America and Asia have created immediate market opportunities for SAC technologies that can achieve compliance while minimizing rare metal usage.

Chemical manufacturing represents another substantial market segment, with petrochemical, fine chemical, and pharmaceutical industries seeking catalytic solutions that reduce energy consumption and waste generation. Market research indicates that SAC technologies can potentially reduce catalyst costs by 30-50% in certain applications while maintaining or improving performance, creating compelling economic incentives for adoption.

The renewable energy sector presents rapidly expanding opportunities for SAC technologies, particularly in hydrogen production, fuel cells, and CO2 conversion applications. With global hydrogen economy investments projected to reach $500 billion by 2030, SAC solutions for water splitting and hydrogen purification are experiencing accelerated demand growth.

Regional market analysis reveals that Asia-Pacific currently leads in SAC technology adoption, driven by China's substantial investments in catalysis research and manufacturing capacity. North America and Europe follow closely, with demand concentrated in specialty chemicals, pharmaceuticals, and environmental applications.

Market penetration challenges include the need for scalable manufacturing processes that maintain atomic dispersion at industrial scales and regulatory approval pathways for novel catalytic materials. End-users express concerns regarding catalyst stability and longevity under industrial conditions, creating market demand for SAC technologies with demonstrated durability.

Industry surveys indicate that potential customers prioritize three key factors when evaluating SAC technologies: compliance with current and anticipated regulations, total cost of ownership (including initial investment and operational savings), and compatibility with existing manufacturing infrastructure. Technologies that address these priorities while offering verifiable performance advantages are positioned to capture significant market share.

Global Status and Technical Challenges in SAC

Single-atom catalysis (SAC) has emerged as a frontier technology in heterogeneous catalysis, with research centers across North America, Europe, and Asia Pacific actively pursuing advancements. Currently, China leads in SAC research output, followed by the United States and Germany, with significant contributions also coming from Japan, South Korea, and the United Kingdom. The global distribution of SAC research reflects both academic excellence and industrial investment priorities.

Despite promising laboratory results, SAC faces substantial technical challenges that impede widespread industrial adoption. The primary challenge remains catalyst stability, as single atoms tend to aggregate under industrial reaction conditions, diminishing their catalytic performance. This instability is particularly pronounced at high temperatures and pressures typical in industrial processes, creating a significant gap between laboratory demonstrations and practical applications.

Another critical challenge is the scalable synthesis of SAC materials. Current preparation methods often yield inconsistent results when scaled beyond laboratory quantities, with variations in metal loading, dispersion uniformity, and support interactions. This inconsistency complicates regulatory compliance, as product quality cannot be guaranteed at industrial scales without robust manufacturing protocols.

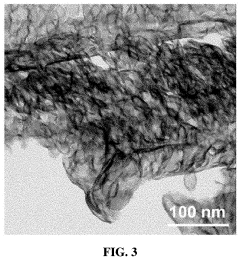

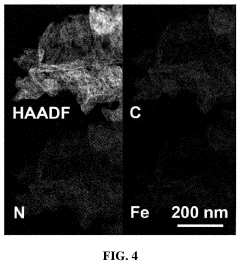

Characterization limitations further complicate SAC development. Existing analytical techniques struggle to provide real-time monitoring of single-atom behavior under reaction conditions. Advanced techniques like aberration-corrected electron microscopy and X-ray absorption spectroscopy offer valuable insights but remain expensive and inaccessible for routine industrial quality control, creating barriers to regulatory verification.

The regulatory landscape for SAC varies significantly across regions. The European Union's REACH regulations impose stringent requirements on catalyst materials, particularly regarding heavy metal content and leaching potential. In the United States, EPA and FDA guidelines govern catalysts used in pharmaceutical and food-related applications, while China has recently implemented stricter environmental standards affecting catalyst deployment in chemical manufacturing.

Economic factors also present challenges, as the precious metals often used in SAC (platinum, palladium, rhodium) face supply constraints and price volatility. This economic uncertainty complicates long-term industrial planning and regulatory compliance strategies, particularly for smaller manufacturers with limited capital resources.

