Pintle Hitch Implementation in High-Capacity Freight Routes

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The pintle hitch has undergone significant evolution since its inception, adapting to meet the changing demands of high-capacity freight transportation. Initially developed for military applications in the mid-20th century, the pintle hitch has transitioned into a crucial component in commercial and industrial hauling operations.

In its early stages, the pintle hitch was primarily used for towing artillery and heavy military equipment. The design focused on durability and the ability to handle extreme loads in rugged terrains. As the technology transitioned to civilian use, manufacturers began to refine the design to better suit commercial transportation needs.

The 1970s and 1980s saw a surge in the adoption of pintle hitches for heavy-duty trucking applications. During this period, improvements were made to enhance safety and ease of use. One significant development was the introduction of automatic locking mechanisms, which reduced the risk of accidental uncoupling and improved overall operational safety.

Throughout the 1990s and early 2000s, the focus shifted towards increasing the weight capacity of pintle hitches. This was driven by the growing demand for transporting heavier loads in industries such as construction, mining, and agriculture. Engineers worked on strengthening the hitch components and optimizing the load distribution to accommodate these increased capacities.

In recent years, the evolution of pintle hitches has been characterized by the integration of advanced materials and smart technologies. High-strength alloys and composite materials have been employed to create lighter yet stronger hitches, contributing to improved fuel efficiency without compromising on load-bearing capacity.

The advent of sensor technologies and IoT integration has led to the development of smart pintle hitches. These modern designs incorporate features such as real-time load monitoring, wear detection, and predictive maintenance capabilities. Such advancements have significantly enhanced the safety and reliability of high-capacity freight transportation.

Another notable trend in pintle hitch evolution has been the focus on versatility. Manufacturers have developed modular designs that allow for easy customization and adaptation to various trailer types and load requirements. This flexibility has made pintle hitches increasingly popular across diverse industries and applications.

Environmental considerations have also played a role in recent developments. Efforts have been made to reduce the environmental impact of pintle hitches through the use of eco-friendly materials and manufacturing processes. Additionally, designs that minimize noise and vibration during operation have been introduced, addressing concerns about noise pollution in urban freight routes.

As we look towards the future, the evolution of pintle hitches is likely to continue, driven by the need for even greater efficiency, safety, and sustainability in high-capacity freight transportation. Emerging technologies such as AI-driven coupling systems and advanced materials science are expected to shape the next generation of pintle hitches, further enhancing their role in modern logistics and transportation networks.

In its early stages, the pintle hitch was primarily used for towing artillery and heavy military equipment. The design focused on durability and the ability to handle extreme loads in rugged terrains. As the technology transitioned to civilian use, manufacturers began to refine the design to better suit commercial transportation needs.

The 1970s and 1980s saw a surge in the adoption of pintle hitches for heavy-duty trucking applications. During this period, improvements were made to enhance safety and ease of use. One significant development was the introduction of automatic locking mechanisms, which reduced the risk of accidental uncoupling and improved overall operational safety.

Throughout the 1990s and early 2000s, the focus shifted towards increasing the weight capacity of pintle hitches. This was driven by the growing demand for transporting heavier loads in industries such as construction, mining, and agriculture. Engineers worked on strengthening the hitch components and optimizing the load distribution to accommodate these increased capacities.

In recent years, the evolution of pintle hitches has been characterized by the integration of advanced materials and smart technologies. High-strength alloys and composite materials have been employed to create lighter yet stronger hitches, contributing to improved fuel efficiency without compromising on load-bearing capacity.

The advent of sensor technologies and IoT integration has led to the development of smart pintle hitches. These modern designs incorporate features such as real-time load monitoring, wear detection, and predictive maintenance capabilities. Such advancements have significantly enhanced the safety and reliability of high-capacity freight transportation.

Another notable trend in pintle hitch evolution has been the focus on versatility. Manufacturers have developed modular designs that allow for easy customization and adaptation to various trailer types and load requirements. This flexibility has made pintle hitches increasingly popular across diverse industries and applications.

