Carbon-negative Concrete and the Reduction of Urban Heat Islands

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Technology Background and Objectives

Concrete production has historically been a significant contributor to global carbon emissions, accounting for approximately 8% of worldwide CO2 emissions. This environmental impact has driven extensive research into carbon-negative concrete technologies over the past two decades. The evolution of these technologies has progressed from initial concepts of carbon sequestration in the early 2000s to sophisticated carbon capture and utilization methods integrated directly into concrete manufacturing processes today.

The technological trajectory has been marked by key innovations in alternative cementitious materials, carbon capture mechanisms, and novel curing techniques. Recent breakthroughs include the development of calcium silicate-based formulations that actively absorb CO2 during the curing process, effectively transforming concrete from a carbon source to a carbon sink. These advancements represent a paradigm shift in how we conceptualize construction materials in relation to climate change mitigation strategies.

Concurrently, urban heat island (UHI) effects have intensified globally, with metropolitan areas experiencing temperature elevations of 1-7°C compared to surrounding rural regions. This phenomenon exacerbates energy consumption, air pollution, and heat-related health issues. The intersection of carbon-negative concrete technology and UHI mitigation presents a compelling opportunity for synergistic environmental solutions.

The primary technical objectives of carbon-negative concrete research encompass multiple dimensions: achieving net carbon sequestration of at least 10-50 kg CO2 per cubic meter of concrete, maintaining or enhancing structural performance comparable to traditional Portland cement concrete, ensuring economic viability with production costs within 15-20% of conventional concrete, and developing scalable manufacturing processes adaptable to existing infrastructure.

Additionally, specific objectives related to UHI reduction include developing concrete formulations with high solar reflectance index (SRI) values exceeding 29 for pavements and 78 for roofing applications, enhancing evaporative cooling properties through optimized porosity and water retention characteristics, and improving thermal performance with reduced heat capacity and thermal conductivity compared to traditional concrete.

The technological evolution is now trending toward multifunctional carbon-negative concrete solutions that simultaneously address carbon sequestration, UHI mitigation, and conventional performance requirements. Research is increasingly focused on biomimetic approaches, incorporating nature-inspired structures and processes to enhance both carbon capture efficiency and thermal regulation properties. The convergence of these technological pathways represents a promising frontier for sustainable urban development and climate change mitigation.

The technological trajectory has been marked by key innovations in alternative cementitious materials, carbon capture mechanisms, and novel curing techniques. Recent breakthroughs include the development of calcium silicate-based formulations that actively absorb CO2 during the curing process, effectively transforming concrete from a carbon source to a carbon sink. These advancements represent a paradigm shift in how we conceptualize construction materials in relation to climate change mitigation strategies.

Concurrently, urban heat island (UHI) effects have intensified globally, with metropolitan areas experiencing temperature elevations of 1-7°C compared to surrounding rural regions. This phenomenon exacerbates energy consumption, air pollution, and heat-related health issues. The intersection of carbon-negative concrete technology and UHI mitigation presents a compelling opportunity for synergistic environmental solutions.

The primary technical objectives of carbon-negative concrete research encompass multiple dimensions: achieving net carbon sequestration of at least 10-50 kg CO2 per cubic meter of concrete, maintaining or enhancing structural performance comparable to traditional Portland cement concrete, ensuring economic viability with production costs within 15-20% of conventional concrete, and developing scalable manufacturing processes adaptable to existing infrastructure.

Additionally, specific objectives related to UHI reduction include developing concrete formulations with high solar reflectance index (SRI) values exceeding 29 for pavements and 78 for roofing applications, enhancing evaporative cooling properties through optimized porosity and water retention characteristics, and improving thermal performance with reduced heat capacity and thermal conductivity compared to traditional concrete.

The technological evolution is now trending toward multifunctional carbon-negative concrete solutions that simultaneously address carbon sequestration, UHI mitigation, and conventional performance requirements. Research is increasingly focused on biomimetic approaches, incorporating nature-inspired structures and processes to enhance both carbon capture efficiency and thermal regulation properties. The convergence of these technological pathways represents a promising frontier for sustainable urban development and climate change mitigation.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental concerns and regulatory pressures. The global green building materials market was valued at approximately $256 billion in 2020 and is projected to reach $523 billion by 2027, growing at a CAGR of 10.7%. This remarkable expansion reflects the construction industry's shift toward more environmentally responsible practices and materials.

