Single-Atom Catalysis for Improved Kinetics in Redox Reactions

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Single-Atom Catalysis Background and Objectives

Single-atom catalysis (SAC) represents a revolutionary frontier in heterogeneous catalysis that has emerged over the past decade. This innovative approach involves dispersing individual metal atoms onto suitable supports, maximizing atomic efficiency while delivering exceptional catalytic performance. The concept was first formally introduced in 2011, though earlier studies had observed similar phenomena without explicitly defining the field. Since then, SAC has experienced exponential growth in research interest, particularly for applications in redox reactions where electron transfer processes are fundamental.

The evolution of catalysis technology has progressed from traditional bulk catalysts to nanoparticles, and now to the atomic level with SAC. This progression reflects scientists' pursuit of increased active site utilization and enhanced catalytic efficiency. Single-atom catalysts offer unique advantages in redox reactions due to their distinct electronic structures, coordination environments, and quantum effects that emerge at the atomic scale.

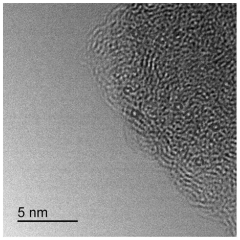

Recent technological advancements in characterization techniques, particularly aberration-corrected electron microscopy and X-ray absorption spectroscopy, have been instrumental in confirming the atomic dispersion of metal centers and understanding their local environments. These developments have accelerated SAC research by providing direct evidence of single-atom structures and their dynamic behavior during catalytic processes.

The primary objective of single-atom catalysis research for redox reactions is to develop highly efficient catalysts with 100% atom utilization, overcoming the kinetic limitations that plague conventional catalytic systems. Specific goals include enhancing reaction rates, improving selectivity, and reducing activation energy barriers in critical redox processes such as oxygen reduction/evolution reactions, hydrogen evolution/oxidation reactions, and CO2 reduction.

Another key objective is understanding the fundamental mechanisms governing single-atom catalytic behavior in redox environments. This includes elucidating the role of metal-support interactions, identifying optimal coordination environments, and determining how electronic properties influence reaction pathways. Such knowledge is essential for rational catalyst design rather than empirical approaches.

From an industrial perspective, the technology aims to develop scalable synthesis methods for single-atom catalysts that maintain stability under realistic operating conditions. Current laboratory demonstrations must evolve into commercially viable processes that can withstand the harsh environments of industrial redox applications while maintaining their atomic dispersion and exceptional activity.

The evolution of catalysis technology has progressed from traditional bulk catalysts to nanoparticles, and now to the atomic level with SAC. This progression reflects scientists' pursuit of increased active site utilization and enhanced catalytic efficiency. Single-atom catalysts offer unique advantages in redox reactions due to their distinct electronic structures, coordination environments, and quantum effects that emerge at the atomic scale.

Recent technological advancements in characterization techniques, particularly aberration-corrected electron microscopy and X-ray absorption spectroscopy, have been instrumental in confirming the atomic dispersion of metal centers and understanding their local environments. These developments have accelerated SAC research by providing direct evidence of single-atom structures and their dynamic behavior during catalytic processes.

The primary objective of single-atom catalysis research for redox reactions is to develop highly efficient catalysts with 100% atom utilization, overcoming the kinetic limitations that plague conventional catalytic systems. Specific goals include enhancing reaction rates, improving selectivity, and reducing activation energy barriers in critical redox processes such as oxygen reduction/evolution reactions, hydrogen evolution/oxidation reactions, and CO2 reduction.

Another key objective is understanding the fundamental mechanisms governing single-atom catalytic behavior in redox environments. This includes elucidating the role of metal-support interactions, identifying optimal coordination environments, and determining how electronic properties influence reaction pathways. Such knowledge is essential for rational catalyst design rather than empirical approaches.

From an industrial perspective, the technology aims to develop scalable synthesis methods for single-atom catalysts that maintain stability under realistic operating conditions. Current laboratory demonstrations must evolve into commercially viable processes that can withstand the harsh environments of industrial redox applications while maintaining their atomic dispersion and exceptional activity.

Market Demand Analysis for Advanced Catalytic Technologies

The global market for advanced catalytic technologies is experiencing robust growth, driven by increasing demands for energy efficiency, environmental sustainability, and cost-effective chemical processes. Single-atom catalysis (SAC) represents a revolutionary approach in this domain, offering unprecedented atom efficiency and selectivity in redox reactions. Current market projections value the global catalyst market at approximately $34 billion, with specialty catalysts for redox applications constituting a significant segment showing annual growth rates of 6-7%.

