Pintle Hitch Design Advances in Safety and Security Features

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The evolution of pintle hitch design has been marked by significant advancements in safety and security features over the years. Initially developed as a simple coupling mechanism for towing vehicles, the pintle hitch has undergone substantial transformations to meet increasing demands for reliability and safety in various industries.

In the early stages of its development, the pintle hitch was primarily used in military applications due to its robust design and ability to handle heavy loads. The basic structure consisted of a hook-like protrusion (the pintle) that would engage with a lunette ring on the towed vehicle. This design allowed for greater articulation and flexibility compared to traditional ball hitches, making it ideal for off-road and rugged terrain use.

As the use of pintle hitches expanded into commercial and industrial sectors, manufacturers began to focus on enhancing safety features. One of the first major improvements was the introduction of locking mechanisms to prevent accidental disengagement during operation. These early locking systems typically involved manual pins or levers that required operator intervention to secure the connection.

The next phase of evolution saw the integration of automatic locking systems. These designs incorporated spring-loaded mechanisms that would automatically secure the lunette ring once it was properly seated on the pintle. This advancement significantly reduced the risk of human error in the coupling process and improved overall operational safety.

With the increasing emphasis on road safety and regulatory compliance, pintle hitch designs began to incorporate additional security features. Manufacturers introduced secondary locking mechanisms, such as safety chains and breakaway systems, to provide redundancy in case of primary coupling failure. These additions helped to prevent complete separation of the towed vehicle in emergency situations.

Recent years have seen a focus on integrating electronic monitoring and control systems into pintle hitch designs. Modern hitches often include sensors that can detect proper coupling, monitor load distribution, and alert operators to potential issues. Some advanced systems even incorporate telematics capabilities, allowing for real-time tracking and remote monitoring of towing operations.

The latest innovations in pintle hitch design have centered around improving ease of use without compromising safety. Quick-connect systems have been developed to streamline the coupling process, reducing the time and effort required for hitching and unhitching. These systems often feature ergonomic designs and visual indicators to ensure proper engagement, further enhancing safety and efficiency.

As industries continue to demand higher levels of safety and security in towing applications, the evolution of pintle hitch design shows no signs of slowing down. Future developments are likely to focus on further integration of smart technologies, advanced materials for increased durability, and enhanced ergonomics to improve operator safety and comfort.

In the early stages of its development, the pintle hitch was primarily used in military applications due to its robust design and ability to handle heavy loads. The basic structure consisted of a hook-like protrusion (the pintle) that would engage with a lunette ring on the towed vehicle. This design allowed for greater articulation and flexibility compared to traditional ball hitches, making it ideal for off-road and rugged terrain use.

As the use of pintle hitches expanded into commercial and industrial sectors, manufacturers began to focus on enhancing safety features. One of the first major improvements was the introduction of locking mechanisms to prevent accidental disengagement during operation. These early locking systems typically involved manual pins or levers that required operator intervention to secure the connection.

The next phase of evolution saw the integration of automatic locking systems. These designs incorporated spring-loaded mechanisms that would automatically secure the lunette ring once it was properly seated on the pintle. This advancement significantly reduced the risk of human error in the coupling process and improved overall operational safety.

With the increasing emphasis on road safety and regulatory compliance, pintle hitch designs began to incorporate additional security features. Manufacturers introduced secondary locking mechanisms, such as safety chains and breakaway systems, to provide redundancy in case of primary coupling failure. These additions helped to prevent complete separation of the towed vehicle in emergency situations.

Recent years have seen a focus on integrating electronic monitoring and control systems into pintle hitch designs. Modern hitches often include sensors that can detect proper coupling, monitor load distribution, and alert operators to potential issues. Some advanced systems even incorporate telematics capabilities, allowing for real-time tracking and remote monitoring of towing operations.

The latest innovations in pintle hitch design have centered around improving ease of use without compromising safety. Quick-connect systems have been developed to streamline the coupling process, reducing the time and effort required for hitching and unhitching. These systems often feature ergonomic designs and visual indicators to ensure proper engagement, further enhancing safety and efficiency.

As industries continue to demand higher levels of safety and security in towing applications, the evolution of pintle hitch design shows no signs of slowing down. Future developments are likely to focus on further integration of smart technologies, advanced materials for increased durability, and enhanced ergonomics to improve operator safety and comfort.

Market Demand Analysis

The market demand for advanced Pintle Hitch designs with enhanced safety and security features has been steadily increasing in recent years. This growth is primarily driven by the rising concerns over towing safety, the need for more secure trailer connections, and the overall expansion of the recreational vehicle (RV) and commercial towing industries.

