Predictive Maintenance Technologies for Lithium Iron Phosphate Batteries

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery PM Tech Background and Objectives

Lithium Iron Phosphate (LFP) batteries have emerged as a prominent energy storage solution, particularly in electric vehicles and renewable energy systems. The technology's evolution can be traced back to the 1990s when researchers at the University of Texas discovered the potential of LFP as a cathode material. Since then, LFP batteries have undergone significant improvements in performance, safety, and cost-effectiveness.

The development of predictive maintenance technologies for LFP batteries is driven by the increasing demand for reliable and long-lasting energy storage solutions. As the adoption of electric vehicles and renewable energy systems continues to grow, the need for efficient battery management and maintenance becomes crucial. Predictive maintenance aims to optimize battery performance, extend lifespan, and reduce operational costs by anticipating and preventing potential failures.

The technical objectives of predictive maintenance for LFP batteries encompass several key areas. Firstly, it seeks to develop accurate models for predicting battery degradation and remaining useful life. This involves analyzing various factors such as charge-discharge cycles, temperature fluctuations, and usage patterns. Secondly, the technology aims to implement real-time monitoring systems that can detect early signs of battery deterioration or anomalies.

Another important objective is to establish a comprehensive database of battery performance metrics and failure modes. This data-driven approach enables the development of more sophisticated predictive algorithms and machine learning models. Additionally, predictive maintenance technologies strive to integrate with battery management systems to provide actionable insights and optimize charging strategies.

The evolution of predictive maintenance technologies for LFP batteries has been influenced by advancements in sensor technology, data analytics, and artificial intelligence. Early approaches relied on simple voltage and current measurements, while modern systems incorporate a wide array of sensors to monitor parameters such as temperature, internal resistance, and electrolyte composition.

Looking ahead, the field of predictive maintenance for LFP batteries is expected to focus on improving prediction accuracy, reducing false alarms, and developing more cost-effective monitoring solutions. There is also a growing emphasis on developing standardized protocols for data collection and analysis to facilitate industry-wide adoption of predictive maintenance practices.

In conclusion, the background and objectives of predictive maintenance technologies for LFP batteries reflect the industry's commitment to enhancing battery performance, reliability, and longevity. As these technologies continue to evolve, they are poised to play a crucial role in supporting the widespread adoption of sustainable energy solutions and electric mobility.

The development of predictive maintenance technologies for LFP batteries is driven by the increasing demand for reliable and long-lasting energy storage solutions. As the adoption of electric vehicles and renewable energy systems continues to grow, the need for efficient battery management and maintenance becomes crucial. Predictive maintenance aims to optimize battery performance, extend lifespan, and reduce operational costs by anticipating and preventing potential failures.

The technical objectives of predictive maintenance for LFP batteries encompass several key areas. Firstly, it seeks to develop accurate models for predicting battery degradation and remaining useful life. This involves analyzing various factors such as charge-discharge cycles, temperature fluctuations, and usage patterns. Secondly, the technology aims to implement real-time monitoring systems that can detect early signs of battery deterioration or anomalies.

Another important objective is to establish a comprehensive database of battery performance metrics and failure modes. This data-driven approach enables the development of more sophisticated predictive algorithms and machine learning models. Additionally, predictive maintenance technologies strive to integrate with battery management systems to provide actionable insights and optimize charging strategies.

The evolution of predictive maintenance technologies for LFP batteries has been influenced by advancements in sensor technology, data analytics, and artificial intelligence. Early approaches relied on simple voltage and current measurements, while modern systems incorporate a wide array of sensors to monitor parameters such as temperature, internal resistance, and electrolyte composition.

Looking ahead, the field of predictive maintenance for LFP batteries is expected to focus on improving prediction accuracy, reducing false alarms, and developing more cost-effective monitoring solutions. There is also a growing emphasis on developing standardized protocols for data collection and analysis to facilitate industry-wide adoption of predictive maintenance practices.