Industrial sectors including petrochemicals, fine chemicals, pharmaceuticals, and renewable energy are actively seeking improved catalytic solutions to enhance reaction kinetics while reducing energy consumption and waste production. The demand for SAC technologies is particularly strong in these sectors due to their potential to dramatically reduce precious metal usage while maintaining or improving catalytic performance.

Environmental regulations worldwide are becoming increasingly stringent, creating substantial market pull for catalytic technologies that can facilitate cleaner production processes. The European Green Deal, China's environmental protection policies, and the U.S. Clean Air Act amendments have all established regulatory frameworks that indirectly boost demand for advanced catalytic solutions. This regulatory landscape has created a market environment where industries are willing to invest in premium catalytic technologies that offer superior environmental performance.

The renewable energy sector presents a rapidly expanding market opportunity for SAC technologies. Hydrogen production through water splitting, fuel cell technologies, and energy storage systems all rely heavily on redox reactions where single-atom catalysts could provide significant performance improvements. Market research indicates that the green hydrogen sector alone is projected to grow at over 50% annually through 2030, creating substantial demand for advanced catalytic materials.

Cost sensitivity varies significantly across market segments. While bulk chemical producers remain highly price-sensitive, specialty chemical and pharmaceutical manufacturers demonstrate greater willingness to adopt premium catalytic solutions that offer improved selectivity and reduced downstream purification requirements. The electronics industry represents another high-value market segment where the precision of SAC technologies commands premium pricing.

Regional market analysis reveals that Asia-Pacific currently represents the largest and fastest-growing market for advanced catalytic technologies, driven by rapid industrialization and stringent new environmental regulations in China, Japan, and South Korea. North America and Europe maintain significant market shares, with demand increasingly focused on sustainable and green chemistry applications.

Customer needs assessment indicates five primary market requirements: improved catalytic activity at lower temperatures, enhanced selectivity for complex reactions, reduced precious metal content, longer catalyst lifetimes, and compatibility with existing industrial infrastructure. Single-atom catalysis for redox reactions potentially addresses all these requirements, positioning it as a highly attractive technology for commercialization.

Industrial sectors including petrochemicals, fine chemicals, pharmaceuticals, and renewable energy are actively seeking improved catalytic solutions to enhance reaction kinetics while reducing energy consumption and waste production. The demand for SAC technologies is particularly strong in these sectors due to their potential to dramatically reduce precious metal usage while maintaining or improving catalytic performance.

Environmental regulations worldwide are becoming increasingly stringent, creating substantial market pull for catalytic technologies that can facilitate cleaner production processes. The European Green Deal, China's environmental protection policies, and the U.S. Clean Air Act amendments have all established regulatory frameworks that indirectly boost demand for advanced catalytic solutions. This regulatory landscape has created a market environment where industries are willing to invest in premium catalytic technologies that offer superior environmental performance.

The renewable energy sector presents a rapidly expanding market opportunity for SAC technologies. Hydrogen production through water splitting, fuel cell technologies, and energy storage systems all rely heavily on redox reactions where single-atom catalysts could provide significant performance improvements. Market research indicates that the green hydrogen sector alone is projected to grow at over 50% annually through 2030, creating substantial demand for advanced catalytic materials.

Cost sensitivity varies significantly across market segments. While bulk chemical producers remain highly price-sensitive, specialty chemical and pharmaceutical manufacturers demonstrate greater willingness to adopt premium catalytic solutions that offer improved selectivity and reduced downstream purification requirements. The electronics industry represents another high-value market segment where the precision of SAC technologies commands premium pricing.

Regional market analysis reveals that Asia-Pacific currently represents the largest and fastest-growing market for advanced catalytic technologies, driven by rapid industrialization and stringent new environmental regulations in China, Japan, and South Korea. North America and Europe maintain significant market shares, with demand increasingly focused on sustainable and green chemistry applications.

Customer needs assessment indicates five primary market requirements: improved catalytic activity at lower temperatures, enhanced selectivity for complex reactions, reduced precious metal content, longer catalyst lifetimes, and compatibility with existing industrial infrastructure. Single-atom catalysis for redox reactions potentially addresses all these requirements, positioning it as a highly attractive technology for commercialization.