Carbon-negative concrete represents a particularly promising segment within this market. Traditional concrete production accounts for nearly 8% of global CO2 emissions, creating an urgent need for alternatives. The carbon-negative concrete market, though currently smaller at around $1.2 billion, is expected to grow at a significantly faster rate of 15-18% annually through 2030, outpacing conventional concrete.

Market demand for sustainable construction materials is being driven by several key factors. Government regulations and policies promoting green building standards, such as LEED certification in the United States and similar programs globally, are creating regulatory incentives. Many jurisdictions are implementing carbon taxes and emissions trading schemes that make conventional concrete increasingly expensive, improving the cost competitiveness of carbon-negative alternatives.

Corporate sustainability commitments represent another significant market driver. Major construction firms and property developers are increasingly adopting science-based targets for emissions reduction, creating substantial demand for materials that can help achieve these goals. The growing consumer preference for environmentally responsible buildings is also influencing purchasing decisions throughout the supply chain.

Regional market analysis reveals varying adoption rates. Europe leads in sustainable construction materials adoption, with Scandinavian countries showing particularly strong demand for carbon-negative concrete. North America follows closely, with significant growth in urban centers where heat island effects are most pronounced. The Asia-Pacific region, despite having the largest construction market overall, shows more uneven adoption but represents the fastest-growing market for sustainable materials.

Market challenges include higher initial costs compared to traditional concrete, with premiums ranging from 15-40% depending on the specific technology and application. Supply chain limitations and production capacity constraints also currently restrict market growth. Additionally, there remains skepticism among some industry stakeholders regarding the long-term performance and durability of newer sustainable concrete formulations.

The competitive landscape features both established construction material companies developing sustainable product lines and innovative startups focused exclusively on carbon-negative solutions. This dynamic is creating a robust ecosystem of suppliers and accelerating technological advancement in the field.

Carbon-negative concrete represents a particularly promising segment within this market. Traditional concrete production accounts for nearly 8% of global CO2 emissions, creating an urgent need for alternatives. The carbon-negative concrete market, though currently smaller at around $1.2 billion, is expected to grow at a significantly faster rate of 15-18% annually through 2030, outpacing conventional concrete.

Market demand for sustainable construction materials is being driven by several key factors. Government regulations and policies promoting green building standards, such as LEED certification in the United States and similar programs globally, are creating regulatory incentives. Many jurisdictions are implementing carbon taxes and emissions trading schemes that make conventional concrete increasingly expensive, improving the cost competitiveness of carbon-negative alternatives.

Corporate sustainability commitments represent another significant market driver. Major construction firms and property developers are increasingly adopting science-based targets for emissions reduction, creating substantial demand for materials that can help achieve these goals. The growing consumer preference for environmentally responsible buildings is also influencing purchasing decisions throughout the supply chain.

Regional market analysis reveals varying adoption rates. Europe leads in sustainable construction materials adoption, with Scandinavian countries showing particularly strong demand for carbon-negative concrete. North America follows closely, with significant growth in urban centers where heat island effects are most pronounced. The Asia-Pacific region, despite having the largest construction market overall, shows more uneven adoption but represents the fastest-growing market for sustainable materials.

Market challenges include higher initial costs compared to traditional concrete, with premiums ranging from 15-40% depending on the specific technology and application. Supply chain limitations and production capacity constraints also currently restrict market growth. Additionally, there remains skepticism among some industry stakeholders regarding the long-term performance and durability of newer sustainable concrete formulations.

The competitive landscape features both established construction material companies developing sustainable product lines and innovative startups focused exclusively on carbon-negative solutions. This dynamic is creating a robust ecosystem of suppliers and accelerating technological advancement in the field.

Current Status and Challenges in Carbon-negative Concrete Development

Carbon-negative concrete technology has witnessed significant advancements globally, though it remains in relatively early stages of commercial deployment. Current carbon-negative concrete solutions primarily utilize two approaches: carbon capture during production and carbon sequestration within the material itself. Leading companies like CarbonCure, Solidia, and Carbicrete have developed processes that inject captured CO2 into concrete during mixing, effectively mineralizing carbon dioxide into stable calcium carbonates while simultaneously improving concrete strength.

