Quantifying Neodymium Magnet Strength in Compaction Scenarios

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Compaction Technology Background and Objectives

Neodymium magnets, discovered in the 1980s by General Motors and Sumitomo Special Metals, represent a significant advancement in permanent magnet technology. These rare-earth magnets, composed primarily of neodymium, iron, and boron (NdFeB), have revolutionized numerous industries due to their exceptional magnetic properties. The evolution of these magnets has been marked by continuous improvements in manufacturing processes, particularly in compaction techniques that directly influence their strength and performance characteristics.

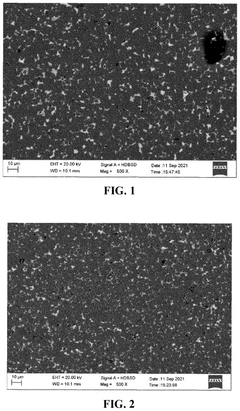

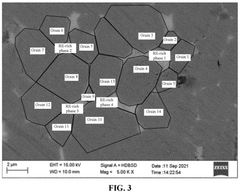

The compaction process, a critical stage in neodymium magnet production, involves pressing powdered magnetic materials under specific pressure and temperature conditions to achieve desired density and alignment of magnetic domains. Historical developments in this field have progressed from basic press-and-sinter methods to more sophisticated techniques including hot deformation, die-upset forging, and pulse magnetic field alignment during compaction.

Recent technological trends indicate a growing focus on precision control of compaction parameters to optimize magnet strength while minimizing material usage. This trend is driven by both economic factors—neodymium's fluctuating supply chain challenges—and performance requirements in emerging applications such as electric vehicles, wind turbines, and advanced medical devices.

The quantification of magnet strength under various compaction scenarios has become increasingly important as industries demand magnets with specific performance characteristics tailored to their applications. Traditional methods of strength measurement often provide incomplete data regarding how compaction variables affect final magnetic properties, creating a technological gap that requires addressing.

The primary objective of this technical research is to develop comprehensive methodologies for accurately quantifying neodymium magnet strength as a function of compaction parameters. This includes establishing correlations between compaction pressure, temperature, duration, and resulting magnetic properties such as coercivity, remanence, and maximum energy product.

Secondary objectives include identifying optimal compaction scenarios for specific application requirements, developing predictive models for magnet performance based on compaction variables, and exploring novel compaction techniques that may enhance magnetic properties while reducing rare earth material dependency.

The significance of this research extends beyond immediate manufacturing improvements. As global demand for high-performance magnets continues to grow, particularly in green energy and transportation sectors, understanding the fundamental relationships between compaction processes and magnetic strength will enable more efficient material utilization and potentially open pathways to new magnet formulations with enhanced properties.

This investigation aims to bridge the gap between theoretical magnetic models and practical manufacturing processes, providing actionable insights for both current production optimization and future innovation in neodymium magnet technology.

The compaction process, a critical stage in neodymium magnet production, involves pressing powdered magnetic materials under specific pressure and temperature conditions to achieve desired density and alignment of magnetic domains. Historical developments in this field have progressed from basic press-and-sinter methods to more sophisticated techniques including hot deformation, die-upset forging, and pulse magnetic field alignment during compaction.

Recent technological trends indicate a growing focus on precision control of compaction parameters to optimize magnet strength while minimizing material usage. This trend is driven by both economic factors—neodymium's fluctuating supply chain challenges—and performance requirements in emerging applications such as electric vehicles, wind turbines, and advanced medical devices.

The quantification of magnet strength under various compaction scenarios has become increasingly important as industries demand magnets with specific performance characteristics tailored to their applications. Traditional methods of strength measurement often provide incomplete data regarding how compaction variables affect final magnetic properties, creating a technological gap that requires addressing.

The primary objective of this technical research is to develop comprehensive methodologies for accurately quantifying neodymium magnet strength as a function of compaction parameters. This includes establishing correlations between compaction pressure, temperature, duration, and resulting magnetic properties such as coercivity, remanence, and maximum energy product.

Secondary objectives include identifying optimal compaction scenarios for specific application requirements, developing predictive models for magnet performance based on compaction variables, and exploring novel compaction techniques that may enhance magnetic properties while reducing rare earth material dependency.

