Flexible Electronics Precision Metrics: Dimensional Stability

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Dimensional Stability Background and Objectives

Flexible electronics represents a revolutionary departure from conventional rigid electronic systems, enabling the development of bendable, stretchable, and conformable electronic devices. The evolution of this technology can be traced back to the early 2000s when researchers began exploring conductive polymers and thin-film transistors on flexible substrates. Over the past two decades, the field has witnessed remarkable advancements, transitioning from basic proof-of-concept demonstrations to sophisticated commercial applications in wearable technology, healthcare monitoring, and smart packaging.

Dimensional stability has emerged as a critical factor in the reliable performance of flexible electronic systems. Unlike rigid electronics, flexible devices must maintain their electrical functionality while undergoing mechanical deformation, creating unique challenges for material selection and structural design. The dimensional changes that occur during bending, stretching, or twisting can significantly impact circuit performance, interconnect reliability, and overall device longevity.

The technical evolution trend points toward increasingly demanding applications requiring greater flexibility while maintaining precise dimensional control. Early flexible electronics could tolerate minimal bending radii of several centimeters, whereas current advanced systems aim to achieve sub-millimeter bending radii with minimal performance degradation. This progression necessitates more sophisticated metrics for quantifying and predicting dimensional stability across diverse operating conditions.

Current dimensional stability metrics primarily focus on basic parameters such as coefficient of thermal expansion (CTE), hygroscopic expansion, and mechanical strain limits. However, these conventional metrics often prove insufficient for characterizing the complex multi-axial deformations and cyclic loading conditions experienced by flexible electronic systems. The development of comprehensive, standardized metrics represents a significant technical objective for advancing the field.

The primary technical objectives for dimensional stability research include: establishing standardized testing protocols that accurately simulate real-world usage conditions; developing multi-parameter metrics that capture the interplay between thermal, mechanical, and environmental factors; creating predictive models that can forecast dimensional changes throughout product lifecycles; and formulating design guidelines that enable engineers to optimize flexible electronic systems for specific application requirements.

Additionally, there is growing recognition of the need for in-situ measurement techniques that can monitor dimensional changes during device operation, particularly for applications in extreme environments or those requiring high reliability. The integration of such monitoring capabilities into flexible electronic systems represents an important frontier for technological development, potentially enabling self-compensating systems that can adapt to dimensional variations.

Dimensional stability has emerged as a critical factor in the reliable performance of flexible electronic systems. Unlike rigid electronics, flexible devices must maintain their electrical functionality while undergoing mechanical deformation, creating unique challenges for material selection and structural design. The dimensional changes that occur during bending, stretching, or twisting can significantly impact circuit performance, interconnect reliability, and overall device longevity.

The technical evolution trend points toward increasingly demanding applications requiring greater flexibility while maintaining precise dimensional control. Early flexible electronics could tolerate minimal bending radii of several centimeters, whereas current advanced systems aim to achieve sub-millimeter bending radii with minimal performance degradation. This progression necessitates more sophisticated metrics for quantifying and predicting dimensional stability across diverse operating conditions.

Current dimensional stability metrics primarily focus on basic parameters such as coefficient of thermal expansion (CTE), hygroscopic expansion, and mechanical strain limits. However, these conventional metrics often prove insufficient for characterizing the complex multi-axial deformations and cyclic loading conditions experienced by flexible electronic systems. The development of comprehensive, standardized metrics represents a significant technical objective for advancing the field.

The primary technical objectives for dimensional stability research include: establishing standardized testing protocols that accurately simulate real-world usage conditions; developing multi-parameter metrics that capture the interplay between thermal, mechanical, and environmental factors; creating predictive models that can forecast dimensional changes throughout product lifecycles; and formulating design guidelines that enable engineers to optimize flexible electronic systems for specific application requirements.

Additionally, there is growing recognition of the need for in-situ measurement techniques that can monitor dimensional changes during device operation, particularly for applications in extreme environments or those requiring high reliability. The integration of such monitoring capabilities into flexible electronic systems represents an important frontier for technological development, potentially enabling self-compensating systems that can adapt to dimensional variations.

