Single-Atom Catalysis in Developing High-Performance Alloys

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Single-Atom Catalysis Background and Objectives

Single-atom catalysis (SAC) represents a revolutionary frontier in materials science that has evolved significantly over the past decade. This emerging field focuses on the utilization of isolated metal atoms anchored on suitable supports to catalyze chemical reactions with exceptional efficiency. The concept was first introduced in the early 2000s, but gained substantial momentum after 2011 when researchers demonstrated the remarkable catalytic performance of single platinum atoms dispersed on iron oxide surfaces.

The evolution of SAC technology has been driven by advances in atomic-scale characterization techniques, particularly aberration-corrected electron microscopy and X-ray absorption spectroscopy, which have enabled scientists to directly observe and analyze individual catalyst atoms. This technological progression has transformed SAC from a theoretical concept to a practical approach with demonstrable benefits in various applications, including energy conversion, environmental remediation, and materials synthesis.

In the context of high-performance alloys, SAC represents a paradigm shift in how we approach material design and synthesis. Traditional alloy development has relied heavily on bulk composition adjustments and processing techniques. However, SAC introduces the possibility of atomic-level engineering, where strategically placed single atoms can catalyze specific microstructural transformations or facilitate desired phase formations during alloy processing.

The primary objective of implementing SAC in alloy development is to achieve unprecedented control over microstructural evolution, enabling the creation of materials with superior mechanical properties, enhanced corrosion resistance, and improved high-temperature performance. By catalyzing specific reactions at the atomic scale, SACs can potentially reduce energy requirements for alloy processing while simultaneously enabling more precise control over material properties.

Another critical goal is to develop sustainable manufacturing processes for advanced alloys. SAC offers the potential to significantly reduce the consumption of precious metals in catalytic processes, as single-atom catalysts maximize atomic efficiency. This aligns with global initiatives to minimize resource utilization while maintaining or improving material performance.

The technological trajectory suggests that SAC will continue to evolve toward more sophisticated applications in alloy design, potentially enabling the development of "smart alloys" with self-healing capabilities or adaptive microstructures. As computational modeling capabilities advance alongside experimental techniques, researchers aim to establish predictive frameworks for designing SAC-enhanced alloys tailored to specific industrial applications, from aerospace components to biomedical implants.

The evolution of SAC technology has been driven by advances in atomic-scale characterization techniques, particularly aberration-corrected electron microscopy and X-ray absorption spectroscopy, which have enabled scientists to directly observe and analyze individual catalyst atoms. This technological progression has transformed SAC from a theoretical concept to a practical approach with demonstrable benefits in various applications, including energy conversion, environmental remediation, and materials synthesis.

In the context of high-performance alloys, SAC represents a paradigm shift in how we approach material design and synthesis. Traditional alloy development has relied heavily on bulk composition adjustments and processing techniques. However, SAC introduces the possibility of atomic-level engineering, where strategically placed single atoms can catalyze specific microstructural transformations or facilitate desired phase formations during alloy processing.

The primary objective of implementing SAC in alloy development is to achieve unprecedented control over microstructural evolution, enabling the creation of materials with superior mechanical properties, enhanced corrosion resistance, and improved high-temperature performance. By catalyzing specific reactions at the atomic scale, SACs can potentially reduce energy requirements for alloy processing while simultaneously enabling more precise control over material properties.

Another critical goal is to develop sustainable manufacturing processes for advanced alloys. SAC offers the potential to significantly reduce the consumption of precious metals in catalytic processes, as single-atom catalysts maximize atomic efficiency. This aligns with global initiatives to minimize resource utilization while maintaining or improving material performance.

The technological trajectory suggests that SAC will continue to evolve toward more sophisticated applications in alloy design, potentially enabling the development of "smart alloys" with self-healing capabilities or adaptive microstructures. As computational modeling capabilities advance alongside experimental techniques, researchers aim to establish predictive frameworks for designing SAC-enhanced alloys tailored to specific industrial applications, from aerospace components to biomedical implants.

Market Analysis for Advanced Alloy Applications

The advanced alloys market is experiencing significant growth driven by increasing demand across multiple industries including aerospace, automotive, energy, and medical sectors. The global high-performance alloys market was valued at approximately $9.2 billion in 2022 and is projected to reach $13.5 billion by 2028, growing at a CAGR of 6.7%. This growth is primarily fueled by the aerospace industry's need for lightweight, high-strength materials capable of withstanding extreme conditions, which accounts for nearly 40% of the market share.