In the recreational sector, the surge in outdoor activities and road trips has led to a significant increase in the use of trailers and RVs. According to industry reports, the global RV market is expected to grow at a compound annual growth rate (CAGR) of over 7% from 2021 to 2026. This growth directly translates to a higher demand for robust and secure towing solutions, including advanced Pintle Hitch designs.

The commercial towing sector, encompassing construction, agriculture, and logistics industries, also contributes substantially to the market demand. With the increasing focus on workplace safety and the need for efficient towing solutions in challenging environments, there is a growing preference for Pintle Hitches that offer improved safety features and higher load capacities.

One of the key drivers of market demand is the emphasis on reducing accidents related to trailer detachment. Statistics from transportation safety agencies highlight that trailer separation incidents, though relatively rare, can have severe consequences. This has led to a push for more secure hitching mechanisms, creating a market opportunity for innovative Pintle Hitch designs that incorporate advanced locking systems and fail-safe features.

The integration of smart technologies in towing equipment is another factor shaping market demand. Consumers and fleet operators are increasingly looking for Pintle Hitches with built-in sensors and connectivity features that can provide real-time data on towing conditions, load distribution, and potential safety issues. This trend aligns with the broader movement towards connected vehicles and IoT applications in the automotive industry.

Regulatory pressures also play a significant role in driving demand for safer towing solutions. Many countries have implemented stricter regulations regarding towing safety, which has prompted manufacturers to develop Pintle Hitch designs that not only meet but exceed these standards. This regulatory environment has created a market for premium, high-performance hitches that offer enhanced safety and security features.

The market analysis also reveals a growing demand for versatile Pintle Hitch designs that can accommodate a wide range of towing applications. This versatility is particularly valued in industries where different types of trailers or equipment need to be towed regularly, driving the development of adaptable and multi-functional hitch designs.

In the recreational sector, the surge in outdoor activities and road trips has led to a significant increase in the use of trailers and RVs. According to industry reports, the global RV market is expected to grow at a compound annual growth rate (CAGR) of over 7% from 2021 to 2026. This growth directly translates to a higher demand for robust and secure towing solutions, including advanced Pintle Hitch designs.

The commercial towing sector, encompassing construction, agriculture, and logistics industries, also contributes substantially to the market demand. With the increasing focus on workplace safety and the need for efficient towing solutions in challenging environments, there is a growing preference for Pintle Hitches that offer improved safety features and higher load capacities.

One of the key drivers of market demand is the emphasis on reducing accidents related to trailer detachment. Statistics from transportation safety agencies highlight that trailer separation incidents, though relatively rare, can have severe consequences. This has led to a push for more secure hitching mechanisms, creating a market opportunity for innovative Pintle Hitch designs that incorporate advanced locking systems and fail-safe features.

The integration of smart technologies in towing equipment is another factor shaping market demand. Consumers and fleet operators are increasingly looking for Pintle Hitches with built-in sensors and connectivity features that can provide real-time data on towing conditions, load distribution, and potential safety issues. This trend aligns with the broader movement towards connected vehicles and IoT applications in the automotive industry.

Regulatory pressures also play a significant role in driving demand for safer towing solutions. Many countries have implemented stricter regulations regarding towing safety, which has prompted manufacturers to develop Pintle Hitch designs that not only meet but exceed these standards. This regulatory environment has created a market for premium, high-performance hitches that offer enhanced safety and security features.

The market analysis also reveals a growing demand for versatile Pintle Hitch designs that can accommodate a wide range of towing applications. This versatility is particularly valued in industries where different types of trailers or equipment need to be towed regularly, driving the development of adaptable and multi-functional hitch designs.

Technical Challenges

The current state of pintle hitch design faces several significant technical challenges in advancing safety and security features. One primary obstacle is the need for enhanced load distribution and stability control. Traditional pintle hitches often struggle with uneven weight distribution, leading to potential swaying and reduced vehicle control, especially during high-speed travel or sudden maneuvers. Developing a system that can dynamically adjust load distribution in real-time remains a complex engineering problem.

Another critical challenge lies in improving the locking mechanisms to prevent unauthorized detachment or theft. While existing designs incorporate basic locking systems, they are often vulnerable to tampering or forced entry. Creating a robust, tamper-resistant locking mechanism that can withstand various environmental conditions and physical attacks, while still allowing for easy legitimate use, presents a significant technical hurdle.

The integration of smart technologies into pintle hitch designs introduces additional complexities. Implementing sensors for real-time monitoring of hitch status, load weight, and connection integrity requires miniaturization of components and development of reliable, weather-resistant electronic systems. Ensuring these smart features can operate consistently in harsh conditions, including extreme temperatures, moisture, and vibration, poses substantial engineering challenges.

