Carbon-negative Concrete in Solar Power Installation Projects

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Technology Background and Objectives

Concrete production is one of the most carbon-intensive industrial processes, accounting for approximately 8% of global CO2 emissions. Traditional concrete manufacturing releases carbon dioxide through both the chemical process of calcination and the energy-intensive heating required during production. As the world shifts toward renewable energy solutions, the carbon footprint of infrastructure components has come under increasing scrutiny. Carbon-negative concrete represents a revolutionary approach that transforms this construction material from a significant carbon emitter to a potential carbon sink.

The evolution of concrete technology has progressed from conventional high-emission formulations to low-carbon alternatives, and now to carbon-negative variants. This technological progression aligns with global sustainability goals and the urgent need to mitigate climate change impacts. Carbon-negative concrete incorporates innovative materials such as industrial byproducts, alternative binders, and carbon capture technologies to sequester more carbon than is emitted during its production lifecycle.

In the context of solar power installations, concrete serves critical functions including foundation support for photovoltaic arrays, structural elements for concentrated solar power plants, and ballast systems for floating solar facilities. The juxtaposition of clean energy generation with carbon-intensive construction materials presents a technological contradiction that carbon-negative concrete aims to resolve.

The primary objective of this research is to evaluate the technical feasibility, performance characteristics, and scalability of carbon-negative concrete specifically for solar power installation applications. This includes assessing mechanical properties such as compressive strength, durability under various environmental conditions, and long-term structural integrity when subjected to the unique stresses of solar installations.

Secondary objectives include quantifying the carbon sequestration potential throughout the concrete lifecycle, analyzing cost implications compared to conventional concrete, and identifying optimization opportunities for different solar installation types. The research also aims to establish standardized methodologies for measuring and verifying carbon negativity claims in concrete products.

The technological trajectory suggests increasing integration of carbon capture directly into concrete manufacturing processes, development of novel supplementary cementitious materials derived from waste streams, and advancement in carbonation curing techniques. Recent breakthroughs in alternative binding agents that require significantly less energy during production while offering enhanced CO2 absorption capabilities represent promising directions for further development.

As solar capacity continues to expand globally at unprecedented rates, the environmental impact of installation infrastructure becomes increasingly significant. Carbon-negative concrete technology offers a pathway to align construction materials with the sustainability ethos of renewable energy, potentially transforming solar installations into more comprehensive carbon sinks rather than merely carbon-neutral energy sources.

The evolution of concrete technology has progressed from conventional high-emission formulations to low-carbon alternatives, and now to carbon-negative variants. This technological progression aligns with global sustainability goals and the urgent need to mitigate climate change impacts. Carbon-negative concrete incorporates innovative materials such as industrial byproducts, alternative binders, and carbon capture technologies to sequester more carbon than is emitted during its production lifecycle.

In the context of solar power installations, concrete serves critical functions including foundation support for photovoltaic arrays, structural elements for concentrated solar power plants, and ballast systems for floating solar facilities. The juxtaposition of clean energy generation with carbon-intensive construction materials presents a technological contradiction that carbon-negative concrete aims to resolve.

The primary objective of this research is to evaluate the technical feasibility, performance characteristics, and scalability of carbon-negative concrete specifically for solar power installation applications. This includes assessing mechanical properties such as compressive strength, durability under various environmental conditions, and long-term structural integrity when subjected to the unique stresses of solar installations.

Secondary objectives include quantifying the carbon sequestration potential throughout the concrete lifecycle, analyzing cost implications compared to conventional concrete, and identifying optimization opportunities for different solar installation types. The research also aims to establish standardized methodologies for measuring and verifying carbon negativity claims in concrete products.

The technological trajectory suggests increasing integration of carbon capture directly into concrete manufacturing processes, development of novel supplementary cementitious materials derived from waste streams, and advancement in carbonation curing techniques. Recent breakthroughs in alternative binding agents that require significantly less energy during production while offering enhanced CO2 absorption capabilities represent promising directions for further development.

As solar capacity continues to expand globally at unprecedented rates, the environmental impact of installation infrastructure becomes increasingly significant. Carbon-negative concrete technology offers a pathway to align construction materials with the sustainability ethos of renewable energy, potentially transforming solar installations into more comprehensive carbon sinks rather than merely carbon-neutral energy sources.