The significance of this research extends beyond immediate manufacturing improvements. As global demand for high-performance magnets continues to grow, particularly in green energy and transportation sectors, understanding the fundamental relationships between compaction processes and magnetic strength will enable more efficient material utilization and potentially open pathways to new magnet formulations with enhanced properties.

This investigation aims to bridge the gap between theoretical magnetic models and practical manufacturing processes, providing actionable insights for both current production optimization and future innovation in neodymium magnet technology.

Market Analysis for High-Performance Magnetic Materials

The global market for high-performance magnetic materials, particularly neodymium magnets, has experienced substantial growth over the past decade, driven by increasing applications in renewable energy, automotive, electronics, and medical devices. The market value for rare earth permanent magnets reached approximately $19.5 billion in 2022, with neodymium magnets accounting for over 65% of this value. Industry analysts project a compound annual growth rate (CAGR) of 8.3% through 2030, potentially reaching $38.5 billion.

Demand for neodymium magnets in compaction scenarios is particularly strong in the automotive sector, where these materials are essential components in electric vehicle motors, power steering systems, and sensors. The global transition toward electric vehicles has created unprecedented demand, with each EV requiring approximately 1-2 kg of neodymium magnets, compared to about 0.1 kg in conventional vehicles. This represents a tenfold increase in per-vehicle consumption.

The renewable energy sector constitutes another significant market driver, particularly wind turbine generators, where direct-drive systems utilizing neodymium magnets offer higher efficiency and reliability. A single large wind turbine can contain up to 600 kg of neodymium magnets. With global wind energy capacity expanding at 10-12% annually, this sector represents a sustained growth opportunity for high-performance magnetic materials.

Regional analysis reveals China's dominance in both production and consumption, controlling approximately 85% of global rare earth processing capacity. However, concerns about supply chain resilience have prompted significant investments in alternative supply chains in North America, Europe, and Australia. The European Union's Critical Raw Materials Act and the United States' CHIPS and Science Act both include provisions to develop domestic capabilities for critical materials including neodymium.

Price volatility remains a significant market challenge, with neodymium prices fluctuating by over 40% in recent years due to export restrictions, environmental regulations, and geopolitical tensions. This volatility has accelerated research into methods for quantifying and optimizing magnet performance in various applications, particularly under compaction conditions where traditional measurement techniques may be insufficient.

Customer segments increasingly demand precise specifications for magnetic performance under varied operational conditions. Industries requiring high reliability, such as aerospace, medical devices, and advanced manufacturing, are willing to pay premium prices for magnets with well-characterized performance under compaction and stress scenarios. This trend has created a specialized market segment for testing equipment and methodologies that can accurately quantify neodymium magnet strength in these conditions.

Demand for neodymium magnets in compaction scenarios is particularly strong in the automotive sector, where these materials are essential components in electric vehicle motors, power steering systems, and sensors. The global transition toward electric vehicles has created unprecedented demand, with each EV requiring approximately 1-2 kg of neodymium magnets, compared to about 0.1 kg in conventional vehicles. This represents a tenfold increase in per-vehicle consumption.

The renewable energy sector constitutes another significant market driver, particularly wind turbine generators, where direct-drive systems utilizing neodymium magnets offer higher efficiency and reliability. A single large wind turbine can contain up to 600 kg of neodymium magnets. With global wind energy capacity expanding at 10-12% annually, this sector represents a sustained growth opportunity for high-performance magnetic materials.

Regional analysis reveals China's dominance in both production and consumption, controlling approximately 85% of global rare earth processing capacity. However, concerns about supply chain resilience have prompted significant investments in alternative supply chains in North America, Europe, and Australia. The European Union's Critical Raw Materials Act and the United States' CHIPS and Science Act both include provisions to develop domestic capabilities for critical materials including neodymium.

Price volatility remains a significant market challenge, with neodymium prices fluctuating by over 40% in recent years due to export restrictions, environmental regulations, and geopolitical tensions. This volatility has accelerated research into methods for quantifying and optimizing magnet performance in various applications, particularly under compaction conditions where traditional measurement techniques may be insufficient.

Customer segments increasingly demand precise specifications for magnetic performance under varied operational conditions. Industries requiring high reliability, such as aerospace, medical devices, and advanced manufacturing, are willing to pay premium prices for magnets with well-characterized performance under compaction and stress scenarios. This trend has created a specialized market segment for testing equipment and methodologies that can accurately quantify neodymium magnet strength in these conditions.

