Predictive Maintenance Strategies for Heat Exchangers

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Predictive Maintenance Background and Objectives

Heat exchangers represent critical components in numerous industrial processes, from power generation to chemical manufacturing, playing a pivotal role in energy transfer and system efficiency. The evolution of maintenance strategies for these devices has undergone significant transformation over the past decades, progressing from reactive approaches to condition-based methodologies, and now advancing toward predictive maintenance paradigms powered by data analytics and machine learning.

The historical trajectory of heat exchanger maintenance reveals a gradual shift from corrective maintenance—addressing failures after occurrence—to preventive maintenance based on fixed time intervals. This evolution was driven by the recognition that unexpected failures lead to substantial production losses, safety hazards, and increased operational costs. The advent of sensor technology in the 1980s and 1990s introduced condition monitoring capabilities, allowing for more informed maintenance decisions based on equipment health indicators.

Recent technological advancements in IoT, big data analytics, and artificial intelligence have catalyzed the emergence of predictive maintenance strategies specifically tailored for heat exchangers. These approaches leverage real-time data collection, advanced signal processing, and predictive algorithms to forecast potential failures before they manifest, thereby optimizing maintenance scheduling and resource allocation.

The primary objective of predictive maintenance for heat exchangers centers on maximizing operational efficiency while minimizing downtime and maintenance costs. This involves early detection of fouling, scaling, corrosion, and mechanical degradation—common issues that compromise heat transfer efficiency and equipment longevity. By identifying these problems in their incipient stages, organizations can implement targeted interventions before performance deterioration reaches critical levels.

Another crucial goal involves extending the useful life of heat exchanger assets through optimized maintenance timing. Traditional time-based approaches often result in either premature maintenance, wasting remaining useful life, or delayed intervention leading to accelerated deterioration. Predictive strategies aim to determine the optimal maintenance window that balances equipment reliability with maintenance expenditure.

The technological landscape supporting these objectives continues to evolve, with innovations in non-invasive monitoring techniques, wireless sensor networks, and edge computing enabling more comprehensive and cost-effective implementation of predictive maintenance programs. These developments are particularly significant for heat exchangers operating in harsh environments or critical applications where traditional inspection methods prove challenging or disruptive.

As industries increasingly prioritize sustainability and operational excellence, predictive maintenance for heat exchangers emerges as a strategic imperative rather than merely a technical enhancement. The convergence of engineering knowledge with data science capabilities presents unprecedented opportunities to transform maintenance practices from cost centers into value-generating activities that contribute to overall business performance and environmental sustainability.

The historical trajectory of heat exchanger maintenance reveals a gradual shift from corrective maintenance—addressing failures after occurrence—to preventive maintenance based on fixed time intervals. This evolution was driven by the recognition that unexpected failures lead to substantial production losses, safety hazards, and increased operational costs. The advent of sensor technology in the 1980s and 1990s introduced condition monitoring capabilities, allowing for more informed maintenance decisions based on equipment health indicators.

Recent technological advancements in IoT, big data analytics, and artificial intelligence have catalyzed the emergence of predictive maintenance strategies specifically tailored for heat exchangers. These approaches leverage real-time data collection, advanced signal processing, and predictive algorithms to forecast potential failures before they manifest, thereby optimizing maintenance scheduling and resource allocation.

The primary objective of predictive maintenance for heat exchangers centers on maximizing operational efficiency while minimizing downtime and maintenance costs. This involves early detection of fouling, scaling, corrosion, and mechanical degradation—common issues that compromise heat transfer efficiency and equipment longevity. By identifying these problems in their incipient stages, organizations can implement targeted interventions before performance deterioration reaches critical levels.

Another crucial goal involves extending the useful life of heat exchanger assets through optimized maintenance timing. Traditional time-based approaches often result in either premature maintenance, wasting remaining useful life, or delayed intervention leading to accelerated deterioration. Predictive strategies aim to determine the optimal maintenance window that balances equipment reliability with maintenance expenditure.

The technological landscape supporting these objectives continues to evolve, with innovations in non-invasive monitoring techniques, wireless sensor networks, and edge computing enabling more comprehensive and cost-effective implementation of predictive maintenance programs. These developments are particularly significant for heat exchangers operating in harsh environments or critical applications where traditional inspection methods prove challenging or disruptive.