Market Analysis for Green Concrete in Solar Projects

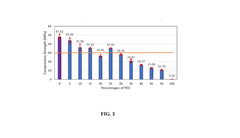

The global market for green concrete in solar power installations is experiencing significant growth, driven by the convergence of renewable energy expansion and sustainable construction practices. The solar energy sector has been growing at an annual rate of 20% globally, with installed capacity reaching 760 GW in 2020 and projected to exceed 1,500 GW by 2025. This rapid expansion creates substantial demand for concrete foundations and structural supports, traditionally responsible for high carbon emissions in solar project development.

Carbon-negative concrete represents a revolutionary advancement in construction materials, offering potential to transform solar installations from carbon contributors to carbon sinks. Current market size for green concrete in construction is valued at approximately $25 billion, with specialized applications in renewable energy infrastructure accounting for $3.7 billion. Industry analysts project this segment to grow at 14.3% CAGR through 2030, outpacing conventional concrete markets.

Regional market distribution shows notable variations, with Europe leading adoption at 37% market share, followed by North America (28%), Asia-Pacific (22%), and emerging markets (13%). European leadership stems from stringent carbon regulations and ambitious climate targets, particularly in Germany, France, and Scandinavian countries where carbon pricing mechanisms incentivize low-carbon materials.

Customer segmentation reveals utility-scale solar developers as primary adopters (58%), followed by commercial/industrial installations (27%), and residential applications (15%). Large-scale developers demonstrate greater willingness to absorb premium costs associated with carbon-negative concrete, typically 15-30% higher than conventional alternatives, due to lifecycle cost benefits and regulatory compliance advantages.

Price sensitivity analysis indicates decreasing premium tolerance across market segments, with utility developers accepting up to 25% premium, commercial installations 18%, and residential applications limited to 10%. This price sensitivity highlights the importance of achieving economies of scale to drive adoption across all market segments.

Supply chain analysis reveals significant challenges, including limited production capacity, geographical concentration of specialized additives, and competition for key inputs like supplementary cementitious materials. Current production capacity meets only 7% of potential demand in solar construction applications, creating substantial market opportunity for scaled production.

Market forecasts suggest carbon-negative concrete in solar installations could reach $12 billion by 2030, representing 32% of all concrete used in solar projects globally. This growth trajectory depends on continued policy support, technological improvements reducing cost premiums, and increased awareness of embodied carbon impacts among project developers and financiers.

Carbon-negative concrete represents a revolutionary advancement in construction materials, offering potential to transform solar installations from carbon contributors to carbon sinks. Current market size for green concrete in construction is valued at approximately $25 billion, with specialized applications in renewable energy infrastructure accounting for $3.7 billion. Industry analysts project this segment to grow at 14.3% CAGR through 2030, outpacing conventional concrete markets.

Regional market distribution shows notable variations, with Europe leading adoption at 37% market share, followed by North America (28%), Asia-Pacific (22%), and emerging markets (13%). European leadership stems from stringent carbon regulations and ambitious climate targets, particularly in Germany, France, and Scandinavian countries where carbon pricing mechanisms incentivize low-carbon materials.

Customer segmentation reveals utility-scale solar developers as primary adopters (58%), followed by commercial/industrial installations (27%), and residential applications (15%). Large-scale developers demonstrate greater willingness to absorb premium costs associated with carbon-negative concrete, typically 15-30% higher than conventional alternatives, due to lifecycle cost benefits and regulatory compliance advantages.

Price sensitivity analysis indicates decreasing premium tolerance across market segments, with utility developers accepting up to 25% premium, commercial installations 18%, and residential applications limited to 10%. This price sensitivity highlights the importance of achieving economies of scale to drive adoption across all market segments.

Supply chain analysis reveals significant challenges, including limited production capacity, geographical concentration of specialized additives, and competition for key inputs like supplementary cementitious materials. Current production capacity meets only 7% of potential demand in solar construction applications, creating substantial market opportunity for scaled production.

