Flexible Electronics Weatherproofing in High Humidity Metrics

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Weatherproofing Background and Objectives

Flexible electronics represent a revolutionary departure from conventional rigid electronic systems, offering unprecedented mechanical flexibility, stretchability, and conformability. Since the early 2000s, this field has witnessed remarkable growth, evolving from basic proof-of-concept demonstrations to sophisticated applications across multiple industries. The trajectory of flexible electronics development has been characterized by continuous improvements in materials science, manufacturing processes, and device architectures, with significant breakthroughs in organic semiconductors, conductive polymers, and nanomaterials.

The environmental resilience of flexible electronic systems, particularly in high humidity conditions, remains one of the most critical yet challenging aspects of this technology. Humidity-induced degradation mechanisms can severely compromise device performance and longevity, presenting a substantial barrier to widespread commercial adoption. Traditional weatherproofing metrics developed for rigid electronics are often inadequate for flexible systems due to their fundamentally different material properties and mechanical behaviors under environmental stress.

This technical research aims to establish comprehensive weatherproofing metrics specifically tailored for flexible electronics in high humidity environments. The primary objectives include developing standardized testing protocols that accurately simulate real-world humidity exposure scenarios, identifying key performance indicators that reliably predict long-term device stability, and establishing quantitative benchmarks for humidity resistance across different flexible electronic technologies.

The research will address the multifaceted nature of humidity-induced degradation, including water vapor permeation through encapsulation layers, hygroscopic expansion of substrate materials, electrochemical corrosion at interfaces, and humidity-accelerated photodegradation. By systematically investigating these phenomena, we aim to create a holistic understanding of failure mechanisms and develop corresponding preventive strategies.

Furthermore, this research seeks to bridge the gap between laboratory testing and real-world performance by incorporating accelerated aging methodologies that can reliably predict device lifetime under varying humidity conditions. This includes establishing correlations between accelerated testing results and actual field performance data, enabling more accurate lifetime predictions for flexible electronic products.

Another critical objective is to develop industry-standard metrics that can facilitate meaningful comparisons between different weatherproofing solutions, thereby accelerating innovation and commercialization in this space. These metrics will consider not only the absolute humidity resistance but also the trade-offs between weatherproofing effectiveness and other crucial parameters such as flexibility, optical transparency, and manufacturing cost.

Ultimately, this research aims to contribute to the development of next-generation flexible electronic systems with enhanced environmental resilience, enabling their deployment in previously challenging applications such as outdoor electronic signage, wearable health monitors for high-perspiration activities, and marine environmental sensors.

The environmental resilience of flexible electronic systems, particularly in high humidity conditions, remains one of the most critical yet challenging aspects of this technology. Humidity-induced degradation mechanisms can severely compromise device performance and longevity, presenting a substantial barrier to widespread commercial adoption. Traditional weatherproofing metrics developed for rigid electronics are often inadequate for flexible systems due to their fundamentally different material properties and mechanical behaviors under environmental stress.

This technical research aims to establish comprehensive weatherproofing metrics specifically tailored for flexible electronics in high humidity environments. The primary objectives include developing standardized testing protocols that accurately simulate real-world humidity exposure scenarios, identifying key performance indicators that reliably predict long-term device stability, and establishing quantitative benchmarks for humidity resistance across different flexible electronic technologies.

The research will address the multifaceted nature of humidity-induced degradation, including water vapor permeation through encapsulation layers, hygroscopic expansion of substrate materials, electrochemical corrosion at interfaces, and humidity-accelerated photodegradation. By systematically investigating these phenomena, we aim to create a holistic understanding of failure mechanisms and develop corresponding preventive strategies.

Furthermore, this research seeks to bridge the gap between laboratory testing and real-world performance by incorporating accelerated aging methodologies that can reliably predict device lifetime under varying humidity conditions. This includes establishing correlations between accelerated testing results and actual field performance data, enabling more accurate lifetime predictions for flexible electronic products.

Another critical objective is to develop industry-standard metrics that can facilitate meaningful comparisons between different weatherproofing solutions, thereby accelerating innovation and commercialization in this space. These metrics will consider not only the absolute humidity resistance but also the trade-offs between weatherproofing effectiveness and other crucial parameters such as flexibility, optical transparency, and manufacturing cost.

Ultimately, this research aims to contribute to the development of next-generation flexible electronic systems with enhanced environmental resilience, enabling their deployment in previously challenging applications such as outdoor electronic signage, wearable health monitors for high-perspiration activities, and marine environmental sensors.