Compatibility across different vehicle types and trailer configurations remains an ongoing issue. Designing a universal pintle hitch system that can adapt to various vehicle heights, weights, and coupling requirements, while maintaining optimal safety performance, demands innovative engineering solutions. This challenge is further compounded by the need to comply with diverse international safety standards and regulations.

Material selection and durability present another set of technical obstacles. Developing materials that offer high strength-to-weight ratios, corrosion resistance, and long-term durability under constant stress and environmental exposure is crucial. Balancing these material properties with cost-effectiveness and manufacturability adds another layer of complexity to the design process.

Lastly, the challenge of integrating advanced safety features, such as automatic emergency braking systems and stability control, with pintle hitch designs requires sophisticated sensor fusion and control algorithms. Ensuring these systems can accurately detect and respond to potential hazards, while accounting for the varied dynamics of different trailer configurations, remains a significant technical hurdle in advancing pintle hitch safety.

Another critical challenge lies in improving the locking mechanisms to prevent unauthorized detachment or theft. While existing designs incorporate basic locking systems, they are often vulnerable to tampering or forced entry. Creating a robust, tamper-resistant locking mechanism that can withstand various environmental conditions and physical attacks, while still allowing for easy legitimate use, presents a significant technical hurdle.

The integration of smart technologies into pintle hitch designs introduces additional complexities. Implementing sensors for real-time monitoring of hitch status, load weight, and connection integrity requires miniaturization of components and development of reliable, weather-resistant electronic systems. Ensuring these smart features can operate consistently in harsh conditions, including extreme temperatures, moisture, and vibration, poses substantial engineering challenges.

Compatibility across different vehicle types and trailer configurations remains an ongoing issue. Designing a universal pintle hitch system that can adapt to various vehicle heights, weights, and coupling requirements, while maintaining optimal safety performance, demands innovative engineering solutions. This challenge is further compounded by the need to comply with diverse international safety standards and regulations.

Material selection and durability present another set of technical obstacles. Developing materials that offer high strength-to-weight ratios, corrosion resistance, and long-term durability under constant stress and environmental exposure is crucial. Balancing these material properties with cost-effectiveness and manufacturability adds another layer of complexity to the design process.

Lastly, the challenge of integrating advanced safety features, such as automatic emergency braking systems and stability control, with pintle hitch designs requires sophisticated sensor fusion and control algorithms. Ensuring these systems can accurately detect and respond to potential hazards, while accounting for the varied dynamics of different trailer configurations, remains a significant technical hurdle in advancing pintle hitch safety.

Current Safety Solutions

01 Locking mechanisms for pintle hitches

Various locking mechanisms are employed to secure pintle hitches, enhancing safety and preventing unauthorized detachment. These include padlocks, integrated locking systems, and electronic locks. Such mechanisms ensure the trailer remains securely attached to the towing vehicle during transit and when parked.- Locking mechanisms for pintle hitches: Various locking mechanisms are employed to secure pintle hitches, preventing unauthorized detachment or theft. These can include padlocks, integrated locking systems, and electronic locks. Such mechanisms ensure the trailer remains securely attached to the towing vehicle, enhancing safety during transport and security when parked.

- Safety pins and secondary securing devices: Safety pins and secondary securing devices are crucial components in pintle hitch systems. These additional safety measures prevent accidental disconnection of the trailer from the towing vehicle. They act as a backup in case the primary locking mechanism fails, providing an extra layer of security during transit.

- Electronic monitoring and alert systems: Advanced pintle hitch systems incorporate electronic monitoring and alert features. These systems can detect unauthorized tampering, monitor the connection status, and alert the user of any potential issues. Some designs include GPS tracking and mobile app integration for real-time monitoring of the trailer's security and location.

- Structural improvements for enhanced safety: Innovations in pintle hitch design focus on structural improvements to enhance safety. These include reinforced materials, improved weight distribution mechanisms, and designs that minimize the risk of jackknifing. Such enhancements contribute to better stability and control during towing, reducing the likelihood of accidents.

- Visual indicators and alignment aids: Visual indicators and alignment aids are incorporated into pintle hitch designs to facilitate safer and more accurate coupling. These features can include LED lights, reflective markers, or guide systems that assist drivers in aligning and connecting the hitch properly. Proper alignment ensures a secure connection and reduces the risk of accidents due to improper hitching.