Market forecasts suggest carbon-negative concrete in solar installations could reach $12 billion by 2030, representing 32% of all concrete used in solar projects globally. This growth trajectory depends on continued policy support, technological improvements reducing cost premiums, and increased awareness of embodied carbon impacts among project developers and financiers.

Current Status and Challenges in Carbon-negative Concrete

Carbon-negative concrete technology is currently in a transitional phase between laboratory research and commercial application. While conventional concrete production accounts for approximately 8% of global CO2 emissions, carbon-negative alternatives have demonstrated the potential to sequester more carbon than they emit during production. Several pioneering companies have developed commercial-scale carbon-negative concrete solutions, including Carbicrete, CarbonCure, and Carbon Upcycling Technologies, each employing different approaches to carbon sequestration.

The primary technological approaches include CO2 mineralization, where carbon dioxide is chemically bound within the concrete matrix; alternative binding materials that replace traditional Portland cement; and carbon-capturing aggregates that incorporate waste materials capable of absorbing CO2. These technologies have shown promising results in laboratory settings, with some achieving carbon reductions of up to 70% compared to traditional concrete.

Despite these advancements, significant challenges remain in scaling carbon-negative concrete for widespread adoption in solar power installations. Cost remains a substantial barrier, with carbon-negative alternatives typically commanding a 15-30% premium over conventional concrete. This price differential is particularly challenging for utility-scale solar projects where foundations represent a significant portion of overall costs.

Technical performance issues also persist, particularly regarding long-term durability and structural integrity under varying environmental conditions. Solar installations often require concrete foundations to withstand decades of exposure to elements, and the long-term performance data for carbon-negative alternatives remains limited. Standardization and certification processes are still evolving, creating uncertainty for project developers and engineers.

Supply chain constraints present another significant challenge. The production of carbon-negative concrete often requires specialized facilities and processes, limiting availability in many regions. This is particularly problematic for remote solar installation sites where transportation costs can become prohibitive.

Regulatory frameworks and carbon accounting methodologies for these innovative materials remain inconsistent across different jurisdictions. While some regions have implemented carbon pricing mechanisms that incentivize the use of carbon-negative materials, many markets lack the policy support necessary to drive adoption.

In the context of solar power installations specifically, there are unique technical challenges related to the integration of carbon-negative concrete with mounting systems and the ability to withstand the specific loading patterns associated with solar arrays. The thermal properties and expansion characteristics of some carbon-negative formulations may differ from conventional concrete, requiring adjustments to foundation design parameters.

The primary technological approaches include CO2 mineralization, where carbon dioxide is chemically bound within the concrete matrix; alternative binding materials that replace traditional Portland cement; and carbon-capturing aggregates that incorporate waste materials capable of absorbing CO2. These technologies have shown promising results in laboratory settings, with some achieving carbon reductions of up to 70% compared to traditional concrete.

Despite these advancements, significant challenges remain in scaling carbon-negative concrete for widespread adoption in solar power installations. Cost remains a substantial barrier, with carbon-negative alternatives typically commanding a 15-30% premium over conventional concrete. This price differential is particularly challenging for utility-scale solar projects where foundations represent a significant portion of overall costs.

Technical performance issues also persist, particularly regarding long-term durability and structural integrity under varying environmental conditions. Solar installations often require concrete foundations to withstand decades of exposure to elements, and the long-term performance data for carbon-negative alternatives remains limited. Standardization and certification processes are still evolving, creating uncertainty for project developers and engineers.

Supply chain constraints present another significant challenge. The production of carbon-negative concrete often requires specialized facilities and processes, limiting availability in many regions. This is particularly problematic for remote solar installation sites where transportation costs can become prohibitive.

Regulatory frameworks and carbon accounting methodologies for these innovative materials remain inconsistent across different jurisdictions. While some regions have implemented carbon pricing mechanisms that incentivize the use of carbon-negative materials, many markets lack the policy support necessary to drive adoption.

In the context of solar power installations specifically, there are unique technical challenges related to the integration of carbon-negative concrete with mounting systems and the ability to withstand the specific loading patterns associated with solar arrays. The thermal properties and expansion characteristics of some carbon-negative formulations may differ from conventional concrete, requiring adjustments to foundation design parameters.

