Refining Mini LED Backlight Uniformity for Better Displays

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mini LED Evolution and Uniformity Objectives

Mini LED technology has evolved significantly since its inception in the early 2010s, representing a critical advancement in display backlighting systems. This evolution bridges the gap between conventional LED backlighting and the more advanced but costly microLED technology. The development trajectory began with traditional edge-lit LED displays, progressed to direct-lit arrays, and has now reached the mini LED stage, characterized by LEDs measuring between 100-200 micrometers, allowing for thousands of individual light sources in a single display.

The primary technological objective in mini LED development centers on achieving superior backlight uniformity. This uniformity is essential for delivering consistent brightness across the entire display surface, eliminating hotspots and dark zones that compromise visual quality. As display resolutions continue to increase, particularly in premium television sets, professional monitors, and high-end tablets, the demand for perfect uniformity becomes increasingly critical.

Current uniformity challenges stem from several technical factors. The physical placement of mini LEDs in arrays creates inherent spacing issues, resulting in potential light distribution inconsistencies. Additionally, manufacturing variations in LED brightness and color temperature contribute to non-uniform illumination. The optical diffusion layers, designed to blend light from individual LEDs, often struggle to completely homogenize light output without sacrificing brightness or increasing device thickness.

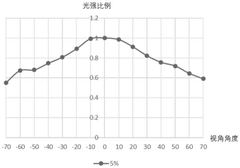

Industry benchmarks for acceptable uniformity have become increasingly stringent, with premium displays now targeting uniformity deviation below 5% across the entire panel. This represents a significant improvement from earlier standards that accepted 10-15% variation. The pursuit of these enhanced uniformity metrics drives continuous innovation in both LED manufacturing precision and optical management systems.

The technological roadmap for mini LED uniformity improvement follows several parallel paths. Advanced manufacturing techniques aim to reduce variance in LED performance characteristics. Sophisticated local dimming algorithms compensate for hardware limitations through software optimization. Novel optical diffusion materials and structures work to better distribute light while maintaining brightness and minimizing device thickness.

These uniformity objectives directly impact critical display performance metrics including contrast ratio, color accuracy, and HDR capability. As mini LED technology continues to mature, achieving near-perfect uniformity remains one of the most significant technical challenges facing display manufacturers, with implications for product differentiation, consumer satisfaction, and market positioning in the premium display segment.

The primary technological objective in mini LED development centers on achieving superior backlight uniformity. This uniformity is essential for delivering consistent brightness across the entire display surface, eliminating hotspots and dark zones that compromise visual quality. As display resolutions continue to increase, particularly in premium television sets, professional monitors, and high-end tablets, the demand for perfect uniformity becomes increasingly critical.

Current uniformity challenges stem from several technical factors. The physical placement of mini LEDs in arrays creates inherent spacing issues, resulting in potential light distribution inconsistencies. Additionally, manufacturing variations in LED brightness and color temperature contribute to non-uniform illumination. The optical diffusion layers, designed to blend light from individual LEDs, often struggle to completely homogenize light output without sacrificing brightness or increasing device thickness.

Industry benchmarks for acceptable uniformity have become increasingly stringent, with premium displays now targeting uniformity deviation below 5% across the entire panel. This represents a significant improvement from earlier standards that accepted 10-15% variation. The pursuit of these enhanced uniformity metrics drives continuous innovation in both LED manufacturing precision and optical management systems.

The technological roadmap for mini LED uniformity improvement follows several parallel paths. Advanced manufacturing techniques aim to reduce variance in LED performance characteristics. Sophisticated local dimming algorithms compensate for hardware limitations through software optimization. Novel optical diffusion materials and structures work to better distribute light while maintaining brightness and minimizing device thickness.

These uniformity objectives directly impact critical display performance metrics including contrast ratio, color accuracy, and HDR capability. As mini LED technology continues to mature, achieving near-perfect uniformity remains one of the most significant technical challenges facing display manufacturers, with implications for product differentiation, consumer satisfaction, and market positioning in the premium display segment.

Display Market Demand Analysis

The global display market is experiencing a significant shift towards higher quality visual experiences, creating substantial demand for advanced technologies like Mini LED backlight solutions. Market research indicates that the premium display segment is growing at a faster rate than the overall display market, with consumers increasingly willing to pay more for superior visual quality. This trend is particularly evident in high-end televisions, professional monitors, and premium laptops where image quality directly impacts user experience and product differentiation.