In academic research, substantial progress has been made in developing alternative cementitious materials that require less energy during production. Geopolymer cements, alkali-activated materials, and magnesium-based cements have demonstrated potential to reduce carbon emissions by 40-80% compared to traditional Portland cement. However, these alternatives often face challenges in scaling production and meeting established performance standards.

The integration of carbon-negative concrete with urban heat island mitigation remains particularly challenging. While high-albedo concrete surfaces can reflect more solar radiation, the manufacturing processes for these specialized concretes often involve additional energy inputs. The technical challenge lies in developing formulations that simultaneously sequester carbon, maintain high albedo properties, and deliver required structural performance.

Regulatory frameworks present another significant hurdle. Current building codes and standards in many jurisdictions do not adequately accommodate innovative concrete formulations, creating market entry barriers for carbon-negative solutions. Additionally, the certification processes for carbon credits related to concrete production remain complex and inconsistent across regions.

Supply chain limitations constitute a critical constraint. The production of carbon-negative concrete often requires specialized additives, alternative binders, or carbon capture equipment that are not widely available. The geographical distribution of technology development shows concentration in North America and Europe, with emerging activities in China and Australia, creating disparities in global implementation potential.

Cost remains perhaps the most significant barrier to widespread adoption. Current carbon-negative concrete solutions typically command a 15-30% price premium over conventional concrete, making economic viability dependent on carbon pricing mechanisms or regulatory mandates. Without these supports, market penetration remains limited primarily to high-profile green building projects and public infrastructure with specific sustainability requirements.

Technical performance verification presents ongoing challenges, particularly regarding long-term durability. With limited field deployment history, questions persist about how carbon-negative formulations will perform over decades-long service lives, especially under varying environmental conditions and in conjunction with urban heat island mitigation strategies.

In academic research, substantial progress has been made in developing alternative cementitious materials that require less energy during production. Geopolymer cements, alkali-activated materials, and magnesium-based cements have demonstrated potential to reduce carbon emissions by 40-80% compared to traditional Portland cement. However, these alternatives often face challenges in scaling production and meeting established performance standards.

The integration of carbon-negative concrete with urban heat island mitigation remains particularly challenging. While high-albedo concrete surfaces can reflect more solar radiation, the manufacturing processes for these specialized concretes often involve additional energy inputs. The technical challenge lies in developing formulations that simultaneously sequester carbon, maintain high albedo properties, and deliver required structural performance.

Regulatory frameworks present another significant hurdle. Current building codes and standards in many jurisdictions do not adequately accommodate innovative concrete formulations, creating market entry barriers for carbon-negative solutions. Additionally, the certification processes for carbon credits related to concrete production remain complex and inconsistent across regions.

Supply chain limitations constitute a critical constraint. The production of carbon-negative concrete often requires specialized additives, alternative binders, or carbon capture equipment that are not widely available. The geographical distribution of technology development shows concentration in North America and Europe, with emerging activities in China and Australia, creating disparities in global implementation potential.

Cost remains perhaps the most significant barrier to widespread adoption. Current carbon-negative concrete solutions typically command a 15-30% price premium over conventional concrete, making economic viability dependent on carbon pricing mechanisms or regulatory mandates. Without these supports, market penetration remains limited primarily to high-profile green building projects and public infrastructure with specific sustainability requirements.

Technical performance verification presents ongoing challenges, particularly regarding long-term durability. With limited field deployment history, questions persist about how carbon-negative formulations will perform over decades-long service lives, especially under varying environmental conditions and in conjunction with urban heat island mitigation strategies.

Current Technical Solutions for Carbon-negative Concrete Production

01 Carbon-capturing concrete formulations

Innovative concrete formulations designed to absorb and sequester carbon dioxide from the atmosphere, creating carbon-negative building materials. These formulations incorporate materials like calcium silicates that actively capture CO2 during the curing process and throughout the concrete's lifecycle. This approach not only reduces the carbon footprint of construction but also helps mitigate urban heat island effects by creating more environmentally sustainable building materials.- Carbon-capturing concrete formulations: Innovative concrete formulations designed to absorb and sequester carbon dioxide from the atmosphere, creating carbon-negative building materials. These formulations incorporate materials like calcium silicates that actively capture CO2 during the curing process and throughout the concrete's lifecycle, effectively reducing the carbon footprint of urban infrastructure while maintaining structural integrity and performance characteristics.