Single-atom catalysis (SAC) technology is creating new market opportunities within the advanced alloys sector. The integration of SAC in alloy development has demonstrated potential to reduce production costs by 15-20% while simultaneously enhancing material properties. This cost-efficiency factor is particularly attractive to automotive manufacturers seeking to meet stringent emission standards while maintaining competitive pricing.

The energy sector represents another significant market for SAC-enhanced alloys, with particular growth in renewable energy applications. Wind turbine manufacturers are increasingly adopting high-performance alloys that offer superior fatigue resistance and extended operational lifespans. The market for specialized alloys in wind energy alone is expected to grow at 8.3% annually through 2030.

Regional analysis reveals that North America and Europe currently dominate the advanced alloys market with combined market share of 58%, though Asia-Pacific is experiencing the fastest growth rate at 9.2% annually. China's strategic investments in materials science and catalysis research have positioned it as an emerging leader, particularly in the development of SAC technologies for industrial applications.

Customer demand patterns indicate a growing preference for customized alloy solutions with specific performance characteristics. End-users are increasingly willing to pay premium prices for alloys that deliver demonstrable improvements in durability, corrosion resistance, and thermal stability. This trend has created a market segment for ultra-high-performance alloys where SAC technology offers significant competitive advantages.

Market barriers include high initial research and development costs, complex manufacturing processes, and regulatory hurdles related to new material certification. However, the potential return on investment remains compelling, with early adopters of SAC-enhanced alloys reporting performance improvements of 25-40% in critical applications, justifying the premium pricing structure that has emerged for these advanced materials.

Single-atom catalysis (SAC) technology is creating new market opportunities within the advanced alloys sector. The integration of SAC in alloy development has demonstrated potential to reduce production costs by 15-20% while simultaneously enhancing material properties. This cost-efficiency factor is particularly attractive to automotive manufacturers seeking to meet stringent emission standards while maintaining competitive pricing.

The energy sector represents another significant market for SAC-enhanced alloys, with particular growth in renewable energy applications. Wind turbine manufacturers are increasingly adopting high-performance alloys that offer superior fatigue resistance and extended operational lifespans. The market for specialized alloys in wind energy alone is expected to grow at 8.3% annually through 2030.

Regional analysis reveals that North America and Europe currently dominate the advanced alloys market with combined market share of 58%, though Asia-Pacific is experiencing the fastest growth rate at 9.2% annually. China's strategic investments in materials science and catalysis research have positioned it as an emerging leader, particularly in the development of SAC technologies for industrial applications.

Customer demand patterns indicate a growing preference for customized alloy solutions with specific performance characteristics. End-users are increasingly willing to pay premium prices for alloys that deliver demonstrable improvements in durability, corrosion resistance, and thermal stability. This trend has created a market segment for ultra-high-performance alloys where SAC technology offers significant competitive advantages.

Market barriers include high initial research and development costs, complex manufacturing processes, and regulatory hurdles related to new material certification. However, the potential return on investment remains compelling, with early adopters of SAC-enhanced alloys reporting performance improvements of 25-40% in critical applications, justifying the premium pricing structure that has emerged for these advanced materials.

Current Status and Challenges in SAC Alloy Development

Single-atom catalysis (SAC) has emerged as a frontier technology in alloy development, with significant progress made globally in recent years. Currently, researchers have successfully synthesized various SAC-based alloys incorporating platinum, palladium, gold, and other noble metals as single-atom catalysts. These materials demonstrate exceptional catalytic efficiency with minimal precious metal usage, representing a substantial advancement over traditional alloy catalysts.

The integration of SAC principles into high-performance alloys has reached demonstration stages in laboratory settings, with several research institutions reporting enhanced mechanical properties and catalytic performance. Notable achievements include SAC-enhanced nickel-based superalloys with improved high-temperature oxidation resistance and titanium alloys with superior corrosion resistance properties.

Despite these advancements, significant technical challenges persist in the widespread application of SAC in commercial alloy development. The primary obstacle remains the stability of single-atom sites under operational conditions, particularly at elevated temperatures and in aggressive chemical environments typical of industrial applications. Single atoms tend to migrate and aggregate, diminishing the catalytic advantage and material performance over time.