02 Electronic monitoring and alert systems

Advanced electronic systems are incorporated into pintle hitches to monitor their status and provide alerts. These systems can detect proper coupling, unauthorized tampering, and potential safety issues. They may include sensors, GPS tracking, and wireless communication capabilities to enhance security and provide real-time information to the user.Expand Specific Solutions03 Structural improvements for enhanced safety

Pintle hitches are designed with structural improvements to increase their overall safety and durability. These enhancements may include reinforced materials, improved weight distribution, and ergonomic designs that facilitate easier and more secure coupling. Such improvements aim to reduce the risk of failure and increase the hitch's lifespan.Expand Specific Solutions04 Visual indicators and alignment aids

To improve safety during the coupling process, pintle hitches are equipped with visual indicators and alignment aids. These features help ensure proper connection between the hitch and the trailer, reducing the risk of accidents due to improper coupling. They may include color-coded markers, LED lights, or mechanical indicators that provide clear visual feedback to the user.Expand Specific Solutions05 Integration with vehicle systems

Pintle hitches are increasingly integrated with vehicle systems to enhance safety and security. This integration may include connections to the vehicle's electrical system, brake controls, and onboard computers. Such integration allows for better coordination between the towing vehicle and the trailer, improving overall safety and performance during towing operations.Expand Specific Solutions

Key Industry Players

The pintle hitch design market is in a growth phase, driven by increasing demand for safer and more secure towing solutions. The market size is expanding as manufacturers focus on developing advanced features to enhance safety and security. Technologically, the field is evolving rapidly, with companies like Dexter Axle, AL-KO Technology, and Curt Manufacturing leading innovation. These firms are investing in R&D to create smart hitches with improved locking mechanisms, anti-theft features, and integrated sensors for better stability control. The Naval Research Laboratory's involvement suggests potential military applications, further broadening the market scope and driving technological advancements in this sector.

Dexter Axle Co. LLC

Technical Solution: Dexter Axle Co. LLC has focused on improving pintle hitch safety through innovative design features. They have developed a self-aligning system that facilitates easier and safer coupling, reducing the risk of misalignment and potential accidents[4]. The company has also introduced a visual indicator system that clearly shows when the pintle hitch is properly engaged, enhancing user confidence and safety[5]. Dexter's pintle hitches incorporate high-strength materials and advanced manufacturing techniques to increase load capacity while maintaining a compact design[6].

Strengths: User-friendly design, clear safety indicators, and high load capacity. Weaknesses: May be less suitable for extremely rugged terrains, and the self-aligning system could be prone to wear over time.

AL-KO Technology Austria GmbH

Technical Solution: AL-KO Technology Austria GmbH has made significant advances in pintle hitch safety and security. They have developed a patented anti-theft locking mechanism that integrates seamlessly with the hitch design, providing an additional layer of security[7]. The company has also implemented a modular design approach, allowing for easy customization and upgrades to meet specific safety requirements across different industries[8]. AL-KO's pintle hitches feature an advanced shock absorption system that reduces stress on both the towing vehicle and the trailer, enhancing overall safety during transport[9].

Strengths: Enhanced security features, adaptable design, and improved towing dynamics. Weaknesses: The modular system may increase complexity and potentially cost.