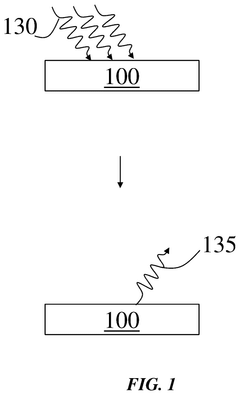

- Heat-reflective concrete technologies for urban heat island mitigation: Advanced concrete technologies that incorporate reflective materials or coatings to increase solar reflectance and reduce heat absorption in urban environments. These technologies include high-albedo concrete surfaces, specialized pigments, and reflective aggregates that help lower surface temperatures of pavements and buildings, thereby mitigating urban heat island effects and reducing cooling energy demands in cities.

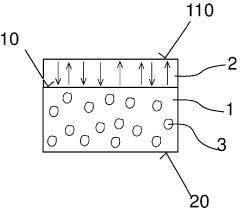

- Porous concrete systems for temperature regulation: Permeable concrete systems designed to improve water management and temperature regulation in urban environments. These systems allow water infiltration and evaporation, which provides natural cooling through evaporative processes. The porous structure also reduces heat storage capacity compared to traditional concrete, helping to lower ambient temperatures in urban areas while simultaneously addressing stormwater management issues.

- Integration of vegetation with concrete structures: Hybrid systems that combine concrete infrastructure with vegetation to create living walls, green roofs, or bioretention features. These integrated systems leverage the natural cooling effects of plants through evapotranspiration while benefiting from the structural properties of concrete. The vegetation component actively sequesters carbon while the specialized concrete designs minimize carbon emissions, creating a synergistic approach to addressing both urban heat islands and carbon footprint.

- Smart concrete monitoring and management systems: Intelligent systems for monitoring and managing concrete infrastructure to optimize carbon sequestration and thermal performance. These technologies incorporate sensors, data analytics, and control systems to track carbon uptake, surface temperatures, and other parameters in real-time. The systems enable adaptive management of concrete structures to maximize their environmental benefits, including carbon negativity and heat island mitigation, throughout their lifecycle.

02 Heat-reflective concrete technologies

Advanced concrete technologies that incorporate reflective materials or coatings to increase the albedo (reflectivity) of urban surfaces. These technologies help reduce heat absorption and retention in concrete structures, thereby mitigating urban heat island effects. The concrete formulations may include light-colored aggregates, reflective pigments, or special surface treatments that reflect solar radiation rather than absorbing it, keeping urban areas cooler.Expand Specific Solutions03 Porous concrete systems for urban cooling

Permeable concrete systems designed to improve water management and natural cooling in urban environments. These systems allow water to percolate through the concrete, enabling evaporative cooling and reducing surface temperatures. The porous structure also helps manage stormwater runoff while contributing to carbon sequestration through specialized additives. This dual-function approach addresses both urban heat islands and carbon emissions simultaneously.Expand Specific Solutions04 Integration of biological materials in concrete

Incorporation of biological materials such as algae, fungi, or plant-based additives into concrete to enhance carbon sequestration capabilities. These bio-integrated concrete formulations can actively remove carbon dioxide from the atmosphere through biological processes while providing additional benefits such as improved thermal regulation properties. The living components continue to capture carbon throughout the concrete's lifecycle, creating truly carbon-negative building materials that help cool urban environments.Expand Specific Solutions05 Smart concrete systems for urban climate management

Intelligent concrete systems that adapt to environmental conditions to optimize both carbon capture and heat management. These systems incorporate phase-change materials, sensors, or responsive components that can adjust properties based on temperature or carbon dioxide levels. Some formulations include materials that enhance carbon sequestration during high CO2 periods while maximizing heat reflection during hot weather, providing dynamic solutions to both carbon emissions and urban heat island challenges.Expand Specific Solutions

Key Industry Players in Sustainable Concrete Innovation

The carbon-negative concrete and urban heat island reduction market is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The market is expanding rapidly, driven by global decarbonization initiatives and urban sustainability goals, with projections suggesting significant growth potential. Technologically, the field shows varying maturity levels across players. Academic institutions like Chongqing Jiaotong University, Southeast University, and Tianjin University are advancing fundamental research, while companies such as Carbon Limit Co. and Taiheiyo Cement are developing commercial applications. Carbon Limit's technology for capturing atmospheric CO2 in concrete represents a leading edge innovation, while established players like China Academy of Building Research and IS DONGSEO are integrating these technologies into broader construction practices, indicating a gradual industry transition toward carbon-negative building materials.