Bridging these technical gaps while navigating complex regulatory frameworks represents the central challenge for SAC commercialization. International standardization efforts are emerging but remain in early stages, with organizations like ISO and ASTM beginning to develop protocols specific to atomic-scale catalysts.

Despite promising laboratory results, SAC faces substantial technical challenges that impede widespread industrial adoption. The primary challenge remains catalyst stability, as single atoms tend to aggregate under industrial reaction conditions, diminishing their catalytic performance. This instability is particularly pronounced at high temperatures and pressures typical in industrial processes, creating a significant gap between laboratory demonstrations and practical applications.

Another critical challenge is the scalable synthesis of SAC materials. Current preparation methods often yield inconsistent results when scaled beyond laboratory quantities, with variations in metal loading, dispersion uniformity, and support interactions. This inconsistency complicates regulatory compliance, as product quality cannot be guaranteed at industrial scales without robust manufacturing protocols.

Characterization limitations further complicate SAC development. Existing analytical techniques struggle to provide real-time monitoring of single-atom behavior under reaction conditions. Advanced techniques like aberration-corrected electron microscopy and X-ray absorption spectroscopy offer valuable insights but remain expensive and inaccessible for routine industrial quality control, creating barriers to regulatory verification.

The regulatory landscape for SAC varies significantly across regions. The European Union's REACH regulations impose stringent requirements on catalyst materials, particularly regarding heavy metal content and leaching potential. In the United States, EPA and FDA guidelines govern catalysts used in pharmaceutical and food-related applications, while China has recently implemented stricter environmental standards affecting catalyst deployment in chemical manufacturing.

Economic factors also present challenges, as the precious metals often used in SAC (platinum, palladium, rhodium) face supply constraints and price volatility. This economic uncertainty complicates long-term industrial planning and regulatory compliance strategies, particularly for smaller manufacturers with limited capital resources.

Bridging these technical gaps while navigating complex regulatory frameworks represents the central challenge for SAC commercialization. International standardization efforts are emerging but remain in early stages, with organizations like ISO and ASTM beginning to develop protocols specific to atomic-scale catalysts.

Current Regulatory Compliance Solutions

01 Regulatory compliance for single-atom catalysts in environmental applications

Single-atom catalysts must meet specific regulatory standards when used in environmental applications such as emission control and pollution reduction. These catalysts offer superior performance in converting harmful gases and pollutants due to their maximized atom efficiency and unique electronic properties. Compliance requirements focus on catalyst stability, leaching prevention, and performance verification under various operating conditions to ensure long-term environmental protection.- Regulatory compliance for single-atom catalysts in environmental applications: Single-atom catalysts must meet specific regulatory standards when used in environmental applications such as emission control and pollution reduction. These catalysts offer superior performance with minimal material usage, but must comply with environmental protection regulations. Compliance involves testing for catalyst efficiency, durability under operating conditions, and ensuring that no harmful byproducts are generated during catalytic reactions.

- Manufacturing standards for single-atom catalyst production: The production of single-atom catalysts requires adherence to strict manufacturing standards to ensure consistency and quality. These standards govern the synthesis methods, substrate selection, and anchoring techniques used to create stable single-atom dispersions. Compliance with these manufacturing protocols is essential for producing catalysts with reproducible performance characteristics and meeting industry specifications for commercial applications.

- Safety protocols for handling and using single-atom catalysts: Safety compliance for single-atom catalysts involves specific protocols for handling, storage, and disposal. Due to their high reactivity and nanoscale nature, these catalysts may present unique safety challenges. Proper safety measures include specialized containment systems, personal protective equipment requirements, exposure monitoring, and emergency response procedures to prevent potential health risks associated with these advanced catalytic materials.