Current Status and Challenges in Single-Atom Catalysis

Single-atom catalysis (SAC) has emerged as a frontier in heterogeneous catalysis research, offering unprecedented atom efficiency and selectivity for redox reactions. Currently, significant progress has been made in synthesizing stable single-atom catalysts with various metal centers (Pt, Pd, Ru, Fe, Co, Ni) anchored on diverse supports including metal oxides, carbon-based materials, and metal-organic frameworks.

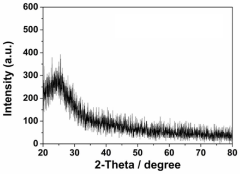

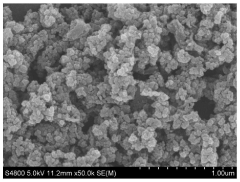

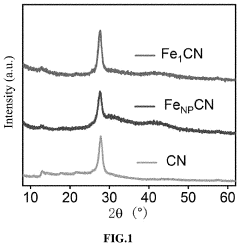

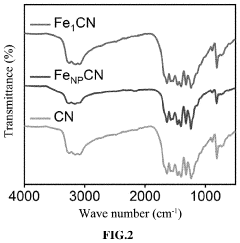

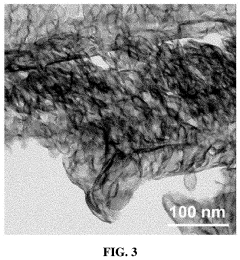

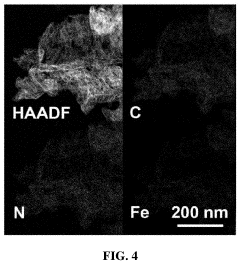

The field has witnessed remarkable advancements in characterization techniques, particularly in aberration-corrected scanning transmission electron microscopy (AC-STEM) and X-ray absorption spectroscopy (XAS), which have enabled direct visualization and electronic structure analysis of isolated metal atoms. These techniques have been crucial in confirming the single-atom nature of catalysts and understanding their coordination environments.

Despite these achievements, several significant challenges persist in SAC development for redox applications. The primary challenge remains the stability of single atoms under reaction conditions, as isolated metal atoms tend to aggregate into nanoparticles, especially at elevated temperatures or in reducing environments. This instability directly impacts catalyst longevity and practical industrial applications.

Another major hurdle is the limited loading capacity of metal atoms on supports, typically below 2 wt%, which constrains catalytic activity per unit volume. This limitation stems from the thermodynamic tendency of metal atoms to cluster when their concentration increases beyond critical thresholds on support surfaces.

The mechanistic understanding of SAC in redox reactions remains incomplete, particularly regarding the dynamic changes in oxidation states and coordination environments during catalytic cycles. This knowledge gap hampers rational catalyst design and optimization for specific redox transformations.

Scalable and reproducible synthesis methods represent another significant challenge. Current laboratory-scale preparation techniques often yield inconsistent results when scaled up, creating barriers to industrial implementation. The precise control of metal atom distribution and coordination environment becomes increasingly difficult at larger scales.

Geographically, SAC research shows distinct patterns with major contributions from China, the United States, and Europe. Chinese institutions lead in publication volume, particularly in synthesis methodologies, while US and European research groups focus more on fundamental mechanistic studies and advanced characterization. Japan and South Korea have also established strong positions in specific SAC applications for energy conversion.

The economic viability of SAC technologies presents additional challenges, as many current systems rely on precious metals like platinum and palladium. The development of earth-abundant metal SACs (Fe, Co, Ni) has progressed but often with lower activity or stability compared to noble metal counterparts.

The field has witnessed remarkable advancements in characterization techniques, particularly in aberration-corrected scanning transmission electron microscopy (AC-STEM) and X-ray absorption spectroscopy (XAS), which have enabled direct visualization and electronic structure analysis of isolated metal atoms. These techniques have been crucial in confirming the single-atom nature of catalysts and understanding their coordination environments.

Despite these achievements, several significant challenges persist in SAC development for redox applications. The primary challenge remains the stability of single atoms under reaction conditions, as isolated metal atoms tend to aggregate into nanoparticles, especially at elevated temperatures or in reducing environments. This instability directly impacts catalyst longevity and practical industrial applications.