Taiheiyo Cement Corp.

Technical Solution: Taiheiyo Cement has pioneered the "CO2-SUICOM" (CO2-Storage Under Infrastructure by Concrete Materials) technology, a carbon-negative concrete that absorbs more CO2 than is emitted during its production. Their innovative approach involves special additives and a unique curing process where concrete actively absorbs atmospheric CO2. The company has developed a gamma-C2S-rich cement that requires lower calcination temperatures (around 1200°C versus traditional 1450°C), significantly reducing production emissions. Their concrete formulation incorporates industrial byproducts like fly ash and blast furnace slag, further reducing the carbon footprint. For urban heat island mitigation, Taiheiyo has developed high-albedo concrete surfaces that reflect solar radiation and specialized porous concrete that enhances evaporative cooling in urban environments.

Strengths: Established manufacturing infrastructure with global distribution capabilities; extensive R&D resources; proven technology with multiple successful implementations. Weaknesses: Higher production costs compared to traditional cement; requires specialized curing conditions for optimal carbon absorption; limited availability in some markets.

Carbon Limit Co.

Technical Solution: Carbon Limit has developed a groundbreaking carbon-negative concrete solution called "Carbon Limit C-Crete" that actively absorbs CO2 during the curing process. Their proprietary technology incorporates CO2-absorbing minerals and industrial byproducts that sequester carbon dioxide while maintaining structural integrity. The company's concrete formulation can absorb up to 100kg of CO2 per cubic meter, effectively turning concrete from a carbon source into a carbon sink. Their process also utilizes lower-temperature manufacturing methods, reducing the energy requirements by approximately 30% compared to traditional Portland cement production. Carbon Limit has implemented pilot projects in urban environments where their concrete pavements and structures not only sequester carbon but also incorporate reflective properties to mitigate urban heat island effects.

Strengths: Dual-benefit technology addressing both carbon sequestration and urban heat reduction; scalable manufacturing process compatible with existing concrete production facilities. Weaknesses: Higher initial production costs compared to conventional concrete; limited long-term performance data in extreme weather conditions; requires specialized knowledge for optimal implementation.

Core Patents and Research in CO2 Absorption Concrete Technologies

Concrete paving block, method for its manufacture, concrete mixtures therefor and use of self-cooling concrete paving blocks to reduce the urban heat island effect

PatentInactiveDE102015100581A1

Innovation

- A concrete paving stone design with a first concrete area acting as a water reservoir and a second, capillary-active concrete area for bidirectional water transport, incorporating polymer fibers to enhance water absorption and evaporation, using recycled concrete for efficient water storage and distribution.

Cementitious compositions and systems with enhanced solar reflectance and thermal emittance and related methods

PatentPendingUS20250250201A1

Innovation

- Developing cementitious compositions with enhanced solar reflectance and thermal emittance using materials like silicon-containing waste glass, light-reflecting materials such as barium sulfate, and thermal emittance enhancers like pumice, which reduce heat absorption and increase reflectivity.

Urban Heat Island Mitigation Strategies Using Advanced Concrete

Urban heat islands (UHIs) represent a significant environmental challenge in modern urban landscapes, with concrete surfaces being major contributors to this phenomenon. Advanced concrete technologies offer promising solutions for mitigating UHI effects through innovative material science approaches. These strategies focus on modifying concrete's thermal properties to reduce heat absorption and retention.