Innovative Locking Mechanisms

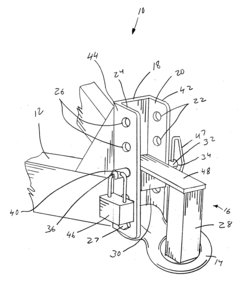

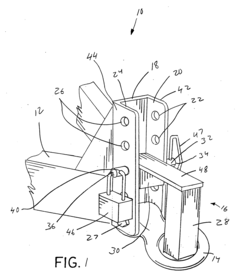

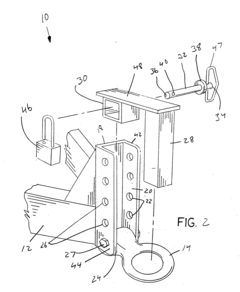

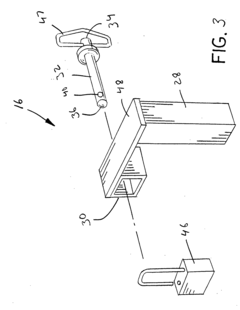

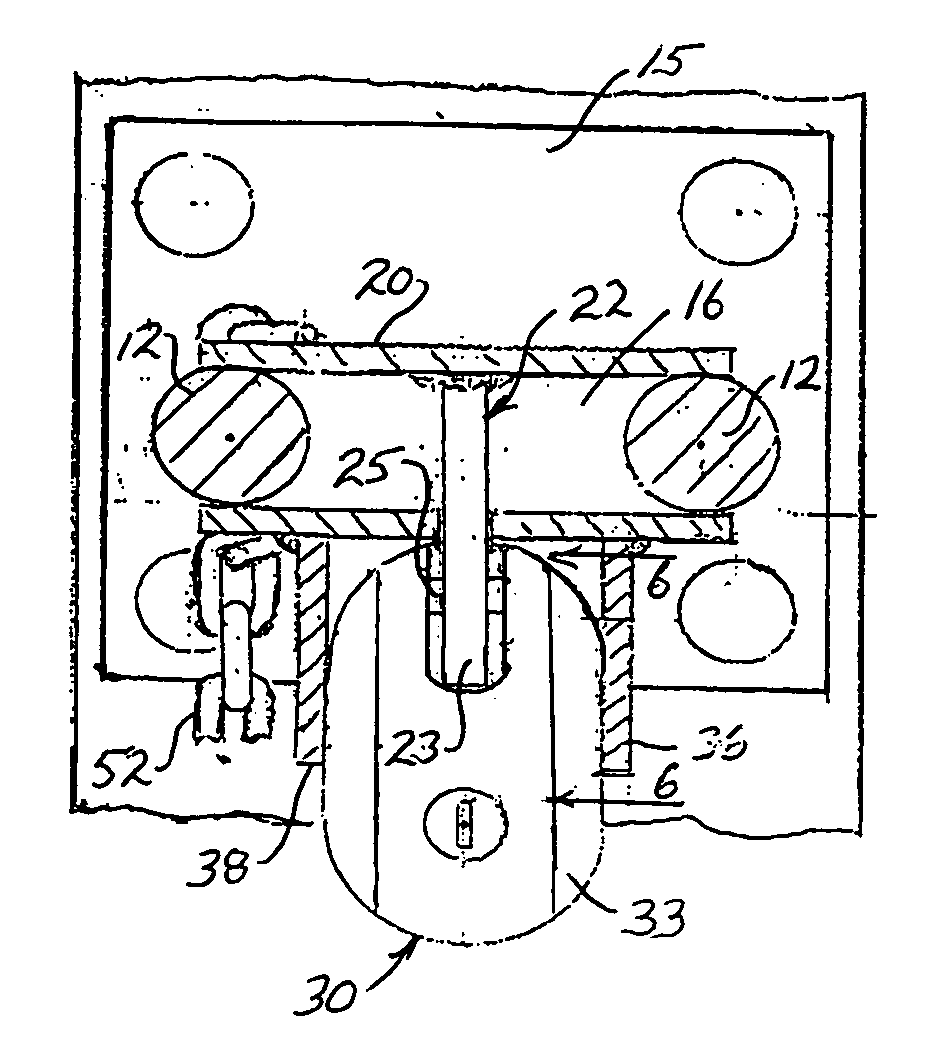

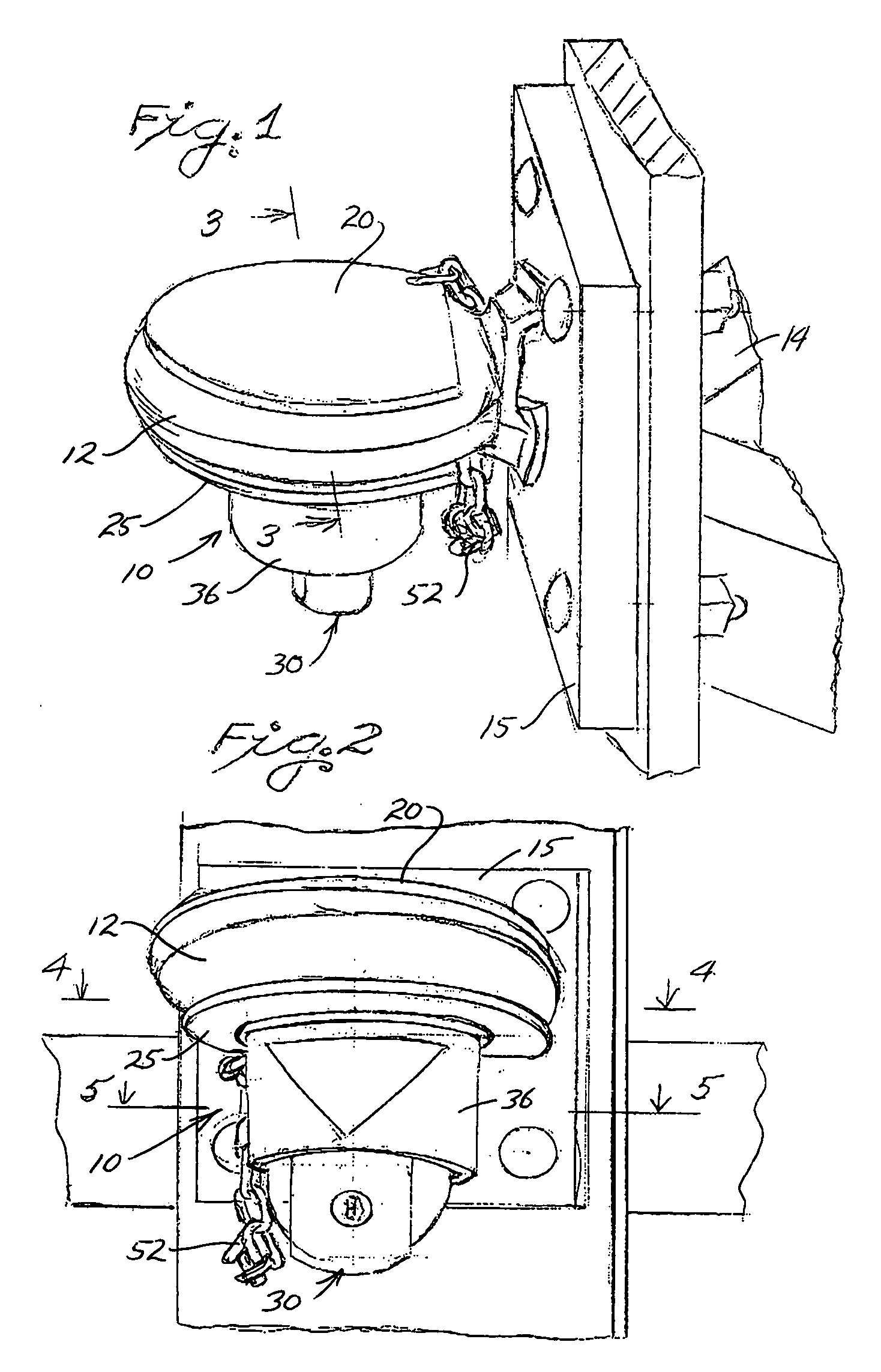

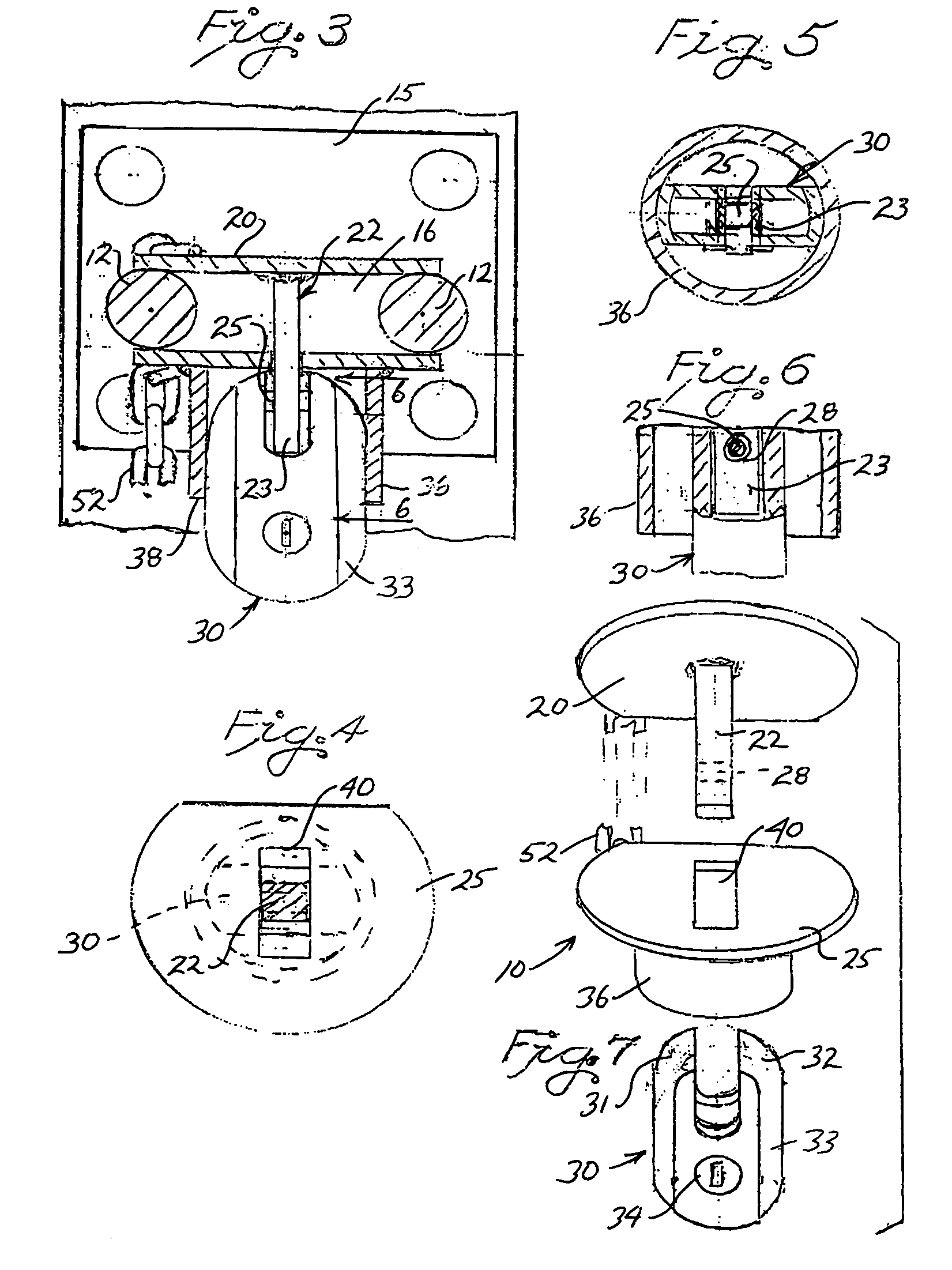

Pintle hitch lock

PatentInactiveUS20070108732A1

Innovation

- A pintle hitch lock design that includes a jam mounted through the pintle ring, a clasp connected to the trailer tongue, and a pin inserted through both, allowing for secure locking without requiring complex mechanisms or machined parts, and can use a readily available padlock.

Pintle hitch protective lock assembly

PatentInactiveUS6862904B1

Innovation

- A protective lock assembly comprising opposing plates that engage over the hitch surfaces, with a projecting tongue and a surrounding housing that conceals and secures the shackle or bolt of a conventional lock, preventing access and tampering, and optionally using a flexibly jointed design to facilitate handling.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and implementation of Pintle Hitch Design Advances in Safety and Security Features. As these innovative designs aim to enhance safety and security, they must adhere to various national and international standards and regulations.

In the United States, the Department of Transportation (DOT) and the National Highway Traffic Safety Administration (NHTSA) set forth guidelines for towing equipment, including pintle hitches. These regulations cover aspects such as load capacity, structural integrity, and safety features. Manufacturers must ensure their advanced pintle hitch designs meet or exceed these requirements to obtain necessary certifications.

