Pintle Hitch in the Evolution of Towing Mechanisms

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Background and Objectives

The pintle hitch, a crucial component in the evolution of towing mechanisms, has a rich history dating back to the early 20th century. Originally developed for military applications, this robust coupling system quickly found its way into civilian use due to its simplicity and durability. The primary objective of the pintle hitch was to provide a secure and versatile connection between a towing vehicle and a trailer, capable of withstanding heavy loads and rough terrain.

As transportation needs evolved, so did the pintle hitch design. Early versions consisted of a simple hook and eye system, which, while effective, had limitations in terms of safety and stability. The introduction of the lunette ring in conjunction with the pintle hook marked a significant improvement, allowing for greater articulation and reducing the risk of accidental uncoupling.

Throughout its development, the pintle hitch has been driven by several key objectives. Foremost among these is the need for increased towing capacity, as industrial and commercial applications demanded the ability to move heavier loads. This led to the development of reinforced pintle hooks and stronger materials capable of handling greater stress.

Another critical goal in the evolution of pintle hitches has been enhancing safety features. This includes the integration of locking mechanisms to prevent unintended disconnection, as well as the incorporation of secondary safety chains or cables. These advancements have significantly reduced the risk of trailer separation during transit, a crucial consideration for both commercial and personal use.

Adaptability has also been a key focus in pintle hitch development. Modern designs often feature adjustable height settings and interchangeable components, allowing for greater flexibility in matching various towing vehicles with different trailer configurations. This versatility has expanded the application range of pintle hitches across diverse industries, from agriculture to construction.

The ongoing technological evolution of pintle hitches aims to address several contemporary challenges. These include improving weight distribution to enhance vehicle stability, reducing noise and vibration during towing, and incorporating smart technologies for real-time monitoring of hitch integrity and performance.

Looking ahead, the future development of pintle hitches is likely to focus on further enhancing safety, efficiency, and ease of use. This may involve the integration of advanced materials for lighter weight and greater strength, as well as the incorporation of electronic systems for automated coupling and uncoupling processes. Additionally, as environmental concerns grow, there is an increasing emphasis on designing pintle hitches that contribute to overall vehicle aerodynamics and fuel efficiency.

As transportation needs evolved, so did the pintle hitch design. Early versions consisted of a simple hook and eye system, which, while effective, had limitations in terms of safety and stability. The introduction of the lunette ring in conjunction with the pintle hook marked a significant improvement, allowing for greater articulation and reducing the risk of accidental uncoupling.

Throughout its development, the pintle hitch has been driven by several key objectives. Foremost among these is the need for increased towing capacity, as industrial and commercial applications demanded the ability to move heavier loads. This led to the development of reinforced pintle hooks and stronger materials capable of handling greater stress.

Another critical goal in the evolution of pintle hitches has been enhancing safety features. This includes the integration of locking mechanisms to prevent unintended disconnection, as well as the incorporation of secondary safety chains or cables. These advancements have significantly reduced the risk of trailer separation during transit, a crucial consideration for both commercial and personal use.

Adaptability has also been a key focus in pintle hitch development. Modern designs often feature adjustable height settings and interchangeable components, allowing for greater flexibility in matching various towing vehicles with different trailer configurations. This versatility has expanded the application range of pintle hitches across diverse industries, from agriculture to construction.

The ongoing technological evolution of pintle hitches aims to address several contemporary challenges. These include improving weight distribution to enhance vehicle stability, reducing noise and vibration during towing, and incorporating smart technologies for real-time monitoring of hitch integrity and performance.

Looking ahead, the future development of pintle hitches is likely to focus on further enhancing safety, efficiency, and ease of use. This may involve the integration of advanced materials for lighter weight and greater strength, as well as the incorporation of electronic systems for automated coupling and uncoupling processes. Additionally, as environmental concerns grow, there is an increasing emphasis on designing pintle hitches that contribute to overall vehicle aerodynamics and fuel efficiency.

Market Analysis for Towing Mechanisms

The towing mechanisms market has experienced significant growth in recent years, driven by increasing demand in various sectors such as automotive, agriculture, construction, and logistics. The global towing equipment market size was valued at approximately $5.9 billion in 2020 and is projected to reach $8.2 billion by 2027, growing at a CAGR of 4.8% during the forecast period.

The pintle hitch, a crucial component in the evolution of towing mechanisms, has played a vital role in shaping market dynamics. This robust and versatile hitch type has gained popularity due to its ability to handle heavy loads and operate in challenging terrains, making it particularly attractive for commercial and industrial applications.