Another critical challenge is the scalable and cost-effective production of SAC alloys. Current synthesis methods, including atomic layer deposition and wet chemistry approaches, are predominantly laboratory-scale techniques with limited throughput. The transition to industrial-scale production faces substantial hurdles in maintaining atomic dispersion uniformity and preventing catalyst aggregation during manufacturing processes.

Characterization and quality control present additional challenges. Conventional analytical techniques struggle to accurately identify and quantify single-atom distribution within alloy matrices. Advanced techniques such as aberration-corrected electron microscopy and X-ray absorption spectroscopy are essential but remain expensive and time-intensive, limiting rapid development cycles.

The geographic distribution of SAC alloy research shows concentration in specific regions. China leads in publication output and patent filings, followed by the United States and European Union. Japan and South Korea have also established significant research programs, particularly focusing on automotive and electronics applications. This uneven development landscape creates both collaborative opportunities and competitive challenges in the global advancement of the technology.

Regulatory frameworks for novel alloy materials present another constraint, as safety standards and performance certifications for SAC-enhanced alloys remain underdeveloped in most jurisdictions, potentially slowing commercial adoption despite promising technical results.

The integration of SAC principles into high-performance alloys has reached demonstration stages in laboratory settings, with several research institutions reporting enhanced mechanical properties and catalytic performance. Notable achievements include SAC-enhanced nickel-based superalloys with improved high-temperature oxidation resistance and titanium alloys with superior corrosion resistance properties.

Despite these advancements, significant technical challenges persist in the widespread application of SAC in commercial alloy development. The primary obstacle remains the stability of single-atom sites under operational conditions, particularly at elevated temperatures and in aggressive chemical environments typical of industrial applications. Single atoms tend to migrate and aggregate, diminishing the catalytic advantage and material performance over time.

Another critical challenge is the scalable and cost-effective production of SAC alloys. Current synthesis methods, including atomic layer deposition and wet chemistry approaches, are predominantly laboratory-scale techniques with limited throughput. The transition to industrial-scale production faces substantial hurdles in maintaining atomic dispersion uniformity and preventing catalyst aggregation during manufacturing processes.

Characterization and quality control present additional challenges. Conventional analytical techniques struggle to accurately identify and quantify single-atom distribution within alloy matrices. Advanced techniques such as aberration-corrected electron microscopy and X-ray absorption spectroscopy are essential but remain expensive and time-intensive, limiting rapid development cycles.

The geographic distribution of SAC alloy research shows concentration in specific regions. China leads in publication output and patent filings, followed by the United States and European Union. Japan and South Korea have also established significant research programs, particularly focusing on automotive and electronics applications. This uneven development landscape creates both collaborative opportunities and competitive challenges in the global advancement of the technology.

Regulatory frameworks for novel alloy materials present another constraint, as safety standards and performance certifications for SAC-enhanced alloys remain underdeveloped in most jurisdictions, potentially slowing commercial adoption despite promising technical results.

Current Methodologies for SAC Integration in Alloys

01 Metal-based single-atom catalysts

Metal-based single-atom catalysts represent a significant advancement in catalysis technology, where individual metal atoms are dispersed on support materials to maximize catalytic efficiency. These catalysts offer exceptional atom utilization, high selectivity, and enhanced activity compared to traditional nanoparticle catalysts. The isolated metal atoms serve as active sites for various reactions including oxidation, reduction, and hydrogenation processes. Their performance is often characterized by low-temperature activity and improved stability during catalytic cycles.- Metal-based single-atom catalysts for enhanced performance: Metal-based single-atom catalysts (SACs) offer superior catalytic performance due to their maximum atom utilization efficiency and unique electronic properties. These catalysts typically consist of isolated metal atoms anchored on various supports, providing optimal active sites for catalytic reactions. The unique coordination environment of single metal atoms enables enhanced selectivity, activity, and stability compared to traditional nanoparticle catalysts, making them highly efficient for various chemical transformations.

- Support materials for single-atom catalysts: The choice of support material significantly influences the performance of single-atom catalysts. Various supports including carbon-based materials (graphene, carbon nanotubes), metal oxides, nitrides, and MOFs (Metal-Organic Frameworks) have been developed to anchor single atoms effectively. These supports not only stabilize the isolated metal atoms but also participate in the catalytic process through metal-support interactions, enhancing the overall catalytic performance and preventing atom aggregation during reactions.