The Society of Automotive Engineers (SAE) has established specific standards for pintle hitches, including SAE J847 and SAE J2638. These standards define the performance criteria, testing procedures, and safety requirements for pintle hitches used in various applications. Compliance with these standards is essential for manufacturers to demonstrate the reliability and safety of their advanced designs.

In the European Union, the Economic Commission for Europe (ECE) Regulation No. 55 governs mechanical coupling components, including pintle hitches. This regulation outlines the technical requirements, testing methods, and approval procedures for such devices. Advanced pintle hitch designs must comply with these regulations to be legally used within the EU market.

As safety and security features become more sophisticated, incorporating electronic components and sensors, additional regulations come into play. For instance, electromagnetic compatibility (EMC) regulations ensure that these advanced features do not interfere with other vehicle systems or nearby electronic devices.

Cybersecurity regulations are also becoming increasingly relevant as pintle hitches incorporate smart technologies. Manufacturers must consider data protection and secure communication protocols to prevent unauthorized access or manipulation of safety-critical systems.

Environmental regulations, such as those related to materials used in manufacturing and end-of-life recycling, also impact the development of advanced pintle hitch designs. Compliance with these regulations ensures that the products are not only safe and secure but also environmentally sustainable.

As the technology evolves, regulatory bodies continue to update their standards and introduce new requirements. Manufacturers and designers must stay informed about these changes and adapt their products accordingly. This ongoing process of regulatory compliance drives innovation while ensuring that safety and security remain paramount in pintle hitch design advancements.