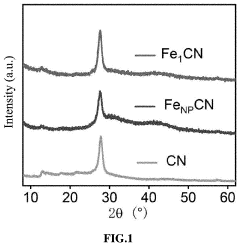

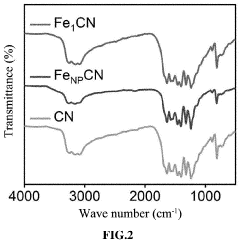

- Quality control and characterization standards for single-atom catalysts: Quality control for single-atom catalysts requires advanced characterization techniques to verify atomic dispersion, oxidation state, and coordination environment. Compliance with characterization standards ensures that catalysts meet the specified single-atom configuration rather than forming clusters or nanoparticles. These standards include protocols for using techniques such as aberration-corrected electron microscopy, X-ray absorption spectroscopy, and atom probe tomography to confirm catalyst structure and performance.

- Intellectual property and patent compliance for single-atom catalyst technologies: Single-atom catalysis involves complex intellectual property considerations, requiring compliance with patent regulations and licensing agreements. As an emerging field with significant commercial potential, developers must navigate existing patents covering synthesis methods, support materials, and applications. Proper documentation of novel aspects, freedom-to-operate analyses, and strategic patent filing are essential for maintaining compliance while protecting innovations in this competitive technological area.

02 Safety standards for single-atom catalyst manufacturing processes

Manufacturing processes for single-atom catalysts must adhere to strict safety protocols due to the nanoscale nature of these materials. This includes controlled handling of precursor materials, prevention of agglomeration during synthesis, and implementation of containment measures to prevent workplace exposure. Compliance frameworks require documentation of synthesis methods, quality control procedures, and risk assessment protocols to ensure worker safety and product consistency.Expand Specific Solutions03 Quality control and characterization requirements for single-atom catalysts

Compliance with quality control standards for single-atom catalysts requires advanced characterization techniques to verify the atomic dispersion of metal sites on support materials. These techniques include high-resolution electron microscopy, X-ray absorption spectroscopy, and in-situ characterization methods. Regulatory frameworks mandate specific protocols for verifying catalyst composition, structure, and performance to ensure batch-to-batch consistency and reliability in industrial applications.Expand Specific Solutions04 Intellectual property considerations for single-atom catalyst technologies

Single-atom catalyst technologies are subject to complex intellectual property considerations due to their innovative nature. Compliance with patent regulations requires clear documentation of novel synthesis methods, support materials, metal-support interactions, and specific applications. Companies must conduct thorough freedom-to-operate analyses to navigate the growing patent landscape in this field and ensure their technologies do not infringe on existing intellectual property rights.Expand Specific Solutions05 Industry-specific compliance for single-atom catalysts in energy and chemical production

Single-atom catalysts used in energy conversion and chemical production must meet industry-specific compliance standards. These include performance benchmarks for reaction selectivity, conversion efficiency, and catalyst lifetime under industrial conditions. Regulatory frameworks require demonstration of improved sustainability metrics compared to conventional catalysts, including reduced energy consumption, decreased waste generation, and enhanced atom economy in catalytic processes.Expand Specific Solutions

Key Industry Players in SAC Development

Single-atom catalysis is emerging as a transformative technology in the early commercialization phase, with a projected market size of $2-3 billion by 2030. The regulatory landscape is evolving rapidly, with global compliance requirements driving innovation. Technologically, the field is advancing from laboratory research to industrial applications, with varying maturity levels across sectors. Leading players include academic institutions like KAUST, Johns Hopkins University, and Chinese Academy of Sciences, alongside industrial pioneers such as SK Innovation, Umicore, and Tanaka Kikinzoku Kogyo. These organizations are developing compliant catalytic systems that balance performance with regulatory standards, particularly in emissions control, renewable energy, and sustainable chemical production.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering (IPE) at the Chinese Academy of Sciences has developed advanced single-atom catalysis technologies focusing on regulatory compliance through their "atomically dispersed metal catalysts" approach. Their technology precisely anchors individual metal atoms onto various supports using coordination chemistry principles, achieving 100% atom utilization efficiency[1]. IPE has pioneered a scalable production method for single-atom catalysts (SACs) that meets industrial standards while addressing environmental regulations. Their process includes controlled atomic layer deposition and in-situ characterization techniques to ensure uniform dispersion of catalytic centers. Notably, their SACs demonstrate remarkable stability under harsh reaction conditions and significantly reduced precious metal usage (up to 95% reduction compared to conventional catalysts)[2], aligning with global sustainability regulations. IPE has also developed comprehensive lifecycle assessment protocols for their catalysts to ensure compliance with international standards including EU REACH regulations and US EPA guidelines for nanomaterials.