Market Analysis for Dimensionally Stable Flexible Electronics

The flexible electronics market is experiencing robust growth, with a projected market value reaching $48.5 billion by 2028, representing a compound annual growth rate (CAGR) of 15.3% from 2023. This significant expansion is driven by increasing demand across multiple sectors including consumer electronics, healthcare, automotive, and aerospace industries. Dimensional stability has emerged as a critical factor influencing market adoption, as it directly impacts product reliability, performance, and consumer satisfaction.

Consumer electronics represents the largest market segment, accounting for approximately 35% of the flexible electronics market. Within this segment, smartphones and wearable devices are the primary drivers, with consumers increasingly demanding bendable displays and conformable electronic components that maintain functionality through repeated flexing cycles. The healthcare sector follows closely, growing at 18.7% annually, with applications in medical wearables, biosensors, and smart patches requiring exceptional dimensional stability under various environmental conditions.

Market research indicates that 73% of electronics manufacturers consider dimensional stability as a "very important" or "critical" parameter when selecting flexible substrate materials. This prioritization has created a premium market segment for dimensionally stable materials, with price premiums of 30-45% compared to standard flexible substrates. Polyimide films with enhanced dimensional stability command the highest market share at 42%, followed by polyethylene naphthalate (PEN) at 27%.

Regional analysis reveals Asia-Pacific as the dominant market for dimensionally stable flexible electronics, accounting for 58% of global production capacity. This concentration is primarily due to the established electronics manufacturing ecosystem in countries like South Korea, Japan, Taiwan, and China. North America and Europe follow with 22% and 17% market shares respectively, with these regions focusing on high-value applications in aerospace, defense, and advanced medical devices.

The market is witnessing a shift toward integrated measurement systems that can evaluate dimensional stability metrics in real-time during manufacturing processes. This trend is reflected in the 34% annual growth in sales of specialized metrology equipment designed specifically for flexible electronics production lines. Companies offering comprehensive dimensional stability testing solutions are experiencing revenue growth exceeding the overall market rate by approximately 7 percentage points.

Customer surveys reveal that manufacturers are willing to pay premium prices for materials and components with guaranteed dimensional stability metrics, particularly for applications where reliability under mechanical stress and temperature fluctuations is paramount. This has created a specialized market segment for certified dimensionally stable components worth $3.2 billion in 2022, with projections indicating it will reach $7.8 billion by 2027.

Consumer electronics represents the largest market segment, accounting for approximately 35% of the flexible electronics market. Within this segment, smartphones and wearable devices are the primary drivers, with consumers increasingly demanding bendable displays and conformable electronic components that maintain functionality through repeated flexing cycles. The healthcare sector follows closely, growing at 18.7% annually, with applications in medical wearables, biosensors, and smart patches requiring exceptional dimensional stability under various environmental conditions.

Market research indicates that 73% of electronics manufacturers consider dimensional stability as a "very important" or "critical" parameter when selecting flexible substrate materials. This prioritization has created a premium market segment for dimensionally stable materials, with price premiums of 30-45% compared to standard flexible substrates. Polyimide films with enhanced dimensional stability command the highest market share at 42%, followed by polyethylene naphthalate (PEN) at 27%.

Regional analysis reveals Asia-Pacific as the dominant market for dimensionally stable flexible electronics, accounting for 58% of global production capacity. This concentration is primarily due to the established electronics manufacturing ecosystem in countries like South Korea, Japan, Taiwan, and China. North America and Europe follow with 22% and 17% market shares respectively, with these regions focusing on high-value applications in aerospace, defense, and advanced medical devices.

The market is witnessing a shift toward integrated measurement systems that can evaluate dimensional stability metrics in real-time during manufacturing processes. This trend is reflected in the 34% annual growth in sales of specialized metrology equipment designed specifically for flexible electronics production lines. Companies offering comprehensive dimensional stability testing solutions are experiencing revenue growth exceeding the overall market rate by approximately 7 percentage points.

Customer surveys reveal that manufacturers are willing to pay premium prices for materials and components with guaranteed dimensional stability metrics, particularly for applications where reliability under mechanical stress and temperature fluctuations is paramount. This has created a specialized market segment for certified dimensionally stable components worth $3.2 billion in 2022, with projections indicating it will reach $7.8 billion by 2027.