In the automotive sector, the rising popularity of recreational vehicles (RVs) and trailers has significantly contributed to the growth of the towing mechanisms market. The COVID-19 pandemic has further accelerated this trend, as more people opt for road trips and outdoor activities, driving up demand for towing equipment, including pintle hitches.

The agriculture and construction industries have also been key drivers of market growth. As these sectors continue to modernize and expand, the need for efficient and reliable towing solutions has increased. Pintle hitches, known for their durability and high weight capacity, have become a preferred choice for heavy-duty applications in these industries.

Geographically, North America dominates the towing mechanisms market, accounting for approximately 35% of the global market share. This can be attributed to the region's large automotive industry, extensive road networks, and high adoption rates of recreational vehicles. Europe follows closely, with countries like Germany, France, and the UK showing significant demand for advanced towing solutions.

The Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, infrastructure development, and increasing disposable incomes. Countries like China and India are emerging as lucrative markets for towing mechanisms, including pintle hitches, due to their booming construction and logistics sectors.

Key market players in the towing mechanisms industry include Horizon Global Corporation, CURT Manufacturing LLC, B&W Trailer Hitches, and Demco Products. These companies are focusing on product innovation, strategic partnerships, and geographical expansion to maintain their competitive edge in the market.

The pintle hitch, a crucial component in the evolution of towing mechanisms, has played a vital role in shaping market dynamics. This robust and versatile hitch type has gained popularity due to its ability to handle heavy loads and operate in challenging terrains, making it particularly attractive for commercial and industrial applications.

In the automotive sector, the rising popularity of recreational vehicles (RVs) and trailers has significantly contributed to the growth of the towing mechanisms market. The COVID-19 pandemic has further accelerated this trend, as more people opt for road trips and outdoor activities, driving up demand for towing equipment, including pintle hitches.

The agriculture and construction industries have also been key drivers of market growth. As these sectors continue to modernize and expand, the need for efficient and reliable towing solutions has increased. Pintle hitches, known for their durability and high weight capacity, have become a preferred choice for heavy-duty applications in these industries.

Geographically, North America dominates the towing mechanisms market, accounting for approximately 35% of the global market share. This can be attributed to the region's large automotive industry, extensive road networks, and high adoption rates of recreational vehicles. Europe follows closely, with countries like Germany, France, and the UK showing significant demand for advanced towing solutions.

The Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, infrastructure development, and increasing disposable incomes. Countries like China and India are emerging as lucrative markets for towing mechanisms, including pintle hitches, due to their booming construction and logistics sectors.

Key market players in the towing mechanisms industry include Horizon Global Corporation, CURT Manufacturing LLC, B&W Trailer Hitches, and Demco Products. These companies are focusing on product innovation, strategic partnerships, and geographical expansion to maintain their competitive edge in the market.

Current Pintle Hitch Technology and Challenges

Pintle hitch technology has evolved significantly over the years, becoming a crucial component in modern towing mechanisms. Currently, the standard pintle hitch design consists of a hook-shaped coupling device mounted on the towing vehicle, which connects with a lunette ring on the trailer. This simple yet effective design allows for greater articulation and flexibility compared to traditional ball hitches, making it ideal for heavy-duty and off-road applications.

One of the primary challenges facing current pintle hitch technology is the need for improved safety features. While the basic design is robust, there is a growing demand for advanced locking mechanisms to prevent accidental disconnections during towing. Some manufacturers have introduced automatic locking systems that engage when the lunette ring is properly seated, but these solutions are not yet universally adopted.

Another significant challenge is the reduction of noise and vibration during towing. The inherent play in the pintle-lunette connection, which allows for greater articulation, can also lead to increased noise and wear over time. Engineers are working on developing new materials and damping systems to mitigate these issues without compromising the hitch's flexibility and strength.

Weight distribution and load capacity remain ongoing concerns in pintle hitch design. As vehicles and trailers become heavier and more specialized, there is a constant push to increase the load-bearing capabilities of pintle hitches. This challenge is being addressed through the use of high-strength materials and improved structural designs, but it often comes at the cost of increased weight and complexity.

Corrosion resistance is another area where current pintle hitch technology faces challenges. Given the frequent exposure to harsh environmental conditions, including road salt and moisture, maintaining the integrity of the hitch over time is crucial. While galvanization and protective coatings have improved durability, there is still room for advancement in this area.