Environmental considerations have also played a role in recent developments. Efforts have been made to reduce the environmental impact of pintle hitches through the use of eco-friendly materials and manufacturing processes. Additionally, designs that minimize noise and vibration during operation have been introduced, addressing concerns about noise pollution in urban freight routes.

As we look towards the future, the evolution of pintle hitches is likely to continue, driven by the need for even greater efficiency, safety, and sustainability in high-capacity freight transportation. Emerging technologies such as AI-driven coupling systems and advanced materials science are expected to shape the next generation of pintle hitches, further enhancing their role in modern logistics and transportation networks.

Freight Route Demands

The demand for efficient and high-capacity freight routes continues to grow as global trade and e-commerce expand. This increasing demand is driven by several factors, including the need for cost-effective transportation, faster delivery times, and the ability to move larger volumes of goods. High-capacity freight routes are essential for supporting economic growth, reducing transportation costs, and improving supply chain efficiency.

In recent years, there has been a significant shift towards intermodal transportation, which combines different modes of transport such as rail, road, and sea. This approach allows for greater flexibility and efficiency in moving goods over long distances. The demand for high-capacity freight routes is particularly strong in regions with well-developed infrastructure and high population densities, where the movement of goods is critical to sustaining economic activities.

The implementation of pintle hitch technology in high-capacity freight routes addresses several key demands in the industry. Pintle hitches offer increased towing capacity, improved stability, and enhanced safety for heavy-duty applications. These features are particularly valuable for transporting oversized or overweight loads, which are becoming more common in industries such as construction, mining, and energy.

One of the primary demands driving the adoption of pintle hitch systems is the need for greater payload capacity. As businesses seek to maximize efficiency and reduce the number of trips required to transport goods, there is a growing emphasis on vehicles capable of hauling heavier loads. Pintle hitches, with their robust design and high weight ratings, can significantly increase the towing capacity of freight vehicles, allowing for the transportation of larger and heavier cargo.

Safety considerations also play a crucial role in shaping freight route demands. The increased stability provided by pintle hitch systems is particularly important when transporting heavy or irregularly shaped loads over long distances or challenging terrains. This enhanced stability contributes to reduced accident risks and improved overall road safety, addressing concerns of both regulators and transportation companies.

Furthermore, the versatility of pintle hitch systems aligns well with the demand for adaptable freight solutions. As supply chains become more complex and diverse, there is a growing need for transportation systems that can accommodate a wide range of trailer types and configurations. Pintle hitches offer the flexibility to connect various types of trailers and equipment, making them well-suited for multi-purpose freight operations.

The demand for high-capacity freight routes is also influenced by environmental considerations. As governments and businesses focus on reducing carbon emissions, there is an increasing emphasis on maximizing load efficiency to minimize the number of vehicles on the road. Pintle hitch systems, by enabling higher payload capacities, contribute to this goal by potentially reducing the total number of trips required to transport a given volume of goods.

In recent years, there has been a significant shift towards intermodal transportation, which combines different modes of transport such as rail, road, and sea. This approach allows for greater flexibility and efficiency in moving goods over long distances. The demand for high-capacity freight routes is particularly strong in regions with well-developed infrastructure and high population densities, where the movement of goods is critical to sustaining economic activities.

The implementation of pintle hitch technology in high-capacity freight routes addresses several key demands in the industry. Pintle hitches offer increased towing capacity, improved stability, and enhanced safety for heavy-duty applications. These features are particularly valuable for transporting oversized or overweight loads, which are becoming more common in industries such as construction, mining, and energy.

One of the primary demands driving the adoption of pintle hitch systems is the need for greater payload capacity. As businesses seek to maximize efficiency and reduce the number of trips required to transport goods, there is a growing emphasis on vehicles capable of hauling heavier loads. Pintle hitches, with their robust design and high weight ratings, can significantly increase the towing capacity of freight vehicles, allowing for the transportation of larger and heavier cargo.

Safety considerations also play a crucial role in shaping freight route demands. The increased stability provided by pintle hitch systems is particularly important when transporting heavy or irregularly shaped loads over long distances or challenging terrains. This enhanced stability contributes to reduced accident risks and improved overall road safety, addressing concerns of both regulators and transportation companies.