Current Challenges in Quantifying Magnet Strength Under Compaction

The quantification of neodymium magnet strength under compaction conditions presents several significant technical challenges that have yet to be fully resolved by current methodologies. Traditional magnetic strength measurement techniques such as Helmholtz coils, vibrating sample magnetometers (VSM), and Hall effect sensors are primarily designed for stable, non-compressed environments, making them inadequate for real-time measurement during compaction processes.

One major challenge is the dynamic nature of magnetic properties during compaction. As neodymium magnets undergo pressure, their domain structures experience realignment, potentially causing fluctuations in magnetic field strength and orientation. These changes occur at microscopic levels and at rapid rates, making accurate measurement extremely difficult with conventional equipment.

The physical constraints of compaction equipment further complicate measurement efforts. The enclosed nature of most compaction chambers limits access for measurement devices, while the presence of metallic components in these chambers can distort magnetic field readings. This creates a significant barrier to obtaining accurate, real-time data during the actual compaction process.

Temperature variations during compaction pose another substantial challenge. Neodymium magnets are highly sensitive to temperature changes, with their magnetic properties degrading significantly as temperatures approach their Curie point (approximately 320-340°C). Compaction processes often generate heat through friction, potentially altering magnetic properties during measurement and introducing additional variables that must be accounted for.

The non-uniform nature of pressure distribution during compaction creates inconsistent deformation patterns across the magnet volume. This non-uniformity results in varying magnetic field strengths throughout the material, making it difficult to obtain representative measurements of overall magnet performance.

Current sensor technologies also face limitations in high-pressure environments. Many magnetic sensors suffer from pressure-induced drift or damage when subjected to compaction forces, compromising measurement accuracy. Additionally, the spatial resolution of existing sensors is often insufficient to capture the detailed magnetic field variations that occur during compaction.

Data interpretation presents yet another challenge. The correlation between applied pressure, resulting deformation, and changes in magnetic properties involves complex multiphysics relationships that are not fully understood. Current mathematical models struggle to accurately predict these relationships, particularly for newer neodymium magnet compositions with specialized additives.

Standardization issues further complicate the field, as there is currently no universally accepted methodology for quantifying magnet strength under dynamic compaction conditions. This lack of standardization makes it difficult to compare results across different research efforts and manufacturing processes.

One major challenge is the dynamic nature of magnetic properties during compaction. As neodymium magnets undergo pressure, their domain structures experience realignment, potentially causing fluctuations in magnetic field strength and orientation. These changes occur at microscopic levels and at rapid rates, making accurate measurement extremely difficult with conventional equipment.

The physical constraints of compaction equipment further complicate measurement efforts. The enclosed nature of most compaction chambers limits access for measurement devices, while the presence of metallic components in these chambers can distort magnetic field readings. This creates a significant barrier to obtaining accurate, real-time data during the actual compaction process.

Temperature variations during compaction pose another substantial challenge. Neodymium magnets are highly sensitive to temperature changes, with their magnetic properties degrading significantly as temperatures approach their Curie point (approximately 320-340°C). Compaction processes often generate heat through friction, potentially altering magnetic properties during measurement and introducing additional variables that must be accounted for.

The non-uniform nature of pressure distribution during compaction creates inconsistent deformation patterns across the magnet volume. This non-uniformity results in varying magnetic field strengths throughout the material, making it difficult to obtain representative measurements of overall magnet performance.

Current sensor technologies also face limitations in high-pressure environments. Many magnetic sensors suffer from pressure-induced drift or damage when subjected to compaction forces, compromising measurement accuracy. Additionally, the spatial resolution of existing sensors is often insufficient to capture the detailed magnetic field variations that occur during compaction.

Data interpretation presents yet another challenge. The correlation between applied pressure, resulting deformation, and changes in magnetic properties involves complex multiphysics relationships that are not fully understood. Current mathematical models struggle to accurately predict these relationships, particularly for newer neodymium magnet compositions with specialized additives.

Standardization issues further complicate the field, as there is currently no universally accepted methodology for quantifying magnet strength under dynamic compaction conditions. This lack of standardization makes it difficult to compare results across different research efforts and manufacturing processes.