Current Challenges in Dimensional Stability Measurement

Dimensional stability measurement for flexible electronics presents significant technical challenges that impede standardized evaluation and industry-wide adoption. Current measurement methodologies, primarily developed for rigid electronics, fail to adequately address the unique deformation characteristics of flexible substrates under various mechanical stresses and environmental conditions.

The absence of universally accepted metrics creates substantial obstacles in comparing performance across different flexible electronic systems. While traditional electronics rely on established parameters like thermal expansion coefficients, flexible electronics require more complex multi-dimensional metrics that account for reversible and irreversible deformations under bending, folding, stretching, and twisting forces.

Resolution limitations in existing measurement equipment pose another critical challenge. Most conventional dimensional analysis tools lack the precision required to detect nanoscale deformations that significantly impact the performance of flexible electronic components. This precision gap becomes particularly problematic when measuring cumulative dimensional changes over thousands of flexing cycles, where even minor deviations can lead to catastrophic device failure.

Environmental factors introduce additional complexity to measurement protocols. Temperature and humidity fluctuations can dramatically alter the dimensional properties of flexible substrates, yet current testing methodologies rarely incorporate standardized environmental conditioning. This oversight results in inconsistent data across research institutions and manufacturing facilities, hampering collaborative advancement in the field.

Real-time measurement during dynamic deformation represents perhaps the most formidable technical hurdle. Current approaches typically measure dimensions in static states before and after deformation, failing to capture critical transitional behaviors. The development of in-situ measurement techniques capable of monitoring dimensional changes during active flexing remains in its infancy, limited by both hardware capabilities and analytical frameworks.

The multi-material nature of flexible electronic systems further complicates measurement efforts. Different materials within the same device often exhibit varying dimensional responses to identical stimuli, creating complex stress patterns at interfaces. Current measurement techniques struggle to isolate and quantify these differential responses, particularly at material boundaries where delamination and fracture typically initiate.

Accelerated aging protocols for predicting long-term dimensional stability suffer from validation deficiencies. The correlation between accelerated testing results and real-world performance remains poorly understood, with few longitudinal studies available to verify the predictive accuracy of current testing methodologies. This uncertainty undermines confidence in lifetime performance estimates, a critical factor for commercial adoption of flexible electronic technologies.

The absence of universally accepted metrics creates substantial obstacles in comparing performance across different flexible electronic systems. While traditional electronics rely on established parameters like thermal expansion coefficients, flexible electronics require more complex multi-dimensional metrics that account for reversible and irreversible deformations under bending, folding, stretching, and twisting forces.

Resolution limitations in existing measurement equipment pose another critical challenge. Most conventional dimensional analysis tools lack the precision required to detect nanoscale deformations that significantly impact the performance of flexible electronic components. This precision gap becomes particularly problematic when measuring cumulative dimensional changes over thousands of flexing cycles, where even minor deviations can lead to catastrophic device failure.

Environmental factors introduce additional complexity to measurement protocols. Temperature and humidity fluctuations can dramatically alter the dimensional properties of flexible substrates, yet current testing methodologies rarely incorporate standardized environmental conditioning. This oversight results in inconsistent data across research institutions and manufacturing facilities, hampering collaborative advancement in the field.

Real-time measurement during dynamic deformation represents perhaps the most formidable technical hurdle. Current approaches typically measure dimensions in static states before and after deformation, failing to capture critical transitional behaviors. The development of in-situ measurement techniques capable of monitoring dimensional changes during active flexing remains in its infancy, limited by both hardware capabilities and analytical frameworks.

The multi-material nature of flexible electronic systems further complicates measurement efforts. Different materials within the same device often exhibit varying dimensional responses to identical stimuli, creating complex stress patterns at interfaces. Current measurement techniques struggle to isolate and quantify these differential responses, particularly at material boundaries where delamination and fracture typically initiate.

Accelerated aging protocols for predicting long-term dimensional stability suffer from validation deficiencies. The correlation between accelerated testing results and real-world performance remains poorly understood, with few longitudinal studies available to verify the predictive accuracy of current testing methodologies. This uncertainty undermines confidence in lifetime performance estimates, a critical factor for commercial adoption of flexible electronic technologies.