Consumer electronics manufacturers are facing intensifying pressure to deliver displays with better contrast ratios, deeper blacks, and more uniform brightness - all areas where Mini LED technology excels compared to conventional LED backlighting. Market surveys reveal that brightness uniformity ranks among the top five factors influencing purchase decisions for premium displays, highlighting the commercial importance of addressing the uniformity challenges in Mini LED implementation.

The professional display market segment shows particularly strong demand for uniform backlighting solutions. Content creators, including video editors, photographers, and graphic designers, require displays with exceptional color accuracy and brightness uniformity across the entire screen. This professional segment represents a high-value market where the price premium for superior uniformity can be substantial, with professional-grade monitors commanding 30-50% higher prices than consumer equivalents with similar specifications.

In the consumer television market, the trend toward larger screen sizes (65" and above) has amplified the visibility of backlight uniformity issues. As viewing distances remain relatively constant while screen sizes increase, consumers become more sensitive to uniformity problems. Market feedback indicates that negative reviews citing "clouding," "spotlighting," or "uneven brightness" significantly impact brand perception and return rates.

The automotive display market is emerging as another significant driver for Mini LED technology with uniform backlighting. As vehicles incorporate larger and more numerous displays, the automotive industry's stringent requirements for reliability, readability in various lighting conditions, and aesthetic quality create demand for advanced backlighting solutions. Industry projections suggest that premium automotive displays will increasingly adopt Mini LED technology over the next five years.

Regional analysis shows that Asian markets, particularly China, Japan, and South Korea, are leading in both production capacity and consumer adoption of Mini LED displays. However, North American and European markets show stronger price elasticity for quality improvements in display technology, suggesting these regions may represent the most profitable markets for displays with refined Mini LED uniformity.

Consumer electronics manufacturers are facing intensifying pressure to deliver displays with better contrast ratios, deeper blacks, and more uniform brightness - all areas where Mini LED technology excels compared to conventional LED backlighting. Market surveys reveal that brightness uniformity ranks among the top five factors influencing purchase decisions for premium displays, highlighting the commercial importance of addressing the uniformity challenges in Mini LED implementation.

The professional display market segment shows particularly strong demand for uniform backlighting solutions. Content creators, including video editors, photographers, and graphic designers, require displays with exceptional color accuracy and brightness uniformity across the entire screen. This professional segment represents a high-value market where the price premium for superior uniformity can be substantial, with professional-grade monitors commanding 30-50% higher prices than consumer equivalents with similar specifications.

In the consumer television market, the trend toward larger screen sizes (65" and above) has amplified the visibility of backlight uniformity issues. As viewing distances remain relatively constant while screen sizes increase, consumers become more sensitive to uniformity problems. Market feedback indicates that negative reviews citing "clouding," "spotlighting," or "uneven brightness" significantly impact brand perception and return rates.

The automotive display market is emerging as another significant driver for Mini LED technology with uniform backlighting. As vehicles incorporate larger and more numerous displays, the automotive industry's stringent requirements for reliability, readability in various lighting conditions, and aesthetic quality create demand for advanced backlighting solutions. Industry projections suggest that premium automotive displays will increasingly adopt Mini LED technology over the next five years.

Regional analysis shows that Asian markets, particularly China, Japan, and South Korea, are leading in both production capacity and consumer adoption of Mini LED displays. However, North American and European markets show stronger price elasticity for quality improvements in display technology, suggesting these regions may represent the most profitable markets for displays with refined Mini LED uniformity.

Mini LED Backlight Technical Challenges

Mini LED backlight technology represents a significant advancement in display technology, bridging conventional LED backlighting and the more advanced micro LED displays. However, despite its promising features, Mini LED faces several critical technical challenges that impact its performance and widespread adoption.

The primary challenge in Mini LED backlight technology is achieving uniform brightness across the entire display panel. With thousands of miniaturized LEDs packed into a backlight unit, ensuring consistent luminance becomes increasingly complex. Variations in LED brightness, even minor ones, can result in visible hotspots or dark regions that compromise display quality. This non-uniformity becomes particularly noticeable in scenes with uniform backgrounds, such as when displaying a single color across the screen.