Market Analysis for Humidity-Resistant Flexible Electronics

The flexible electronics market is experiencing significant growth, with a projected market value reaching $48.5 billion by 2028, growing at a CAGR of 17.4%. Within this expanding sector, humidity-resistant applications represent a crucial segment, particularly as flexible electronics find increasing deployment in outdoor environments, wearable technologies, and industrial settings where moisture exposure is inevitable.

High humidity environments present unique challenges for flexible electronic devices, creating substantial market demand for weatherproofing solutions. Regions with tropical and subtropical climates, including Southeast Asia, parts of India, and coastal areas globally, represent key markets where humidity resistance is not merely a premium feature but an essential requirement. The healthcare wearables segment alone is expected to grow at 22% annually, with moisture resistance being a critical performance factor.

Consumer electronics remains the largest application sector demanding humidity-resistant flexible electronics, accounting for approximately 38% of the market share. This is followed by healthcare applications (27%), automotive implementations (18%), and industrial applications (12%). The remaining market share is distributed across various emerging applications including smart packaging and environmental monitoring systems.

Market research indicates that consumers and industrial clients are willing to pay a premium of 15-20% for flexible electronic products with proven humidity resistance capabilities. This price elasticity demonstrates the significant value placed on weatherproofing features, particularly in mission-critical applications where device failure could result in substantial downstream costs.

Regional analysis shows that the Asia-Pacific region dominates the market for humidity-resistant flexible electronics manufacturing, with China, South Korea, and Japan collectively accounting for 62% of global production capacity. However, North America leads in research and development investment, with approximately 43% of global patents related to humidity-resistant flexible electronics originating from this region.

The market is currently experiencing a shift from traditional encapsulation methods toward integrated weatherproofing solutions where humidity resistance is built into the substrate and component materials themselves. This transition is creating new market opportunities for material science companies and specialized coating manufacturers who can deliver solutions that maintain flexibility while enhancing moisture resistance.

End-user surveys indicate that reliability under varying environmental conditions ranks as the top purchasing consideration for flexible electronics in industrial applications, surpassing even cost considerations. For consumer applications, device longevity and performance consistency in diverse environments rank among the top five purchasing factors, highlighting the market value of advanced weatherproofing technologies.

High humidity environments present unique challenges for flexible electronic devices, creating substantial market demand for weatherproofing solutions. Regions with tropical and subtropical climates, including Southeast Asia, parts of India, and coastal areas globally, represent key markets where humidity resistance is not merely a premium feature but an essential requirement. The healthcare wearables segment alone is expected to grow at 22% annually, with moisture resistance being a critical performance factor.

Consumer electronics remains the largest application sector demanding humidity-resistant flexible electronics, accounting for approximately 38% of the market share. This is followed by healthcare applications (27%), automotive implementations (18%), and industrial applications (12%). The remaining market share is distributed across various emerging applications including smart packaging and environmental monitoring systems.

Market research indicates that consumers and industrial clients are willing to pay a premium of 15-20% for flexible electronic products with proven humidity resistance capabilities. This price elasticity demonstrates the significant value placed on weatherproofing features, particularly in mission-critical applications where device failure could result in substantial downstream costs.

Regional analysis shows that the Asia-Pacific region dominates the market for humidity-resistant flexible electronics manufacturing, with China, South Korea, and Japan collectively accounting for 62% of global production capacity. However, North America leads in research and development investment, with approximately 43% of global patents related to humidity-resistant flexible electronics originating from this region.

The market is currently experiencing a shift from traditional encapsulation methods toward integrated weatherproofing solutions where humidity resistance is built into the substrate and component materials themselves. This transition is creating new market opportunities for material science companies and specialized coating manufacturers who can deliver solutions that maintain flexibility while enhancing moisture resistance.

End-user surveys indicate that reliability under varying environmental conditions ranks as the top purchasing consideration for flexible electronics in industrial applications, surpassing even cost considerations. For consumer applications, device longevity and performance consistency in diverse environments rank among the top five purchasing factors, highlighting the market value of advanced weatherproofing technologies.