Current Methodologies for Dimensional Stability Assessment

01 Substrate materials for dimensional stability

Various substrate materials can be used in flexible electronics to enhance dimensional stability. These include polymer films, composite materials, and specially treated substrates that maintain their dimensions under mechanical stress and temperature variations. The selection of appropriate substrate materials is crucial for ensuring that flexible electronic devices maintain their form and functionality during bending, folding, or stretching operations.- Substrate materials for dimensional stability: Various substrate materials can be used in flexible electronics to enhance dimensional stability. These include polymer films, composite materials, and specially treated substrates that maintain their dimensions under mechanical stress and temperature variations. The selection of appropriate substrate materials is crucial for ensuring that flexible electronic devices maintain their form and functionality during bending, folding, or stretching operations.

- Thermal management techniques: Thermal management is essential for maintaining dimensional stability in flexible electronics. Techniques include the use of heat-dissipating materials, thermal interface materials, and structural designs that minimize thermal expansion. Effective thermal management prevents warping, delamination, and other dimensional changes that can occur due to temperature fluctuations during operation of flexible electronic devices.

- Encapsulation and protective layers: Encapsulation and protective layers play a significant role in maintaining the dimensional stability of flexible electronics. These layers shield the electronic components from environmental factors such as moisture and oxygen, which can cause degradation and dimensional changes. Advanced encapsulation techniques using barrier films, inorganic layers, or hybrid materials can significantly improve the long-term dimensional stability of flexible electronic devices.

- Structural design for flexibility and stability: Innovative structural designs can balance flexibility with dimensional stability in electronic devices. These include the use of neutral mechanical plane concepts, strain-isolation structures, and engineered patterns that allow for bending while maintaining critical dimensions. Strategic placement of rigid and flexible components, along with interconnect designs that accommodate movement, helps maintain overall device integrity during flexing operations.

- Manufacturing processes for dimensional control: Specialized manufacturing processes are developed to ensure dimensional stability in flexible electronics production. These include precise deposition techniques, controlled curing processes, and stress-management methods during fabrication. Advanced manufacturing approaches such as roll-to-roll processing with tension control, laser patterning with minimal thermal impact, and low-temperature processing help maintain dimensional accuracy throughout the production of flexible electronic devices.

02 Structural design for flexibility and stability

Innovative structural designs can improve the dimensional stability of flexible electronics. These designs include layered structures, reinforcement patterns, and strategic placement of rigid and flexible components. By optimizing the physical arrangement of electronic components and supporting materials, manufacturers can create devices that maintain their dimensional integrity while allowing for the desired flexibility.Expand Specific Solutions03 Thermal management techniques

Thermal management is essential for maintaining dimensional stability in flexible electronics. Various techniques such as heat dissipation layers, thermal interface materials, and temperature-compensating structures can be employed to minimize thermal expansion and contraction. Effective thermal management prevents warping, delamination, and other dimensional changes that can occur due to temperature fluctuations during operation.Expand Specific Solutions04 Coating and encapsulation methods

Protective coatings and encapsulation methods can significantly enhance the dimensional stability of flexible electronic devices. These include barrier films, conformal coatings, and specialized encapsulants that protect against environmental factors while maintaining flexibility. The right coating can prevent moisture ingress and chemical degradation that might otherwise lead to dimensional changes in the flexible substrate or electronic components.Expand Specific Solutions05 Manufacturing processes for dimensional control

Specific manufacturing processes can be employed to enhance dimensional stability in flexible electronics. These include precision deposition techniques, controlled curing methods, and stress-relief processes that minimize internal stresses. Advanced manufacturing approaches such as roll-to-roll processing with tension control and laser patterning can also help maintain dimensional accuracy throughout the production and lifetime of flexible electronic devices.Expand Specific Solutions

Key Industry Players in Flexible Electronics Metrology

The flexible electronics market is currently in a growth phase, characterized by increasing adoption across consumer electronics, healthcare, and automotive sectors. The global market size is projected to expand significantly, driven by demand for bendable, lightweight devices. Technologically, dimensional stability metrics remain a critical challenge, with academic institutions like Tsinghua University, University of Illinois, and Northwestern University leading fundamental research. Commercial players demonstrate varying maturity levels: established corporations like Samsung Electronics, IBM, and Nikon possess advanced manufacturing capabilities, while specialized companies like Nano Dimension and Panelsemi focus on innovative solutions for specific applications. Research collaborations between academic institutions and industry players, particularly in Asia and North America, are accelerating technological advancements in substrate materials and measurement methodologies.