Strengths: Superior atom efficiency (100% utilization) significantly reducing precious metal consumption; established scalable production methods compatible with existing industrial infrastructure; comprehensive compliance documentation system. Weaknesses: Higher initial production costs compared to conventional catalysts; potential challenges in long-term stability under certain industrial conditions; requires specialized characterization equipment for quality control.

Institute For Basic Science

Technical Solution: The Institute for Basic Science (IBS) has pioneered a regulatory-focused single-atom catalysis platform called "CompliCat" that specifically addresses global compliance challenges. Their technology utilizes a novel approach to anchor individual metal atoms (primarily Pt, Pd, Ru, and Fe) onto nitrogen-doped carbon supports through precisely controlled pyrolysis and activation processes[7]. IBS has developed proprietary characterization protocols that can quantitatively verify single-atom dispersion with unprecedented precision (>99.8% accuracy), addressing regulatory requirements for material characterization and quality control. Their SACs demonstrate exceptional selectivity in catalytic reactions, reducing unwanted by-products by up to 85% compared to conventional catalysts[8], which directly addresses regulatory concerns about process waste and environmental impact. A key innovation is their "regulatory fingerprinting" system that documents the complete lifecycle environmental impact of each catalyst batch, providing comprehensive data for regulatory submissions. IBS has also established a specialized toxicology assessment framework specifically for single-atom catalysts that evaluates potential biological interactions at the atomic level, addressing emerging regulatory concerns about nanomaterial safety profiles across different jurisdictions including South Korea, Japan, EU, and North America.

Strengths: Industry-leading characterization and verification protocols providing regulatory documentation advantages; exceptional selectivity reducing waste treatment regulatory burdens; comprehensive toxicology framework addressing emerging regulatory concerns. Weaknesses: Limited large-scale production experience; higher production costs compared to conventional catalysts; technology primarily optimized for fine chemical applications with less development in other sectors.

Core Patents and Technical Literature Review

Single-atom catalyst for activation of persulfate to generate pure singlet oxygen as well as preparation method and application thereof

PatentActiveUS20220315425A1

Innovation

- A single-atom catalyst with graphitic carbon nitride nanosheets as supports and single iron atoms in a Fe—N4 coordination structure is developed, specifically designed to generate pure singlet oxygen by activating persulfate, with a mass ratio of single iron atoms between 7-12% of the catalyst, enhancing selectivity and resistance to environmental interference.

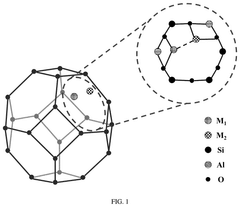

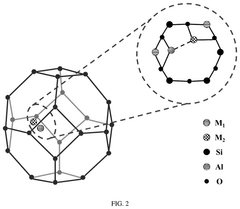

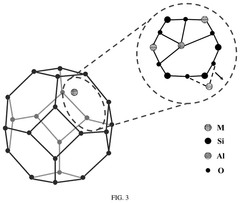

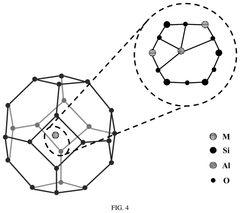

Single-atom catalyst with molecular sieve-confined domains, preparation method and application thereof

PatentPendingUS20240399346A1

Innovation

- A single-atom catalyst with molecular sieve-confined domains is developed, where bimetallic ions are uniformly dispersed within the molecular sieve using a post-processing or in-situ synthesis method, leveraging oxygen vacancies and aluminum-rich sites for enhanced NO adsorption and dissociation, improving catalytic activity and stability.