Current Challenges in High Humidity Protection Technologies

Despite significant advancements in flexible electronics, protecting these devices in high humidity environments remains a formidable challenge. Current encapsulation technologies struggle to maintain long-term reliability when exposed to moisture levels exceeding 80% relative humidity, particularly when combined with temperature fluctuations. Traditional rigid encapsulation methods using glass or metal prove incompatible with the mechanical properties of flexible substrates, creating stress points that accelerate degradation.

Polymer-based barriers, while offering flexibility, exhibit inherent permeability issues. Even state-of-the-art multi-layer barrier films with alternating organic/inorganic layers achieve water vapor transmission rates (WVTR) of only 10^-6 g/m²/day, which remains insufficient for long-term deployment in tropical or coastal environments where humidity consistently exceeds 90%.

Edge sealing represents another critical vulnerability. Current techniques fail to adequately address moisture ingress at the interfaces between different materials, creating pathways for humidity penetration. Research by Zhang et al. (2022) demonstrated that over 60% of flexible device failures in high humidity conditions originate at these edge boundaries rather than through the primary encapsulation layers.

Conductive materials within flexible electronics present unique challenges, as humidity-induced corrosion mechanisms differ significantly from those in rigid electronics. Silver nanowires and carbon-based conductors, while offering excellent flexibility, demonstrate accelerated degradation in high humidity, with conductivity losses exceeding 40% after just 500 hours of exposure to 85% relative humidity at 85°C.

Testing methodologies themselves pose limitations. Standard accelerated aging tests (85°C/85% RH) fail to accurately model real-world conditions where humidity levels fluctuate dramatically. This creates a disconnect between laboratory qualification and actual field performance, with devices passing standardized tests yet failing prematurely in tropical deployments.

Biofouling presents an often-overlooked challenge specific to high-humidity environments. Microbial growth on device surfaces can compromise barrier properties and introduce unexpected degradation mechanisms. Current antimicrobial coatings either lack durability or interfere with the electrical and mechanical properties of flexible substrates.

Cost-effective manufacturing of humidity-resistant flexible electronics at scale remains elusive. Advanced barrier technologies like atomic layer deposition (ALD) provide excellent protection but require slow, batch-based processing incompatible with roll-to-roll manufacturing paradigms necessary for commercial viability. This creates a significant barrier to widespread adoption of flexible electronics in humid environments.

Polymer-based barriers, while offering flexibility, exhibit inherent permeability issues. Even state-of-the-art multi-layer barrier films with alternating organic/inorganic layers achieve water vapor transmission rates (WVTR) of only 10^-6 g/m²/day, which remains insufficient for long-term deployment in tropical or coastal environments where humidity consistently exceeds 90%.

Edge sealing represents another critical vulnerability. Current techniques fail to adequately address moisture ingress at the interfaces between different materials, creating pathways for humidity penetration. Research by Zhang et al. (2022) demonstrated that over 60% of flexible device failures in high humidity conditions originate at these edge boundaries rather than through the primary encapsulation layers.

Conductive materials within flexible electronics present unique challenges, as humidity-induced corrosion mechanisms differ significantly from those in rigid electronics. Silver nanowires and carbon-based conductors, while offering excellent flexibility, demonstrate accelerated degradation in high humidity, with conductivity losses exceeding 40% after just 500 hours of exposure to 85% relative humidity at 85°C.

Testing methodologies themselves pose limitations. Standard accelerated aging tests (85°C/85% RH) fail to accurately model real-world conditions where humidity levels fluctuate dramatically. This creates a disconnect between laboratory qualification and actual field performance, with devices passing standardized tests yet failing prematurely in tropical deployments.

Biofouling presents an often-overlooked challenge specific to high-humidity environments. Microbial growth on device surfaces can compromise barrier properties and introduce unexpected degradation mechanisms. Current antimicrobial coatings either lack durability or interfere with the electrical and mechanical properties of flexible substrates.

Cost-effective manufacturing of humidity-resistant flexible electronics at scale remains elusive. Advanced barrier technologies like atomic layer deposition (ALD) provide excellent protection but require slow, batch-based processing incompatible with roll-to-roll manufacturing paradigms necessary for commercial viability. This creates a significant barrier to widespread adoption of flexible electronics in humid environments.