Nikon Corp.

Technical Solution: Nikon has leveraged its expertise in precision optics to develop an ultra-high-resolution measurement system for dimensional stability analysis in flexible electronics. Their technology employs a proprietary interferometric measurement approach capable of detecting nanometer-scale deformations across flexible substrates up to 600mm × 600mm. The system incorporates environmental chambers that can simulate temperature cycles from -40°C to 120°C and humidity variations from 5% to 95% RH while maintaining measurement accuracy. Nikon has developed specialized image processing algorithms that can isolate and quantify different modes of dimensional instability, including isotropic expansion/contraction, anisotropic deformation, and localized distortion. Their measurement protocol includes standardized testing procedures that evaluate stability under combined stressors including temperature, humidity, and mechanical strain, providing comprehensive stability metrics that correlate with real-world performance. Additionally, Nikon offers a modular system that can be integrated directly into production lines for in-situ monitoring of dimensional stability during manufacturing processes.

Strengths: Exceptional measurement precision and optical expertise; comprehensive environmental testing capabilities; established reputation in precision instrumentation. Weaknesses: Primary focus may be on measurement systems rather than materials or device solutions; technology may be expensive for smaller manufacturers or research institutions.

Innolux Corp.

Technical Solution: Innolux has developed a proprietary "Dimensional Stability Enhancement Framework" for flexible display manufacturing that combines material engineering and process optimization. Their approach utilizes a multi-layer substrate architecture with alternating organic and inorganic films to create a mechanically balanced structure that minimizes dimensional variations under thermal and mechanical stress. The company has implemented an advanced optical metrology system capable of measuring dimensional changes with precision of ±0.2μm across panels up to Gen 8.5 size. Innolux's technology incorporates a specialized pre-treatment process for polymer substrates that reduces hygroscopic expansion by approximately 65% compared to untreated materials, significantly improving stability in varying humidity conditions. Their manufacturing process includes a controlled stress-relief annealing step that operates at precisely controlled temperature gradients to minimize residual stress while maintaining a cycle time compatible with high-volume manufacturing requirements. Additionally, Innolux has developed a computational model that predicts dimensional behavior under complex mechanical deformations, enabling design optimization for specific use cases.

Strengths: Strong focus on manufacturing scalability and production efficiency; extensive experience in display technologies; solutions designed for commercial implementation. Weaknesses: May prioritize cost-effectiveness over ultimate performance metrics; research may be more incremental than breakthrough-oriented.

Critical Patents and Research on Dimensional Stability Metrics

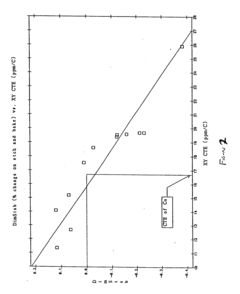

Fluoropolymer composites containing two or more ceramic fillers to achieve independent control of dielectric constant and dimensional stability

PatentInactiveUS20050244662A1

Innovation

- A fluoropolymeric composite material using a combination of two chemically different ceramic fillers, one with a high dielectric constant (K' > 30) and another with a lower K', to achieve independent control of K' and CTE, ensuring dimensional stability of less than 0.1% change, and matching the CTE of the composite to that of copper for improved fabrication.