In the United States, the Department of Transportation (DOT) and the National Highway Traffic Safety Administration (NHTSA) set forth guidelines for towing equipment, including pintle hitches. These regulations cover aspects such as load capacity, structural integrity, and safety features. Manufacturers must ensure their advanced pintle hitch designs meet or exceed these requirements to obtain necessary certifications.

The Society of Automotive Engineers (SAE) has established specific standards for pintle hitches, including SAE J847 and SAE J2638. These standards define the performance criteria, testing procedures, and safety requirements for pintle hitches used in various applications. Compliance with these standards is essential for manufacturers to demonstrate the reliability and safety of their advanced designs.

In the European Union, the Economic Commission for Europe (ECE) Regulation No. 55 governs mechanical coupling components, including pintle hitches. This regulation outlines the technical requirements, testing methods, and approval procedures for such devices. Advanced pintle hitch designs must comply with these regulations to be legally used within the EU market.

As safety and security features become more sophisticated, incorporating electronic components and sensors, additional regulations come into play. For instance, electromagnetic compatibility (EMC) regulations ensure that these advanced features do not interfere with other vehicle systems or nearby electronic devices.

Cybersecurity regulations are also becoming increasingly relevant as pintle hitches incorporate smart technologies. Manufacturers must consider data protection and secure communication protocols to prevent unauthorized access or manipulation of safety-critical systems.