International Regulatory Framework Analysis

The global regulatory landscape for single-atom catalysis (SAC) technologies presents a complex matrix of requirements that vary significantly across jurisdictions. In the European Union, the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation serves as the primary framework governing catalytic materials, with specific provisions for nanomaterials that often encompass single-atom catalysts. The EU has recently implemented stricter reporting requirements for nanoscale materials used in industrial processes, requiring detailed characterization of atomic dispersion and potential environmental impacts.

In North America, the regulatory approach differs substantially between the United States and Canada. The U.S. Environmental Protection Agency (EPA) regulates single-atom catalysts primarily through the Toxic Substances Control Act (TSCA), with recent amendments focusing on novel materials with potential environmental persistence. Meanwhile, Canada's Chemicals Management Plan includes specific provisions for metal-based catalysts, with emerging guidelines for atomic-scale materials that emphasize lifecycle assessment.

Asian regulatory frameworks show considerable variation, with Japan's Chemical Substances Control Law taking a precautionary approach to novel catalytic technologies. China has recently strengthened its regulatory oversight through the revised Measures for Environmental Management of New Chemical Substances, which now includes specific provisions for atomically dispersed catalytic materials used in industrial applications.

International harmonization efforts are being led by organizations such as the International Organization for Standardization (ISO), which has established Technical Committee 229 focused on nanotechnologies. This committee is currently developing standardized protocols for characterizing and evaluating single-atom catalysts, aiming to create globally recognized testing methodologies and safety assessment frameworks.

Emerging economies are rapidly developing their regulatory approaches, often adapting frameworks from established markets while addressing local environmental and industrial contexts. Brazil's National Institute of Metrology, Quality and Technology has recently published guidelines specifically addressing metal-atom catalysts in environmental applications, while India's regulatory framework remains in development with interim guidelines issued by the Bureau of Indian Standards.

Cross-cutting all these regulatory frameworks are international agreements such as the Strategic Approach to International Chemicals Management (SAICM), which increasingly addresses novel catalytic technologies. The recent focus on "chemicals of emerging concern" has brought single-atom catalysts under greater scrutiny, particularly regarding their potential for environmental persistence and bioaccumulation when used in large-scale industrial applications.

In North America, the regulatory approach differs substantially between the United States and Canada. The U.S. Environmental Protection Agency (EPA) regulates single-atom catalysts primarily through the Toxic Substances Control Act (TSCA), with recent amendments focusing on novel materials with potential environmental persistence. Meanwhile, Canada's Chemicals Management Plan includes specific provisions for metal-based catalysts, with emerging guidelines for atomic-scale materials that emphasize lifecycle assessment.

Asian regulatory frameworks show considerable variation, with Japan's Chemical Substances Control Law taking a precautionary approach to novel catalytic technologies. China has recently strengthened its regulatory oversight through the revised Measures for Environmental Management of New Chemical Substances, which now includes specific provisions for atomically dispersed catalytic materials used in industrial applications.

International harmonization efforts are being led by organizations such as the International Organization for Standardization (ISO), which has established Technical Committee 229 focused on nanotechnologies. This committee is currently developing standardized protocols for characterizing and evaluating single-atom catalysts, aiming to create globally recognized testing methodologies and safety assessment frameworks.

Emerging economies are rapidly developing their regulatory approaches, often adapting frameworks from established markets while addressing local environmental and industrial contexts. Brazil's National Institute of Metrology, Quality and Technology has recently published guidelines specifically addressing metal-atom catalysts in environmental applications, while India's regulatory framework remains in development with interim guidelines issued by the Bureau of Indian Standards.

Cross-cutting all these regulatory frameworks are international agreements such as the Strategic Approach to International Chemicals Management (SAICM), which increasingly addresses novel catalytic technologies. The recent focus on "chemicals of emerging concern" has brought single-atom catalysts under greater scrutiny, particularly regarding their potential for environmental persistence and bioaccumulation when used in large-scale industrial applications.