The integration of smart technologies into pintle hitch systems represents both an opportunity and a challenge. There is growing interest in incorporating sensors and connectivity features to monitor hitch status, load distribution, and provide real-time data to drivers. However, implementing these technologies in a rugged, reliable manner that can withstand the harsh conditions of heavy-duty towing remains a significant engineering challenge.

Standardization across different manufacturers and vehicle types continues to be an issue in the pintle hitch industry. While there are established norms, the lack of universal standards can lead to compatibility issues between different towing vehicles and trailers. This challenge is particularly evident in international markets where regional differences in regulations and specifications can complicate the use of pintle hitches across borders.

One of the primary challenges facing current pintle hitch technology is the need for improved safety features. While the basic design is robust, there is a growing demand for advanced locking mechanisms to prevent accidental disconnections during towing. Some manufacturers have introduced automatic locking systems that engage when the lunette ring is properly seated, but these solutions are not yet universally adopted.

Another significant challenge is the reduction of noise and vibration during towing. The inherent play in the pintle-lunette connection, which allows for greater articulation, can also lead to increased noise and wear over time. Engineers are working on developing new materials and damping systems to mitigate these issues without compromising the hitch's flexibility and strength.

Weight distribution and load capacity remain ongoing concerns in pintle hitch design. As vehicles and trailers become heavier and more specialized, there is a constant push to increase the load-bearing capabilities of pintle hitches. This challenge is being addressed through the use of high-strength materials and improved structural designs, but it often comes at the cost of increased weight and complexity.

Corrosion resistance is another area where current pintle hitch technology faces challenges. Given the frequent exposure to harsh environmental conditions, including road salt and moisture, maintaining the integrity of the hitch over time is crucial. While galvanization and protective coatings have improved durability, there is still room for advancement in this area.

The integration of smart technologies into pintle hitch systems represents both an opportunity and a challenge. There is growing interest in incorporating sensors and connectivity features to monitor hitch status, load distribution, and provide real-time data to drivers. However, implementing these technologies in a rugged, reliable manner that can withstand the harsh conditions of heavy-duty towing remains a significant engineering challenge.

Standardization across different manufacturers and vehicle types continues to be an issue in the pintle hitch industry. While there are established norms, the lack of universal standards can lead to compatibility issues between different towing vehicles and trailers. This challenge is particularly evident in international markets where regional differences in regulations and specifications can complicate the use of pintle hitches across borders.

Existing Pintle Hitch Design Solutions

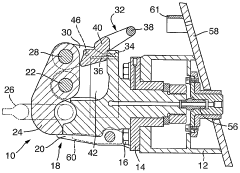

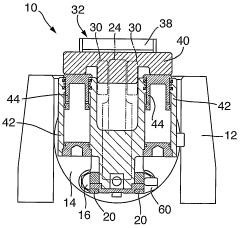

01 Pintle hitch design and structure

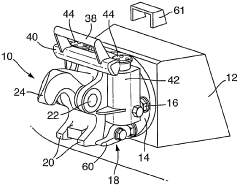

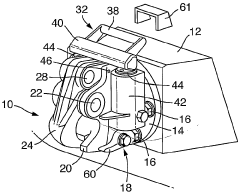

Pintle hitches are designed with a hook-like structure that allows for secure coupling between a towing vehicle and a trailer. The design typically includes a robust hook mechanism that can withstand heavy loads and provide flexibility in towing various types of trailers. Some designs incorporate additional features for improved safety and ease of use.- Pintle hitch design and structure: Pintle hitches are designed with a hook-like structure that allows for secure coupling with a lunette ring or eye. The design typically includes a locking mechanism to ensure the connection remains secure during towing. These hitches are known for their durability and ability to handle heavy loads, making them suitable for various towing applications.

- Safety features in pintle hitches: Modern pintle hitches incorporate various safety features to enhance towing security. These may include secondary locking mechanisms, visual indicators for proper coupling, and integrated safety chains. Some designs also feature anti-rattle components to reduce noise and improve stability during towing.

- Adjustable and multi-functional pintle hitches: Innovative pintle hitch designs offer adjustability and multi-functionality. These hitches may feature adjustable height settings, interchangeable components for different towing needs, or the ability to convert between pintle and ball hitch configurations. Such versatility allows for a wider range of towing applications with a single hitch system.

- Integration with vehicle systems: Advanced pintle hitch designs integrate with vehicle systems for improved functionality and safety. This may include electronic connections for trailer brake control, lighting systems, and sensors for load monitoring. Some designs also incorporate compatibility with backup cameras and parking assist systems for easier maneuvering.