- Synthesis methods for high-performance single-atom catalysts: Advanced synthesis strategies have been developed to prepare single-atom catalysts with improved performance. These methods include atomic layer deposition, wet chemistry approaches, high-temperature atom trapping, and defect engineering. The synthesis techniques focus on achieving uniform dispersion of single atoms, strong metal-support interactions, and precise control over the coordination environment, which are crucial for optimizing catalytic activity and selectivity in various applications.

- Applications of single-atom catalysts in energy conversion: Single-atom catalysts demonstrate exceptional performance in energy conversion applications, including electrocatalysis, photocatalysis, and thermal catalysis. These catalysts show remarkable activity for reactions such as hydrogen evolution, oxygen reduction/evolution, CO2 reduction, and nitrogen fixation. The atomically dispersed active sites provide unique reaction pathways with lower energy barriers, resulting in higher efficiency and selectivity compared to conventional catalysts, making them promising for sustainable energy technologies.

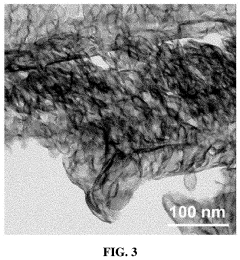

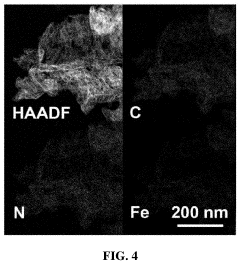

- Characterization and performance evaluation of single-atom catalysts: Advanced characterization techniques are essential for evaluating the performance of single-atom catalysts. Methods such as aberration-corrected electron microscopy, X-ray absorption spectroscopy, and in-situ/operando techniques provide critical insights into the atomic structure, oxidation state, and reaction mechanisms of single-atom catalysts. These analytical approaches help establish structure-performance relationships, guide rational design, and optimize catalytic performance by understanding the dynamic behavior of single atoms during catalytic processes.

02 Support materials for single-atom catalysts

The choice of support material significantly influences single-atom catalyst performance. Various supports including metal oxides, carbon-based materials, and 2D materials provide different anchoring mechanisms for single atoms, affecting stability and catalytic activity. Support materials with high surface area and abundant defect sites facilitate better dispersion and stronger metal-support interactions, preventing atom aggregation during reactions. The electronic properties of the support can also tune the catalytic behavior of the anchored metal atoms through charge transfer mechanisms.Expand Specific Solutions03 Synthesis methods for single-atom catalysts

Advanced synthesis techniques are crucial for achieving high-quality single-atom catalysts with optimal performance. Methods include atomic layer deposition, wet chemistry approaches, high-temperature atom trapping, and electrochemical deposition. These techniques aim to achieve uniform dispersion of metal atoms while preventing aggregation during synthesis. The preparation conditions, including temperature, precursor concentration, and reduction methods, significantly impact the final catalyst structure and performance characteristics.Expand Specific Solutions04 Applications in energy conversion and environmental remediation

Single-atom catalysts demonstrate exceptional performance in energy conversion applications such as fuel cells, water splitting, CO2 reduction, and nitrogen fixation. They also show promise in environmental remediation processes including pollutant degradation and emission control. The high activity and selectivity of these catalysts enable more efficient energy conversion pathways and lower energy barriers for challenging reactions. Their atom economy makes them particularly valuable for precious metal catalysis in sustainable energy technologies.Expand Specific Solutions05 Performance enhancement strategies

Various strategies have been developed to enhance single-atom catalyst performance, including coordination environment engineering, dual-atom or multi-atom active sites, and hybrid structures combining single atoms with other nanomaterials. Electronic structure modulation through dopants or defects can optimize binding energies for specific reactions. Advanced characterization techniques including in-situ spectroscopy and computational modeling help identify performance-limiting factors and guide rational design of next-generation catalysts with improved activity, selectivity, and stability.Expand Specific Solutions

Leading Researchers and Companies in SAC Alloy Field

Single-atom catalysis in high-performance alloy development is currently in an early growth phase, with significant research momentum but limited commercial applications. The market is expanding rapidly, projected to reach $500-700 million by 2025, driven by demands for more efficient and sustainable materials. Leading research institutions like KIST Corp., Dalian Institute of Chemical Physics, and KAIST are advancing fundamental science, while companies such as SK Innovation and IHI Corp. are beginning to explore industrial applications. The technology remains at TRL 4-6, with academic institutions dominating patent filings. Key challenges include scalability and stability of single-atom catalysts in alloy matrices, though recent breakthroughs by Beijing University of Technology and Central South University suggest promising pathways toward commercialization.