Existing Methods for Neodymium Magnet Strength Quantification

01 Composition and manufacturing methods for high-strength neodymium magnets

Various compositions and manufacturing processes can significantly enhance the strength of neodymium magnets. These include specific alloy formulations with rare earth elements, precise heat treatment protocols, and advanced sintering techniques. The manufacturing methods often involve controlling grain structure and alignment to maximize magnetic properties, resulting in magnets with superior field strength and resistance to demagnetization.- Composition and manufacturing methods to enhance magnetic strength: Various compositions and manufacturing processes can significantly enhance the magnetic strength of neodymium magnets. These include specific alloy formulations with rare earth elements, precise heat treatment protocols, and advanced sintering techniques. The manufacturing methods focus on optimizing crystal structure alignment and increasing coercivity, resulting in magnets with superior magnetic field strength and performance characteristics.

- Structural designs for maximizing magnetic force: Innovative structural designs can maximize the effective strength of neodymium magnets in various applications. These designs include specific geometric configurations, strategic placement of multiple magnets in arrays, and the use of magnetic flux concentrators. By optimizing the shape, size, and arrangement of neodymium magnets, the effective magnetic force can be significantly increased for specific applications while minimizing material usage.

- Protective coatings and treatments for durability: Various protective coatings and surface treatments can be applied to neodymium magnets to maintain their strength over time by preventing corrosion and degradation. These include nickel-copper-nickel plating, epoxy coatings, and specialized surface passivation techniques. These protective measures ensure that the magnets maintain their magnetic strength in challenging environments, including exposure to moisture, chemicals, and varying temperatures.

- Testing and measurement methods for magnetic strength: Specialized testing and measurement techniques are essential for accurately determining the strength of neodymium magnets. These include Helmholtz coils, fluxmeters, pull-force testing, and advanced magnetic field mapping. These methods allow for precise characterization of magnetic properties such as remanence, coercivity, and maximum energy product, enabling quality control in manufacturing and appropriate selection for specific applications.

- Application-specific strength optimization: Neodymium magnets can be optimized for specific applications by tailoring their strength characteristics to meet particular requirements. This includes customizing the magnetic field distribution for motors and generators, designing gradient magnetic fields for medical devices, and creating specialized magnetic circuits for consumer electronics. By focusing on application-specific performance parameters, the effective strength of neodymium magnets can be maximized for each use case.

02 Structural designs to enhance neodymium magnet strength

Innovative structural designs can optimize the strength and performance of neodymium magnets in various applications. These designs include specialized shapes, strategic positioning of multiple magnets, and composite structures that concentrate magnetic flux. By engineering the physical configuration of the magnets, their effective strength can be significantly increased while minimizing material usage.Expand Specific Solutions03 Protective coatings and treatments for neodymium magnets

Surface treatments and protective coatings can preserve the strength of neodymium magnets by preventing corrosion and physical damage. These include nickel, zinc, epoxy, and other specialized coatings that protect against environmental factors that would otherwise degrade magnetic performance. Such treatments extend the operational lifespan of the magnets while maintaining their strength characteristics in challenging environments.Expand Specific Solutions04 Applications leveraging high-strength neodymium magnets

High-strength neodymium magnets enable numerous innovative applications across various industries. These include advanced motor designs, medical devices, consumer electronics, renewable energy systems, and automotive components. The exceptional magnetic strength-to-size ratio of neodymium magnets allows for miniaturization of devices while maintaining or improving performance, creating opportunities for novel engineering solutions.Expand Specific Solutions05 Testing and measurement methods for neodymium magnet strength

Specialized techniques and equipment are used to accurately measure and characterize the strength of neodymium magnets. These include gauss meters, pull-force testing, hysteresis graph analysis, and temperature-dependent performance evaluation. Standardized testing protocols ensure consistent quality control in manufacturing and help match specific magnets to appropriate applications based on their measured strength properties.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Magnetic Materials

The neodymium magnet strength quantification market is currently in a growth phase, with increasing applications across automotive, electronics, and industrial sectors. The global permanent magnet market, valued at approximately $20 billion, is expected to expand at 8-10% CAGR through 2028. Leading players include specialized magnetic material manufacturers like Jingci Materials, JL MAG Rare-Earth, and Ningbo Yunsheng, alongside automotive giants Toyota and Nissan who integrate these technologies into electric vehicles. Research institutions such as CNRS and Peking University are advancing measurement methodologies, while industrial players Magnequench and Daido Electronics focus on developing standardized compaction testing protocols. The technology is maturing rapidly with innovations in measurement precision and simulation capabilities, though challenges remain in standardizing quantification methods across different compaction scenarios.