- Specialized pintle hitches for heavy-duty applications: Specialized pintle hitch designs cater to heavy-duty and industrial applications. These hitches feature reinforced construction, higher weight capacities, and enhanced durability to withstand extreme towing conditions. Some designs may include additional stabilizing components or compatibility with air-ride suspension systems for improved performance in challenging environments.

02 Locking mechanisms for pintle hitches

Various locking mechanisms are employed in pintle hitches to ensure secure attachment and prevent accidental uncoupling during towing. These may include spring-loaded latches, safety pins, or automated locking systems that engage when the trailer is properly connected. Some designs incorporate multiple locking points for added security.Expand Specific Solutions03 Adjustable and multi-functional pintle hitches

Adjustable pintle hitches allow for customization of the hitch height or position to accommodate different trailer types or towing vehicles. Some designs incorporate multiple attachment points or interchangeable components to serve various towing needs. These versatile hitches may also include features for quick release or easy conversion between different towing configurations.Expand Specific Solutions04 Integration of pintle hitches with other towing components

Some pintle hitch designs integrate additional towing components such as ball hitches, drawbars, or weight distribution systems. These combination hitches provide increased versatility and allow for towing a wider range of trailers with a single hitch assembly. Integration may also include features for improved stability or load distribution during towing.Expand Specific Solutions05 Safety features and enhancements for pintle hitches

Various safety features are incorporated into pintle hitch designs to improve towing safety and prevent accidents. These may include visual indicators for proper coupling, integrated brake controllers, or sensors that detect trailer movement or uncoupling. Some designs also focus on reducing wear and tear on the hitch components or minimizing noise and vibration during towing.Expand Specific Solutions

Key Players in Pintle Hitch Manufacturing

The pintle hitch market in towing mechanisms is in a mature stage, with a stable global market size estimated at several billion dollars. The technology is well-established, with key players like Curt Manufacturing LLC and Horizon Global Americas, Inc. leading innovation in the commercial sector. These companies focus on improving durability, weight capacity, and ease of use. The military sector, represented by the Naval Research Laboratory, continues to refine pintle hitch designs for heavy-duty applications. Emerging players like Teleswivel LLC are introducing novel swiveling designs, indicating ongoing technological advancements. The market is characterized by a mix of established manufacturers and niche innovators, with competition driving incremental improvements in pintle hitch technology.

Curt Manufacturing LLC

Technical Solution: Curt Manufacturing LLC has been at the forefront of pintle hitch innovation in towing mechanisms. Their advanced pintle hitch designs incorporate high-strength steel construction and precision engineering to enhance durability and load capacity. The company has developed a patented anti-rattle system that significantly reduces noise and movement during towing[1]. Curt's pintle hitches feature a unique locking mechanism that ensures secure coupling between the tow vehicle and trailer, improving safety in various towing conditions[2]. They have also integrated advanced corrosion-resistant coatings to extend the lifespan of their pintle hitches, addressing one of the primary concerns in towing equipment longevity[3].

Strengths: Robust construction, innovative anti-rattle technology, and enhanced safety features. Weaknesses: Potentially higher cost due to advanced features and materials used.

Horizon Global Americas, Inc.

Technical Solution: Horizon Global Americas, Inc. has made significant strides in pintle hitch technology through their Draw-Tite and Reese brands. Their pintle hitches incorporate a unique swivel design that allows for greater articulation and flexibility in towing, particularly useful in off-road and uneven terrain conditions[4]. The company has developed a proprietary coating process that provides superior rust and corrosion resistance, extending the life of their pintle hitches in harsh environments[5]. Horizon Global's pintle hitches also feature an innovative quick-release mechanism, allowing for faster and easier coupling and uncoupling of trailers, improving efficiency in commercial and industrial applications[6].

Strengths: Enhanced flexibility with swivel design, superior corrosion resistance, and quick-release functionality. Weaknesses: May be more complex to install and maintain due to advanced features.

Core Innovations in Pintle Hitch Technology

Method of converting a trailer configuration

PatentInactiveUS8151426B2

Innovation

- A convertible trailer design featuring an adjustable neck with pivot and slide couplings that allows the trailer to be reconfigured between a pintle and a fifth-wheel configuration, enabling it to accommodate different hitch types by adjusting the position and securing the coupler support with pivot and slide locks.