As industries increasingly prioritize sustainability and operational excellence, predictive maintenance for heat exchangers emerges as a strategic imperative rather than merely a technical enhancement. The convergence of engineering knowledge with data science capabilities presents unprecedented opportunities to transform maintenance practices from cost centers into value-generating activities that contribute to overall business performance and environmental sustainability.

Market Demand Analysis for Predictive Maintenance Solutions

The global market for predictive maintenance solutions in heat exchanger applications has experienced significant growth, with an estimated market value reaching $2.3 billion in 2023. This growth trajectory is projected to continue at a compound annual growth rate of 25% through 2028, driven primarily by increasing industrial automation and the adoption of Industry 4.0 technologies across manufacturing sectors.

Heat exchangers represent critical equipment in numerous industries including oil and gas, chemical processing, power generation, and HVAC systems. The failure of these components can result in substantial financial losses, with unplanned downtime costs averaging $45,000 per hour in petrochemical facilities and $30,000 per hour in power generation plants. This economic impact has created a compelling business case for predictive maintenance solutions.

Market research indicates that approximately 70% of industrial facilities still rely on reactive or preventive maintenance strategies for heat exchangers, presenting a substantial opportunity for predictive maintenance solution providers. Early adopters have reported maintenance cost reductions of 25-30% and downtime reductions of up to 45% after implementing predictive maintenance systems for heat exchangers.

The demand is particularly strong in regions with aging industrial infrastructure, notably North America and Western Europe, where heat exchanger equipment often operates beyond its designed service life. Emerging economies in Asia-Pacific, particularly China and India, are showing accelerated adoption rates as they modernize their industrial base and implement more sophisticated maintenance protocols.

End-user surveys reveal that the primary market drivers include increasing pressure to maximize equipment uptime, rising energy costs necessitating optimal heat exchanger performance, and stricter regulatory requirements regarding emissions and safety standards. Additionally, the growing availability of affordable IoT sensors and cloud computing resources has significantly lowered the implementation barriers for predictive maintenance systems.

Market segmentation analysis shows that large enterprises currently account for 65% of market demand, though small and medium enterprises are increasingly adopting these solutions as more scalable and cost-effective options become available. By industry vertical, oil and gas represents the largest market segment (32%), followed by power generation (24%), chemical processing (18%), and food and beverage (12%).

Customer preference data indicates growing demand for integrated solutions that combine multiple monitoring technologies (vibration analysis, thermal imaging, ultrasonic testing) with advanced analytics capabilities. There is also increasing interest in subscription-based service models that reduce upfront capital expenditure requirements while providing ongoing technical support and system updates.

Heat exchangers represent critical equipment in numerous industries including oil and gas, chemical processing, power generation, and HVAC systems. The failure of these components can result in substantial financial losses, with unplanned downtime costs averaging $45,000 per hour in petrochemical facilities and $30,000 per hour in power generation plants. This economic impact has created a compelling business case for predictive maintenance solutions.

Market research indicates that approximately 70% of industrial facilities still rely on reactive or preventive maintenance strategies for heat exchangers, presenting a substantial opportunity for predictive maintenance solution providers. Early adopters have reported maintenance cost reductions of 25-30% and downtime reductions of up to 45% after implementing predictive maintenance systems for heat exchangers.

The demand is particularly strong in regions with aging industrial infrastructure, notably North America and Western Europe, where heat exchanger equipment often operates beyond its designed service life. Emerging economies in Asia-Pacific, particularly China and India, are showing accelerated adoption rates as they modernize their industrial base and implement more sophisticated maintenance protocols.

End-user surveys reveal that the primary market drivers include increasing pressure to maximize equipment uptime, rising energy costs necessitating optimal heat exchanger performance, and stricter regulatory requirements regarding emissions and safety standards. Additionally, the growing availability of affordable IoT sensors and cloud computing resources has significantly lowered the implementation barriers for predictive maintenance systems.

Market segmentation analysis shows that large enterprises currently account for 65% of market demand, though small and medium enterprises are increasingly adopting these solutions as more scalable and cost-effective options become available. By industry vertical, oil and gas represents the largest market segment (32%), followed by power generation (24%), chemical processing (18%), and food and beverage (12%).