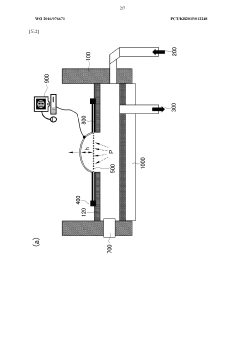

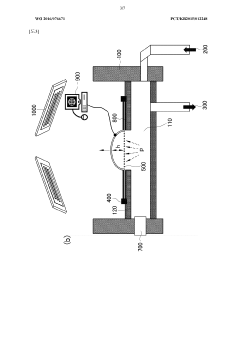

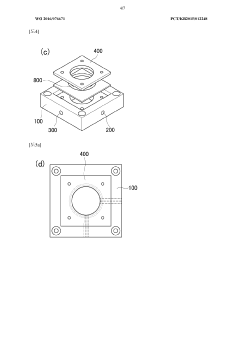

Method and apparatus for testing flexible element

PatentWO2016076671A1

Innovation

- A test method and apparatus that gradually deforms flexible elements by adjusting pressure within a chamber, using electrode pads for electrical contact and a control unit to measure mechanical and electrical characteristics in various deformation states.

Materials Science Impact on Dimensional Stability

The material composition and properties fundamentally determine the dimensional stability performance of flexible electronic devices. Advanced polymer substrates such as polyimide (PI), polyethylene terephthalate (PET), and polyethylene naphthalate (PEN) exhibit varying coefficients of thermal expansion (CTE), which directly impacts their dimensional response to temperature fluctuations. PI demonstrates superior thermal stability with a CTE of approximately 20 ppm/°C, while PET exhibits higher values around 59 ppm/°C, making it more susceptible to dimensional changes under thermal stress.

Material crystallinity plays a crucial role in dimensional stability, with semi-crystalline polymers showing anisotropic expansion behaviors that must be carefully managed in flexible electronics design. The degree of crystallinity affects not only thermal expansion but also mechanical properties such as Young's modulus and tensile strength, which influence how materials respond to mechanical stresses during fabrication and operation.

Composite materials represent a significant advancement in addressing dimensional stability challenges. By incorporating inorganic fillers like silica, alumina, or boron nitride into polymer matrices, researchers have achieved reduced CTEs while maintaining flexibility. These composites can be engineered with tailored expansion coefficients that match those of conductive materials, minimizing internal stresses at interfaces.

Surface treatments and material modifications have emerged as effective approaches to enhance dimensional stability. Techniques such as plasma treatment, UV-ozone processing, and chemical functionalization alter the surface properties of substrate materials, improving adhesion between layers and reducing delamination risks that compromise dimensional integrity during thermal cycling.

Moisture absorption characteristics of materials significantly impact dimensional stability in variable humidity environments. Hydrophilic polymers can experience swelling and contraction cycles that induce stress in conductive pathways. Hydrophobic coatings and moisture barrier layers have been developed to mitigate these effects, with advanced multilayer structures achieving water vapor transmission rates below 10^-6 g/m²/day.

Recent innovations in materials science include self-healing polymers that can recover from mechanical damage and strain-responsive materials that maintain electrical connectivity despite dimensional changes. Additionally, the development of liquid crystal polymers with extremely low CTEs (below 5 ppm/°C) offers promising pathways for next-generation flexible electronics with enhanced dimensional stability across broader operating temperature ranges.

Material crystallinity plays a crucial role in dimensional stability, with semi-crystalline polymers showing anisotropic expansion behaviors that must be carefully managed in flexible electronics design. The degree of crystallinity affects not only thermal expansion but also mechanical properties such as Young's modulus and tensile strength, which influence how materials respond to mechanical stresses during fabrication and operation.

Composite materials represent a significant advancement in addressing dimensional stability challenges. By incorporating inorganic fillers like silica, alumina, or boron nitride into polymer matrices, researchers have achieved reduced CTEs while maintaining flexibility. These composites can be engineered with tailored expansion coefficients that match those of conductive materials, minimizing internal stresses at interfaces.

Surface treatments and material modifications have emerged as effective approaches to enhance dimensional stability. Techniques such as plasma treatment, UV-ozone processing, and chemical functionalization alter the surface properties of substrate materials, improving adhesion between layers and reducing delamination risks that compromise dimensional integrity during thermal cycling.

Moisture absorption characteristics of materials significantly impact dimensional stability in variable humidity environments. Hydrophilic polymers can experience swelling and contraction cycles that induce stress in conductive pathways. Hydrophobic coatings and moisture barrier layers have been developed to mitigate these effects, with advanced multilayer structures achieving water vapor transmission rates below 10^-6 g/m²/day.