Environmental regulations, such as those related to materials used in manufacturing and end-of-life recycling, also impact the development of advanced pintle hitch designs. Compliance with these regulations ensures that the products are not only safe and secure but also environmentally sustainable.

As the technology evolves, regulatory bodies continue to update their standards and introduce new requirements. Manufacturers and designers must stay informed about these changes and adapt their products accordingly. This ongoing process of regulatory compliance drives innovation while ensuring that safety and security remain paramount in pintle hitch design advancements.

Material Advancements

Material advancements have played a crucial role in enhancing the safety and security features of pintle hitch designs. The evolution of materials used in these hitches has significantly improved their durability, strength, and overall performance.

High-strength alloys, such as chromoly steel and aerospace-grade aluminum, have become increasingly prevalent in modern pintle hitch designs. These materials offer superior tensile strength and fatigue resistance compared to traditional steel, allowing for lighter yet more robust constructions. The reduced weight contributes to improved fuel efficiency without compromising the hitch's load-bearing capacity.

Corrosion-resistant coatings and treatments have also seen substantial advancements. Zinc-based coatings, such as hot-dip galvanization and zinc-nickel plating, provide excellent protection against rust and corrosion, extending the lifespan of pintle hitches exposed to harsh environmental conditions. Additionally, advanced powder coating techniques offer both corrosion resistance and customizable aesthetics.

Composite materials, including carbon fiber reinforced polymers (CFRP) and high-performance thermoplastics, are being explored for specific components of pintle hitches. These materials offer exceptional strength-to-weight ratios and can be engineered to provide tailored mechanical properties. While not yet widely adopted for entire hitch assemblies, composites show promise for reducing weight and enhancing performance in select applications.

Nanotechnology has also made inroads in pintle hitch material development. Nanostructured coatings and additives can significantly improve wear resistance, reduce friction, and enhance the overall durability of critical components. These advancements contribute to extended service life and reduced maintenance requirements.

Smart materials, such as shape memory alloys and piezoelectric materials, are being researched for potential integration into pintle hitch designs. These materials could enable self-adjusting mechanisms or provide real-time feedback on hitch status, further enhancing safety and ease of use.

The integration of advanced sensors and electronic components has necessitated the development of materials that can withstand both mechanical stresses and electrical requirements. Conductive polymers and flexible electronics are being explored to create seamless interfaces between mechanical and electronic systems in smart pintle hitch designs.

As environmental concerns grow, there is an increasing focus on sustainable and recyclable materials in pintle hitch manufacturing. Bio-based composites and recycled metal alloys are being investigated as potential alternatives to traditional materials, aiming to reduce the environmental impact of production and end-of-life disposal.

High-strength alloys, such as chromoly steel and aerospace-grade aluminum, have become increasingly prevalent in modern pintle hitch designs. These materials offer superior tensile strength and fatigue resistance compared to traditional steel, allowing for lighter yet more robust constructions. The reduced weight contributes to improved fuel efficiency without compromising the hitch's load-bearing capacity.

Corrosion-resistant coatings and treatments have also seen substantial advancements. Zinc-based coatings, such as hot-dip galvanization and zinc-nickel plating, provide excellent protection against rust and corrosion, extending the lifespan of pintle hitches exposed to harsh environmental conditions. Additionally, advanced powder coating techniques offer both corrosion resistance and customizable aesthetics.

Composite materials, including carbon fiber reinforced polymers (CFRP) and high-performance thermoplastics, are being explored for specific components of pintle hitches. These materials offer exceptional strength-to-weight ratios and can be engineered to provide tailored mechanical properties. While not yet widely adopted for entire hitch assemblies, composites show promise for reducing weight and enhancing performance in select applications.

Nanotechnology has also made inroads in pintle hitch material development. Nanostructured coatings and additives can significantly improve wear resistance, reduce friction, and enhance the overall durability of critical components. These advancements contribute to extended service life and reduced maintenance requirements.

Smart materials, such as shape memory alloys and piezoelectric materials, are being researched for potential integration into pintle hitch designs. These materials could enable self-adjusting mechanisms or provide real-time feedback on hitch status, further enhancing safety and ease of use.

The integration of advanced sensors and electronic components has necessitated the development of materials that can withstand both mechanical stresses and electrical requirements. Conductive polymers and flexible electronics are being explored to create seamless interfaces between mechanical and electronic systems in smart pintle hitch designs.

As environmental concerns grow, there is an increasing focus on sustainable and recyclable materials in pintle hitch manufacturing. Bio-based composites and recycled metal alloys are being investigated as potential alternatives to traditional materials, aiming to reduce the environmental impact of production and end-of-life disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!