Customer preference data indicates growing demand for integrated solutions that combine multiple monitoring technologies (vibration analysis, thermal imaging, ultrasonic testing) with advanced analytics capabilities. There is also increasing interest in subscription-based service models that reduce upfront capital expenditure requirements while providing ongoing technical support and system updates.

Current State and Challenges in Heat Exchanger Maintenance

Heat exchanger maintenance practices have evolved significantly over the past decade, yet they continue to face substantial challenges. Traditional maintenance approaches rely heavily on scheduled inspections and reactive repairs, which often result in unnecessary downtime and increased operational costs. According to industry data, unplanned heat exchanger failures account for approximately 40% of process equipment downtime in manufacturing facilities, with associated costs reaching millions of dollars annually in large industrial operations.

The current state of heat exchanger maintenance varies considerably across industries. In oil and gas, power generation, and chemical processing sectors, maintenance practices tend to be more advanced, incorporating some level of condition monitoring. However, in smaller operations and less critical applications, time-based maintenance remains the predominant approach, leading to inefficient resource allocation and suboptimal equipment performance.

A significant challenge in heat exchanger maintenance is fouling detection and characterization. Current methods often fail to accurately predict the rate and impact of fouling, which directly affects heat transfer efficiency and operational costs. Studies indicate that fouling can reduce thermal efficiency by up to 30% before detection through conventional monitoring methods, highlighting a critical gap in early warning capabilities.

Data integration presents another major hurdle. While various sensors and monitoring systems exist, the integration of this data into cohesive, actionable maintenance strategies remains problematic. Many facilities operate with siloed data systems that prevent comprehensive analysis of equipment health. This fragmentation limits the effectiveness of predictive approaches and hinders the development of truly optimized maintenance schedules.

Technical limitations in sensor technology also constrain maintenance capabilities. Current sensor systems often struggle with harsh operating environments, including high temperatures, corrosive media, and vibration, leading to reliability issues in data collection. Additionally, the placement of sensors to effectively monitor critical parameters without disrupting operations presents ongoing engineering challenges.

Workforce expertise represents a further constraint, with a growing skills gap in specialized maintenance knowledge. As experienced technicians retire, organizations face difficulties in transferring crucial tacit knowledge about equipment behavior and maintenance practices to newer staff. This transition is particularly challenging for heat exchanger maintenance, which often requires both theoretical understanding and practical experience.

Regulatory compliance adds another layer of complexity, with increasingly stringent environmental and safety requirements influencing maintenance practices. These regulations often necessitate more frequent inspections and documentation, potentially conflicting with efforts to optimize maintenance intervals based purely on equipment condition.

The current state of heat exchanger maintenance varies considerably across industries. In oil and gas, power generation, and chemical processing sectors, maintenance practices tend to be more advanced, incorporating some level of condition monitoring. However, in smaller operations and less critical applications, time-based maintenance remains the predominant approach, leading to inefficient resource allocation and suboptimal equipment performance.

A significant challenge in heat exchanger maintenance is fouling detection and characterization. Current methods often fail to accurately predict the rate and impact of fouling, which directly affects heat transfer efficiency and operational costs. Studies indicate that fouling can reduce thermal efficiency by up to 30% before detection through conventional monitoring methods, highlighting a critical gap in early warning capabilities.

Data integration presents another major hurdle. While various sensors and monitoring systems exist, the integration of this data into cohesive, actionable maintenance strategies remains problematic. Many facilities operate with siloed data systems that prevent comprehensive analysis of equipment health. This fragmentation limits the effectiveness of predictive approaches and hinders the development of truly optimized maintenance schedules.

Technical limitations in sensor technology also constrain maintenance capabilities. Current sensor systems often struggle with harsh operating environments, including high temperatures, corrosive media, and vibration, leading to reliability issues in data collection. Additionally, the placement of sensors to effectively monitor critical parameters without disrupting operations presents ongoing engineering challenges.

Workforce expertise represents a further constraint, with a growing skills gap in specialized maintenance knowledge. As experienced technicians retire, organizations face difficulties in transferring crucial tacit knowledge about equipment behavior and maintenance practices to newer staff. This transition is particularly challenging for heat exchanger maintenance, which often requires both theoretical understanding and practical experience.