Another major hurdle is the limited loading capacity of metal atoms on supports, typically below 2 wt%, which constrains catalytic activity per unit volume. This limitation stems from the thermodynamic tendency of metal atoms to cluster when their concentration increases beyond critical thresholds on support surfaces.

The mechanistic understanding of SAC in redox reactions remains incomplete, particularly regarding the dynamic changes in oxidation states and coordination environments during catalytic cycles. This knowledge gap hampers rational catalyst design and optimization for specific redox transformations.

Scalable and reproducible synthesis methods represent another significant challenge. Current laboratory-scale preparation techniques often yield inconsistent results when scaled up, creating barriers to industrial implementation. The precise control of metal atom distribution and coordination environment becomes increasingly difficult at larger scales.

Geographically, SAC research shows distinct patterns with major contributions from China, the United States, and Europe. Chinese institutions lead in publication volume, particularly in synthesis methodologies, while US and European research groups focus more on fundamental mechanistic studies and advanced characterization. Japan and South Korea have also established strong positions in specific SAC applications for energy conversion.

The economic viability of SAC technologies presents additional challenges, as many current systems rely on precious metals like platinum and palladium. The development of earth-abundant metal SACs (Fe, Co, Ni) has progressed but often with lower activity or stability compared to noble metal counterparts.

Current Technical Solutions for Redox Reaction Enhancement

01 Kinetic mechanisms of single-atom catalysts

Single-atom catalysts exhibit unique kinetic behaviors due to their isolated active sites. The kinetic mechanisms involve electron transfer processes, activation energy pathways, and reaction rate determinations that differ from traditional catalysts. These isolated metal atoms anchored on supports show distinctive reaction pathways and rate-determining steps that can be characterized through various analytical techniques to understand their fundamental catalytic performance.- Kinetic mechanisms of single-atom catalysts: Single-atom catalysts exhibit unique kinetic behaviors due to their isolated active sites. The kinetic mechanisms involve electron transfer processes, activation energy pathways, and reaction rate determinants that differ from traditional catalysts. These isolated metal atoms anchored on supports show distinctive reaction pathways with altered rate-determining steps, enabling more efficient catalytic conversions with lower energy barriers.

- Support materials for single-atom catalysis: The choice of support material significantly influences the kinetics of single-atom catalysts. Various supports including metal oxides, carbon-based materials, and 2D materials provide different coordination environments and electronic structures that affect catalytic performance. The interaction between the single metal atoms and support determines stability, activity, and selectivity, with proper selection enabling fine-tuning of reaction kinetics.

- Characterization techniques for single-atom catalyst kinetics: Advanced characterization methods are essential for understanding the kinetic behavior of single-atom catalysts. Techniques including in-situ spectroscopy, aberration-corrected electron microscopy, X-ray absorption spectroscopy, and computational modeling help reveal reaction intermediates, transition states, and rate constants. These approaches enable researchers to monitor catalytic processes in real-time and establish structure-activity relationships for kinetic optimization.

- Environmental factors affecting single-atom catalysis kinetics: Environmental conditions significantly impact the kinetic performance of single-atom catalysts. Factors such as temperature, pressure, pH, and the presence of inhibitors or promoters can alter reaction pathways and rates. Understanding these environmental influences allows for optimizing reaction conditions to enhance catalytic efficiency, selectivity, and stability during practical applications.

- Industrial applications of single-atom catalyst kinetics: The unique kinetic properties of single-atom catalysts enable various industrial applications. These catalysts show promising performance in energy conversion, environmental remediation, fine chemical synthesis, and electrochemical processes. Their high atom efficiency, selectivity, and activity under mild conditions make them economically attractive alternatives to traditional catalysts, with ongoing research focusing on scaling up production while maintaining their distinctive kinetic advantages.