Recent innovations in materials science include self-healing polymers that can recover from mechanical damage and strain-responsive materials that maintain electrical connectivity despite dimensional changes. Additionally, the development of liquid crystal polymers with extremely low CTEs (below 5 ppm/°C) offers promising pathways for next-generation flexible electronics with enhanced dimensional stability across broader operating temperature ranges.

Standardization Efforts for Flexible Electronics Metrics

The standardization of dimensional stability metrics for flexible electronics represents a critical foundation for industry-wide advancement. Currently, several international organizations are leading efforts to establish unified measurement protocols and performance benchmarks. The International Electrotechnical Commission (IEC) has formed specialized technical committees focused on flexible display technologies, working to define standard testing methodologies for dimensional changes under various environmental conditions. These efforts aim to create universally accepted parameters that manufacturers can reference when developing and marketing flexible electronic products.

Similarly, the Institute of Electrical and Electronics Engineers (IEEE) has launched initiatives to standardize terminology and testing procedures specifically for flexible hybrid electronics. Their P2739 working group is developing comprehensive guidelines for characterizing mechanical reliability, including dimensional stability metrics that account for repeated bending, folding, and stretching scenarios. This standardization work addresses the unique challenges posed by dynamic deformation in flexible systems that traditional rigid electronics standards cannot adequately cover.

In Asia, the Japan Electronics and Information Technology Industries Association (JEITA) has published preliminary standards for flexible display components, including specific protocols for measuring dimensional changes during thermal cycling and humidity exposure. These standards have gained significant traction among manufacturers in East Asia, creating a regional benchmark that influences global practices.

The International Organization for Standardization (ISO) has also recognized the importance of this field, with technical committee ISO/TC 229 incorporating flexible electronics considerations into nanomaterial characterization standards. Their work includes protocols for measuring dimensional stability at the nanoscale, particularly relevant for thin-film technologies used in flexible electronics.

Industry consortia are playing an equally important role in standardization efforts. The Flexible Electronics and Display Center (FEDC) has developed a set of recommended practices for dimensional stability assessment that many manufacturers have voluntarily adopted. These industry-led initiatives often serve as precursors to formal international standards, allowing for practical field testing before codification.

Despite these advances, significant challenges remain in standardization efforts. The rapid pace of innovation in flexible electronics often outstrips the standardization process, creating temporary gaps between cutting-edge technology and established metrics. Additionally, harmonizing standards across different regions and application domains requires ongoing coordination between stakeholders with sometimes divergent priorities and technological approaches.

Similarly, the Institute of Electrical and Electronics Engineers (IEEE) has launched initiatives to standardize terminology and testing procedures specifically for flexible hybrid electronics. Their P2739 working group is developing comprehensive guidelines for characterizing mechanical reliability, including dimensional stability metrics that account for repeated bending, folding, and stretching scenarios. This standardization work addresses the unique challenges posed by dynamic deformation in flexible systems that traditional rigid electronics standards cannot adequately cover.

In Asia, the Japan Electronics and Information Technology Industries Association (JEITA) has published preliminary standards for flexible display components, including specific protocols for measuring dimensional changes during thermal cycling and humidity exposure. These standards have gained significant traction among manufacturers in East Asia, creating a regional benchmark that influences global practices.

The International Organization for Standardization (ISO) has also recognized the importance of this field, with technical committee ISO/TC 229 incorporating flexible electronics considerations into nanomaterial characterization standards. Their work includes protocols for measuring dimensional stability at the nanoscale, particularly relevant for thin-film technologies used in flexible electronics.

Industry consortia are playing an equally important role in standardization efforts. The Flexible Electronics and Display Center (FEDC) has developed a set of recommended practices for dimensional stability assessment that many manufacturers have voluntarily adopted. These industry-led initiatives often serve as precursors to formal international standards, allowing for practical field testing before codification.

Despite these advances, significant challenges remain in standardization efforts. The rapid pace of innovation in flexible electronics often outstrips the standardization process, creating temporary gaps between cutting-edge technology and established metrics. Additionally, harmonizing standards across different regions and application domains requires ongoing coordination between stakeholders with sometimes divergent priorities and technological approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!