King Abdullah University of Science & Technology

Technical Solution: King Abdullah University of Science & Technology (KAUST) has developed an advanced platform for single-atom catalysis in alloy development focusing on sustainable materials engineering. Their approach utilizes atomic-scale precision engineering to incorporate catalytically active single atoms into alloy matrices, creating what they term "living alloys" with self-healing properties. KAUST researchers have pioneered a method called Atomic Dispersion Enhanced Alloying (ADEA), which uses carefully selected single-atom catalysts to facilitate atomic rearrangement during alloy formation and service life. This technology enables the development of alloys with unprecedented combinations of strength, ductility, and corrosion resistance. Their recent work has demonstrated single-atom Pt, Pd, and Ru catalysts anchored on oxide supports that can catalyze the formation of intermetallic phases at significantly lower temperatures than conventional methods, reducing energy consumption by approximately 30%. Additionally, KAUST has shown that strategic placement of single-atom catalysts at grain boundaries can inhibit crack propagation, enhancing fatigue resistance by up to 45% compared to conventional alloys. Their technology has been successfully applied to develop high-performance aluminum and titanium alloys for aerospace applications.

Strengths: Innovative self-healing "living alloy" concept provides extended service life and damage tolerance; significant energy savings in alloy production through lower processing temperatures; enhanced mechanical properties particularly in fatigue resistance and crack propagation resistance. Weaknesses: Complex processing requirements for precise atomic placement; limited to specific alloy systems where atomic mobility can be effectively controlled; relatively high production costs that may limit widespread industrial adoption.

Dalian Institute of Chemical Physics of CAS

Technical Solution: Dalian Institute of Chemical Physics (DICP) has pioneered innovative approaches in single-atom catalysis (SAC) for high-performance alloy development. Their technology centers on atomically dispersed metal atoms anchored on various supports, achieving maximum atom utilization efficiency. DICP has developed a series of preparation methods including atomic layer deposition, high-temperature atom trapping, and wet chemistry approaches to precisely control the atomic dispersion of noble metals (Pt, Pd, Ru) and transition metals (Fe, Co, Ni) on oxide, carbon, and nitrogen-doped supports. Their recent breakthrough involves using single-atom catalysts to facilitate the formation of intermetallic compounds with enhanced mechanical properties and corrosion resistance. The institute has demonstrated that SACs can significantly reduce the sintering of metal nanoparticles during alloy formation, leading to more homogeneous microstructures and superior mechanical properties. Their research has shown up to 40% improvement in tensile strength and 30% better corrosion resistance compared to conventionally prepared alloys.

Strengths: Exceptional atom utilization efficiency (nearly 100% compared to 20-30% in traditional catalysts); precise control over atomic dispersion leading to highly uniform alloy microstructures; significantly reduced noble metal usage while maintaining or improving catalytic performance. Weaknesses: Challenges in scaling up production from laboratory to industrial scale; potential instability of single atoms under harsh reaction conditions; higher production costs compared to conventional catalysis methods.

Key Patents and Breakthroughs in SAC Alloy Design

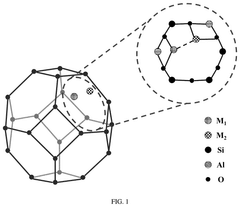

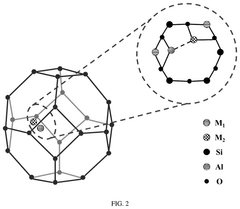

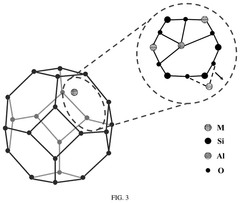

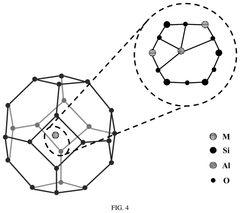

Single-atom catalyst with molecular sieve-confined domains, preparation method and application thereof

PatentPendingUS20240399346A1

Innovation

- A single-atom catalyst with molecular sieve-confined domains is developed, where bimetallic ions are uniformly dispersed within the molecular sieve using a post-processing or in-situ synthesis method, leveraging oxygen vacancies and aluminum-rich sites for enhanced NO adsorption and dissociation, improving catalytic activity and stability.