02 Support materials for single-atom catalysts affecting kinetics

The choice of support material significantly influences the kinetic behavior of single-atom catalysts. Different supports such as metal oxides, carbon-based materials, and zeolites provide varying electronic environments and coordination structures that alter reaction pathways and activation barriers. The support-catalyst interface plays a crucial role in determining adsorption energies, intermediate stabilization, and overall reaction rates in catalytic processes.Expand Specific Solutions03 Environmental factors affecting single-atom catalysis kinetics

Environmental conditions such as temperature, pressure, and reaction medium composition significantly impact the kinetic behavior of single-atom catalysts. These factors influence the stability of active sites, diffusion rates of reactants and products, and the formation of intermediates. Understanding how these environmental parameters affect reaction kinetics is essential for optimizing catalytic performance and developing more efficient catalytic systems.Expand Specific Solutions04 Computational modeling of single-atom catalyst kinetics

Advanced computational methods are employed to model and predict the kinetic behavior of single-atom catalysts. Density functional theory calculations, molecular dynamics simulations, and machine learning approaches help elucidate reaction mechanisms, transition states, and energy profiles. These computational tools enable the rational design of single-atom catalysts with optimized kinetic properties for specific applications, reducing the need for extensive experimental screening.Expand Specific Solutions05 Industrial applications and performance metrics of single-atom catalysis kinetics

Single-atom catalysts demonstrate unique kinetic advantages in various industrial processes including hydrogenation, oxidation, and electrocatalysis. Their high atom efficiency and selectivity lead to improved reaction rates and product yields compared to conventional catalysts. Performance metrics such as turnover frequency, activation energy, and stability under operating conditions are critical parameters for evaluating their practical applications and economic viability in industrial settings.Expand Specific Solutions

Key Industry Players in Single-Atom Catalyst Development

Single-atom catalysis (SAC) for redox reactions is emerging as a transformative technology in the early commercialization phase, with a rapidly growing market projected to reach significant scale by 2030. The competitive landscape features academic institutions like Beijing University of Chemical Technology, Zhejiang University, and Northwestern University driving fundamental research, while industrial players including Umicore SA, SK Innovation, and Sumitomo Chemical are developing commercial applications. Research institutes such as KIST, Institute of Process Engineering (CAS), and KAIST are bridging the gap between theory and application. The technology is advancing from proof-of-concept to practical implementation, with companies focusing on energy storage, environmental remediation, and chemical synthesis applications, though challenges in scalability and stability remain before widespread industrial adoption.

Umicore SA

Technical Solution: Umicore has developed proprietary single-atom catalysis (SAC) technology focused on precious metal atomization for redox reactions. Their approach involves anchoring isolated metal atoms (primarily Pt, Pd, and Ir) onto metal oxide supports through advanced atomic layer deposition techniques. This creates highly dispersed active sites with maximized atom efficiency, achieving up to 95% metal utilization compared to 20-40% in conventional catalysts. Umicore's process incorporates in-situ characterization methods including aberration-corrected STEM and XAFS to precisely control metal-support interactions. Their catalysts demonstrate enhanced stability through engineered coordination environments that prevent atom migration and agglomeration during redox cycling, maintaining performance for over 5,000 hours in industrial testing conditions.

Strengths: Superior atom efficiency (up to 95%) significantly reduces precious metal loading while maintaining catalytic activity; proprietary stabilization techniques prevent deactivation during redox cycling. Weaknesses: Higher production costs compared to conventional catalysts; requires specialized manufacturing facilities; performance may be sensitive to specific reaction conditions and impurities.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering (IPE-CAS) has pioneered innovative approaches to single-atom catalysis for redox reactions through their "coordination engineering" methodology. Their technology focuses on precise control of the coordination environment around isolated metal atoms (Fe, Co, Ni) anchored on nitrogen-doped carbon supports. IPE-CAS has developed a scalable pyrolysis-based synthesis route that achieves metal loadings of 3-5 wt% while maintaining atomic dispersion, significantly higher than conventional methods limited to <1%. Their catalysts feature engineered electronic structures with optimized d-band centers for targeted redox reactions, particularly in oxygen reduction/evolution and hydrogen evolution reactions. Recent advances include dual-metal single-atom catalysts that leverage synergistic effects between different metal centers to enhance reaction kinetics by modifying activation energy barriers and intermediate stabilization.

Strengths: High metal loading (3-5 wt%) while maintaining atomic dispersion; tunable electronic properties through coordination engineering; demonstrated scalability for industrial applications. Weaknesses: Carbon-based supports may have limited thermal stability in high-temperature applications; potential metal leaching during long-term operation in acidic environments.