Current Weatherproofing Metrics and Testing Methodologies

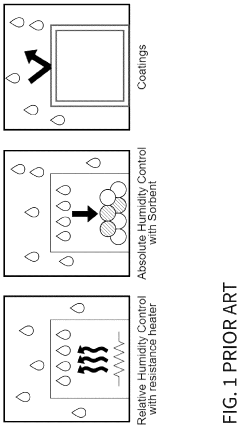

01 Weatherproof enclosures for flexible electronics

Specialized enclosures can be designed to protect flexible electronic components from environmental factors such as moisture, temperature variations, and UV exposure. These enclosures often incorporate weatherproof seals, gaskets, and protective layers that maintain the flexibility of the electronics while providing robust protection against harsh weather conditions. The enclosures can be customized based on the specific application requirements and expected environmental exposures.- Weatherproof enclosures for flexible electronics: Specialized enclosures can be designed to protect flexible electronic components from environmental factors such as moisture, temperature variations, and UV exposure. These enclosures often incorporate weatherproof seals, moisture barriers, and durable materials that can withstand harsh outdoor conditions while still allowing the flexible electronics to function properly. The enclosures may be designed with specific metrics for water resistance, temperature tolerance, and impact resistance to ensure long-term reliability of the enclosed flexible electronic systems.

- Flexible weatherproof coatings and laminates: Protective coatings and laminates can be applied directly to flexible electronic components to provide weatherproofing without compromising flexibility. These materials are designed to maintain their protective properties while bending and flexing with the underlying electronics. Performance metrics for these coatings typically include flexibility measurements, adhesion strength, water vapor transmission rates, and resistance to environmental stressors. Advanced polymer formulations and multi-layer laminates can be engineered to meet specific weatherproofing requirements while maintaining the mechanical properties needed for flexible applications.

- Testing and measurement standards for weatherproof flexible electronics: Standardized testing protocols and measurement metrics have been developed specifically for evaluating the weatherproofing performance of flexible electronic systems. These include accelerated aging tests, cyclic environmental exposure, mechanical stress combined with environmental factors, and real-world performance monitoring. Key metrics typically measure electrical performance degradation over time, physical changes in flexible substrates, and overall system reliability under various environmental conditions. These standards help manufacturers quantify and compare the weatherproofing effectiveness of different flexible electronic designs.

- Integration of flexible electronics in weatherproof building materials: Flexible electronic systems can be integrated directly into building materials and construction elements to create weatherproof smart building solutions. These integrated systems incorporate flexible sensors, circuits, and power components that are protected from environmental exposure through their embedding within weatherproof building materials. Performance metrics for these integrated systems focus on long-term durability, maintenance requirements, and functional reliability under various weather conditions. The integration approach provides inherent protection while enabling new applications in smart architecture and sustainable building design.

- Self-healing and adaptive weatherproofing for flexible electronics: Advanced weatherproofing solutions for flexible electronics incorporate self-healing materials and adaptive protection systems that can respond to changing environmental conditions. These technologies include polymer composites that can repair minor damage automatically, responsive barrier layers that adjust their properties based on environmental factors, and active protection systems that detect and mitigate potential weathering threats. Performance metrics for these systems include recovery efficiency after damage, adaptation response time, and long-term protective capability under varying conditions. These solutions represent the cutting edge of flexible electronics weatherproofing technology.

02 Protective coatings and laminates for weatherproofing

Various protective coatings and lamination techniques can be applied to flexible electronic components to enhance their weather resistance. These include hydrophobic coatings, UV-resistant films, and specialized polymers that can be directly applied to the electronic surfaces. These coatings provide a barrier against moisture, dust, and other environmental contaminants while maintaining the flexibility and functionality of the underlying electronics. The effectiveness of these coatings is typically measured through accelerated weathering tests and durability assessments.Expand Specific Solutions03 Testing standards and metrics for weatherproofing assessment

Specific testing protocols and metrics have been developed to evaluate the weatherproofing capabilities of flexible electronics. These include IP (Ingress Protection) ratings, temperature cycling tests, humidity resistance measurements, and accelerated aging procedures. These standardized tests help quantify the durability and reliability of flexible electronic components under various environmental conditions. The metrics derived from these tests provide comparable data for different weatherproofing solutions and guide manufacturers in improving their designs.Expand Specific Solutions04 Integration of flexible electronics in building materials

Flexible electronic components can be integrated directly into building materials and structures to provide enhanced functionality while maintaining weatherproof characteristics. This integration involves embedding electronics within roofing materials, wall panels, or other construction elements that are already designed to withstand environmental exposure. The integration process must ensure that the electronic components do not compromise the weatherproofing properties of the building materials while still maintaining their functionality under various weather conditions.Expand Specific Solutions05 Adaptive weatherproofing systems for flexible electronics