In conclusion, the background and objectives of predictive maintenance technologies for LFP batteries reflect the industry's commitment to enhancing battery performance, reliability, and longevity. As these technologies continue to evolve, they are poised to play a crucial role in supporting the widespread adoption of sustainable energy solutions and electric mobility.

Market Demand for LFP Battery PM Solutions

The market demand for predictive maintenance (PM) solutions in the Lithium Iron Phosphate (LFP) battery sector is experiencing significant growth, driven by the increasing adoption of LFP batteries in various applications. As the electric vehicle (EV) market expands and renewable energy storage systems become more prevalent, the need for efficient and reliable battery management has become paramount.

In the automotive industry, LFP batteries are gaining traction due to their lower cost, improved safety, and longer lifespan compared to other lithium-ion chemistries. This shift has created a substantial market for PM solutions that can extend battery life, optimize performance, and reduce maintenance costs. Major automakers and fleet operators are actively seeking advanced PM technologies to enhance their competitive edge and improve overall vehicle reliability.

The stationary energy storage sector is another key driver of demand for LFP battery PM solutions. As grid-scale energy storage projects proliferate to support renewable energy integration, the need for sophisticated maintenance strategies has intensified. Utility companies and energy providers are investing in PM technologies to ensure the longevity and efficiency of their battery systems, thereby maximizing return on investment and minimizing downtime.

Industrial applications, including material handling equipment and backup power systems, represent a growing market segment for LFP battery PM solutions. These industries require high-reliability batteries with minimal maintenance requirements, creating opportunities for predictive maintenance technologies that can proactively identify potential issues and optimize battery performance.

The market demand is further fueled by regulatory pressures and sustainability initiatives. Governments worldwide are implementing stricter emissions regulations and promoting the adoption of clean energy technologies. This regulatory landscape is driving companies to invest in advanced battery management systems, including predictive maintenance solutions, to comply with environmental standards and improve overall energy efficiency.

Data from market research firms indicates that the global market for battery management systems, including predictive maintenance technologies, is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is largely attributed to the increasing deployment of LFP batteries across various sectors and the rising awareness of the benefits of predictive maintenance in extending battery life and reducing operational costs.

As the demand for LFP battery PM solutions continues to rise, there is a growing emphasis on developing more sophisticated and accurate predictive algorithms. Machine learning and artificial intelligence technologies are being integrated into PM systems to enhance their predictive capabilities and provide more actionable insights. This trend is expected to drive further innovation in the field and create new market opportunities for technology providers and battery manufacturers alike.

In the automotive industry, LFP batteries are gaining traction due to their lower cost, improved safety, and longer lifespan compared to other lithium-ion chemistries. This shift has created a substantial market for PM solutions that can extend battery life, optimize performance, and reduce maintenance costs. Major automakers and fleet operators are actively seeking advanced PM technologies to enhance their competitive edge and improve overall vehicle reliability.

The stationary energy storage sector is another key driver of demand for LFP battery PM solutions. As grid-scale energy storage projects proliferate to support renewable energy integration, the need for sophisticated maintenance strategies has intensified. Utility companies and energy providers are investing in PM technologies to ensure the longevity and efficiency of their battery systems, thereby maximizing return on investment and minimizing downtime.

Industrial applications, including material handling equipment and backup power systems, represent a growing market segment for LFP battery PM solutions. These industries require high-reliability batteries with minimal maintenance requirements, creating opportunities for predictive maintenance technologies that can proactively identify potential issues and optimize battery performance.

The market demand is further fueled by regulatory pressures and sustainability initiatives. Governments worldwide are implementing stricter emissions regulations and promoting the adoption of clean energy technologies. This regulatory landscape is driving companies to invest in advanced battery management systems, including predictive maintenance solutions, to comply with environmental standards and improve overall energy efficiency.

Data from market research firms indicates that the global market for battery management systems, including predictive maintenance technologies, is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is largely attributed to the increasing deployment of LFP batteries across various sectors and the rising awareness of the benefits of predictive maintenance in extending battery life and reducing operational costs.