Critical Patents and Literature in Single-Atom Catalysis

A kind of preparation method of nitrogen-doped carbon supported single-atom catalyst

PatentActiveCN109999883B

Innovation

- Adopting the idea of complex capture adsorption, through hydrothermal reaction and heat treatment technology, transition metal acetate and pyrrole monomer are used to form a complex. After stirring, hydrothermal, acid etching and heat treatment, a nitrogen-doped carbon load is generated. Single atom catalyst avoids agglomeration of metal ions and achieves single atom distribution.

Single-atom catalyst for activation of persulfate to generate pure singlet oxygen as well as preparation method and application thereof

PatentActiveUS11629052B2

Innovation

- A single-atom catalyst with graphitic carbon nitride nanosheets as supports and single iron atoms in a Fe—N4 coordination structure is developed, specifically designed to activate persulfate and generate pure singlet oxygen, enhancing selectivity and resistance to environmental interference.

Sustainability Impact of Single-Atom Catalytic Technologies

Single-atom catalysis represents a paradigm shift in sustainable chemical processes, offering unprecedented environmental benefits compared to traditional catalytic systems. The atomically dispersed active sites in single-atom catalysts (SACs) maximize atom efficiency, dramatically reducing the amount of precious metals required for catalytic reactions. This resource efficiency is particularly significant for elements facing critical supply challenges, such as platinum, palladium, and rhodium, which are extensively used in redox reactions.

The environmental footprint of SAC technologies extends beyond material conservation. In redox reactions, the improved kinetics facilitated by SACs translate to lower energy requirements, as reactions can proceed under milder conditions with reduced activation barriers. Studies have demonstrated energy savings of 15-30% in various oxidation and reduction processes when utilizing properly designed single-atom catalysts compared to conventional nanoparticle catalysts.

Waste reduction constitutes another substantial sustainability advantage. The enhanced selectivity of SACs minimizes unwanted side reactions, thereby reducing byproduct formation. This selectivity improvement has been particularly evident in electrochemical CO2 reduction and nitrogen fixation processes, where faradaic efficiencies exceeding 90% have been achieved with certain single-atom catalytic systems.

Life cycle assessments of SAC implementation in industrial processes reveal significant reductions in greenhouse gas emissions. For instance, SAC-based hydrogen evolution reactions demonstrate up to 40% lower carbon footprints compared to traditional platinum-based catalysts when considering the entire production chain from catalyst synthesis to operational lifetime.

The longevity of single-atom catalysts further enhances their sustainability profile. Their resistance to sintering—a common deactivation mechanism in conventional catalysts—extends operational lifetimes, reducing the frequency of catalyst replacement and associated environmental impacts. Some iron-based SACs have demonstrated remarkable stability over thousands of operational hours in oxygen reduction reactions.

From a circular economy perspective, SACs offer promising recyclability pathways. The atomically dispersed nature of the active metal sites facilitates more efficient recovery processes compared to nanoparticle catalysts. Advanced recovery techniques can reclaim up to 95% of the precious metals from spent SACs, creating closed-loop systems that further minimize environmental impact.

As regulatory frameworks increasingly emphasize sustainability metrics, SAC technologies position industries to meet stringent environmental standards while maintaining or improving process efficiency. This alignment with global sustainability goals makes single-atom catalysis not merely a scientific advancement but a critical enabler of green chemistry principles in industrial applications.

The environmental footprint of SAC technologies extends beyond material conservation. In redox reactions, the improved kinetics facilitated by SACs translate to lower energy requirements, as reactions can proceed under milder conditions with reduced activation barriers. Studies have demonstrated energy savings of 15-30% in various oxidation and reduction processes when utilizing properly designed single-atom catalysts compared to conventional nanoparticle catalysts.

Waste reduction constitutes another substantial sustainability advantage. The enhanced selectivity of SACs minimizes unwanted side reactions, thereby reducing byproduct formation. This selectivity improvement has been particularly evident in electrochemical CO2 reduction and nitrogen fixation processes, where faradaic efficiencies exceeding 90% have been achieved with certain single-atom catalytic systems.

Life cycle assessments of SAC implementation in industrial processes reveal significant reductions in greenhouse gas emissions. For instance, SAC-based hydrogen evolution reactions demonstrate up to 40% lower carbon footprints compared to traditional platinum-based catalysts when considering the entire production chain from catalyst synthesis to operational lifetime.