Thermal management presents another significant hurdle for Mini LED technology. The high density of LEDs generates considerable heat during operation, which can affect both performance and longevity. Without effective thermal dissipation mechanisms, localized heating can cause LED degradation, color shift, and reduced lifespan. Additionally, thermal expansion may create mechanical stress on the panel structure, potentially leading to warping or component failure over time.

The manufacturing precision required for Mini LED backlights poses substantial production challenges. Placing thousands of tiny LEDs with extreme accuracy demands advanced manufacturing processes. Even minor placement errors can result in visible defects or non-uniform illumination. The yield rates for high-quality Mini LED panels remain lower than conventional technologies, contributing to higher production costs and retail prices.

Optical design complexities further complicate Mini LED implementation. Engineers must carefully balance the number of LEDs, their arrangement, and the design of light diffusion layers to achieve optimal brightness uniformity while minimizing the panel thickness. The optical stack must effectively manage light distribution without introducing moiré patterns or other visual artifacts that could degrade image quality.

Power efficiency remains a concern despite improvements over traditional LED backlighting. While local dimming capabilities allow for energy savings, the control circuitry required to manage thousands of individual LEDs consumes additional power. Optimizing the power delivery system while maintaining precise brightness control across numerous dimming zones presents ongoing engineering challenges.

Cost factors continue to limit widespread adoption of Mini LED technology. The increased component count, complex manufacturing processes, and sophisticated control systems all contribute to higher production expenses compared to conventional LCD displays. Finding the optimal balance between performance improvements and cost-effectiveness remains crucial for broader market acceptance.

The primary challenge in Mini LED backlight technology is achieving uniform brightness across the entire display panel. With thousands of miniaturized LEDs packed into a backlight unit, ensuring consistent luminance becomes increasingly complex. Variations in LED brightness, even minor ones, can result in visible hotspots or dark regions that compromise display quality. This non-uniformity becomes particularly noticeable in scenes with uniform backgrounds, such as when displaying a single color across the screen.

Thermal management presents another significant hurdle for Mini LED technology. The high density of LEDs generates considerable heat during operation, which can affect both performance and longevity. Without effective thermal dissipation mechanisms, localized heating can cause LED degradation, color shift, and reduced lifespan. Additionally, thermal expansion may create mechanical stress on the panel structure, potentially leading to warping or component failure over time.

The manufacturing precision required for Mini LED backlights poses substantial production challenges. Placing thousands of tiny LEDs with extreme accuracy demands advanced manufacturing processes. Even minor placement errors can result in visible defects or non-uniform illumination. The yield rates for high-quality Mini LED panels remain lower than conventional technologies, contributing to higher production costs and retail prices.

Optical design complexities further complicate Mini LED implementation. Engineers must carefully balance the number of LEDs, their arrangement, and the design of light diffusion layers to achieve optimal brightness uniformity while minimizing the panel thickness. The optical stack must effectively manage light distribution without introducing moiré patterns or other visual artifacts that could degrade image quality.

Power efficiency remains a concern despite improvements over traditional LED backlighting. While local dimming capabilities allow for energy savings, the control circuitry required to manage thousands of individual LEDs consumes additional power. Optimizing the power delivery system while maintaining precise brightness control across numerous dimming zones presents ongoing engineering challenges.

Cost factors continue to limit widespread adoption of Mini LED technology. The increased component count, complex manufacturing processes, and sophisticated control systems all contribute to higher production expenses compared to conventional LCD displays. Finding the optimal balance between performance improvements and cost-effectiveness remains crucial for broader market acceptance.

Current Uniformity Enhancement Solutions

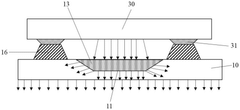

01 Light guide plate design for uniform illumination

Specialized light guide plate designs can significantly improve Mini LED backlight uniformity. These designs include optimized microstructures, diffusion patterns, and reflective elements that help distribute light evenly across the display surface. The light guide plates can be engineered with specific patterns or textures that redirect light to eliminate hotspots and dark areas, ensuring consistent brightness throughout the display.- Light guide plate design for uniform illumination: Specialized light guide plate designs can significantly improve Mini LED backlight uniformity. These designs include optimized microstructures, diffusion patterns, and reflective elements that help distribute light evenly across the display surface. By carefully engineering the light guide geometry and surface treatments, hotspots and dark areas can be minimized, resulting in more consistent illumination across the entire display.