Furthermore, the versatility of pintle hitch systems aligns well with the demand for adaptable freight solutions. As supply chains become more complex and diverse, there is a growing need for transportation systems that can accommodate a wide range of trailer types and configurations. Pintle hitches offer the flexibility to connect various types of trailers and equipment, making them well-suited for multi-purpose freight operations.

The demand for high-capacity freight routes is also influenced by environmental considerations. As governments and businesses focus on reducing carbon emissions, there is an increasing emphasis on maximizing load efficiency to minimize the number of vehicles on the road. Pintle hitch systems, by enabling higher payload capacities, contribute to this goal by potentially reducing the total number of trips required to transport a given volume of goods.

Technical Challenges

The implementation of pintle hitches in high-capacity freight routes presents several significant technical challenges that must be addressed to ensure safe and efficient operations. One of the primary concerns is the increased stress and wear on the hitch mechanism due to the higher loads associated with high-capacity freight. The pintle hitch must be designed to withstand greater forces, both in terms of vertical load and horizontal pulling forces, without compromising its structural integrity or safety features.

Another challenge lies in the dynamic behavior of the hitch during transit, particularly when navigating curves, inclines, or uneven terrain. The increased mass of high-capacity freight can lead to more pronounced oscillations and potential instability, requiring advanced engineering solutions to maintain control and stability throughout the journey. This may involve the integration of sophisticated damping systems or active stabilization technologies to mitigate unwanted movements and ensure smooth operation.

Compatibility issues also pose a significant hurdle in the widespread adoption of pintle hitches for high-capacity freight routes. The diverse range of existing trailer designs and coupling systems in use across different regions and industries necessitates the development of standardized interfaces or adaptable hitch designs. This challenge is compounded by the need to ensure backward compatibility with existing equipment while simultaneously pushing forward with innovations to support higher capacities.

The integration of smart technologies into pintle hitch systems presents both opportunities and challenges. While sensors and electronic monitoring systems can enhance safety and efficiency by providing real-time data on hitch status, load distribution, and potential issues, their implementation requires careful consideration of reliability, durability, and resistance to harsh environmental conditions typically encountered in freight operations.

Maintenance and serviceability of pintle hitches in high-capacity applications also present technical challenges. The increased wear and tear associated with heavier loads necessitates the development of more durable materials and advanced lubrication systems. Additionally, designing hitches that allow for easy inspection, maintenance, and replacement of components without compromising structural integrity or safety is crucial for minimizing downtime and ensuring long-term operational efficiency.

Environmental considerations add another layer of complexity to the technical challenges. As the transportation industry faces increasing pressure to reduce emissions and improve fuel efficiency, the design of pintle hitches for high-capacity freight must also consider aerodynamics and weight optimization. This may involve the use of advanced materials and innovative designs that can maintain the necessary strength while reducing overall weight and drag.

Another challenge lies in the dynamic behavior of the hitch during transit, particularly when navigating curves, inclines, or uneven terrain. The increased mass of high-capacity freight can lead to more pronounced oscillations and potential instability, requiring advanced engineering solutions to maintain control and stability throughout the journey. This may involve the integration of sophisticated damping systems or active stabilization technologies to mitigate unwanted movements and ensure smooth operation.

Compatibility issues also pose a significant hurdle in the widespread adoption of pintle hitches for high-capacity freight routes. The diverse range of existing trailer designs and coupling systems in use across different regions and industries necessitates the development of standardized interfaces or adaptable hitch designs. This challenge is compounded by the need to ensure backward compatibility with existing equipment while simultaneously pushing forward with innovations to support higher capacities.

The integration of smart technologies into pintle hitch systems presents both opportunities and challenges. While sensors and electronic monitoring systems can enhance safety and efficiency by providing real-time data on hitch status, load distribution, and potential issues, their implementation requires careful consideration of reliability, durability, and resistance to harsh environmental conditions typically encountered in freight operations.