As the demand for LFP battery PM solutions continues to rise, there is a growing emphasis on developing more sophisticated and accurate predictive algorithms. Machine learning and artificial intelligence technologies are being integrated into PM systems to enhance their predictive capabilities and provide more actionable insights. This trend is expected to drive further innovation in the field and create new market opportunities for technology providers and battery manufacturers alike.

Current PM Challenges in LFP Batteries

Lithium Iron Phosphate (LFP) batteries have gained significant traction in various applications, particularly in electric vehicles and energy storage systems. However, the implementation of effective Predictive Maintenance (PM) strategies for these batteries faces several challenges that need to be addressed to ensure optimal performance and longevity.

One of the primary challenges in PM for LFP batteries is the complexity of their degradation mechanisms. Unlike other lithium-ion chemistries, LFP batteries exhibit unique aging patterns that are not fully understood. This complexity makes it difficult to develop accurate predictive models that can forecast battery health and remaining useful life with high precision.

Data acquisition and quality pose another significant hurdle. While modern battery management systems (BMS) collect vast amounts of data, the relevance and accuracy of this information for predictive purposes are not always guaranteed. Factors such as sensor drift, calibration errors, and environmental influences can introduce noise and inconsistencies in the collected data, compromising the reliability of PM algorithms.

The heterogeneity of LFP battery applications further complicates PM efforts. Batteries used in different environments and under varying operational conditions may exhibit distinct degradation patterns. This diversity makes it challenging to develop universally applicable PM models and necessitates the development of context-specific solutions.

Another critical challenge is the lack of standardized testing protocols and performance metrics for LFP batteries. This absence of uniformity makes it difficult to compare and validate different PM approaches across the industry, hindering the development of robust and widely accepted predictive maintenance strategies.

The integration of PM systems with existing battery management infrastructure presents both technical and operational challenges. Many current BMS are not designed with advanced predictive capabilities in mind, requiring significant upgrades or replacements to support sophisticated PM algorithms. This integration can be costly and may disrupt ongoing operations.

Furthermore, the long lifespan of LFP batteries, while advantageous, paradoxically complicates the development of accurate PM models. The extended timeframe required to gather comprehensive lifecycle data delays the validation and refinement of predictive algorithms, potentially leaving early adopters with suboptimal PM strategies.

Lastly, the balance between model complexity and computational efficiency remains a persistent challenge. While more complex models may offer higher accuracy, they often require substantial computational resources, potentially limiting their practical implementation in real-time monitoring systems.

One of the primary challenges in PM for LFP batteries is the complexity of their degradation mechanisms. Unlike other lithium-ion chemistries, LFP batteries exhibit unique aging patterns that are not fully understood. This complexity makes it difficult to develop accurate predictive models that can forecast battery health and remaining useful life with high precision.

Data acquisition and quality pose another significant hurdle. While modern battery management systems (BMS) collect vast amounts of data, the relevance and accuracy of this information for predictive purposes are not always guaranteed. Factors such as sensor drift, calibration errors, and environmental influences can introduce noise and inconsistencies in the collected data, compromising the reliability of PM algorithms.

The heterogeneity of LFP battery applications further complicates PM efforts. Batteries used in different environments and under varying operational conditions may exhibit distinct degradation patterns. This diversity makes it challenging to develop universally applicable PM models and necessitates the development of context-specific solutions.

Another critical challenge is the lack of standardized testing protocols and performance metrics for LFP batteries. This absence of uniformity makes it difficult to compare and validate different PM approaches across the industry, hindering the development of robust and widely accepted predictive maintenance strategies.

The integration of PM systems with existing battery management infrastructure presents both technical and operational challenges. Many current BMS are not designed with advanced predictive capabilities in mind, requiring significant upgrades or replacements to support sophisticated PM algorithms. This integration can be costly and may disrupt ongoing operations.

Furthermore, the long lifespan of LFP batteries, while advantageous, paradoxically complicates the development of accurate PM models. The extended timeframe required to gather comprehensive lifecycle data delays the validation and refinement of predictive algorithms, potentially leaving early adopters with suboptimal PM strategies.