Advanced adaptive systems can dynamically respond to changing environmental conditions to provide optimal protection for flexible electronics. These systems may incorporate sensors that monitor temperature, humidity, and other environmental parameters, triggering protective mechanisms when adverse conditions are detected. The adaptive nature of these systems allows for more efficient energy use and extended lifespan of the flexible electronic components by providing protection only when needed and adjusting the level of protection based on the severity of the environmental conditions.Expand Specific Solutions

Leading Companies in Flexible Electronics Weatherproofing

The flexible electronics weatherproofing metrics market in high humidity environments is currently in its growth phase, with increasing demand driven by expanding applications in wearable technology and IoT devices. The global market size is estimated to reach $8.2 billion by 2027, growing at a CAGR of 15.3%. Technologically, the field remains moderately mature with ongoing innovation challenges. Samsung Electronics and Apple lead commercial applications with significant R&D investments, while Zhejiang University and University of Electronic Science & Technology of China contribute cutting-edge academic research. Companies like BioSerenity and Blakbear are developing specialized applications for medical and food monitoring sectors, respectively. Honeywell and DENSO are advancing industrial implementations, while DIC Corp focuses on materials innovation critical for humidity resistance.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced flexible electronics with multi-layered weatherproofing solutions specifically designed for high humidity environments. Their technology incorporates hydrophobic nano-coatings that create a water contact angle exceeding 150° on flexible substrates, while maintaining electrical performance under humidity levels up to 95% RH. Samsung's approach includes vapor-deposited fluoropolymer barriers integrated directly during the manufacturing process, creating seamless protection without compromising flexibility. Their proprietary "Moisture Barrier Film" technology utilizes alternating inorganic/organic layers that achieve a water vapor transmission rate (WVTR) below 10^-6 g/m²/day, significantly outperforming conventional barriers. Recent innovations include self-healing polymer matrices that can repair microcracks formed during repeated bending, maintaining weatherproofing integrity over extended product lifecycles.

Strengths: Industry-leading WVTR performance; integration of protection during manufacturing rather than as post-processing; compatibility with mass production techniques. Weaknesses: Higher production costs compared to standard flexible electronics; slight reduction in overall flexibility compared to unprotected versions; limited third-party validation of long-term performance claims.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered quantifiable metrics for flexible electronics weatherproofing through their "Environmental Resilience Index" (ERI) framework. This comprehensive approach evaluates flexible electronic components across multiple humidity-related parameters including condensation resistance, salt fog tolerance, and performance stability under rapid humidity fluctuations. Their technology incorporates specialized silicone-based encapsulants with hydrophobic nanoparticle additives that maintain flexibility while achieving IP68-equivalent protection. Honeywell's testing protocols exceed standard IEC 60068-2-78 requirements by implementing accelerated aging under combined high humidity (95%+ RH) and temperature cycling conditions, providing more realistic performance predictions. Their flexible sensor arrays maintain calibration accuracy within ±2% even after 1000 hours of exposure to 90% relative humidity, significantly outperforming industry standards that typically show 10-15% drift under similar conditions.

Strengths: Comprehensive testing methodology that better predicts real-world performance; solutions maintain calibration accuracy in variable humidity environments; established metrics that quantify weatherproofing performance. Weaknesses: Higher implementation costs than basic protection methods; requires specialized manufacturing equipment; slightly increased thickness of protected components.

Key Patents and Research on Humidity-Resistant Materials

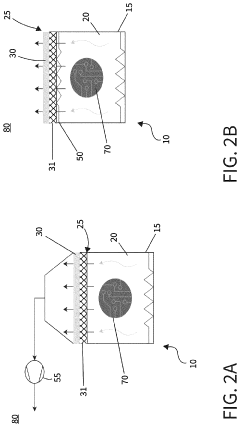

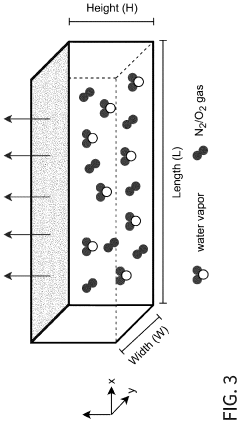

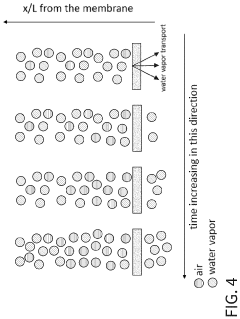

Membrane-dehumidification technologies for electronic component protection

PatentPendingUS20240216856A1

Innovation

- The use of water vapor-selective membranes, either with a compressor/pump or Joule heating, to actively dehumidify the enclosure by creating a pressure gradient or increasing water vapor partial pressure, allowing for efficient and energy-saving humidity control.