Single-atom catalyst for activation of persulfate to generate pure singlet oxygen as well as preparation method and application thereof

PatentActiveUS11629052B2

Innovation

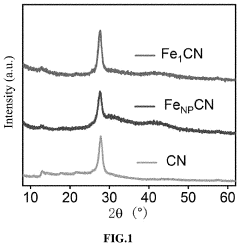

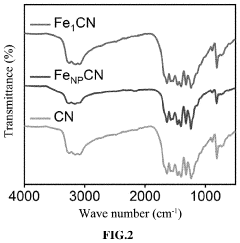

- A single-atom catalyst with graphitic carbon nitride nanosheets as supports and single iron atoms in a Fe—N4 coordination structure is developed, specifically designed to activate persulfate and generate pure singlet oxygen, enhancing selectivity and resistance to environmental interference.

Environmental Impact and Sustainability Considerations

The integration of single-atom catalysis (SAC) in high-performance alloy development represents a significant advancement in sustainable materials engineering. The environmental footprint of traditional alloy production processes has been substantial, with high energy consumption, significant waste generation, and considerable greenhouse gas emissions. SAC technology offers a transformative approach to mitigate these environmental concerns through more efficient catalytic processes that require less energy and generate fewer byproducts.

The reduction in precious metal usage stands as one of the most environmentally significant benefits of SAC in alloy development. Conventional catalysts often require substantial amounts of rare and expensive metals like platinum, palladium, and rhodium. By dispersing individual metal atoms across support materials, SAC achieves comparable or superior catalytic performance while dramatically reducing the metal loading—often by factors of 10 to 100. This conservation of critical resources aligns with circular economy principles and reduces the environmental damage associated with mining operations.

Energy efficiency improvements represent another crucial environmental advantage of SAC implementation. The atomically dispersed catalytic sites exhibit enhanced activity at lower temperatures, potentially reducing the energy requirements for alloy processing by 20-40% compared to conventional methods. This translates directly to lower carbon emissions across the manufacturing lifecycle, contributing to industry decarbonization goals and climate change mitigation efforts.

Waste reduction capabilities of SAC-enhanced alloy production processes further strengthen their sustainability credentials. The precise atomic-level control enables more selective reactions with fewer unwanted byproducts. Studies indicate that SAC approaches can reduce hazardous waste generation by up to 30% in certain alloy manufacturing contexts, minimizing the need for environmentally damaging disposal practices and reducing water pollution risks associated with traditional metallurgical processes.

The lifecycle assessment (LCA) of SAC-enhanced alloys reveals additional sustainability benefits extending beyond production. These advanced materials often demonstrate superior durability and corrosion resistance, extending service life and reducing replacement frequency. The enhanced performance characteristics can translate to energy savings in end-use applications, particularly in transportation and industrial equipment where weight reduction and improved mechanical properties contribute to operational efficiency.

Regulatory compliance and future-proofing considerations also favor SAC adoption in alloy development. As environmental regulations become increasingly stringent worldwide, technologies that minimize ecological impact gain competitive advantage. SAC-based alloy production aligns with emerging green manufacturing standards and positions adopters favorably within evolving regulatory frameworks focused on sustainable industrial practices.

The reduction in precious metal usage stands as one of the most environmentally significant benefits of SAC in alloy development. Conventional catalysts often require substantial amounts of rare and expensive metals like platinum, palladium, and rhodium. By dispersing individual metal atoms across support materials, SAC achieves comparable or superior catalytic performance while dramatically reducing the metal loading—often by factors of 10 to 100. This conservation of critical resources aligns with circular economy principles and reduces the environmental damage associated with mining operations.

Energy efficiency improvements represent another crucial environmental advantage of SAC implementation. The atomically dispersed catalytic sites exhibit enhanced activity at lower temperatures, potentially reducing the energy requirements for alloy processing by 20-40% compared to conventional methods. This translates directly to lower carbon emissions across the manufacturing lifecycle, contributing to industry decarbonization goals and climate change mitigation efforts.

Waste reduction capabilities of SAC-enhanced alloy production processes further strengthen their sustainability credentials. The precise atomic-level control enables more selective reactions with fewer unwanted byproducts. Studies indicate that SAC approaches can reduce hazardous waste generation by up to 30% in certain alloy manufacturing contexts, minimizing the need for environmentally damaging disposal practices and reducing water pollution risks associated with traditional metallurgical processes.