- Multi-zone local dimming control systems: Advanced control systems for Mini LED backlights enable precise multi-zone local dimming capabilities. These systems incorporate sophisticated algorithms to adjust brightness levels across different regions of the display, compensating for inherent variations in LED output. By independently controlling multiple LED zones, these systems can achieve more uniform brightness distribution while maintaining high contrast ratios and reducing power consumption.

- Optical diffuser and reflector arrangements: Specialized optical diffuser and reflector arrangements help achieve uniform light distribution in Mini LED backlight systems. These components work together to scatter and redirect light, eliminating bright spots and shadows. Multi-layer diffuser designs with varying haze properties and strategically placed reflective elements ensure that light is evenly spread across the display area, resulting in improved backlight uniformity.

- LED array configuration and placement optimization: Optimized Mini LED array configurations focus on strategic placement and density distribution of LEDs to achieve uniform illumination. These designs consider factors such as LED spacing, arrangement patterns, and density gradients to minimize brightness variations. By carefully calculating the optimal positions and quantities of LEDs in different regions of the backlight unit, manufacturers can significantly improve backlight uniformity while managing cost and power efficiency.

- Thermal management solutions for consistent LED performance: Effective thermal management systems are crucial for maintaining uniform Mini LED backlight performance. These solutions include advanced heat dissipation structures, thermal interface materials, and cooling mechanisms that prevent temperature variations across the LED array. By ensuring consistent operating temperatures, these systems help maintain uniform LED brightness and color characteristics over time, preventing degradation in display uniformity due to thermal issues.

02 Optical film stack configuration

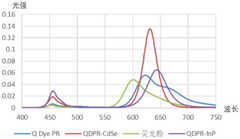

Multi-layer optical film stacks can enhance Mini LED backlight uniformity by managing light diffusion and distribution. These stacks typically include combinations of diffusion films, prism sheets, reflective polarizers, and brightness enhancement films. The strategic arrangement of these optical films helps to homogenize light output, reduce moiré patterns, and improve overall luminance uniformity across the display panel.Expand Specific Solutions03 LED array arrangement and driving techniques

The physical arrangement of Mini LEDs and their driving methods significantly impact backlight uniformity. Techniques include optimized LED spacing, zonal dimming algorithms, and current compensation circuits that adjust individual LED brightness to achieve uniform illumination. Advanced driving schemes can dynamically adjust LED output based on image content and temperature variations to maintain consistent brightness across the display.Expand Specific Solutions04 Reflector and diffuser design optimization

Specialized reflectors and diffusers play a crucial role in achieving uniform Mini LED backlighting. These components can be designed with specific shapes, materials, and surface treatments to redirect and scatter light effectively. Advanced reflector designs can minimize light loss while ensuring even distribution, and optimized diffuser structures can eliminate hotspots while maintaining high optical efficiency.Expand Specific Solutions05 Feedback control systems for uniformity compensation

Adaptive feedback control systems can detect and correct non-uniformities in Mini LED backlights in real-time. These systems typically employ optical sensors to measure brightness variations across the display and then apply compensation algorithms to adjust individual LED outputs accordingly. Some advanced designs incorporate temperature sensors and aging compensation to maintain uniformity throughout the display's operational lifetime.Expand Specific Solutions

Key Mini LED Display Manufacturers

The Mini LED backlight uniformity refinement market is currently in a growth phase, with an estimated market size exceeding $2 billion and projected to expand at 15-20% annually through 2025. The technology is approaching maturity, with key players demonstrating varying levels of expertise. BOE Technology Group leads with advanced uniformity control algorithms, while Samsung Electronics and LG Electronics leverage their vertical integration advantages. TCL China Star and Tianma Microelectronics have made significant progress in mass production efficiency. APT Electronics and Citizen Electronics focus on specialized optical solutions, while emerging players like Beijing Xianxin Technology are developing innovative driver ICs. The competitive landscape shows established display manufacturers increasingly collaborating with specialized component suppliers to overcome technical challenges in brightness consistency and color uniformity.

BOE Technology Group Co., Ltd.