Towing pintle assembly

PatentWO2005058619A1

Innovation

- A towing pintle assembly with a pivotally mounted locking member and fluid-operated means, allowing for rapid release and re-engagement, utilizing hydraulic rams to move the locking member from a locked to a release position, enabling remote operation without explosive bolts.

Safety Standards for Towing Equipment

Safety standards for towing equipment have evolved significantly alongside the development of pintle hitch mechanisms. These standards are crucial for ensuring the safe operation of towing vehicles and trailers, protecting both operators and other road users. The primary focus of safety standards in this domain is on the structural integrity, load capacity, and secure coupling of towing components.

One of the key aspects of safety standards for pintle hitches is the specification of minimum strength requirements. These standards typically define the vertical and horizontal loads that the hitch must withstand without failure. For instance, the Society of Automotive Engineers (SAE) J847 standard outlines the performance requirements for pintle hooks and drawbars used in highway trailer applications.

Coupling security is another critical area addressed by safety standards. Regulations often mandate the use of secondary coupling devices, such as safety chains or cables, to prevent complete separation of the trailer from the towing vehicle in case of primary coupling failure. The proper installation and use of these secondary devices are detailed in standards to ensure their effectiveness in emergency situations.

Compatibility between different towing components is also a significant concern in safety standards. Guidelines are provided to ensure that pintle hooks and lunette eyes are properly matched in terms of size and load capacity. This compatibility is essential for preventing unexpected decoupling or excessive wear that could compromise safety.

Maintenance and inspection requirements form an integral part of towing equipment safety standards. Regular checks of pintle hitches, drawbars, and associated components are mandated to identify wear, damage, or potential failure points. These inspections help maintain the integrity of the towing system over time and prevent accidents due to equipment failure.

Visibility and marking requirements are included in safety standards to enhance the visibility of towing equipment, especially in low-light conditions. Reflective materials or lighting may be required on certain components to alert other road users to the presence of a towed vehicle or trailer.

As vehicle technologies advance, safety standards for towing equipment are also evolving to incorporate electronic systems. For example, trailer sway control systems and electronic brake controllers are becoming more common, and standards are being developed to ensure their reliable operation and integration with towing vehicles.

The implementation of these safety standards is typically overseen by national and international regulatory bodies. In the United States, the National Highway Traffic Safety Administration (NHTSA) plays a key role in developing and enforcing towing safety standards. Similarly, in Europe, the United Nations Economic Commission for Europe (UNECE) provides regulations that many countries adopt for towing equipment safety.

One of the key aspects of safety standards for pintle hitches is the specification of minimum strength requirements. These standards typically define the vertical and horizontal loads that the hitch must withstand without failure. For instance, the Society of Automotive Engineers (SAE) J847 standard outlines the performance requirements for pintle hooks and drawbars used in highway trailer applications.

Coupling security is another critical area addressed by safety standards. Regulations often mandate the use of secondary coupling devices, such as safety chains or cables, to prevent complete separation of the trailer from the towing vehicle in case of primary coupling failure. The proper installation and use of these secondary devices are detailed in standards to ensure their effectiveness in emergency situations.

Compatibility between different towing components is also a significant concern in safety standards. Guidelines are provided to ensure that pintle hooks and lunette eyes are properly matched in terms of size and load capacity. This compatibility is essential for preventing unexpected decoupling or excessive wear that could compromise safety.

Maintenance and inspection requirements form an integral part of towing equipment safety standards. Regular checks of pintle hitches, drawbars, and associated components are mandated to identify wear, damage, or potential failure points. These inspections help maintain the integrity of the towing system over time and prevent accidents due to equipment failure.

Visibility and marking requirements are included in safety standards to enhance the visibility of towing equipment, especially in low-light conditions. Reflective materials or lighting may be required on certain components to alert other road users to the presence of a towed vehicle or trailer.

As vehicle technologies advance, safety standards for towing equipment are also evolving to incorporate electronic systems. For example, trailer sway control systems and electronic brake controllers are becoming more common, and standards are being developed to ensure their reliable operation and integration with towing vehicles.

The implementation of these safety standards is typically overseen by national and international regulatory bodies. In the United States, the National Highway Traffic Safety Administration (NHTSA) plays a key role in developing and enforcing towing safety standards. Similarly, in Europe, the United Nations Economic Commission for Europe (UNECE) provides regulations that many countries adopt for towing equipment safety.

Environmental Impact of Towing Technologies

The environmental impact of towing technologies, particularly the pintle hitch system, has become an increasingly important consideration in the evolution of towing mechanisms. As vehicle manufacturers and transportation industries strive for greater sustainability, the environmental implications of towing systems have come under scrutiny.