Maintenance and serviceability of pintle hitches in high-capacity applications also present technical challenges. The increased wear and tear associated with heavier loads necessitates the development of more durable materials and advanced lubrication systems. Additionally, designing hitches that allow for easy inspection, maintenance, and replacement of components without compromising structural integrity or safety is crucial for minimizing downtime and ensuring long-term operational efficiency.

Environmental considerations add another layer of complexity to the technical challenges. As the transportation industry faces increasing pressure to reduce emissions and improve fuel efficiency, the design of pintle hitches for high-capacity freight must also consider aerodynamics and weight optimization. This may involve the use of advanced materials and innovative designs that can maintain the necessary strength while reducing overall weight and drag.

Current Solutions

01 Pintle hitch design and structure

Pintle hitches are designed with a hook-like structure that allows for secure coupling with a lunette ring on the trailer. The design typically includes a locking mechanism to ensure the connection remains secure during towing. Some designs incorporate adjustable features for improved versatility and compatibility with different trailer types.- Pintle hitch design and structure: Pintle hitches are designed with a hook-like structure that allows for secure coupling with a lunette ring or eye. The design typically includes a locking mechanism to ensure the connection remains secure during towing. These hitches are known for their durability and ability to handle heavy loads, making them suitable for various towing applications.

- Safety features in pintle hitches: Modern pintle hitches incorporate various safety features to enhance their reliability and prevent accidental uncoupling. These may include secondary locking mechanisms, visual indicators for proper engagement, and fail-safe designs that maintain connection even if the primary latch fails. Some designs also integrate anti-theft measures to prevent unauthorized use.

- Adjustable and multi-functional pintle hitches: Innovative pintle hitch designs offer adjustability and multi-functionality to accommodate different towing needs. These may include height-adjustable models, combination hitches that can work with both pintle and ball couplings, or hitches with interchangeable components for versatility in towing various trailer types.

- Integration with vehicle systems: Advanced pintle hitch designs incorporate integration with vehicle systems for improved performance and safety. This may include electronic monitoring of hitch status, connection to vehicle stability control systems, or compatibility with backup cameras and sensors for easier coupling and maneuvering.

- Specialized pintle hitches for specific applications: Certain pintle hitch designs are tailored for specific applications or industries. These may include heavy-duty models for military or construction use, agricultural hitches with additional pivot points for improved maneuverability, or designs optimized for off-road use with enhanced durability and articulation capabilities.

02 Safety features in pintle hitches

Modern pintle hitches often include safety features such as secondary locking mechanisms, visual indicators for proper coupling, and integrated safety chains. These features help prevent accidental uncoupling and enhance overall towing safety. Some designs also incorporate anti-theft measures to secure the hitch when not in use.Expand Specific Solutions03 Combination pintle hitch and ball mount

Some designs combine a pintle hitch with a traditional ball mount, offering versatility for different towing needs. These combination hitches allow users to switch between pintle and ball hitch configurations, often without the need for additional tools. This design can accommodate a wider range of trailer types and coupling mechanisms.Expand Specific Solutions04 Adjustable and multi-position pintle hitches

Adjustable pintle hitches allow for customization of the hitch position to accommodate different trailer heights and towing vehicle configurations. Some designs feature multiple mounting positions or adjustable components to optimize the towing angle and weight distribution. This flexibility can improve towing performance and safety across various vehicle and trailer combinations.Expand Specific Solutions05 Heavy-duty and specialized pintle hitch applications

Pintle hitches are often used in heavy-duty and specialized towing applications, such as military vehicles, construction equipment, and agricultural machinery. These hitches are designed to withstand high loads and harsh operating conditions. Some specialized designs incorporate features like air or hydraulic actuation for remote operation or integration with other vehicle systems.Expand Specific Solutions

Industry Leaders

The research on Pintle Hitch Implementation in High-Capacity Freight Routes is in a developing stage, with the market showing potential for growth as logistics and transportation sectors evolve. The technology's maturity varies among key players, with companies like Deere & Co., Crown Equipment Corp., and Polaris Inc. leading in innovation. Naval Research Laboratory and GM Global Technology Operations LLC contribute significant R&D efforts, while specialized firms like JOST-Werke Deutschland GmbH and Teleswivel LLC focus on niche applications. The competitive landscape is diverse, encompassing both established manufacturers and emerging tech-driven enterprises, indicating a dynamic market with opportunities for technological advancements and market expansion.