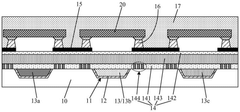

Technical Solution: BOE has developed a comprehensive Mini LED backlight solution focusing on uniformity enhancement through their Active Matrix Mini LED (AM Mini LED) technology. Their approach integrates thousands of individually controlled Mini LED units (typically 0.1-0.2mm) arranged in a matrix pattern with specialized diffuser layers to eliminate hotspots. BOE's proprietary optical design includes multi-layer light guide plates with micro-lens arrays that help distribute light more evenly across the display surface. Their advanced driving ICs enable 1,024-4,096 dimming zones with 12-16 bit grayscale precision, allowing for fine-tuned brightness control. BOE has also implemented an AI-based compensation algorithm that continuously monitors and adjusts brightness variations in real-time, addressing uniformity issues caused by manufacturing tolerances and LED aging. Their latest displays feature over 10,000 Mini LEDs with zone-specific calibration to maintain consistent luminance across the entire panel.

Strengths: Highly scalable manufacturing process allowing implementation across various display sizes; advanced optical film stack design that effectively eliminates hotspots; sophisticated real-time compensation algorithms. Weaknesses: Higher production costs compared to traditional backlighting; increased power consumption requirements; thermal management challenges in ultra-thin display designs that can affect long-term uniformity performance.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has developed a comprehensive Mini LED backlight solution called "OD Zero" (Optical Distance Zero) that specifically addresses uniformity challenges. Their technology minimizes the distance between the Mini LED backlight layer and the LCD panel to nearly zero, significantly reducing light diffusion issues that typically cause uniformity problems. TCL's approach incorporates thousands of Mini LEDs (typically 0.1-0.15mm) arranged in a precise matrix pattern with up to 1,920 independent dimming zones in their premium models. They've implemented a sophisticated optical film stack with specialized diffuser and prism sheets that help eliminate hotspots and ensure consistent luminance. Their proprietary "Intelligent Control Algorithm" continuously monitors and adjusts brightness levels across different zones based on content analysis. TCL has also developed an advanced manufacturing calibration process that measures and compensates for inherent brightness variations between individual Mini LEDs, ensuring panel-to-panel consistency.

Strengths: Innovative OD Zero design significantly reduces light diffusion issues; excellent contrast performance with minimal blooming; advanced zone-specific calibration process ensures consistent brightness across the display. Weaknesses: Complex manufacturing process increases production costs; thermal management challenges in the ultra-thin design; higher power consumption compared to conventional LED backlighting despite efficiency improvements.

Breakthrough Patents in Backlight Uniformity

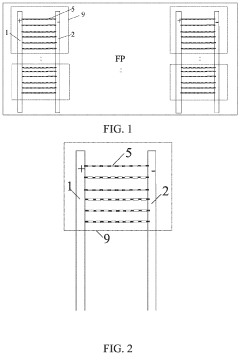

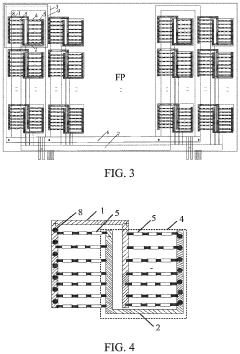

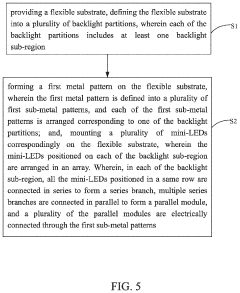

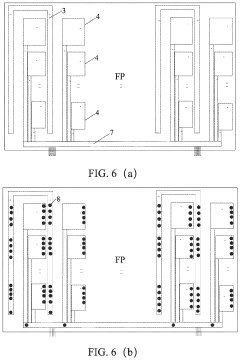

Mini-led backlight module, manufacturing method thereof, and display panel

PatentActiveUS11921375B2

Innovation

- A mini-LED backlight module design featuring a flexible substrate with backlight partitions and metal patterns, where mini-LEDs are arranged in series and parallel branches, connected through sub-metal patterns to reduce driving voltage and current, and improve brightness uniformity by independent signal input to each sub-region.

Light-emitting module and display device

PatentPendingCN119439555A

Innovation

- A light emitting module is adopted, including a substrate, a transverse film layer, a color modulation layer and a light modulation layer, and reflects a part of the light ray through the transverse film layer and modulates the third light ray through the transverse film layer to make it pass through the transverse film layer. The outer periphery of the reverse film layer reduces the number of light emitted directly, increases the number of light emitted outside, and improves the uniformity of light emitted.