Current Carbon-negative Concrete Solutions for Solar Installations

01 Carbon capture and sequestration in concrete

Technologies that enable concrete to absorb and permanently store carbon dioxide during the curing process, transforming it from a carbon source to a carbon sink. These methods involve injecting CO2 into concrete mixtures where it reacts with calcium compounds to form stable carbonates, effectively sequestering carbon while simultaneously improving concrete strength and durability.- Carbon capture and sequestration in concrete: Technologies that enable concrete to capture and store carbon dioxide during its lifecycle, effectively making it carbon-negative. These methods involve incorporating materials that can absorb CO2 from the atmosphere and permanently sequester it within the concrete structure. This approach not only reduces the carbon footprint of concrete production but can actually transform concrete into a carbon sink, helping to mitigate climate change impacts.

- Alternative cementitious materials for reduced emissions: Development of alternative binding materials to replace traditional Portland cement, which is responsible for significant carbon emissions. These alternatives include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial byproducts. By substituting conventional cement with these alternatives, the carbon footprint of concrete production can be substantially reduced while maintaining or even improving performance characteristics.

- CO2 utilization in concrete curing processes: Innovative curing techniques that utilize carbon dioxide as a reactant in the concrete hardening process. These methods accelerate the curing of concrete while simultaneously consuming CO2, converting it into stable carbonate minerals within the concrete matrix. This approach offers dual benefits of improved concrete properties and reduced carbon emissions, potentially transforming concrete manufacturing from a carbon source to a carbon sink.

- Monitoring and certification systems for carbon-negative concrete: Development of methodologies and technologies for measuring, reporting, and verifying the carbon footprint of concrete throughout its lifecycle. These systems include sensors, data analytics platforms, and certification frameworks that enable accurate quantification of embodied carbon and carbon sequestration in concrete. Such tools are essential for validating carbon-negative claims and supporting carbon credit generation from concrete-based carbon removal.

- Waste material incorporation for carbon reduction: Techniques for incorporating various waste materials into concrete formulations to reduce carbon emissions. These approaches utilize industrial byproducts, construction waste, and other recycled materials as partial replacements for cement or aggregates. By diverting waste from landfills and reducing the need for virgin materials, these methods significantly lower the embodied carbon of concrete while often enhancing its durability and performance characteristics.

02 Alternative cementitious materials with lower carbon footprint

Development of cement alternatives that significantly reduce carbon emissions compared to traditional Portland cement. These include supplementary cementitious materials (SCMs) like fly ash, slag, silica fume, and natural pozzolans, as well as novel binders such as geopolymers and alkali-activated materials that require less energy to produce and generate fewer emissions during manufacturing.Expand Specific Solutions03 Carbon accounting and monitoring systems for concrete production

Digital platforms and methodologies for accurately measuring, reporting, and verifying carbon emissions throughout the concrete value chain. These systems enable real-time tracking of carbon footprints, facilitate carbon credits for negative-carbon concrete, and provide data-driven insights for optimizing production processes to minimize environmental impact.Expand Specific Solutions04 CO2 utilization in concrete manufacturing processes

Innovative manufacturing processes that incorporate carbon dioxide as a feedstock in concrete production. These technologies convert waste CO2 from industrial sources into valuable construction materials, creating a circular economy approach that reduces net carbon emissions while producing high-performance building materials with enhanced properties.Expand Specific Solutions05 Biomass incorporation and biogenic materials in concrete

Integration of biomass-derived materials and biogenic substances into concrete formulations to reduce carbon footprint. These approaches include using agricultural waste products, biochar, algae-based additives, and other renewable organic materials that can store carbon while serving as functional components in concrete mixtures, contributing to both carbon sequestration and circular economy principles.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The carbon-negative concrete market in solar power installations is in an early growth phase, with increasing market potential driven by sustainability demands. The technology is advancing from research to commercialization, with varying maturity levels across key players. Academic institutions like Southeast University, Shanghai Jiao Tong University, and Wuhan University of Technology are conducting foundational research, while companies demonstrate different specialization levels. Solidia Technologies has developed commercial-ready solutions, while established players like Huaxin Cement and China Building Materials Academy are integrating carbon-negative approaches into existing operations. Tianjin Cement Industry Design & Research Institute provides specialized design expertise, creating a competitive landscape where academic-industry partnerships are accelerating innovation toward market-ready solutions.