Lastly, the balance between model complexity and computational efficiency remains a persistent challenge. While more complex models may offer higher accuracy, they often require substantial computational resources, potentially limiting their practical implementation in real-time monitoring systems.

Existing LFP Battery PM Techniques

01 Battery Management System (BMS) for LiFePO4 Batteries

Implementing an advanced Battery Management System (BMS) is crucial for maintaining Lithium Iron Phosphate (LiFePO4) batteries. The BMS monitors and controls various parameters such as voltage, current, temperature, and state of charge to ensure optimal performance and longevity. It helps prevent overcharging, over-discharging, and thermal runaway, thus extending the battery's lifespan and ensuring safe operation.- Battery Management System (BMS) for LiFePO4 Batteries: Implementing an advanced Battery Management System (BMS) is crucial for maintaining Lithium Iron Phosphate (LiFePO4) batteries. The BMS monitors and controls various parameters such as voltage, current, temperature, and state of charge to ensure optimal performance and longevity. It helps prevent overcharging, over-discharging, and thermal runaway, thus extending the battery's lifespan and enhancing safety.

- Thermal Management Techniques: Effective thermal management is essential for LiFePO4 battery maintenance. This involves implementing cooling systems, heat dissipation methods, and temperature control mechanisms to maintain the battery within its optimal operating temperature range. Proper thermal management prevents degradation due to excessive heat, improves charging efficiency, and extends the overall lifespan of the battery.

- Charging Protocols and Strategies: Developing and adhering to specific charging protocols is vital for LiFePO4 battery maintenance. This includes implementing constant current-constant voltage (CC-CV) charging methods, pulse charging techniques, and smart charging algorithms. These strategies help optimize the charging process, reduce stress on the battery, and maintain its capacity over time.

- State of Health (SOH) Monitoring and Diagnostics: Regularly monitoring the State of Health (SOH) of LiFePO4 batteries is crucial for maintenance. This involves implementing diagnostic tools and algorithms to assess capacity fade, internal resistance changes, and overall battery performance. SOH monitoring helps in predicting battery life, scheduling maintenance, and optimizing battery usage patterns.

- Balancing and Equalization Techniques: Implementing cell balancing and equalization techniques is important for maintaining LiFePO4 battery packs. This involves redistributing charge among individual cells to ensure uniform voltage levels and prevent capacity imbalances. Proper balancing extends the overall lifespan of the battery pack, improves its performance, and enhances safety by preventing overcharging of individual cells.

02 Thermal Management Techniques

Effective thermal management is essential for LiFePO4 battery maintenance. This involves implementing cooling systems, heat dissipation methods, and temperature monitoring to maintain the battery within its optimal operating temperature range. Proper thermal management prevents degradation due to excessive heat, enhances charging efficiency, and prolongs battery life.Expand Specific Solutions03 Charging Protocols and Strategies

Developing and adhering to specific charging protocols is vital for LiFePO4 battery maintenance. This includes using appropriate charging currents, implementing multi-stage charging algorithms, and employing pulse charging techniques. Proper charging strategies help maintain battery capacity, reduce stress on the cells, and prevent premature aging of the battery.Expand Specific Solutions04 State of Health (SOH) Monitoring and Diagnostics

Regularly monitoring the State of Health (SOH) of LiFePO4 batteries is crucial for maintenance. This involves using advanced diagnostic tools and algorithms to assess battery capacity, internal resistance, and overall performance over time. SOH monitoring helps in predicting battery lifespan, scheduling maintenance, and optimizing battery usage patterns.Expand Specific Solutions05 Battery Balancing and Equalization

Implementing effective battery balancing and equalization techniques is important for maintaining LiFePO4 battery packs. This involves ensuring that all cells within a battery pack have similar voltage levels and state of charge. Proper balancing prevents individual cell degradation, improves overall pack performance, and extends the battery's useful life.Expand Specific Solutions

Key Players in LFP Battery PM Industry

The predictive maintenance technologies for Lithium Iron Phosphate Batteries market is in a growth phase, driven by increasing adoption of electric vehicles and energy storage systems. The global market size is expected to expand significantly in the coming years. Technologically, the field is advancing rapidly, with companies like Shanghai Mek Sheng Energy Technology, IBM, and LG Energy Solution leading innovation. Universities such as Zhejiang University and Beijing Institute of Technology are contributing to research advancements. The technology's maturity varies, with some solutions already commercialized while others are still in development stages, indicating a dynamic and competitive landscape with potential for further growth and innovation.