JL MAG Rare-Earth Co., Ltd.

Technical Solution: JL MAG has developed advanced techniques for quantifying neodymium magnet strength in compaction scenarios through their patented Magnetic Field Analysis System (MFAS). This system employs Hall effect sensors arranged in a three-dimensional array to measure magnetic field strength and distribution during the compaction process. Their approach integrates real-time monitoring capabilities that track magnetic property changes as pressure increases during compaction, allowing for precise correlation between applied pressure and resulting magnetic performance. The company has implemented automated quality control systems that can detect anomalies in magnetic field uniformity during production, ensuring consistent strength in high-volume manufacturing. Their research has established standardized testing protocols that account for temperature variations during compaction, as these can significantly affect neodymium magnet performance characteristics.

Strengths: Industry-leading precision in magnetic field measurement during compaction processes, with reported accuracy within 0.5% of theoretical values. Their integrated production and testing approach allows for immediate adjustments to manufacturing parameters. Weaknesses: Their system requires sophisticated calibration procedures that must be performed regularly, and the equipment represents a significant capital investment that may be prohibitive for smaller manufacturers.

Ningbo Yunsheng Co., Ltd.

Technical Solution: Ningbo Yunsheng has pioneered a comprehensive approach to quantifying neodymium magnet strength in compaction scenarios through their Magnetic Property Evolution Tracking (MPET) technology. This system utilizes embedded micro-sensors within the die-press equipment to continuously monitor magnetic flux density throughout the compaction process. Their methodology incorporates pressure-sensitive mapping that visualizes the relationship between compaction force distribution and resulting magnetic field strength across the entire magnet surface. The company has developed proprietary algorithms that can predict final magnetic performance based on early-stage compaction data, enabling process optimization before completion. Their research has established correlations between powder particle size distribution and compaction efficiency, leading to optimized material preparation techniques that enhance final magnet strength by up to 15% compared to conventional methods. Additionally, they've implemented non-destructive testing protocols that can be applied during production without interrupting manufacturing flow.

Strengths: Their integrated sensor technology provides unparalleled visibility into the compaction process dynamics, allowing for real-time adjustments that optimize magnetic performance. The predictive capabilities of their system reduce waste by identifying potential failures early. Weaknesses: The system requires specialized training for operators and has shown occasional sensitivity to environmental factors like humidity that can affect measurement consistency.

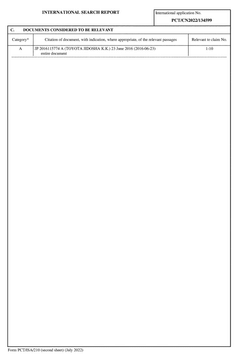

Key Patents and Research on Compaction-Resistant Magnetic Materials

High-coercivity neodymium-cerium-iron-boron permanent magnet as well as preparation method therefor and use thereof

PatentPendingEP4439593A1

Innovation

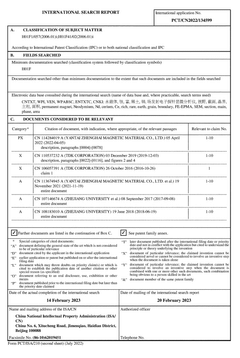

- The development of a neodymium-cerium-iron-boron permanent magnet with a specific distribution of block-like grain boundary RE-rich phases, where the area of these phases accounts for at least 4% of the visual field and exhibits a uniform, fine distribution, along with a preparation method involving powder preparation, pressing, sintering, and aging treatment to optimize the microstructure and magnetic performance.