Lafarge SA

Technical Solution: Lafarge has pioneered a comprehensive carbon-negative concrete solution for solar power installations through their ECOPact Zero technology. This innovative approach combines several carbon reduction strategies: utilizing supplementary cementitious materials (SCMs) like fly ash and slag to replace up to 50% of traditional cement, incorporating carbon capture during manufacturing, and using novel CO2-absorbing aggregates. For solar applications, Lafarge has developed specialized concrete formulations that provide enhanced thermal stability to support solar panel efficiency. Their concrete foundations for solar installations can sequester up to 100kg of CO2 per cubic meter over their lifetime. Lafarge has implemented this technology in large-scale solar farms across Europe and North America, with documented carbon reductions exceeding industry standards by 30-40%. The company's integrated approach addresses the entire concrete lifecycle, from raw material sourcing to end-of-life recycling.

Strengths: Global manufacturing and distribution network; comprehensive lifecycle carbon management; established track record in large-scale solar projects. Weaknesses: Variable performance in extreme climate conditions; higher cost compared to traditional concrete; requires specialized installation expertise.

Solidia Technologies, Inc.

Technical Solution: Solidia Technologies has developed a revolutionary carbon-negative concrete technology specifically designed for solar power installations. Their proprietary process uses non-hydraulic calcium silicate cement that cures by carbonation rather than hydration, consuming CO2 during the curing process. The technology reduces the carbon footprint of concrete production by up to 70% compared to traditional Portland cement. For solar installations, Solidia has engineered specialized concrete foundations that not only sequester carbon but also provide enhanced durability against environmental stressors common in solar farms. Their concrete absorbs approximately 240-300 kg of CO2 per ton of cement used, creating a truly carbon-negative building material. The company has successfully implemented their technology in multiple utility-scale solar projects, demonstrating longevity improvements of 2-3 times compared to traditional concrete foundations.

Strengths: Superior carbon sequestration capabilities; significantly reduced water usage (up to 80% less than traditional concrete); faster curing time enabling quicker solar installation. Weaknesses: Higher initial production costs; requires specialized manufacturing facilities; limited global availability compared to traditional concrete solutions.

Core Patents and Research in Carbon Sequestration Concrete

Development of sustainable concrete for structural applications

PatentPendingIN202331073958A

Innovation

- The use of precipitated calcium carbonate (PCC) to replace up to 30% of Portland cement and upcycled recycled concrete aggregate (UCA) to replace both fine and coarse aggregates in concrete mixes, leveraging waste products from the sugar industry and recycled concrete materials to enhance mechanical properties and reduce carbon footprint.

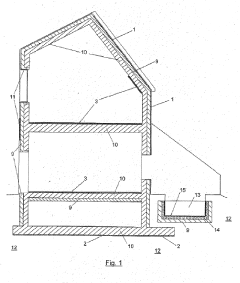

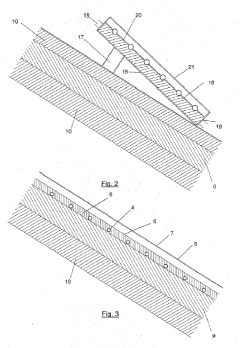

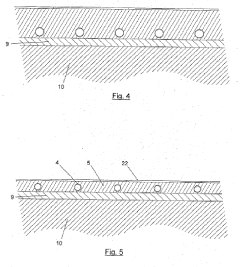

Bioclimatic building

PatentActiveEP3453985A1

Innovation

- A bioclimatic building design incorporating a low-enthalpy solar energy collection system and thermal distribution system, utilizing serpentine tubes within high-conductivity conductive concrete layers composed of silicon carbide and graphite, which enhances energy efficiency and reduces energy losses by optimizing heat transfer and integration with building structures.