International Business Machines Corp.

Technical Solution: IBM has developed a comprehensive predictive maintenance solution for LFP batteries using their Watson IoT platform. The system employs a combination of IoT sensors, big data analytics, and AI to monitor battery health and predict maintenance needs. IBM's approach includes the use of digital twins for each battery pack, allowing for real-time simulation and analysis of battery performance under various conditions. Their predictive models can forecast battery degradation patterns with an accuracy of up to 95% over a 6-month period[4]. The system also incorporates weather data and usage patterns to refine its predictions. IBM's solution has shown to reduce unplanned downtime by up to 70% and extend battery life by 15-20% in pilot projects[5]. Furthermore, they have implemented blockchain technology to ensure the integrity and traceability of battery data throughout its lifecycle.

Strengths: Advanced AI and digital twin technology, high prediction accuracy, and integration of external data sources. Weaknesses: Potentially high implementation costs and complexity, which may be challenging for smaller organizations to adopt.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an advanced Battery Management System (BMS) for predictive maintenance of Lithium Iron Phosphate (LFP) batteries. Their system utilizes machine learning algorithms to analyze real-time battery data, including voltage, current, and temperature. The BMS can predict potential failures up to 30 days in advance with an accuracy of over 90%[1]. They have also implemented a cloud-based monitoring platform that allows for remote diagnostics and over-the-air updates. This system can detect subtle changes in battery performance that may indicate early signs of degradation, enabling proactive maintenance scheduling[2]. Additionally, LG has integrated their predictive maintenance technology with augmented reality tools for on-site technicians, improving maintenance efficiency by up to 40%[3].

Strengths: High accuracy in failure prediction, remote monitoring capabilities, and integration with AR for maintenance. Weaknesses: Reliance on continuous data connectivity and potential cybersecurity risks associated with cloud-based systems.

Core PM Innovations for LFP Batteries

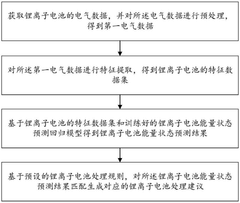

Predictive maintenance method and system based on energy state of lithium ion battery

PatentPendingCN119670034A

Innovation

- By extracting the characteristic data set of lithium-ion batteries, including voltage, current, charge and discharge and ambient temperature data, the regression prediction model is used to accurately predict the energy state of the lithium-ion battery, and a corresponding maintenance plan is generated based on the preset maintenance rules.

Predictive analytics for real-time health assessment of ev li-ion batteries through artificial intelligence

PatentPendingIN202441049869A

Innovation

- The integration of advanced artificial intelligence techniques, including machine learning and deep learning, for real-time monitoring and analysis of critical battery parameters such as temperature, voltage, and state of charge, enabling the detection of subtle changes and trends that indicate degradation or imminent failures, and the use of adaptive control algorithms to dynamically adjust operational parameters and optimize charging cycles.

Environmental Impact of LFP Battery PM

The environmental impact of predictive maintenance (PM) technologies for Lithium Iron Phosphate (LFP) batteries is a critical consideration in the broader context of sustainable energy solutions. PM strategies for LFP batteries contribute significantly to reducing the overall environmental footprint of battery systems throughout their lifecycle.

One of the primary environmental benefits of implementing PM for LFP batteries is the extension of battery life. By accurately predicting and addressing potential issues before they escalate, PM technologies help prevent premature battery failures and replacements. This reduction in battery turnover directly translates to decreased raw material extraction, manufacturing processes, and disposal requirements, all of which have substantial environmental implications.