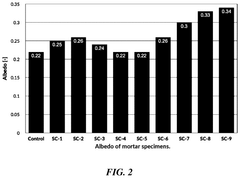

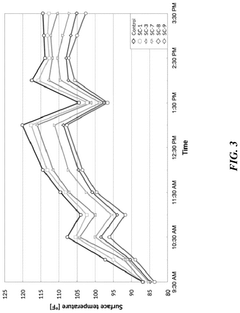

Reflective concrete formulations incorporate high-albedo materials that increase solar reflectance, significantly reducing surface temperatures compared to conventional concrete. These formulations typically achieve solar reflectance indices (SRI) of 35-50, compared to traditional concrete's 25-35, resulting in surface temperature reductions of 8-15°C during peak summer conditions.

Permeable concrete systems provide dual benefits for UHI mitigation. By allowing water infiltration, these systems facilitate evaporative cooling while reducing surface runoff. Research indicates that permeable concrete surfaces can maintain temperatures 6-10°C lower than conventional concrete during hot weather periods, while simultaneously improving urban water management.

Phase-change material (PCM) integrated concrete represents an emerging technology with significant potential. These advanced composites incorporate microencapsulated PCMs that absorb thermal energy during temperature increases and release it during cooling periods, effectively dampening temperature fluctuations. Laboratory studies demonstrate that PCM-concrete can reduce daily temperature variations by 4-7°C in urban settings.

Vegetation-compatible concrete systems, including grid pavers and specialized porous formulations, enable integration of greenery within hardscaped areas. These hybrid solutions combine the structural benefits of concrete with the cooling effects of vegetation, creating "green infrastructure" that can reduce local temperatures by 2-5°C while supporting biodiversity.

Carbon-negative concrete variants offer particular promise by addressing both UHI effects and climate change concerns. These formulations sequester CO2 during production and curing processes, while often incorporating reflective or cooling properties. Recent field implementations have demonstrated temperature reductions of 3-6°C compared to standard concrete, with carbon sequestration capabilities of 5-15 kg CO2 per cubic meter of material.

Implementation strategies for these advanced concrete solutions must consider local climate conditions, urban density patterns, and existing infrastructure. Pilot projects in various climate zones have demonstrated that strategic deployment of advanced concrete in high-impact areas such as pedestrian zones, parking facilities, and building surrounds can create significant cooling effects that extend beyond the immediate installation area.

Reflective concrete formulations incorporate high-albedo materials that increase solar reflectance, significantly reducing surface temperatures compared to conventional concrete. These formulations typically achieve solar reflectance indices (SRI) of 35-50, compared to traditional concrete's 25-35, resulting in surface temperature reductions of 8-15°C during peak summer conditions.

Permeable concrete systems provide dual benefits for UHI mitigation. By allowing water infiltration, these systems facilitate evaporative cooling while reducing surface runoff. Research indicates that permeable concrete surfaces can maintain temperatures 6-10°C lower than conventional concrete during hot weather periods, while simultaneously improving urban water management.

Phase-change material (PCM) integrated concrete represents an emerging technology with significant potential. These advanced composites incorporate microencapsulated PCMs that absorb thermal energy during temperature increases and release it during cooling periods, effectively dampening temperature fluctuations. Laboratory studies demonstrate that PCM-concrete can reduce daily temperature variations by 4-7°C in urban settings.

Vegetation-compatible concrete systems, including grid pavers and specialized porous formulations, enable integration of greenery within hardscaped areas. These hybrid solutions combine the structural benefits of concrete with the cooling effects of vegetation, creating "green infrastructure" that can reduce local temperatures by 2-5°C while supporting biodiversity.

Carbon-negative concrete variants offer particular promise by addressing both UHI effects and climate change concerns. These formulations sequester CO2 during production and curing processes, while often incorporating reflective or cooling properties. Recent field implementations have demonstrated temperature reductions of 3-6°C compared to standard concrete, with carbon sequestration capabilities of 5-15 kg CO2 per cubic meter of material.

Implementation strategies for these advanced concrete solutions must consider local climate conditions, urban density patterns, and existing infrastructure. Pilot projects in various climate zones have demonstrated that strategic deployment of advanced concrete in high-impact areas such as pedestrian zones, parking facilities, and building surrounds can create significant cooling effects that extend beyond the immediate installation area.