Thermal Management Considerations

Thermal management represents a critical challenge in Mini LED backlight technology implementation. As Mini LED arrays become increasingly dense to achieve better local dimming capabilities, the heat generated by thousands of closely packed LEDs creates significant thermal issues. These thermal challenges directly impact display uniformity, as temperature variations across the backlight panel can cause inconsistent LED performance, affecting brightness, color accuracy, and overall image quality.

The thermal behavior of Mini LED backlights exhibits complex characteristics due to the high-density arrangement of light sources. When operating at high brightness levels, Mini LEDs can generate localized hotspots that, if not properly managed, lead to differential thermal expansion of materials and subsequent optical distortions. Research indicates that temperature variations as small as 5°C across the display can result in perceptible uniformity issues, particularly in dark scenes where inconsistencies become more noticeable.

Advanced thermal simulation models have become essential tools for predicting heat distribution patterns in Mini LED arrays. These computational fluid dynamics (CFD) simulations help engineers identify potential thermal bottlenecks before physical prototyping, significantly reducing development cycles. Recent advancements in these simulation techniques have improved accuracy by incorporating detailed LED junction temperature models and material thermal interface properties.

Several thermal management strategies have emerged to address these challenges. Passive cooling solutions utilizing graphite sheets and copper heat spreaders effectively distribute heat across larger surface areas. These materials, with thermal conductivity ratings of 400-1500 W/m·K, significantly outperform traditional aluminum (237 W/m·K) in lateral heat spreading capabilities. For premium display applications, active cooling systems incorporating microfluidic channels or miniaturized heat pipes provide enhanced thermal performance but introduce additional complexity and cost considerations.

Thermal interface materials (TIMs) play a crucial role in establishing efficient heat transfer pathways from LED junctions to cooling structures. Next-generation TIMs incorporating nanoparticles and phase-change materials have demonstrated thermal conductivity improvements of 30-50% compared to conventional silicone-based compounds, while maintaining the mechanical compliance necessary for reliable long-term operation.

The relationship between thermal management and power efficiency creates an important design consideration. Implementing dynamic thermal management algorithms that adjust LED driving currents based on real-time temperature monitoring has shown promise in maintaining uniformity while optimizing power consumption. These systems can reduce peak temperatures by 15-20% during high-brightness operation while extending LED lifespan through reduced thermal stress cycling.

Future thermal management approaches are exploring integration with the display's mechanical structure, creating multifunctional components that serve both structural and thermal purposes. This holistic design philosophy represents a paradigm shift from treating thermal management as an afterthought to incorporating it as a fundamental design parameter from the earliest development stages.

The thermal behavior of Mini LED backlights exhibits complex characteristics due to the high-density arrangement of light sources. When operating at high brightness levels, Mini LEDs can generate localized hotspots that, if not properly managed, lead to differential thermal expansion of materials and subsequent optical distortions. Research indicates that temperature variations as small as 5°C across the display can result in perceptible uniformity issues, particularly in dark scenes where inconsistencies become more noticeable.

Advanced thermal simulation models have become essential tools for predicting heat distribution patterns in Mini LED arrays. These computational fluid dynamics (CFD) simulations help engineers identify potential thermal bottlenecks before physical prototyping, significantly reducing development cycles. Recent advancements in these simulation techniques have improved accuracy by incorporating detailed LED junction temperature models and material thermal interface properties.

Several thermal management strategies have emerged to address these challenges. Passive cooling solutions utilizing graphite sheets and copper heat spreaders effectively distribute heat across larger surface areas. These materials, with thermal conductivity ratings of 400-1500 W/m·K, significantly outperform traditional aluminum (237 W/m·K) in lateral heat spreading capabilities. For premium display applications, active cooling systems incorporating microfluidic channels or miniaturized heat pipes provide enhanced thermal performance but introduce additional complexity and cost considerations.

Thermal interface materials (TIMs) play a crucial role in establishing efficient heat transfer pathways from LED junctions to cooling structures. Next-generation TIMs incorporating nanoparticles and phase-change materials have demonstrated thermal conductivity improvements of 30-50% compared to conventional silicone-based compounds, while maintaining the mechanical compliance necessary for reliable long-term operation.

The relationship between thermal management and power efficiency creates an important design consideration. Implementing dynamic thermal management algorithms that adjust LED driving currents based on real-time temperature monitoring has shown promise in maintaining uniformity while optimizing power consumption. These systems can reduce peak temperatures by 15-20% during high-brightness operation while extending LED lifespan through reduced thermal stress cycling.