Regulatory compliance adds another layer of complexity, with increasingly stringent environmental and safety requirements influencing maintenance practices. These regulations often necessitate more frequent inspections and documentation, potentially conflicting with efforts to optimize maintenance intervals based purely on equipment condition.

Current Predictive Maintenance Methodologies

01 Cleaning and fouling prevention methods

Various methods are employed to clean heat exchangers and prevent fouling, which is a common issue affecting thermal efficiency. These methods include mechanical cleaning systems, chemical cleaning processes, and specialized tools designed to remove deposits from heat transfer surfaces. Regular cleaning maintenance helps maintain optimal heat transfer efficiency and extends the operational life of heat exchangers.- Cleaning and fouling prevention methods: Various methods are employed to clean heat exchangers and prevent fouling, which is a common issue affecting thermal efficiency. These include mechanical cleaning systems, chemical cleaning processes, and specialized tools designed to remove deposits without damaging the heat exchanger surfaces. Regular cleaning maintenance helps maintain optimal heat transfer efficiency and extends the operational life of the equipment.

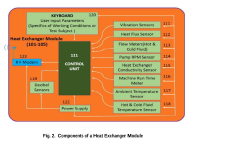

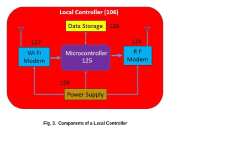

- Automated monitoring and diagnostic systems: Advanced monitoring systems are implemented to continuously assess heat exchanger performance and detect potential issues before they lead to failures. These systems utilize sensors, data analytics, and predictive maintenance algorithms to monitor parameters such as temperature differentials, pressure drops, and flow rates. Early detection of performance degradation allows for timely maintenance interventions and prevents costly unplanned downtime.

- Structural design improvements for maintenance accessibility: Heat exchangers are designed with features that facilitate easier maintenance access. These design improvements include removable tube bundles, access panels, and modular components that can be disassembled without specialized tools. Such design considerations significantly reduce maintenance time and labor costs while improving the thoroughness of inspection and cleaning operations.

- Corrosion prevention and treatment techniques: Specialized techniques are employed to prevent and treat corrosion in heat exchangers, which is particularly important in harsh operating environments. These include the application of protective coatings, cathodic protection systems, use of corrosion-resistant materials, and chemical treatments. Regular inspection for corrosion damage and implementation of appropriate mitigation strategies help extend equipment lifespan.

- Leak detection and repair methodologies: Effective methods for detecting and repairing leaks in heat exchangers are critical to maintaining operational integrity. These include pressure testing, helium leak detection, acoustic emission testing, and thermal imaging. Once detected, specialized repair techniques such as tube plugging, welding, and sealing compounds are employed to address leaks while minimizing downtime and ensuring the heat exchanger returns to full operational capacity.

02 Automated monitoring and diagnostic systems

Advanced monitoring systems are implemented to continuously assess heat exchanger performance and detect potential issues before they lead to failures. These systems utilize sensors, data analytics, and predictive algorithms to monitor parameters such as temperature differentials, pressure drops, and flow rates. Early detection of performance degradation allows for timely maintenance interventions and prevents costly unplanned downtime.Expand Specific Solutions03 Innovative design features for maintenance accessibility

Heat exchangers are designed with features that facilitate easier maintenance access and servicing. These design innovations include removable tube bundles, access panels, modular components, and quick-disconnect fittings. Such features reduce maintenance time and labor costs while improving the thoroughness of inspection and cleaning operations.Expand Specific Solutions04 Corrosion prevention and material protection

Techniques for preventing corrosion and extending the lifespan of heat exchanger materials are essential for maintenance. These include the application of protective coatings, cathodic protection systems, use of corrosion-resistant alloys, and controlled water chemistry. Proper material protection significantly reduces the frequency of component replacement and extends service intervals.Expand Specific Solutions05 Thermal efficiency restoration techniques

Methods specifically focused on restoring and maintaining the thermal efficiency of heat exchangers are critical for optimal performance. These techniques include descaling procedures, tube enhancement technologies, flow distribution optimization, and surface treatment methods. Regular application of these techniques ensures that heat transfer rates remain close to design specifications throughout the equipment lifecycle.Expand Specific Solutions