Life Cycle Assessment and Environmental Impact Metrics

Life Cycle Assessment (LCA) provides a comprehensive framework for evaluating the environmental impacts of carbon-negative concrete throughout its entire lifecycle. This methodology encompasses raw material extraction, manufacturing processes, transportation, installation, use phase, and end-of-life scenarios. For carbon-negative concrete, LCA reveals significant potential for carbon sequestration during production and throughout the service life, offering a net environmental benefit compared to traditional concrete formulations.

Key environmental impact metrics for carbon-negative concrete include Global Warming Potential (GWP), measured in CO2-equivalent emissions. Unlike conventional concrete which typically emits 400-500 kg CO2e per cubic meter, carbon-negative formulations can sequester between 50-200 kg CO2e per cubic meter, depending on the specific technology employed. This represents a paradigm shift in construction material environmental performance.

Energy consumption metrics are equally important, with embodied energy measurements revealing that some carbon-negative concrete formulations require 15-30% less energy during production compared to Portland cement-based alternatives. Water usage metrics indicate potential reductions of up to 40% in freshwater consumption, addressing another critical environmental concern.

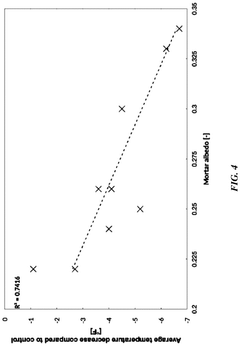

When evaluating urban heat island mitigation capabilities, albedo measurements become essential. Carbon-negative concrete can be engineered to achieve albedo values of 0.3-0.5, significantly higher than conventional concrete's typical 0.2-0.35 range. This increased reflectivity directly contributes to reduced surface temperatures in urban environments, with field studies documenting temperature reductions of 2-4°C during peak summer conditions.

Resource depletion indicators demonstrate that carbon-negative concrete often utilizes industrial byproducts and waste materials, reducing virgin resource extraction by up to 60% compared to conventional concrete. This circular economy approach transforms waste streams into valuable construction inputs while avoiding landfill disposal.

Toxicity and human health impact assessments reveal reduced heavy metal leaching and lower particulate emissions during production. These benefits stem from alternative curing methods and the incorporation of binding agents that effectively immobilize potential contaminants. Biodiversity impact metrics further demonstrate reduced ecosystem disruption due to decreased mining activities for raw materials.

Standardized reporting frameworks such as Environmental Product Declarations (EPDs) are increasingly being adopted to communicate these metrics in a transparent, comparable format. This standardization enables stakeholders to make informed decisions based on verified environmental performance data rather than marketing claims alone.

Key environmental impact metrics for carbon-negative concrete include Global Warming Potential (GWP), measured in CO2-equivalent emissions. Unlike conventional concrete which typically emits 400-500 kg CO2e per cubic meter, carbon-negative formulations can sequester between 50-200 kg CO2e per cubic meter, depending on the specific technology employed. This represents a paradigm shift in construction material environmental performance.

Energy consumption metrics are equally important, with embodied energy measurements revealing that some carbon-negative concrete formulations require 15-30% less energy during production compared to Portland cement-based alternatives. Water usage metrics indicate potential reductions of up to 40% in freshwater consumption, addressing another critical environmental concern.

When evaluating urban heat island mitigation capabilities, albedo measurements become essential. Carbon-negative concrete can be engineered to achieve albedo values of 0.3-0.5, significantly higher than conventional concrete's typical 0.2-0.35 range. This increased reflectivity directly contributes to reduced surface temperatures in urban environments, with field studies documenting temperature reductions of 2-4°C during peak summer conditions.

Resource depletion indicators demonstrate that carbon-negative concrete often utilizes industrial byproducts and waste materials, reducing virgin resource extraction by up to 60% compared to conventional concrete. This circular economy approach transforms waste streams into valuable construction inputs while avoiding landfill disposal.

Toxicity and human health impact assessments reveal reduced heavy metal leaching and lower particulate emissions during production. These benefits stem from alternative curing methods and the incorporation of binding agents that effectively immobilize potential contaminants. Biodiversity impact metrics further demonstrate reduced ecosystem disruption due to decreased mining activities for raw materials.

Standardized reporting frameworks such as Environmental Product Declarations (EPDs) are increasingly being adopted to communicate these metrics in a transparent, comparable format. This standardization enables stakeholders to make informed decisions based on verified environmental performance data rather than marketing claims alone.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!