Future thermal management approaches are exploring integration with the display's mechanical structure, creating multifunctional components that serve both structural and thermal purposes. This holistic design philosophy represents a paradigm shift from treating thermal management as an afterthought to incorporating it as a fundamental design parameter from the earliest development stages.

Manufacturing Process Optimization

Manufacturing process optimization for Mini LED backlight technology represents a critical frontier in display advancement. Current manufacturing challenges primarily revolve around precise placement of thousands of miniature LED chips across the backlight unit. Traditional pick-and-place methods struggle with the required speed and accuracy, resulting in inconsistent light distribution and visible "hot spots" that compromise display quality.

Advanced transfer printing techniques have emerged as promising solutions, enabling simultaneous placement of multiple Mini LEDs with improved positioning accuracy. These methods utilize elastomeric stamps or laser-assisted transfer processes that significantly reduce placement errors from ±20μm to under ±5μm, directly enhancing backlight uniformity.

Automated optical inspection (AOI) systems integrated into production lines have become essential for real-time quality control. These systems can detect defective LEDs, misalignments, and uniformity issues before final assembly, reducing waste and improving yield rates from typical 85% to over 95% in optimized facilities.

Thermal management during manufacturing has proven crucial for maintaining consistent LED performance. Optimized reflow soldering profiles with precise temperature control prevent thermal damage while ensuring proper electrical connections. Advanced facilities now implement zone-controlled reflow systems that maintain temperature variations within ±2°C across the substrate.

Substrate material selection and preparation techniques significantly impact backlight uniformity. Recent innovations include nano-imprinted reflective patterns on substrate surfaces that enhance light extraction efficiency by 15-20% while improving diffusion characteristics. Additionally, specialized coating processes create more uniform phosphor layers for color-converted Mini LEDs, eliminating the "yellow edge" effect common in earlier implementations.

Mass transfer technologies represent the latest manufacturing breakthrough, allowing simultaneous placement of hundreds or thousands of Mini LEDs. Fluidic self-assembly and micro-transfer printing techniques have demonstrated placement rates exceeding 10,000 units per hour with positional accuracy better than ±3μm, dramatically reducing production time and cost while improving uniformity.

Post-placement calibration processes have also evolved significantly. Advanced manufacturers now implement individual LED current compensation algorithms during panel assembly, measuring the luminance of each Mini LED zone and applying digital correction factors to achieve uniformity variations below 5%, compared to 15-20% in non-optimized processes.

Advanced transfer printing techniques have emerged as promising solutions, enabling simultaneous placement of multiple Mini LEDs with improved positioning accuracy. These methods utilize elastomeric stamps or laser-assisted transfer processes that significantly reduce placement errors from ±20μm to under ±5μm, directly enhancing backlight uniformity.

Automated optical inspection (AOI) systems integrated into production lines have become essential for real-time quality control. These systems can detect defective LEDs, misalignments, and uniformity issues before final assembly, reducing waste and improving yield rates from typical 85% to over 95% in optimized facilities.

Thermal management during manufacturing has proven crucial for maintaining consistent LED performance. Optimized reflow soldering profiles with precise temperature control prevent thermal damage while ensuring proper electrical connections. Advanced facilities now implement zone-controlled reflow systems that maintain temperature variations within ±2°C across the substrate.

Substrate material selection and preparation techniques significantly impact backlight uniformity. Recent innovations include nano-imprinted reflective patterns on substrate surfaces that enhance light extraction efficiency by 15-20% while improving diffusion characteristics. Additionally, specialized coating processes create more uniform phosphor layers for color-converted Mini LEDs, eliminating the "yellow edge" effect common in earlier implementations.

Mass transfer technologies represent the latest manufacturing breakthrough, allowing simultaneous placement of hundreds or thousands of Mini LEDs. Fluidic self-assembly and micro-transfer printing techniques have demonstrated placement rates exceeding 10,000 units per hour with positional accuracy better than ±3μm, dramatically reducing production time and cost while improving uniformity.

Post-placement calibration processes have also evolved significantly. Advanced manufacturers now implement individual LED current compensation algorithms during panel assembly, measuring the luminance of each Mini LED zone and applying digital correction factors to achieve uniformity variations below 5%, compared to 15-20% in non-optimized processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!