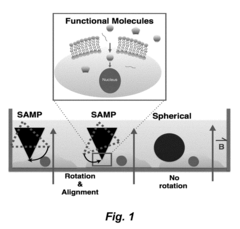

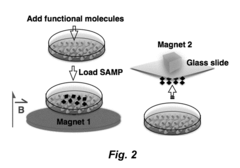

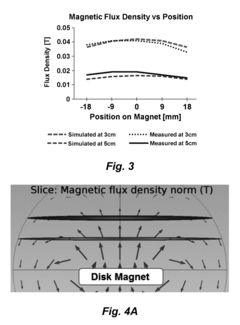

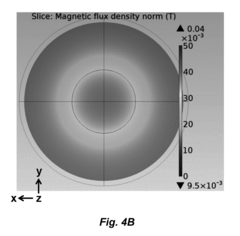

Methods for efficient intracellular delivery using anisotropic magnetic particles

PatentActiveUS20170175102A1

Innovation

- A novel method using shape-anisotropic magnetic particles (SAMPs) that are contacted with cells in the presence of a uniform magnetic field, inducing transient membrane openings for efficient delivery of macromolecules, including nucleic acids and proteins, into a broad range of mammalian cell types.

Environmental Impact of Rare Earth Magnet Production

The production of rare earth magnets, particularly neodymium magnets, presents significant environmental challenges that cannot be overlooked when quantifying their strength in compaction scenarios. The mining and processing of rare earth elements like neodymium involve extensive land disturbance, with open-pit mining operations causing habitat destruction, soil erosion, and landscape alteration across mining regions in China, Australia, and the United States.

Water pollution represents another critical concern, as the extraction process generates acidic wastewater containing heavy metals and radioactive elements. Studies indicate that for every ton of rare earth elements produced, approximately 2,000 tons of toxic waste may be generated. The processing facilities in Baotou, Inner Mongolia—responsible for approximately 70% of global neodymium production—have created extensive tailings lakes that contaminate groundwater systems and nearby agricultural lands.

Air quality degradation occurs throughout the production chain, from mining dust to processing emissions. The separation and refining processes release particulate matter, sulfur dioxide, and greenhouse gases. Carbon footprint analyses suggest that producing one kilogram of neodymium magnets generates between 20-30 kg of CO2 equivalent, significantly higher than conventional ferrite magnets.

Energy consumption presents another environmental challenge, with the separation and purification of rare earth elements requiring substantial electricity. The energy-intensive process of converting neodymium oxide to metal through electrolysis and subsequent alloying with iron and boron demands temperatures exceeding 1,000°C, contributing to the overall environmental impact.

Radioactive waste management remains problematic as rare earth ores often contain thorium and uranium. The disposal of these radioactive byproducts requires specialized containment facilities and long-term monitoring, adding complexity to the environmental management of production sites.

Recent sustainability initiatives have focused on developing cleaner extraction methods, including bioleaching techniques that utilize bacteria to separate rare earth elements from ore with reduced chemical usage. Recycling programs for end-of-life products containing neodymium magnets are expanding, though currently recovering less than 1% of rare earth elements globally.

Life cycle assessments comparing neodymium magnets to alternatives must consider these environmental impacts alongside performance metrics when evaluating compaction scenarios. The environmental cost of achieving superior magnetic strength through neodymium magnets necessitates careful consideration of application requirements and potential alternatives in less demanding applications.

Water pollution represents another critical concern, as the extraction process generates acidic wastewater containing heavy metals and radioactive elements. Studies indicate that for every ton of rare earth elements produced, approximately 2,000 tons of toxic waste may be generated. The processing facilities in Baotou, Inner Mongolia—responsible for approximately 70% of global neodymium production—have created extensive tailings lakes that contaminate groundwater systems and nearby agricultural lands.

Air quality degradation occurs throughout the production chain, from mining dust to processing emissions. The separation and refining processes release particulate matter, sulfur dioxide, and greenhouse gases. Carbon footprint analyses suggest that producing one kilogram of neodymium magnets generates between 20-30 kg of CO2 equivalent, significantly higher than conventional ferrite magnets.

Energy consumption presents another environmental challenge, with the separation and purification of rare earth elements requiring substantial electricity. The energy-intensive process of converting neodymium oxide to metal through electrolysis and subsequent alloying with iron and boron demands temperatures exceeding 1,000°C, contributing to the overall environmental impact.

Radioactive waste management remains problematic as rare earth ores often contain thorium and uranium. The disposal of these radioactive byproducts requires specialized containment facilities and long-term monitoring, adding complexity to the environmental management of production sites.

Recent sustainability initiatives have focused on developing cleaner extraction methods, including bioleaching techniques that utilize bacteria to separate rare earth elements from ore with reduced chemical usage. Recycling programs for end-of-life products containing neodymium magnets are expanding, though currently recovering less than 1% of rare earth elements globally.