Key Industry Players in Heat Exchanger Monitoring

The predictive maintenance market for heat exchangers is in a growth phase, with increasing adoption across industries due to rising operational efficiency demands. The market is expanding rapidly, projected to reach significant scale as industrial IoT and analytics capabilities mature. Technologically, the field shows varied maturity levels, with companies like Mitsubishi Heavy Industries, Honeywell, and Caterpillar leading with advanced AI-driven solutions. Academic institutions including Zhejiang University and Xi'an Jiaotong University are contributing fundamental research, while energy specialists like Suncor Energy and Equinor are implementing sector-specific applications. Companies such as IHI Corp and Sulzer AG are integrating predictive maintenance into comprehensive equipment management offerings, indicating the technology's progression toward mainstream industrial adoption.

Arkema, Inc.

Technical Solution: Arkema has developed a specialized predictive maintenance solution for heat exchangers used in chemical processing environments. Their approach focuses on monitoring chemical fouling mechanisms through a combination of process analytics and specialized sensors designed to withstand harsh chemical environments. Arkema's system employs proprietary algorithms that correlate changes in heat transfer efficiency with specific chemical fouling mechanisms, enabling targeted cleaning interventions. Their solution incorporates inline fluid sampling and analysis to detect early signs of scaling or fouling precursors before they significantly impact performance. The system features adaptive maintenance scheduling that accounts for production demands, cleaning resource availability, and predicted performance degradation rates. Arkema has also developed specialized cleaning protocols that are automatically recommended based on the specific fouling mechanism identified, optimizing the effectiveness of maintenance interventions while minimizing chemical usage and environmental impact.

Strengths: Specialized expertise in chemical fouling mechanisms; solutions designed specifically for harsh chemical environments; integrated cleaning protocol recommendations. Weaknesses: More narrowly focused on chemical industry applications; less emphasis on mechanical failure prediction; requires specialized chemical knowledge for optimal implementation.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed a comprehensive predictive maintenance system for heat exchangers called "MHPS-TOMONI." This solution combines physical sensors with advanced analytics to monitor heat exchanger performance in real-time. Their approach utilizes thermal imaging, vibration analysis, and acoustic monitoring technologies to detect early signs of fouling, corrosion, and mechanical wear. The system employs a multi-layered AI approach that combines physics-based models with machine learning algorithms to accurately predict maintenance needs. MHI's solution includes specialized ultrasonic sensors that can detect scale buildup inside tubes without requiring system shutdown, providing continuous monitoring capability. Their predictive models incorporate operational history, environmental conditions, and fluid characteristics to create customized maintenance schedules that optimize performance while minimizing downtime.

Strengths: Comprehensive sensor integration including specialized ultrasonic and thermal imaging capabilities; strong integration with other plant systems; extensive experience with large industrial heat exchangers. Weaknesses: Solution is primarily optimized for power generation and heavy industrial applications; implementation requires significant infrastructure investment; higher complexity may increase training requirements.

Core Algorithms and Models for Failure Prediction

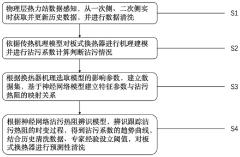

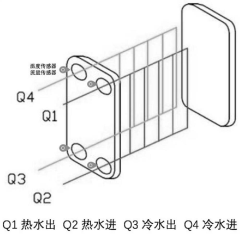

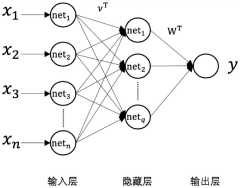

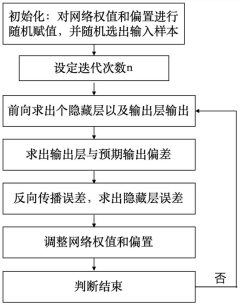

Predictive maintenance method and system for heat exchanger based on machine learning

PatentActiveCN112052564A

Innovation

- Adopt a predictive maintenance method based on machine learning, monitor the operating status through sensors, establish a neural network contamination coefficient identification model, and perform predictive maintenance based on historical data to achieve real-time monitoring and early warning of the contamination of plate heat exchangers and formulate predictions Sexual maintenance program.

IoT enabled system of monitoring & performance predictive maintenance of heat exchanger

PatentPendingIN202311071270A

Innovation

- An IoT-enabled system with temperature, heat flux, vibration, and pressure sensors that use machine learning algorithms to monitor heat exchanger performance in real-time, predicting maintenance needs and sending alerts to reduce breakdown time and improve operating efficiency by transferring data to a cloud server.