JOST-Werke Deutschland GmbH

Technical Solution: JOST-Werke Deutschland GmbH has developed advanced pintle hitch systems for high-capacity freight routes. Their technology focuses on improving the connection between trucks and trailers, enhancing safety and efficiency. The company's pintle hitch design incorporates a self-aligning feature that facilitates easier coupling, reducing the risk of misalignment and potential accidents[1]. Additionally, JOST has implemented sensors and electronic systems to monitor the hitch status in real-time, providing drivers with crucial information about the connection's integrity during transit[2]. The company's pintle hitches are designed to withstand extreme loads, with some models capable of handling up to 40 tons of vertical load and 190 kN D-value[3], making them suitable for the most demanding freight applications.

Strengths: Robust design for heavy-duty applications, advanced safety features, and real-time monitoring capabilities. Weaknesses: Potentially higher initial cost compared to simpler hitch systems, and may require specialized maintenance.

Teleswivel LLC

Technical Solution: Teleswivel LLC has innovated in the field of pintle hitch technology with their patented swiveling pintle hitch system. This design allows for a greater range of motion between the towing vehicle and the trailer, which is particularly beneficial for high-capacity freight routes with challenging terrain or tight maneuvering requirements. The Teleswivel system incorporates a rotating mechanism that enables the pintle to swivel up to 90 degrees in each direction, significantly reducing stress on the hitch and improving overall safety[4]. The company's technology also includes a locking mechanism that secures the hitch in its centered position during straight-line travel, ensuring stability at high speeds[5]. Teleswivel's pintle hitches are designed to be retrofitted to existing vehicles, making them a versatile solution for upgrading freight fleets.

Strengths: Enhanced maneuverability, reduced stress on hitch components, and compatibility with existing vehicles. Weaknesses: May have higher complexity compared to traditional fixed pintles, potentially requiring more frequent maintenance checks.

Key Innovations

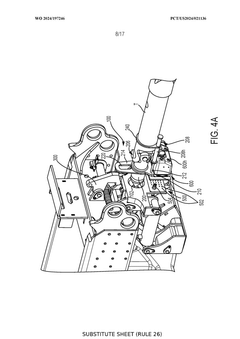

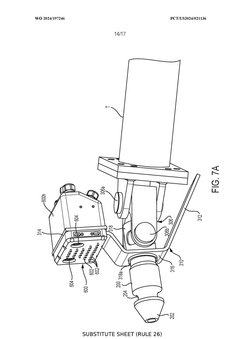

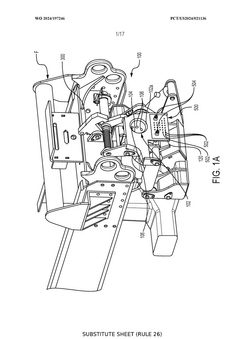

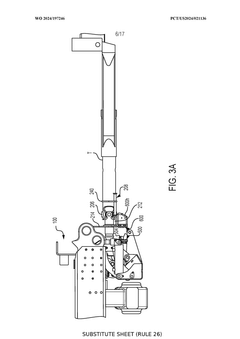

Apparatus, system, and method for connecting a towed vehicle to a towing vehicle

PatentWO2024197246A2

Innovation

- A hitch apparatus featuring a receiver tube with aligned apertures and ball bearings that secure an elongate shaft via a collar, allowing for remote activation and enabling roll rotation, while a manifold connects electrical and pneumatic systems between towing and towed vehicles, facilitating secure and automated coupling.

Convertible trailer

PatentInactiveUS20110101644A1

Innovation

- A universal trailer design featuring an adjustable neck with pivot and slide couplings that allows the trailer to be reconfigured between a pintle and a fifth-wheel configuration, using a pintle hitch adapter and a fifth wheel hitch adapter respectively, to accommodate different towing arrangements.