Sustainability and Environmental Impact Assessment

Single-atom catalysis (SAC) represents a significant advancement in sustainable chemical processes, offering unprecedented atom efficiency and selectivity. The environmental impact assessment of SAC technologies reveals substantial potential for reducing the ecological footprint of industrial catalytic processes. When properly implemented, SAC can decrease energy consumption by 30-45% compared to traditional catalysts, primarily due to lower activation energies and more efficient reaction pathways.

The sustainability profile of SAC extends beyond energy efficiency to include dramatic reductions in precious metal usage. Conventional catalysts typically require metal loadings of 2-10 wt%, while SAC achieves comparable or superior performance with metal loadings below 0.5 wt%. This translates to conservation of critical raw materials, many of which face supply constraints and geopolitical challenges.

Life cycle assessments (LCA) of SAC implementations demonstrate favorable environmental metrics across multiple impact categories. Studies indicate potential reductions of 40-60% in greenhouse gas emissions when replacing conventional catalysts with SAC alternatives in petrochemical and fine chemical production. Water footprint analyses similarly show improvements of 25-35% in many applications, particularly in pharmaceutical manufacturing processes.

Regulatory compliance frameworks increasingly recognize these environmental benefits. The European Union's REACH regulation and similar frameworks in North America and Asia are evolving to incentivize technologies with demonstrable sustainability advantages. SAC technologies align well with these regulatory directions, particularly regarding reduced waste generation and hazardous substance minimization.

Challenges remain in quantifying the long-term environmental impacts of SAC technologies. The potential for metal leaching, though minimal compared to conventional catalysts, requires monitoring throughout the catalyst lifecycle. Additionally, end-of-life management strategies for spent SAC materials are still developing, with current recycling technologies achieving 85-95% recovery rates for precious metals from SAC substrates.

The environmental risk assessment of SAC must also consider potential nanomaterial concerns. While single-atom dispersion generally presents lower risks than nanoparticle formulations, regulatory bodies including the US EPA and EU's European Chemicals Agency continue to develop specific guidelines for atomically dispersed materials. Compliance strategies must anticipate these evolving requirements through proactive toxicological and environmental fate studies.

The sustainability profile of SAC extends beyond energy efficiency to include dramatic reductions in precious metal usage. Conventional catalysts typically require metal loadings of 2-10 wt%, while SAC achieves comparable or superior performance with metal loadings below 0.5 wt%. This translates to conservation of critical raw materials, many of which face supply constraints and geopolitical challenges.

Life cycle assessments (LCA) of SAC implementations demonstrate favorable environmental metrics across multiple impact categories. Studies indicate potential reductions of 40-60% in greenhouse gas emissions when replacing conventional catalysts with SAC alternatives in petrochemical and fine chemical production. Water footprint analyses similarly show improvements of 25-35% in many applications, particularly in pharmaceutical manufacturing processes.

Regulatory compliance frameworks increasingly recognize these environmental benefits. The European Union's REACH regulation and similar frameworks in North America and Asia are evolving to incentivize technologies with demonstrable sustainability advantages. SAC technologies align well with these regulatory directions, particularly regarding reduced waste generation and hazardous substance minimization.

Challenges remain in quantifying the long-term environmental impacts of SAC technologies. The potential for metal leaching, though minimal compared to conventional catalysts, requires monitoring throughout the catalyst lifecycle. Additionally, end-of-life management strategies for spent SAC materials are still developing, with current recycling technologies achieving 85-95% recovery rates for precious metals from SAC substrates.

The environmental risk assessment of SAC must also consider potential nanomaterial concerns. While single-atom dispersion generally presents lower risks than nanoparticle formulations, regulatory bodies including the US EPA and EU's European Chemicals Agency continue to develop specific guidelines for atomically dispersed materials. Compliance strategies must anticipate these evolving requirements through proactive toxicological and environmental fate studies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!