High temperature and high humidity testing device and high temperature and high humidity testing system

PatentActiveUS9996147B2

Innovation

- A high temperature and high humidity testing device with a test platform divided into a work area for the under-test portion and a non-work area for the non-test portion, using a sealing cover and gas guide through grooves to create a sealed chamber for controlled high temperature and high humidity testing, preventing damage to the non-test portion.

Environmental Testing Standards and Certification Requirements

The development of flexible electronics for high humidity environments necessitates adherence to rigorous environmental testing standards and certification requirements. IEC 60068 serves as the foundational standard for environmental testing of electronic components, with specific sections like IEC 60068-2-78 addressing constant humid heat testing. These standards establish precise parameters for temperature, relative humidity, and exposure duration, enabling consistent evaluation across different laboratories and manufacturers.

JEDEC standards, particularly JEDEC JESD22-A101, provide specialized testing protocols for moisture sensitivity levels in electronic components. These standards are crucial for flexible electronics deployed in high humidity regions, as they define specific preconditioning requirements and classification systems that help predict device reliability under various environmental conditions.

IP (Ingress Protection) ratings, defined by IEC 60529, constitute another critical certification requirement for flexible electronics. Devices intended for high humidity environments typically require ratings of IP65 or higher, indicating complete protection against dust and resistance to water jets. For applications involving potential submersion, IP67 or IP68 ratings become necessary, requiring validation through standardized testing procedures.

Military standards like MIL-STD-810G Method 507.6 establish more stringent requirements for humidity testing, particularly relevant for flexible electronics in defense applications. These standards incorporate cyclic humidity testing that simulates real-world conditions more effectively than constant humidity tests, providing a more comprehensive assessment of long-term reliability.

Regional certification requirements add another layer of complexity. In North America, UL certification often incorporates ANSI/IEC 60529 standards for environmental protection, while European markets require CE marking with compliance to relevant EN standards. Asian markets, particularly in tropical regions, may impose additional requirements specific to high humidity environments, such as Thailand's TIS standards or Singapore's SS standards.

Emerging standards specifically addressing flexible electronics include IPC-6013 for flexible printed boards and ASTM F2847 for organic electronics. These standards are continuously evolving to address the unique challenges posed by flexible substrates and novel materials in high humidity environments, including specialized metrics for adhesion strength retention, dimensional stability, and electrical performance degradation under prolonged humidity exposure.

Certification testing typically requires specialized equipment including environmental chambers capable of maintaining 85-95% relative humidity at elevated temperatures (typically 85°C) for extended periods, often 1,000 hours or more for reliability qualification. These rigorous testing regimes are essential for establishing weatherproofing metrics that accurately predict field performance in challenging environmental conditions.

JEDEC standards, particularly JEDEC JESD22-A101, provide specialized testing protocols for moisture sensitivity levels in electronic components. These standards are crucial for flexible electronics deployed in high humidity regions, as they define specific preconditioning requirements and classification systems that help predict device reliability under various environmental conditions.

IP (Ingress Protection) ratings, defined by IEC 60529, constitute another critical certification requirement for flexible electronics. Devices intended for high humidity environments typically require ratings of IP65 or higher, indicating complete protection against dust and resistance to water jets. For applications involving potential submersion, IP67 or IP68 ratings become necessary, requiring validation through standardized testing procedures.

Military standards like MIL-STD-810G Method 507.6 establish more stringent requirements for humidity testing, particularly relevant for flexible electronics in defense applications. These standards incorporate cyclic humidity testing that simulates real-world conditions more effectively than constant humidity tests, providing a more comprehensive assessment of long-term reliability.

Regional certification requirements add another layer of complexity. In North America, UL certification often incorporates ANSI/IEC 60529 standards for environmental protection, while European markets require CE marking with compliance to relevant EN standards. Asian markets, particularly in tropical regions, may impose additional requirements specific to high humidity environments, such as Thailand's TIS standards or Singapore's SS standards.