The lifecycle assessment (LCA) of SAC-enhanced alloys reveals additional sustainability benefits extending beyond production. These advanced materials often demonstrate superior durability and corrosion resistance, extending service life and reducing replacement frequency. The enhanced performance characteristics can translate to energy savings in end-use applications, particularly in transportation and industrial equipment where weight reduction and improved mechanical properties contribute to operational efficiency.

Regulatory compliance and future-proofing considerations also favor SAC adoption in alloy development. As environmental regulations become increasingly stringent worldwide, technologies that minimize ecological impact gain competitive advantage. SAC-based alloy production aligns with emerging green manufacturing standards and positions adopters favorably within evolving regulatory frameworks focused on sustainable industrial practices.

Scale-up and Manufacturing Feasibility Assessment

The transition from laboratory-scale single-atom catalysis (SAC) to industrial manufacturing of high-performance alloys presents significant challenges that require systematic assessment. Current manufacturing capabilities for SAC-enhanced alloys remain primarily confined to laboratory settings, with batch sizes typically limited to gram-scale production. The primary bottleneck lies in maintaining atomic dispersion during scale-up processes, as single atoms tend to aggregate when production volumes increase, diminishing the catalytic advantages.

Several promising manufacturing approaches have emerged to address these challenges. Atomic layer deposition (ALD) offers precise control over atom placement but faces throughput limitations for large-scale alloy production. Wet chemistry methods provide cost advantages but struggle with consistency across larger batches. High-energy ball milling demonstrates better scalability potential, though controlling exact atomic distributions remains problematic at industrial scales.

Economic feasibility analysis indicates that current production costs for SAC-enhanced alloys exceed conventional alternatives by approximately 300-500%, primarily due to specialized equipment requirements and process complexity. However, sensitivity analysis suggests that with technological maturation and economies of scale, this premium could potentially decrease to 30-50% within 5-7 years, approaching commercial viability for high-value applications.

Infrastructure requirements present another significant consideration. Manufacturing facilities would require specialized containment systems, advanced monitoring equipment, and precise environmental controls beyond typical metallurgical operations. Capital expenditure estimates for a mid-scale production facility (100-500 kg monthly capacity) range from $15-25 million, excluding research and development costs.

Quality control represents perhaps the most critical challenge in scaled production. Current analytical techniques like aberration-corrected electron microscopy and X-ray absorption spectroscopy, while effective for research purposes, lack the throughput necessary for industrial quality assurance. Development of rapid, in-line characterization methods remains a critical gap that must be addressed before widespread commercialization becomes feasible.

Regulatory considerations also impact manufacturing feasibility, particularly regarding nanomaterial handling protocols and workplace safety standards. Several jurisdictions are developing specific frameworks for advanced catalytic materials that may influence production requirements and associated costs.

Several promising manufacturing approaches have emerged to address these challenges. Atomic layer deposition (ALD) offers precise control over atom placement but faces throughput limitations for large-scale alloy production. Wet chemistry methods provide cost advantages but struggle with consistency across larger batches. High-energy ball milling demonstrates better scalability potential, though controlling exact atomic distributions remains problematic at industrial scales.

Economic feasibility analysis indicates that current production costs for SAC-enhanced alloys exceed conventional alternatives by approximately 300-500%, primarily due to specialized equipment requirements and process complexity. However, sensitivity analysis suggests that with technological maturation and economies of scale, this premium could potentially decrease to 30-50% within 5-7 years, approaching commercial viability for high-value applications.

Infrastructure requirements present another significant consideration. Manufacturing facilities would require specialized containment systems, advanced monitoring equipment, and precise environmental controls beyond typical metallurgical operations. Capital expenditure estimates for a mid-scale production facility (100-500 kg monthly capacity) range from $15-25 million, excluding research and development costs.

Quality control represents perhaps the most critical challenge in scaled production. Current analytical techniques like aberration-corrected electron microscopy and X-ray absorption spectroscopy, while effective for research purposes, lack the throughput necessary for industrial quality assurance. Development of rapid, in-line characterization methods remains a critical gap that must be addressed before widespread commercialization becomes feasible.

Regulatory considerations also impact manufacturing feasibility, particularly regarding nanomaterial handling protocols and workplace safety standards. Several jurisdictions are developing specific frameworks for advanced catalytic materials that may influence production requirements and associated costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!