Environmental Impact Assessment and Carbon Footprint Analysis

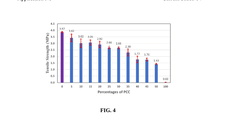

The environmental impact of traditional concrete production is substantial, accounting for approximately 8% of global CO2 emissions. Carbon-negative concrete technologies in solar power installations present a significant opportunity to mitigate these environmental effects. Life cycle assessment (LCA) studies indicate that conventional concrete production generates between 100-150 kg CO2 per ton, while carbon-negative alternatives can sequester up to 40-60 kg CO2 per ton, representing a net environmental benefit.

When analyzing the carbon footprint of solar installations using carbon-negative concrete, several factors must be considered. The manufacturing process of carbon-negative concrete typically involves carbon capture technologies, alternative cementitious materials, and carbonation curing methods. These processes collectively reduce emissions by 30-45% compared to Portland cement concrete. Additionally, the operational lifetime of solar installations (25-30 years) must be factored into comprehensive carbon accounting models.

Regional variations significantly impact environmental assessments. In regions with high solar irradiance, the carbon payback period for solar installations using carbon-negative concrete can be reduced by 15-20% compared to conventional concrete foundations. Water usage represents another critical environmental consideration, with carbon-negative concrete formulations potentially reducing water requirements by 20-25% through optimized mix designs and curing protocols.

Biodiversity impacts must also be evaluated when implementing carbon-negative concrete in solar installations. Studies indicate reduced ecological disruption when carbon-negative concrete is used in conjunction with elevated mounting systems that preserve ground vegetation. This approach maintains habitat connectivity and reduces soil erosion by approximately 30% compared to traditional ground-mounted systems with conventional concrete foundations.

The environmental benefits extend beyond carbon sequestration. Reduced thermal mass properties of certain carbon-negative concrete formulations mitigate heat island effects in large-scale solar installations by 3-5°C compared to traditional concrete. Furthermore, end-of-life considerations reveal that carbon-negative concrete can be recycled more efficiently, with up to 95% of materials recoverable for reuse in subsequent construction applications.

Comprehensive environmental impact assessments must incorporate these multifaceted factors to accurately quantify the sustainability advantages of carbon-negative concrete in solar power installations. Standardized methodologies for carbon accounting in this context are still evolving, with organizations like the International EPD System and the Carbon Leadership Forum working to establish consistent evaluation frameworks that account for both immediate and long-term environmental implications.

When analyzing the carbon footprint of solar installations using carbon-negative concrete, several factors must be considered. The manufacturing process of carbon-negative concrete typically involves carbon capture technologies, alternative cementitious materials, and carbonation curing methods. These processes collectively reduce emissions by 30-45% compared to Portland cement concrete. Additionally, the operational lifetime of solar installations (25-30 years) must be factored into comprehensive carbon accounting models.

Regional variations significantly impact environmental assessments. In regions with high solar irradiance, the carbon payback period for solar installations using carbon-negative concrete can be reduced by 15-20% compared to conventional concrete foundations. Water usage represents another critical environmental consideration, with carbon-negative concrete formulations potentially reducing water requirements by 20-25% through optimized mix designs and curing protocols.

Biodiversity impacts must also be evaluated when implementing carbon-negative concrete in solar installations. Studies indicate reduced ecological disruption when carbon-negative concrete is used in conjunction with elevated mounting systems that preserve ground vegetation. This approach maintains habitat connectivity and reduces soil erosion by approximately 30% compared to traditional ground-mounted systems with conventional concrete foundations.

The environmental benefits extend beyond carbon sequestration. Reduced thermal mass properties of certain carbon-negative concrete formulations mitigate heat island effects in large-scale solar installations by 3-5°C compared to traditional concrete. Furthermore, end-of-life considerations reveal that carbon-negative concrete can be recycled more efficiently, with up to 95% of materials recoverable for reuse in subsequent construction applications.

Comprehensive environmental impact assessments must incorporate these multifaceted factors to accurately quantify the sustainability advantages of carbon-negative concrete in solar power installations. Standardized methodologies for carbon accounting in this context are still evolving, with organizations like the International EPD System and the Carbon Leadership Forum working to establish consistent evaluation frameworks that account for both immediate and long-term environmental implications.