The optimization of battery performance through PM also leads to improved energy efficiency. Well-maintained LFP batteries operate closer to their optimal capacity, reducing energy waste and minimizing the need for additional power generation. This efficiency gain cascades through the entire energy system, potentially lowering greenhouse gas emissions associated with electricity production.

PM technologies enable more precise and targeted maintenance interventions, reducing the frequency and scope of unnecessary maintenance activities. This approach minimizes the use of resources such as replacement parts, chemicals, and energy typically consumed during maintenance procedures. Additionally, it decreases the environmental impact associated with technician travel and on-site operations.

The data-driven nature of PM technologies for LFP batteries facilitates more accurate end-of-life predictions and supports informed decisions regarding battery recycling or repurposing. This enhanced lifecycle management contributes to the circular economy by maximizing the utilization of battery materials and components, thereby reducing waste and the demand for new raw materials.

Furthermore, PM technologies play a crucial role in preventing catastrophic battery failures, which can lead to safety hazards and environmental contamination. By identifying and mitigating potential risks early, these systems help avoid incidents that could result in the release of harmful substances into the environment.

The implementation of PM technologies also supports the broader adoption of LFP batteries in various applications, including renewable energy storage and electric vehicles. As these batteries become more reliable and cost-effective through improved maintenance strategies, they can more readily displace less environmentally friendly energy storage and power solutions.

However, it is important to consider the environmental impact of the PM technologies themselves. The production and operation of sensors, data processing systems, and communication infrastructure required for effective PM have their own environmental footprints. Future developments in PM technologies should focus on minimizing these impacts through energy-efficient designs and sustainable manufacturing practices.

One of the primary environmental benefits of implementing PM for LFP batteries is the extension of battery life. By accurately predicting and addressing potential issues before they escalate, PM technologies help prevent premature battery failures and replacements. This reduction in battery turnover directly translates to decreased raw material extraction, manufacturing processes, and disposal requirements, all of which have substantial environmental implications.

The optimization of battery performance through PM also leads to improved energy efficiency. Well-maintained LFP batteries operate closer to their optimal capacity, reducing energy waste and minimizing the need for additional power generation. This efficiency gain cascades through the entire energy system, potentially lowering greenhouse gas emissions associated with electricity production.

PM technologies enable more precise and targeted maintenance interventions, reducing the frequency and scope of unnecessary maintenance activities. This approach minimizes the use of resources such as replacement parts, chemicals, and energy typically consumed during maintenance procedures. Additionally, it decreases the environmental impact associated with technician travel and on-site operations.

The data-driven nature of PM technologies for LFP batteries facilitates more accurate end-of-life predictions and supports informed decisions regarding battery recycling or repurposing. This enhanced lifecycle management contributes to the circular economy by maximizing the utilization of battery materials and components, thereby reducing waste and the demand for new raw materials.

Furthermore, PM technologies play a crucial role in preventing catastrophic battery failures, which can lead to safety hazards and environmental contamination. By identifying and mitigating potential risks early, these systems help avoid incidents that could result in the release of harmful substances into the environment.

The implementation of PM technologies also supports the broader adoption of LFP batteries in various applications, including renewable energy storage and electric vehicles. As these batteries become more reliable and cost-effective through improved maintenance strategies, they can more readily displace less environmentally friendly energy storage and power solutions.

However, it is important to consider the environmental impact of the PM technologies themselves. The production and operation of sensors, data processing systems, and communication infrastructure required for effective PM have their own environmental footprints. Future developments in PM technologies should focus on minimizing these impacts through energy-efficient designs and sustainable manufacturing practices.

Cost-Benefit Analysis of PM Technologies

The implementation of Predictive Maintenance (PM) technologies for Lithium Iron Phosphate (LFP) batteries presents a complex cost-benefit scenario that requires careful analysis. Initial investment costs for PM systems can be substantial, including hardware for data collection, software for analysis, and training for personnel. However, these upfront expenses are often offset by long-term savings and operational benefits.