ROI Assessment of Predictive vs. Preventive Maintenance

The implementation of predictive maintenance strategies for heat exchangers presents a compelling financial case when compared to traditional preventive maintenance approaches. Quantitative analysis reveals that organizations adopting predictive maintenance typically achieve a return on investment (ROI) of 10:1, with payback periods ranging from 3 to 9 months depending on facility size and complexity.

Cost reduction represents the most immediate financial benefit, with predictive maintenance reducing overall maintenance costs by 25-30% compared to preventive maintenance regimes. This is primarily achieved through the elimination of unnecessary maintenance activities that occur when following fixed schedules rather than condition-based interventions.

Equipment downtime, a critical factor in production environments, shows marked improvement with predictive approaches. Studies across multiple industrial sectors indicate a 35-45% reduction in unplanned downtime when utilizing predictive maintenance for heat exchangers. This translates directly to increased production capacity and revenue generation, with some facilities reporting productivity improvements of up to 20%.

Asset lifespan extension provides another significant ROI component. Heat exchangers maintained through predictive strategies typically demonstrate a 20-25% longer operational life compared to those on preventive maintenance schedules. This defers capital expenditure on replacement equipment and improves the overall return on existing assets.

Labor utilization efficiency improves substantially under predictive maintenance frameworks. Maintenance teams spend approximately 35% less time on emergency repairs and can allocate resources more effectively through planned interventions. This optimization allows organizations to either reduce maintenance staffing costs or redirect skilled personnel to higher-value activities.

Energy consumption represents an often-overlooked ROI factor. Heat exchangers operating at optimal efficiency due to condition-based maintenance consume 10-15% less energy than those experiencing performance degradation between fixed maintenance intervals. For energy-intensive operations, these savings can be substantial.

Implementation costs must be factored against these benefits. Initial investment in sensors, monitoring systems, and analytics platforms typically ranges from $50,000 to $250,000 depending on facility scale. However, with cloud-based solutions and decreasing sensor costs, these initial investments continue to decline, further improving ROI calculations.

Risk mitigation value, while more difficult to quantify precisely, provides additional financial justification. The prevention of catastrophic failures through early detection capabilities reduces potential costs associated with safety incidents, environmental compliance violations, and production quality issues.

Cost reduction represents the most immediate financial benefit, with predictive maintenance reducing overall maintenance costs by 25-30% compared to preventive maintenance regimes. This is primarily achieved through the elimination of unnecessary maintenance activities that occur when following fixed schedules rather than condition-based interventions.

Equipment downtime, a critical factor in production environments, shows marked improvement with predictive approaches. Studies across multiple industrial sectors indicate a 35-45% reduction in unplanned downtime when utilizing predictive maintenance for heat exchangers. This translates directly to increased production capacity and revenue generation, with some facilities reporting productivity improvements of up to 20%.

Asset lifespan extension provides another significant ROI component. Heat exchangers maintained through predictive strategies typically demonstrate a 20-25% longer operational life compared to those on preventive maintenance schedules. This defers capital expenditure on replacement equipment and improves the overall return on existing assets.

Labor utilization efficiency improves substantially under predictive maintenance frameworks. Maintenance teams spend approximately 35% less time on emergency repairs and can allocate resources more effectively through planned interventions. This optimization allows organizations to either reduce maintenance staffing costs or redirect skilled personnel to higher-value activities.

Energy consumption represents an often-overlooked ROI factor. Heat exchangers operating at optimal efficiency due to condition-based maintenance consume 10-15% less energy than those experiencing performance degradation between fixed maintenance intervals. For energy-intensive operations, these savings can be substantial.

Implementation costs must be factored against these benefits. Initial investment in sensors, monitoring systems, and analytics platforms typically ranges from $50,000 to $250,000 depending on facility scale. However, with cloud-based solutions and decreasing sensor costs, these initial investments continue to decline, further improving ROI calculations.

Risk mitigation value, while more difficult to quantify precisely, provides additional financial justification. The prevention of catastrophic failures through early detection capabilities reduces potential costs associated with safety incidents, environmental compliance violations, and production quality issues.