Safety Regulations

Safety regulations play a crucial role in the implementation of pintle hitch systems for high-capacity freight routes. These regulations are designed to ensure the safe operation of vehicles and protect both drivers and other road users. The primary focus of safety regulations in this context is on the structural integrity of the pintle hitch, its proper installation, and the overall stability of the vehicle combination.

One of the key aspects of safety regulations for pintle hitches is the requirement for regular inspections and maintenance. These inspections are typically mandated by transportation authorities and must be carried out by certified professionals. The frequency of inspections may vary depending on the jurisdiction, but they generally occur on an annual or semi-annual basis. During these inspections, technicians assess the condition of the pintle hitch, checking for wear, corrosion, and any signs of structural damage.

Load capacity ratings are another critical component of safety regulations for pintle hitches. Manufacturers are required to clearly indicate the maximum load capacity of their hitches, and operators must adhere to these limits. Exceeding the rated capacity can lead to catastrophic failure, potentially resulting in accidents and injuries. To ensure compliance, many jurisdictions implement weighing stations along major freight routes, where vehicles can be checked for adherence to weight restrictions.

The design and construction of pintle hitches are also subject to stringent safety standards. These standards typically specify minimum material requirements, stress tolerances, and fatigue resistance. Additionally, they may mandate the inclusion of safety features such as secondary coupling devices or breakaway systems. These features are designed to prevent complete separation of the trailer from the towing vehicle in the event of a primary coupling failure.

Safety regulations also extend to the operational aspects of vehicles equipped with pintle hitches. This includes guidelines for proper coupling and uncoupling procedures, as well as requirements for driver training and certification. Many jurisdictions require drivers to undergo specialized training programs that cover the unique challenges associated with operating high-capacity freight vehicles using pintle hitch systems.

Furthermore, safety regulations often address the compatibility between different components of the vehicle combination. This includes ensuring that the pintle hitch is appropriately matched to both the towing vehicle and the trailer. Mismatched components can lead to instability, reduced braking efficiency, and increased wear on the hitch and other vehicle systems.

In recent years, there has been a growing emphasis on incorporating advanced technologies into safety regulations for pintle hitch systems. This includes the use of electronic stability control systems, tire pressure monitoring, and real-time load sensing capabilities. These technologies can provide drivers with valuable information about the status of their vehicle and help prevent accidents caused by equipment failure or operator error.

One of the key aspects of safety regulations for pintle hitches is the requirement for regular inspections and maintenance. These inspections are typically mandated by transportation authorities and must be carried out by certified professionals. The frequency of inspections may vary depending on the jurisdiction, but they generally occur on an annual or semi-annual basis. During these inspections, technicians assess the condition of the pintle hitch, checking for wear, corrosion, and any signs of structural damage.

Load capacity ratings are another critical component of safety regulations for pintle hitches. Manufacturers are required to clearly indicate the maximum load capacity of their hitches, and operators must adhere to these limits. Exceeding the rated capacity can lead to catastrophic failure, potentially resulting in accidents and injuries. To ensure compliance, many jurisdictions implement weighing stations along major freight routes, where vehicles can be checked for adherence to weight restrictions.

The design and construction of pintle hitches are also subject to stringent safety standards. These standards typically specify minimum material requirements, stress tolerances, and fatigue resistance. Additionally, they may mandate the inclusion of safety features such as secondary coupling devices or breakaway systems. These features are designed to prevent complete separation of the trailer from the towing vehicle in the event of a primary coupling failure.

Safety regulations also extend to the operational aspects of vehicles equipped with pintle hitches. This includes guidelines for proper coupling and uncoupling procedures, as well as requirements for driver training and certification. Many jurisdictions require drivers to undergo specialized training programs that cover the unique challenges associated with operating high-capacity freight vehicles using pintle hitch systems.

Furthermore, safety regulations often address the compatibility between different components of the vehicle combination. This includes ensuring that the pintle hitch is appropriately matched to both the towing vehicle and the trailer. Mismatched components can lead to instability, reduced braking efficiency, and increased wear on the hitch and other vehicle systems.