One of the primary environmental concerns associated with towing technologies is fuel efficiency. Traditional towing mechanisms, including older pintle hitch designs, often result in increased drag and reduced aerodynamics, leading to higher fuel consumption. This not only impacts the cost of transportation but also contributes to increased carbon emissions. However, the evolution of pintle hitch designs has led to more streamlined and efficient systems, which can help mitigate these issues to some extent.

The materials used in towing mechanisms also play a crucial role in their environmental impact. Older pintle hitch systems were typically made from heavy, non-recyclable materials, contributing to resource depletion and waste accumulation. Modern designs, however, increasingly incorporate lightweight, recyclable materials such as high-strength aluminum alloys. This shift not only reduces the overall weight of the towing system, improving fuel efficiency, but also enhances the potential for end-of-life recycling.

Noise pollution is another environmental factor influenced by towing technologies. Traditional pintle hitch systems often produced significant noise during operation, particularly when coupling and uncoupling trailers. This noise pollution can have detrimental effects on wildlife and human communities near transportation routes. Advancements in pintle hitch design have led to quieter operation, reducing the overall noise footprint of towing activities.

The durability and longevity of towing mechanisms also impact their environmental footprint. Pintle hitch systems that require frequent replacement or maintenance can lead to increased waste and resource consumption. Modern designs focus on enhancing durability through improved materials and engineering, potentially reducing the environmental impact associated with manufacturing and disposal of towing components.

Furthermore, the evolution of pintle hitch technology has contributed to improved safety features, which indirectly benefit the environment. Enhanced stability and control during towing reduce the likelihood of accidents, which can result in fuel spills, vehicle damage, and other environmental hazards. This aspect of towing technology development underscores the interconnectedness of safety and environmental considerations in transportation systems.

As the transportation industry continues to evolve, there is a growing emphasis on developing towing technologies that are not only efficient and safe but also environmentally sustainable. This includes research into alternative materials, such as bio-based composites, and the integration of smart technologies to optimize towing performance and reduce environmental impact. The ongoing evolution of pintle hitch and other towing mechanisms reflects a broader trend towards more sustainable transportation solutions, aligning with global efforts to reduce the environmental footprint of vehicular activities.

One of the primary environmental concerns associated with towing technologies is fuel efficiency. Traditional towing mechanisms, including older pintle hitch designs, often result in increased drag and reduced aerodynamics, leading to higher fuel consumption. This not only impacts the cost of transportation but also contributes to increased carbon emissions. However, the evolution of pintle hitch designs has led to more streamlined and efficient systems, which can help mitigate these issues to some extent.

The materials used in towing mechanisms also play a crucial role in their environmental impact. Older pintle hitch systems were typically made from heavy, non-recyclable materials, contributing to resource depletion and waste accumulation. Modern designs, however, increasingly incorporate lightweight, recyclable materials such as high-strength aluminum alloys. This shift not only reduces the overall weight of the towing system, improving fuel efficiency, but also enhances the potential for end-of-life recycling.

Noise pollution is another environmental factor influenced by towing technologies. Traditional pintle hitch systems often produced significant noise during operation, particularly when coupling and uncoupling trailers. This noise pollution can have detrimental effects on wildlife and human communities near transportation routes. Advancements in pintle hitch design have led to quieter operation, reducing the overall noise footprint of towing activities.

The durability and longevity of towing mechanisms also impact their environmental footprint. Pintle hitch systems that require frequent replacement or maintenance can lead to increased waste and resource consumption. Modern designs focus on enhancing durability through improved materials and engineering, potentially reducing the environmental impact associated with manufacturing and disposal of towing components.

Furthermore, the evolution of pintle hitch technology has contributed to improved safety features, which indirectly benefit the environment. Enhanced stability and control during towing reduce the likelihood of accidents, which can result in fuel spills, vehicle damage, and other environmental hazards. This aspect of towing technology development underscores the interconnectedness of safety and environmental considerations in transportation systems.

As the transportation industry continues to evolve, there is a growing emphasis on developing towing technologies that are not only efficient and safe but also environmentally sustainable. This includes research into alternative materials, such as bio-based composites, and the integration of smart technologies to optimize towing performance and reduce environmental impact. The ongoing evolution of pintle hitch and other towing mechanisms reflects a broader trend towards more sustainable transportation solutions, aligning with global efforts to reduce the environmental footprint of vehicular activities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!