The longevity of single-atom catalysts further enhances their sustainability profile. Their resistance to sintering—a common deactivation mechanism in conventional catalysts—extends operational lifetimes, reducing the frequency of catalyst replacement and associated environmental impacts. Some iron-based SACs have demonstrated remarkable stability over thousands of operational hours in oxygen reduction reactions.

From a circular economy perspective, SACs offer promising recyclability pathways. The atomically dispersed nature of the active metal sites facilitates more efficient recovery processes compared to nanoparticle catalysts. Advanced recovery techniques can reclaim up to 95% of the precious metals from spent SACs, creating closed-loop systems that further minimize environmental impact.

As regulatory frameworks increasingly emphasize sustainability metrics, SAC technologies position industries to meet stringent environmental standards while maintaining or improving process efficiency. This alignment with global sustainability goals makes single-atom catalysis not merely a scientific advancement but a critical enabler of green chemistry principles in industrial applications.

Scalability and Industrial Implementation Challenges

Despite the promising performance of single-atom catalysts (SACs) in laboratory settings, scaling up these technologies for industrial applications presents significant challenges. The primary obstacle lies in maintaining the atomic dispersion of metal atoms during large-scale synthesis processes. Traditional industrial catalytic systems typically employ bulk or nanoparticle catalysts, which have well-established manufacturing protocols. In contrast, SACs require precise control over metal loading and distribution to prevent aggregation, which becomes increasingly difficult at industrial scales.

Manufacturing consistency represents another major hurdle. The production of SACs with uniform catalytic properties across large batches demands sophisticated quality control measures and advanced characterization techniques. Current industrial infrastructure may lack the necessary precision equipment to ensure homogeneity in large-scale SAC production, potentially leading to variable performance in redox reactions.

Economic considerations also impact scalability. The synthesis of SACs often involves expensive precursors and complex preparation methods, resulting in higher production costs compared to conventional catalysts. For industrial adoption to become viable, cost-effective synthesis routes must be developed without compromising the unique atomic architecture that gives SACs their superior kinetic properties in redox reactions.

Stability under industrial conditions poses additional challenges. While SACs demonstrate excellent activity in controlled laboratory environments, their performance under harsh industrial conditions—including high temperatures, pressures, and the presence of contaminants—requires further investigation. The potential for metal atom leaching or migration during extended operation periods could significantly impact catalyst longevity and reaction efficiency.

Integration with existing industrial processes presents practical implementation barriers. Many current chemical production facilities are designed around conventional catalytic systems, and retrofitting these plants to accommodate SAC technology may require substantial capital investment. Process engineers must develop innovative reactor designs and operational protocols that maximize the benefits of SACs while minimizing disruption to established manufacturing workflows.

Regulatory considerations also influence industrial implementation. New catalytic technologies must meet stringent safety and environmental standards before widespread adoption. Comprehensive toxicological assessments and lifecycle analyses of SACs are necessary to ensure compliance with regulatory frameworks across different jurisdictions.

Manufacturing consistency represents another major hurdle. The production of SACs with uniform catalytic properties across large batches demands sophisticated quality control measures and advanced characterization techniques. Current industrial infrastructure may lack the necessary precision equipment to ensure homogeneity in large-scale SAC production, potentially leading to variable performance in redox reactions.

Economic considerations also impact scalability. The synthesis of SACs often involves expensive precursors and complex preparation methods, resulting in higher production costs compared to conventional catalysts. For industrial adoption to become viable, cost-effective synthesis routes must be developed without compromising the unique atomic architecture that gives SACs their superior kinetic properties in redox reactions.

Stability under industrial conditions poses additional challenges. While SACs demonstrate excellent activity in controlled laboratory environments, their performance under harsh industrial conditions—including high temperatures, pressures, and the presence of contaminants—requires further investigation. The potential for metal atom leaching or migration during extended operation periods could significantly impact catalyst longevity and reaction efficiency.

Integration with existing industrial processes presents practical implementation barriers. Many current chemical production facilities are designed around conventional catalytic systems, and retrofitting these plants to accommodate SAC technology may require substantial capital investment. Process engineers must develop innovative reactor designs and operational protocols that maximize the benefits of SACs while minimizing disruption to established manufacturing workflows.

Regulatory considerations also influence industrial implementation. New catalytic technologies must meet stringent safety and environmental standards before widespread adoption. Comprehensive toxicological assessments and lifecycle analyses of SACs are necessary to ensure compliance with regulatory frameworks across different jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!