One of the primary advantages of PM technologies is the reduction in unexpected downtime. By accurately predicting when maintenance is needed, companies can schedule interventions during planned downtimes, minimizing disruptions to operations. This proactive approach can lead to significant cost savings, particularly in industries where battery failure can result in costly production halts or safety hazards.

The extension of battery life is another crucial benefit. PM technologies enable more efficient use of LFP batteries, potentially extending their operational lifespan by 20-30%. This extension translates directly into reduced replacement costs and improved return on investment for battery assets. Additionally, optimized maintenance schedules can reduce the frequency of unnecessary replacements, further contributing to cost savings.

Improved safety is a critical factor in the cost-benefit analysis. LFP batteries, while generally safer than other lithium-ion variants, still pose risks if not properly maintained. PM technologies can detect early signs of degradation or potential failure, mitigating the risk of thermal runaway or other safety incidents. The avoidance of such events not only prevents direct costs associated with damage but also indirect costs related to reputation damage and potential legal liabilities.

Energy efficiency gains represent another area of potential benefit. PM systems can optimize charging and discharging cycles, potentially improving the overall energy efficiency of LFP battery systems by 5-10%. This improvement can lead to reduced energy costs and a lower environmental footprint, which may be particularly valuable in regions with high energy prices or strict environmental regulations.

However, the implementation of PM technologies also comes with ongoing costs that must be considered. These include regular software updates, data storage and processing expenses, and the need for skilled personnel to interpret and act on the predictive insights. The complexity of integrating PM systems with existing infrastructure and the potential for initial false positives or negatives during the system's learning phase should also be factored into the cost-benefit analysis.

In conclusion, while the initial investment in PM technologies for LFP batteries can be significant, the long-term benefits in terms of reduced downtime, extended battery life, improved safety, and increased energy efficiency often outweigh the costs. The exact return on investment will vary depending on the scale of implementation, the specific industry context, and the effectiveness of the chosen PM solution. As the technology continues to mature and costs potentially decrease, the cost-benefit ratio is likely to become even more favorable for a wider range of applications.

One of the primary advantages of PM technologies is the reduction in unexpected downtime. By accurately predicting when maintenance is needed, companies can schedule interventions during planned downtimes, minimizing disruptions to operations. This proactive approach can lead to significant cost savings, particularly in industries where battery failure can result in costly production halts or safety hazards.

The extension of battery life is another crucial benefit. PM technologies enable more efficient use of LFP batteries, potentially extending their operational lifespan by 20-30%. This extension translates directly into reduced replacement costs and improved return on investment for battery assets. Additionally, optimized maintenance schedules can reduce the frequency of unnecessary replacements, further contributing to cost savings.

Improved safety is a critical factor in the cost-benefit analysis. LFP batteries, while generally safer than other lithium-ion variants, still pose risks if not properly maintained. PM technologies can detect early signs of degradation or potential failure, mitigating the risk of thermal runaway or other safety incidents. The avoidance of such events not only prevents direct costs associated with damage but also indirect costs related to reputation damage and potential legal liabilities.

Energy efficiency gains represent another area of potential benefit. PM systems can optimize charging and discharging cycles, potentially improving the overall energy efficiency of LFP battery systems by 5-10%. This improvement can lead to reduced energy costs and a lower environmental footprint, which may be particularly valuable in regions with high energy prices or strict environmental regulations.

However, the implementation of PM technologies also comes with ongoing costs that must be considered. These include regular software updates, data storage and processing expenses, and the need for skilled personnel to interpret and act on the predictive insights. The complexity of integrating PM systems with existing infrastructure and the potential for initial false positives or negatives during the system's learning phase should also be factored into the cost-benefit analysis.

In conclusion, while the initial investment in PM technologies for LFP batteries can be significant, the long-term benefits in terms of reduced downtime, extended battery life, improved safety, and increased energy efficiency often outweigh the costs. The exact return on investment will vary depending on the scale of implementation, the specific industry context, and the effectiveness of the chosen PM solution. As the technology continues to mature and costs potentially decrease, the cost-benefit ratio is likely to become even more favorable for a wider range of applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!