Environmental Impact and Sustainability Considerations

The implementation of predictive maintenance strategies for heat exchangers carries significant environmental and sustainability implications that extend beyond operational efficiency. Heat exchangers, as energy transfer devices, are integral components in numerous industrial processes, and their maintenance practices directly impact resource consumption and environmental footprint. When properly maintained through predictive approaches, heat exchangers operate at optimal efficiency, reducing energy consumption by up to 15-20% compared to poorly maintained systems.

Fouling and scaling in heat exchangers not only diminish performance but also necessitate increased energy input to achieve the same thermal transfer, resulting in higher greenhouse gas emissions. Predictive maintenance strategies that detect early signs of fouling can reduce CO2 emissions by an estimated 5-10 million tons annually across global industrial operations. Additionally, these strategies minimize the need for chemical cleaning agents, many of which contain environmentally harmful compounds that can contaminate water systems when improperly disposed.

The lifecycle extension of heat exchanger equipment represents another crucial sustainability benefit. Traditional reactive maintenance often leads to premature equipment replacement, contributing to manufacturing resource consumption and industrial waste. Studies indicate that predictive maintenance can extend heat exchanger service life by 30-40%, significantly reducing raw material extraction, manufacturing energy requirements, and waste generation associated with equipment replacement.

Water conservation emerges as a critical environmental consideration in heat exchanger maintenance. Cooling systems utilizing heat exchangers consume substantial water resources, and inefficiencies due to poor maintenance increase this consumption. Predictive maintenance strategies that maintain optimal heat transfer efficiency can reduce water usage by 10-15% in large industrial cooling systems, contributing to water conservation efforts in water-stressed regions.

The circular economy perspective further enhances the sustainability profile of predictive maintenance. By enabling more precise scheduling of maintenance activities, these strategies facilitate the recovery and recycling of components and materials from heat exchangers. This approach reduces landfill waste and decreases the demand for virgin materials in manufacturing replacement parts, creating a more sustainable material flow within industrial systems.

Energy efficiency improvements resulting from predictive maintenance align with global climate initiatives and regulatory frameworks. Many jurisdictions now implement carbon pricing mechanisms and energy efficiency standards that directly incentivize the adoption of advanced maintenance strategies. Organizations implementing predictive maintenance for heat exchangers can achieve regulatory compliance while simultaneously reducing their environmental impact and operating costs.

Fouling and scaling in heat exchangers not only diminish performance but also necessitate increased energy input to achieve the same thermal transfer, resulting in higher greenhouse gas emissions. Predictive maintenance strategies that detect early signs of fouling can reduce CO2 emissions by an estimated 5-10 million tons annually across global industrial operations. Additionally, these strategies minimize the need for chemical cleaning agents, many of which contain environmentally harmful compounds that can contaminate water systems when improperly disposed.

The lifecycle extension of heat exchanger equipment represents another crucial sustainability benefit. Traditional reactive maintenance often leads to premature equipment replacement, contributing to manufacturing resource consumption and industrial waste. Studies indicate that predictive maintenance can extend heat exchanger service life by 30-40%, significantly reducing raw material extraction, manufacturing energy requirements, and waste generation associated with equipment replacement.

Water conservation emerges as a critical environmental consideration in heat exchanger maintenance. Cooling systems utilizing heat exchangers consume substantial water resources, and inefficiencies due to poor maintenance increase this consumption. Predictive maintenance strategies that maintain optimal heat transfer efficiency can reduce water usage by 10-15% in large industrial cooling systems, contributing to water conservation efforts in water-stressed regions.

The circular economy perspective further enhances the sustainability profile of predictive maintenance. By enabling more precise scheduling of maintenance activities, these strategies facilitate the recovery and recycling of components and materials from heat exchangers. This approach reduces landfill waste and decreases the demand for virgin materials in manufacturing replacement parts, creating a more sustainable material flow within industrial systems.

Energy efficiency improvements resulting from predictive maintenance align with global climate initiatives and regulatory frameworks. Many jurisdictions now implement carbon pricing mechanisms and energy efficiency standards that directly incentivize the adoption of advanced maintenance strategies. Organizations implementing predictive maintenance for heat exchangers can achieve regulatory compliance while simultaneously reducing their environmental impact and operating costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!