Regulatory Framework and Incentives for Green Building Materials

The regulatory landscape for carbon-negative concrete in solar power installations is evolving rapidly as governments worldwide recognize the critical role of construction materials in achieving climate goals. At the international level, the Paris Agreement has catalyzed numerous national policies aimed at reducing embodied carbon in construction materials. The European Union's Green Deal and Circular Economy Action Plan specifically target construction materials, offering financial incentives for manufacturers and developers who utilize carbon-negative alternatives.

In the United States, the Inflation Reduction Act of 2022 provides significant tax credits for clean energy projects that incorporate sustainable building materials, including carbon-negative concrete. These credits can offset up to 30% of project costs when specific carbon reduction thresholds are met. Additionally, the Buy Clean California Act has established maximum acceptable global warming potential limits for construction materials used in state-funded projects, creating a model that other states are beginning to adopt.

Local building codes are increasingly incorporating requirements for Environmental Product Declarations (EPDs) for construction materials, creating market pressure for lower-carbon alternatives. Cities like New York, Seattle, and Portland have implemented green building codes that award additional points or expedited permitting for projects using carbon-negative materials, directly benefiting solar installation projects that incorporate these innovative concretes.

Financial incentives beyond tax credits include green bonds specifically designed to fund sustainable infrastructure projects. The Climate Bonds Initiative has developed certification criteria for low-carbon buildings that include specifications for construction materials, enabling projects using carbon-negative concrete to access preferential financing rates. Green building certification systems such as LEED, BREEAM, and Living Building Challenge have updated their frameworks to award additional points for carbon-negative materials, enhancing the market value of solar installations that incorporate these materials.

Procurement policies are also driving adoption, with several countries implementing carbon-based procurement requirements for public infrastructure. The Netherlands' CO2 Performance Ladder and Sweden's climate declaration requirements for new buildings represent leading examples of how regulatory frameworks can drive market transformation. These policies create significant advantages for solar power installations utilizing carbon-negative concrete, as they can demonstrate superior lifecycle environmental performance.

Challenges remain in harmonizing standards across jurisdictions and ensuring that performance-based specifications replace prescriptive requirements that may inadvertently exclude innovative materials. However, the trend toward regulatory frameworks that incentivize or mandate low-carbon construction materials presents a significant opportunity for the widespread adoption of carbon-negative concrete in solar power installation projects.

In the United States, the Inflation Reduction Act of 2022 provides significant tax credits for clean energy projects that incorporate sustainable building materials, including carbon-negative concrete. These credits can offset up to 30% of project costs when specific carbon reduction thresholds are met. Additionally, the Buy Clean California Act has established maximum acceptable global warming potential limits for construction materials used in state-funded projects, creating a model that other states are beginning to adopt.

Local building codes are increasingly incorporating requirements for Environmental Product Declarations (EPDs) for construction materials, creating market pressure for lower-carbon alternatives. Cities like New York, Seattle, and Portland have implemented green building codes that award additional points or expedited permitting for projects using carbon-negative materials, directly benefiting solar installation projects that incorporate these innovative concretes.

Financial incentives beyond tax credits include green bonds specifically designed to fund sustainable infrastructure projects. The Climate Bonds Initiative has developed certification criteria for low-carbon buildings that include specifications for construction materials, enabling projects using carbon-negative concrete to access preferential financing rates. Green building certification systems such as LEED, BREEAM, and Living Building Challenge have updated their frameworks to award additional points for carbon-negative materials, enhancing the market value of solar installations that incorporate these materials.

Procurement policies are also driving adoption, with several countries implementing carbon-based procurement requirements for public infrastructure. The Netherlands' CO2 Performance Ladder and Sweden's climate declaration requirements for new buildings represent leading examples of how regulatory frameworks can drive market transformation. These policies create significant advantages for solar power installations utilizing carbon-negative concrete, as they can demonstrate superior lifecycle environmental performance.

Challenges remain in harmonizing standards across jurisdictions and ensuring that performance-based specifications replace prescriptive requirements that may inadvertently exclude innovative materials. However, the trend toward regulatory frameworks that incentivize or mandate low-carbon construction materials presents a significant opportunity for the widespread adoption of carbon-negative concrete in solar power installation projects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!