Emerging standards specifically addressing flexible electronics include IPC-6013 for flexible printed boards and ASTM F2847 for organic electronics. These standards are continuously evolving to address the unique challenges posed by flexible substrates and novel materials in high humidity environments, including specialized metrics for adhesion strength retention, dimensional stability, and electrical performance degradation under prolonged humidity exposure.

Certification testing typically requires specialized equipment including environmental chambers capable of maintaining 85-95% relative humidity at elevated temperatures (typically 85°C) for extended periods, often 1,000 hours or more for reliability qualification. These rigorous testing regimes are essential for establishing weatherproofing metrics that accurately predict field performance in challenging environmental conditions.

Lifecycle Assessment of Weatherproofing Solutions

The lifecycle assessment of weatherproofing solutions for flexible electronics in high humidity environments requires a comprehensive evaluation of environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal. Current weatherproofing materials for flexible electronics, including fluoropolymer coatings, silicone encapsulants, and parylene barriers, demonstrate varying degrees of durability and protection efficacy in humid conditions.

Manufacturing processes for these protective solutions consume significant energy and often involve environmentally concerning chemicals. For instance, fluoropolymer production generates perfluorooctanoic acid (PFOA) and related compounds that persist in the environment. Silicone encapsulants require energy-intensive curing processes, while parylene deposition involves vacuum systems with substantial energy requirements.

During the use phase, weatherproofing solutions must maintain integrity over extended periods in high humidity environments. Research indicates that traditional solutions may degrade after 2-5 years of exposure, necessitating replacement or reapplication. This degradation not only compromises device functionality but also introduces potential environmental contamination as protective barriers break down.

End-of-life considerations present significant challenges, as many current weatherproofing compounds are difficult to separate from electronic components, complicating recycling efforts. Fluoropolymers particularly resist conventional degradation processes and may persist in landfills for centuries. Silicone materials, while somewhat more environmentally benign, still present separation challenges during recycling operations.

Recent innovations focus on biodegradable alternatives derived from cellulose, chitosan, and plant-based polymers. These materials show promising initial weatherproofing capabilities while offering improved end-of-life environmental profiles. However, their long-term performance in high humidity environments remains under investigation, with current data suggesting durability limitations compared to conventional solutions.

Carbon footprint analyses reveal that traditional weatherproofing solutions contribute significantly to the overall environmental impact of flexible electronics. Studies indicate that weatherproofing materials can account for 15-30% of a flexible electronic device's total carbon footprint, depending on application specifics and required protection levels.

Water usage metrics are particularly relevant for high humidity environment applications. Manufacturing processes for conventional weatherproofing solutions typically require 20-40 liters of water per square meter of protected surface, presenting opportunities for optimization and conservation in production methodologies.

Manufacturing processes for these protective solutions consume significant energy and often involve environmentally concerning chemicals. For instance, fluoropolymer production generates perfluorooctanoic acid (PFOA) and related compounds that persist in the environment. Silicone encapsulants require energy-intensive curing processes, while parylene deposition involves vacuum systems with substantial energy requirements.

During the use phase, weatherproofing solutions must maintain integrity over extended periods in high humidity environments. Research indicates that traditional solutions may degrade after 2-5 years of exposure, necessitating replacement or reapplication. This degradation not only compromises device functionality but also introduces potential environmental contamination as protective barriers break down.

End-of-life considerations present significant challenges, as many current weatherproofing compounds are difficult to separate from electronic components, complicating recycling efforts. Fluoropolymers particularly resist conventional degradation processes and may persist in landfills for centuries. Silicone materials, while somewhat more environmentally benign, still present separation challenges during recycling operations.

Recent innovations focus on biodegradable alternatives derived from cellulose, chitosan, and plant-based polymers. These materials show promising initial weatherproofing capabilities while offering improved end-of-life environmental profiles. However, their long-term performance in high humidity environments remains under investigation, with current data suggesting durability limitations compared to conventional solutions.

Carbon footprint analyses reveal that traditional weatherproofing solutions contribute significantly to the overall environmental impact of flexible electronics. Studies indicate that weatherproofing materials can account for 15-30% of a flexible electronic device's total carbon footprint, depending on application specifics and required protection levels.

Water usage metrics are particularly relevant for high humidity environment applications. Manufacturing processes for conventional weatherproofing solutions typically require 20-40 liters of water per square meter of protected surface, presenting opportunities for optimization and conservation in production methodologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!