Life cycle assessments comparing neodymium magnets to alternatives must consider these environmental impacts alongside performance metrics when evaluating compaction scenarios. The environmental cost of achieving superior magnetic strength through neodymium magnets necessitates careful consideration of application requirements and potential alternatives in less demanding applications.

Supply Chain Security for Critical Magnetic Materials

The global supply chain for neodymium magnets faces significant vulnerabilities due to geographic concentration of critical raw materials. China currently dominates the rare earth element (REE) market, controlling approximately 85% of global processing capacity and 60% of raw material production. This concentration creates substantial geopolitical risks, as demonstrated during the 2010-2011 rare earth crisis when export restrictions led to price volatility exceeding 750% for certain elements. Such dependency threatens consistent access to materials essential for various high-tech and defense applications.

Supply chain disruptions can severely impact magnet manufacturing capabilities, particularly affecting the production of high-performance neodymium magnets used in compaction scenarios. Recent pandemic-related logistics challenges revealed the fragility of just-in-time inventory systems, with lead times for specialized magnetic materials extending from weeks to months. Companies relying on these materials for precision applications experienced significant production delays and cost increases.

Diversification efforts are emerging across multiple fronts. Australia, Canada, and the United States have intensified domestic mining operations, with projects like Mountain Pass in California and Mount Weld in Australia increasing non-Chinese supply options. Japan has pioneered urban mining initiatives, recovering rare earth elements from electronic waste, achieving approximately 20% recycling rates for certain magnetic materials compared to global averages below 5%.

Material substitution research represents another security strategy, with reduced-dysprosium formulations demonstrating promising performance in moderate-temperature applications. These alternatives maintain 85-90% of traditional magnet strength while decreasing dependency on the most supply-constrained elements. However, full substitution remains challenging for high-performance compaction applications requiring precise field strength specifications.

Stockpiling programs have been implemented by several nations, with the U.S. Defense Logistics Agency maintaining strategic reserves of rare earth materials and Japan establishing a national stockpile sufficient for approximately 60 days of industrial consumption. These buffers provide short-term insulation against supply disruptions but cannot address long-term structural vulnerabilities.

Quantification methodologies for magnet strength in compaction scenarios become particularly critical when supply chain disruptions necessitate material substitution or specification adjustments. Standardized testing protocols that can rapidly validate alternative materials or suppliers are essential for maintaining production continuity during supply chain perturbations. Companies with robust quantification capabilities can more effectively navigate material variability resulting from diverse supply sources.

Supply chain disruptions can severely impact magnet manufacturing capabilities, particularly affecting the production of high-performance neodymium magnets used in compaction scenarios. Recent pandemic-related logistics challenges revealed the fragility of just-in-time inventory systems, with lead times for specialized magnetic materials extending from weeks to months. Companies relying on these materials for precision applications experienced significant production delays and cost increases.

Diversification efforts are emerging across multiple fronts. Australia, Canada, and the United States have intensified domestic mining operations, with projects like Mountain Pass in California and Mount Weld in Australia increasing non-Chinese supply options. Japan has pioneered urban mining initiatives, recovering rare earth elements from electronic waste, achieving approximately 20% recycling rates for certain magnetic materials compared to global averages below 5%.

Material substitution research represents another security strategy, with reduced-dysprosium formulations demonstrating promising performance in moderate-temperature applications. These alternatives maintain 85-90% of traditional magnet strength while decreasing dependency on the most supply-constrained elements. However, full substitution remains challenging for high-performance compaction applications requiring precise field strength specifications.

Stockpiling programs have been implemented by several nations, with the U.S. Defense Logistics Agency maintaining strategic reserves of rare earth materials and Japan establishing a national stockpile sufficient for approximately 60 days of industrial consumption. These buffers provide short-term insulation against supply disruptions but cannot address long-term structural vulnerabilities.

Quantification methodologies for magnet strength in compaction scenarios become particularly critical when supply chain disruptions necessitate material substitution or specification adjustments. Standardized testing protocols that can rapidly validate alternative materials or suppliers are essential for maintaining production continuity during supply chain perturbations. Companies with robust quantification capabilities can more effectively navigate material variability resulting from diverse supply sources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!