In recent years, there has been a growing emphasis on incorporating advanced technologies into safety regulations for pintle hitch systems. This includes the use of electronic stability control systems, tire pressure monitoring, and real-time load sensing capabilities. These technologies can provide drivers with valuable information about the status of their vehicle and help prevent accidents caused by equipment failure or operator error.

Economic Impact

The implementation of pintle hitch technology in high-capacity freight routes has the potential to generate significant economic impacts across various sectors. This innovative coupling system can lead to increased efficiency in freight transportation, resulting in substantial cost savings for logistics companies and shippers. By enabling the use of longer combination vehicles (LCVs), pintle hitches allow for the transport of larger payloads with fewer trips, reducing fuel consumption and operational costs.

The adoption of pintle hitch technology can stimulate growth in the manufacturing sector, particularly for companies specializing in heavy-duty vehicle components and trailer systems. As demand for pintle hitch-equipped vehicles rises, manufacturers may experience increased orders and revenue, potentially leading to job creation and economic expansion in related industries.

Infrastructure development is another area likely to see economic benefits from pintle hitch implementation. The need for upgraded roads, bridges, and terminals capable of accommodating LCVs may drive investment in construction projects, creating employment opportunities and stimulating local economies along major freight corridors.

The improved efficiency of freight transportation enabled by pintle hitches can have ripple effects throughout supply chains. Reduced transportation costs may lead to lower prices for consumers on a wide range of goods, potentially increasing purchasing power and stimulating economic activity. Additionally, businesses that rely heavily on freight transportation may see improved profit margins, allowing for reinvestment in growth and innovation.

Environmental benefits associated with pintle hitch technology can also translate into economic advantages. Reduced fuel consumption and fewer vehicle trips can lead to lower emissions, potentially resulting in decreased environmental mitigation costs and improved public health outcomes. This may indirectly contribute to economic gains through reduced healthcare expenses and increased productivity.

The implementation of pintle hitches in high-capacity freight routes may also enhance the competitiveness of regions and countries that adopt this technology early. Improved logistics efficiency can attract businesses and investment, potentially leading to the development of logistics hubs and associated economic clusters.

However, it is important to consider potential economic challenges as well. The initial investment required for upgrading vehicles and infrastructure may be substantial, and some sectors, such as traditional trucking companies with older fleets, may face adaptation costs. Additionally, changes in employment patterns within the transportation sector may occur as fewer drivers may be needed for the same volume of freight, necessitating workforce transitions and retraining programs.

The adoption of pintle hitch technology can stimulate growth in the manufacturing sector, particularly for companies specializing in heavy-duty vehicle components and trailer systems. As demand for pintle hitch-equipped vehicles rises, manufacturers may experience increased orders and revenue, potentially leading to job creation and economic expansion in related industries.

Infrastructure development is another area likely to see economic benefits from pintle hitch implementation. The need for upgraded roads, bridges, and terminals capable of accommodating LCVs may drive investment in construction projects, creating employment opportunities and stimulating local economies along major freight corridors.

The improved efficiency of freight transportation enabled by pintle hitches can have ripple effects throughout supply chains. Reduced transportation costs may lead to lower prices for consumers on a wide range of goods, potentially increasing purchasing power and stimulating economic activity. Additionally, businesses that rely heavily on freight transportation may see improved profit margins, allowing for reinvestment in growth and innovation.

Environmental benefits associated with pintle hitch technology can also translate into economic advantages. Reduced fuel consumption and fewer vehicle trips can lead to lower emissions, potentially resulting in decreased environmental mitigation costs and improved public health outcomes. This may indirectly contribute to economic gains through reduced healthcare expenses and increased productivity.

The implementation of pintle hitches in high-capacity freight routes may also enhance the competitiveness of regions and countries that adopt this technology early. Improved logistics efficiency can attract businesses and investment, potentially leading to the development of logistics hubs and associated economic clusters.

However, it is important to consider potential economic challenges as well. The initial investment required for upgrading vehicles and infrastructure may be substantial, and some sectors, such as traditional trucking companies with older fleets, may face adaptation costs. Additionally, changes in employment patterns within the transportation sector may occur as fewer drivers may be needed for the same volume of freight, necessitating workforce transitions and retraining programs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!